Understanding the intricate elements of a high-performance fishing reel can greatly enhance maintenance and repair tasks. Whether you’re an avid angler or someone looking to improve your gear knowledge, knowing the various mechanisms that work together in your reel is essential. By examining the individual components, you can ensure smooth operation and longevity.

In this section, we’ll explore the internal and external mechanisms of a classic fishing tool. From the spool to the handle, each part plays a vital role in performance. This guide will help you identify key elements, offering clarity for repairs and replacements. You’ll gain a deeper understanding of how these components interact, ensuring optimal functionality.

Maintenance and precision are key aspects of keeping your fishing reel in top shape. With the right knowledge of its internal workings, you’ll be able to troubleshoot issues, replace worn-out elements, and keep your reel in peak condition for years to come. Precision engineering requires attention to each small detail, which this guide aims to provide.

Abu Garcia Ambassadeur 5000 Overview

This iconic fishing reel has earned a reputation for reliability and performance. Known for its durability and precision engineering, it has been a favorite among anglers for decades. Its design combines traditional craftsmanship with modern technology, making it suitable for a wide range of fishing environments.

Key Features

- Robust build quality for long-lasting use

- Precision drag system for smooth operation

- Efficient casting mechanism to maximize distance and accuracy

- Easy maintenance with accessible components

Performance and Usability

The reel is designed to deliver a smooth and consistent experience, whether you’re targeting small or large species. Its balanced construction and ergonomic design ensure comfortable handling over extended periods, while the smooth retrieval system enhances control during intense fishing sessions.

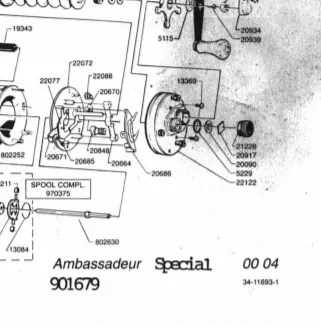

Key Components of Ambassadeur 5000

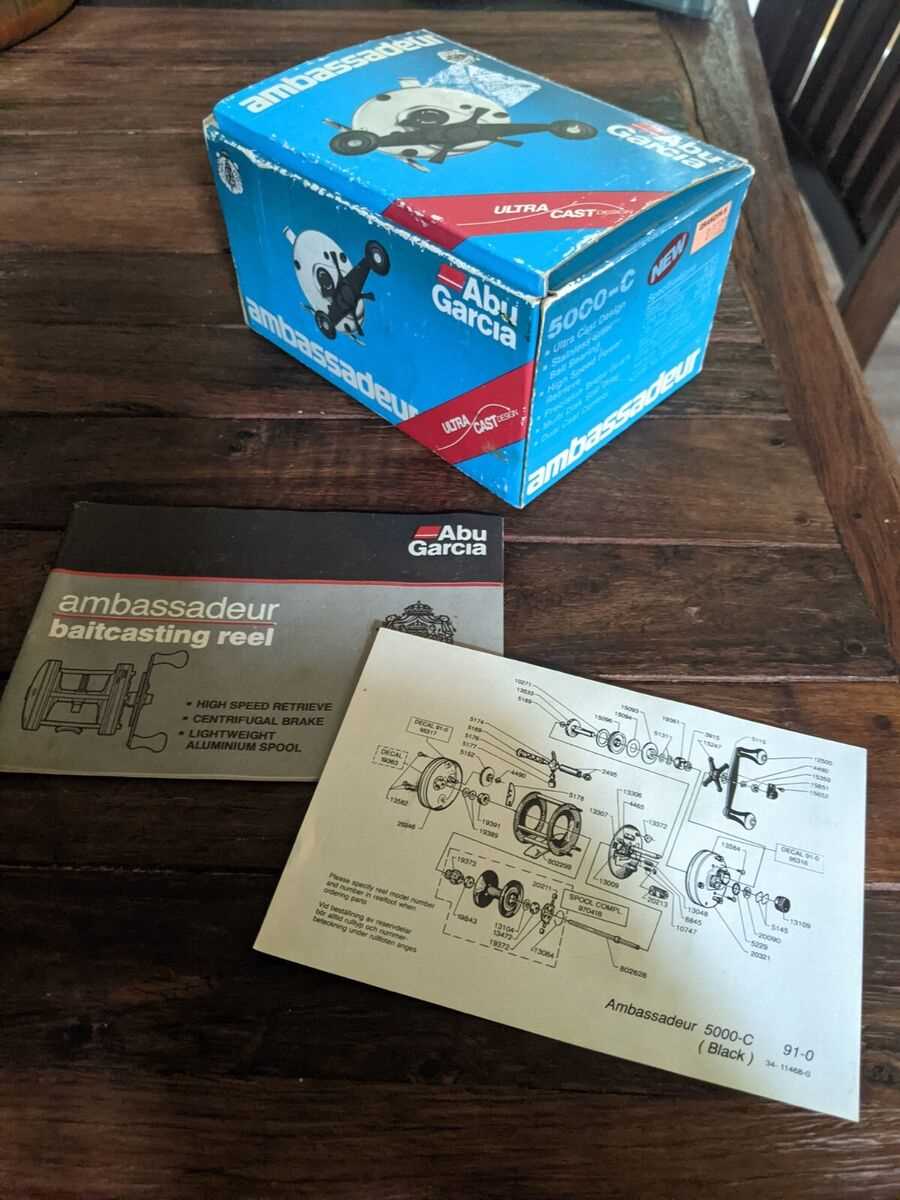

The internal mechanisms and elements of this popular reel model are designed for smooth operation and durability. Understanding its core elements is essential for maintaining and optimizing performance. Each part plays a crucial role in the overall functionality, ensuring a reliable experience for anglers.

- Spool: This rotating drum holds the fishing line and is central to casting and retrieving. A well-maintained spool ensures consistent line flow.

- Drag System: The drag controls tension, allowing anglers to adjust the resistance felt by the fish when reeling it in. It is crucial for managing bigger catches.

- Gear Assembly: The gears convert the handle’s motion into spool rotation. Precision-engineered gears provide smooth, reliable reeling action.

- Brake Mechanism: This part helps control

How to Maintain Reel Parts

Maintaining the components of your fishing reel is essential to ensure smooth operation and prolong its lifespan. Regular care prevents wear and tear, allowing the reel to function effectively during your fishing trips. By performing simple maintenance tasks, you can avoid more complex issues down the line.

Cleaning the Reel

To begin, clean the exterior and interior surfaces to remove dirt, salt, and debris that can accumulate during use. A soft brush and a cloth can be used for cleaning, while specialized oil is applied to moving parts to maintain lubrication.

Inspecting and Lubricating Components

Regular inspection helps identify any damaged or worn-out components. After cleaning, apply lubricant to the key areas of the reel to ensure all mechanisms function smoothly. Avoid over-lubrication, as this can attract more dirt and cause problems in the long term.

Assembly Guide for the 5000 Model

The reassembly of this well-known fishing tool requires careful attention to each individual component to ensure smooth operation. Proper alignment of all pieces is essential for long-lasting performance and functionality.

Step 1: Start by organizing all the components in a clean, spacious area. Make sure that no parts are missing before beginning the assembly process.

Step 2: Begin with the main casing, carefully positioning it as the foundation for the other parts. Ensure that all screws and fasteners are tightened securely, but avoid overtightening.

Step 3: Assemble the internal mechanisms, such as the gears and springs, by placing them in their designated slots. It’s important to use lubrication on any moving pieces to avoid friction and wear.

Step 4: Attach the handle and external features, ensuring that everything is aligned correctly for optimal performance. A final inspection of all connected parts will

Disassembling the Ambassadeur 5000

Taking apart a classic reel can be an intricate process, but with the right approach, it becomes a manageable task. This guide will walk you through the basic steps to dismantle the device, allowing for thorough cleaning, maintenance, or part replacement without damaging the mechanism.

Step-by-Step Breakdown

- Start by removing the handle assembly, which usually involves unscrewing a small retaining nut.

- Once the handle is detached, carefully take off the side plates. Pay attention to the small screws holding them in place.

- After accessing the internal components, take out the gear system. Be mindful of its arrangement to ensure proper reassembly.

- Next,

Identifying Worn-Out Parts

Maintaining a fishing reel in optimal condition requires regular inspection for components that may show signs of wear and tear. Over time, even the highest-quality reels can experience degradation in performance due to the friction and stress placed on their internal mechanisms. Recognizing these issues early can prevent further damage and extend the lifespan of the equipment.

The following are common indicators that a component may need attention:

- Unusual noise: Grinding or clicking sounds while operating the reel often suggest friction between moving parts that have worn down.

- Difficulty in operation: A reel that feels stiff or hard to turn may indicate that the internal gears are starting to degrade.

- Sluggish performance: If the spool or drag system is slow to respond or becomes inconsistent, it may be due to worn-out washers or friction components.

- Visible damage: Cracks, chips, or discoloration on any part of the reel can signal damage from prolonged use or exposure to harsh conditions.

Performing a thorough inspection of these areas can help identify which components need replacement. Addressing issues early will ensure that the reel continues to function smoothly and efficiently.

Replacing Bearings in the 5000 Reel

When maintaining a fishing reel, one critical aspect to focus on is the replacement of worn-out bearings. These small but essential components ensure smooth operation, reducing friction and extending the lifespan of the device. Over time, bearings can deteriorate due to exposure to moisture, dirt, and regular use, making their replacement necessary for optimal performance.

Tools and Preparation

Before starting the bearing replacement process, it is essential to gather the necessary tools and ensure the reel is prepared properly. You will need a set of small screwdrivers, a bearing puller, lubrication, and replacement bearings. Cleaning the reel thoroughly before disassembly is crucial to prevent any debris from causing issues during the reassembly.

Step-by-Step Bearing Replacement

Step Action 1 Remove the reel’s side plate and inspect the bearings to identify which ones need replacement. 2 Using a bearing puller, gently remove the old bearings from their seats. 3 Clean the bearing housing thoroughly to ensure a smooth fit for the new parts. 4 Lubricate the new bearings with a suitable reel oil before inserting them into place. 5 Reassemble the reel, ensuring all parts are securely tightened, and test the functionality. With the new bearings installed, your reel will operate like new, offering improved efficiency and durability during fishing trips.

Exploring the Brake System Design

The brake mechanism of a reel is essential for precise control and smooth operation. It plays a crucial role in managing the tension of the line, allowing anglers to adjust the drag according to their needs. This system ensures that the line does not snap during powerful pulls while maintaining a balance between resistance and flexibility.

Understanding the Components

The core of the brake system consists of several key elements that work together to regulate the spool’s rotation. These components typically include a friction-based setup, which applies resistance as the spool spins. The materials used in this system must be durable and lightweight, ensuring longevity while providing optimal control over casting distance and accuracy.

How the System Affects Performance

A well-designed brake mechanism allows for better accuracy and distance when casting. By adjusting the braking force, the angler can fine-tune the reel’s response, preventing backlash or bird nests. This level of control is crucial for a more enjoyable and successful fishing experience.

Cleaning and Lubricating Your Reel

Maintaining the smooth operation of your fishing reel is essential for ensuring long-term performance and preventing wear. Regular cleaning and lubrication will keep the internal mechanisms functioning properly, reduce friction, and prolong the lifespan of your gear. Proper care also helps prevent rust, dirt buildup, and other environmental factors that can damage your reel over time.

Step-by-Step Cleaning Process

Begin by disassembling the reel, carefully removing any covers and components. Use a soft cloth or brush to remove dirt, dust, and grime from both the exterior and interior. For more stubborn debris, a gentle rinse with warm water can help loosen the particles. Avoid using harsh chemicals, as they can damage the reel’s materials. Once clean, allow all parts to dry completely before proceeding to lubrication.

Lubrication Tips

Once the reel is dry, apply a thin layer of lubricant to the moving parts, focusing on the gears, bearings, and any other areas that experience friction. Use a high-quality reel oil or grease designed for fishing equipment. Be careful not to over-lubricate, as this can attract dirt and create additional friction. Regular lubrication will help maintain smooth casting and retrieval, keeping your reel in top condition.

Choosing Compatible Replacement Parts

When it comes to maintaining your fishing reel, selecting the right replacement components is crucial for ensuring smooth performance and longevity. Compatibility between your current reel and new elements is key to maintaining its functionality. This guide will help you understand how to choose the best substitutes that match your equipment’s specifications.

Understanding Reel Specifications

Before making a purchase, it’s important to understand the specifications of your reel. Each model has unique dimensions and mechanical requirements. By reviewing the manufacturer’s manual or technical details, you can identify the crucial measurements such as gear ratios, spool size, and bearing types that must align with the replacement parts.

Identifying Quality Components

Not all replacement items are created equal. Ensure you select high-quality alternatives that not only fit but also offer durability. Brands that specialize in fishing gear tend to offer parts that meet specific standards, which ensures optimal performance and prevents potential damage to your reel.

Component Recommended Specifications Notes Handle Length: 100mm, Material: Aluminum Ensure it’s ergonomically designed for comfortable handling. Drag System Type: Carbon Fiber, Max Drag: 10kg Carbon fiber systems provide smoother drag and more durability. Spool Material: Stainless Steel, Capacity: 150m of 0.30mm Line Choose a spool that balances line capacity and weight. Upgrading the Ambassadeur 5000 Mechanism

Enhancing the performance of classic reels requires careful attention to their internal components. By upgrading key mechanical elements, anglers can achieve smoother operation, greater durability, and improved casting distance. These improvements not only extend the life of the reel but also enhance the overall fishing experience, offering better precision and reliability in challenging conditions.

The key to a successful upgrade lies in selecting high-quality replacement parts that match the reel’s original design while improving its functionality. Components like the gear system, drag system, and bearing assembly can significantly impact performance when replaced with more advanced materials or precision-engineered alternatives.

With these upgrades, users can enjoy a more responsive and efficient reel, offering a competitive edge in both freshwater and saltwater environments. Careful installation and regular maintenance will ensure that these enhancements contribute to a long-lasting, superior fishing tool.

Common Issues and Troubleshooting

Understanding the frequent problems that can arise with fishing reels is crucial for maintaining their optimal performance. Whether it’s issues with smooth rotation, braking, or general wear and tear, identifying these common faults can help you quickly resolve them without the need for professional repairs. Regular maintenance and keen observation are key to extending the lifespan of your equipment.

One of the most common issues is a lack of smooth operation, often caused by debris or rust in the internal mechanisms. This can lead to inconsistent performance during casting or retrieving. To resolve this, ensure that the reel is properly cleaned and lubricated, focusing on the moving parts.

Another frequent problem is the drag system malfunctioning. If the drag feels too loose or too tight, it may be due to worn-out components or improper adjustment. Periodic checks and adjustment according to the manufacturer’s guidelines can prevent these issues.

Over time, the line may also become tangled or stuck, leading to frustration and poor casting distance. This issue usually stems from improper spool tension or line wear. Regularly replacing the line and adjusting the tension can help prevent tangling and ensure smoother operation.

Proper Storage Tips for Long-Term Use

To ensure your fishing gear remains in optimal condition during extended periods of non-use, it’s essential to follow proper storage guidelines. Adequate care and attention can prevent rust, wear, and other forms of degradation, ensuring that your equipment remains functional and ready for use whenever needed.

Choose the Right Environment

Store your gear in a cool, dry place, away from direct sunlight and excessive moisture. Avoid areas with high humidity, as this can accelerate corrosion. A climate-controlled storage area, such as a garage or basement, is ideal. Keep the equipment in a protective case or bag to shield it from dust and dirt.

Regular Maintenance Before Storing

Before storing your equipment for long periods, thoroughly clean and lubricate all moving parts. This will help prevent internal components from seizing up or becoming corroded. If possible, disassemble certain parts to avoid unnecessary pressure on the components during storage. Additionally, check the line or reel for any signs of wear or fraying, and replace it if necessary.