In the realm of applicators, having a clear understanding of the configuration and components is essential for optimal functionality. Each machine is designed with various elements that work in harmony to ensure effective performance. This section aims to provide insights into the arrangement and roles of these crucial elements, enhancing the user’s grasp of their equipment.

By exploring the intricate arrangement of components, users can gain valuable knowledge that aids in troubleshooting and maintenance. Recognizing how each part contributes to the overall operation can significantly enhance the user experience, allowing for more efficient use and longevity of the applicator. Knowledge of the structure not only empowers users but also fosters a deeper appreciation for the technology involved.

Additionally, familiarizing oneself with the layout can prevent common issues and facilitate smoother operation. This understanding is particularly beneficial for those who frequently engage in application tasks, enabling them to make informed decisions when adjustments or repairs are necessary. Ultimately, a comprehensive overview of the component structure leads to more successful outcomes in various projects.

Essential Components of Paint Sprayers

Understanding the fundamental elements of a spraying apparatus is crucial for achieving optimal results in various coating tasks. Each component plays a specific role in ensuring efficient application and consistency, making it vital to be familiar with their functions and interactions.

The motor serves as the powerhouse, providing the necessary energy to propel the liquid through the system. Coupled with this, the pump is responsible for drawing the material from the container and pushing it through the hose. A well-designed nozzle is essential for controlling the spray pattern and atomization, allowing for precise application on different surfaces.

Another key element is the hose, which transports the fluid from the pump to the nozzle. It must be durable and flexible to withstand the pressure and prevent any leaks. Additionally, a filter is often integrated into the system to ensure that only clean liquid reaches the nozzle, preventing clogs and maintaining a smooth operation.

Lastly, various attachments and accessories, such as extension poles or specialized tips, can enhance the functionality of the device, making it adaptable for different projects and surfaces. Familiarity with these components ensures users can make informed choices and maximize the efficiency of their equipment.

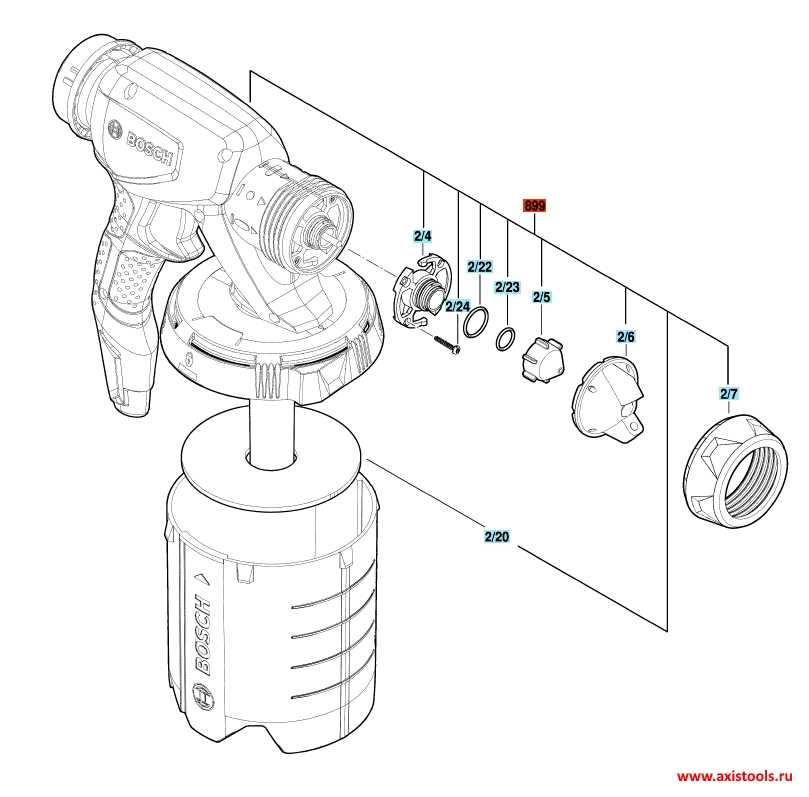

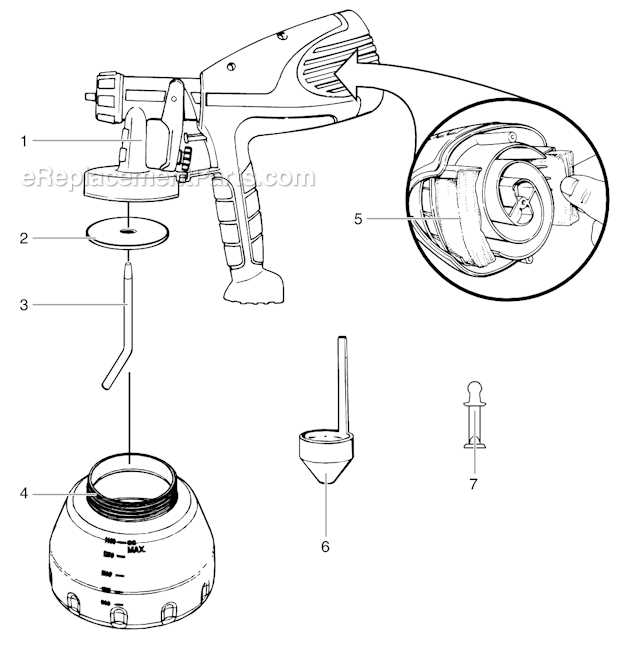

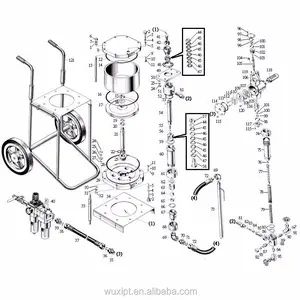

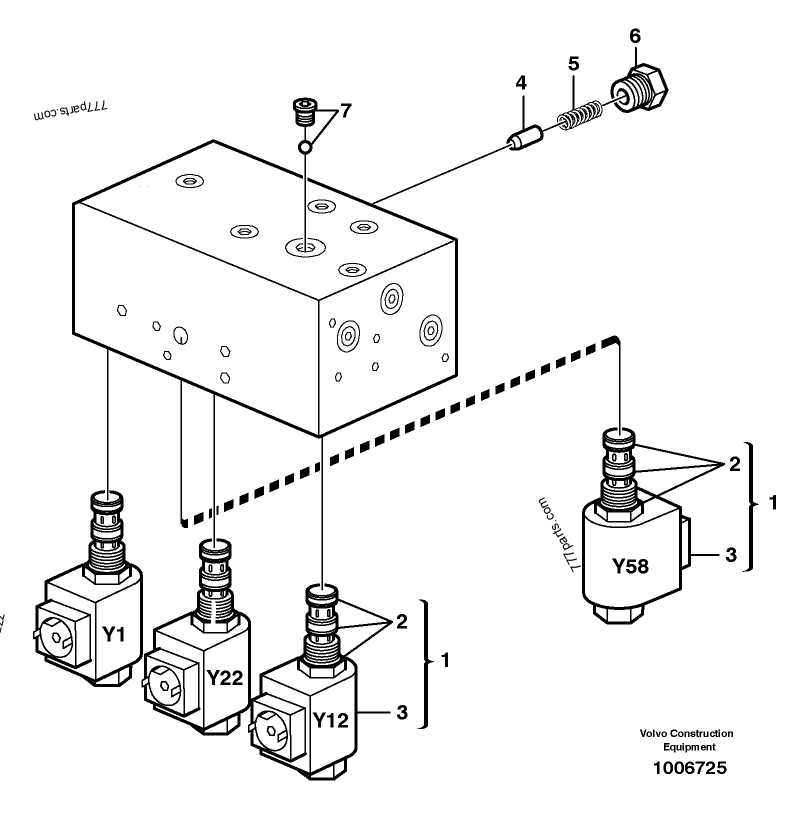

Understanding the Parts Diagram Layout

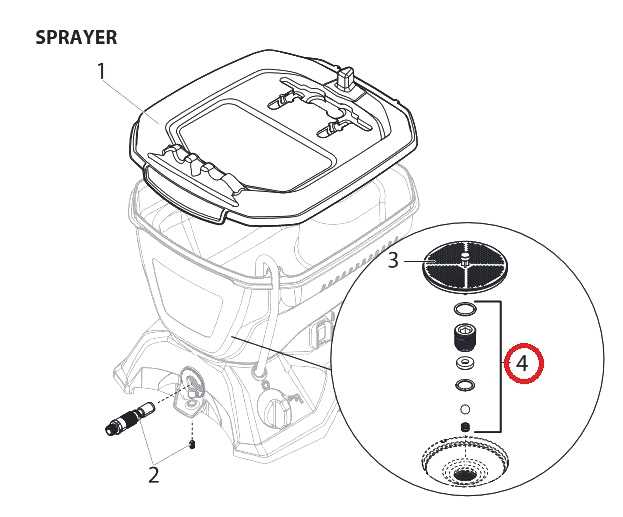

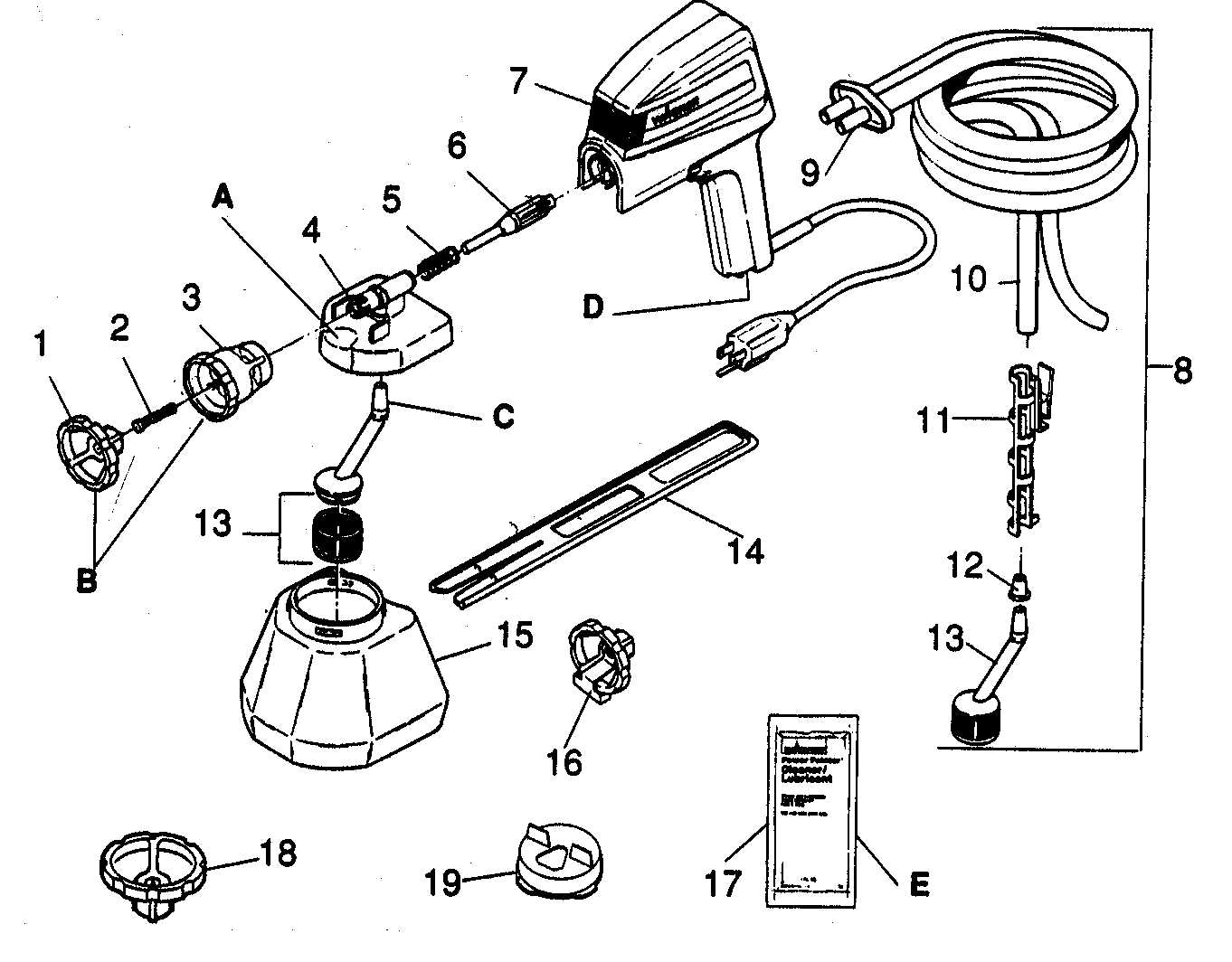

The arrangement of components in a schematic representation plays a crucial role in facilitating comprehension of the system’s structure and functionality. By examining this layout, users can gain insights into how different elements interact and contribute to the overall operation.

Typically, the illustration is organized in a way that highlights the relationships between various sections, allowing for a clear visualization of connections and dependencies. Each segment is usually labeled for easy identification, enhancing the understanding of the respective roles played by each component.

Comprehending the layout is essential for troubleshooting and maintenance, as it enables users to pinpoint specific areas that may require attention or adjustment. Furthermore, an accurate representation fosters a more efficient workflow, streamlining processes and improving overall performance.

Ultimately, familiarity with the schematic structure not only aids in effective usage but also promotes confidence in navigating the intricacies of the system.

Key Functions of Each Part

This section provides an overview of the essential roles played by various components within the equipment. Understanding these functions is crucial for optimizing performance and ensuring effective operation.

Primary Elements and Their Roles

The main elements are designed to facilitate the smooth application of substances, each contributing uniquely to the overall process. For instance, one component regulates the flow of materials, ensuring a consistent output, while another aids in achieving the desired coverage and texture.

Supporting Components

Supporting elements enhance functionality and efficiency. Some parts are responsible for maintaining stability and ease of maneuvering, while others focus on safety features that protect the user during operation. Together, these components create a harmonious system that maximizes productivity.

Common Issues with Paint Equipment

Equipment used for coating surfaces often encounters various challenges that can hinder performance and efficiency. Understanding these common problems can help users troubleshoot and maintain their tools effectively.

Frequent Challenges

One of the most prevalent issues is inconsistent application, which may result from clogged filters or nozzles. Additionally, inadequate pressure levels can lead to uneven coverage, causing frustration during projects. Regular inspection and cleaning of components can mitigate these concerns.

Signs of Wear and Tear

Over time, certain elements of the equipment may exhibit signs of deterioration. Leaks and drips are indicators of potential issues that should be addressed promptly to prevent further damage. Keeping an eye out for these symptoms can prolong the lifespan of the tools.

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent application | Clogged filters or nozzles | Regular cleaning and maintenance |

| Uneven coverage | Inadequate pressure levels | Check and adjust pressure settings |

| Leaks | Worn seals or gaskets | Replace damaged components |

Maintenance Tips for Optimal Performance

To ensure that your equipment operates efficiently and reliably, regular upkeep is essential. Adopting a proactive approach to maintenance can significantly enhance the lifespan of your device and improve its overall functionality. Below are several practical suggestions to help you maintain optimal performance.

Routine Cleaning

Keeping your device clean is crucial for preventing build-up that can affect its operation. After each use, make it a habit to remove any residue or debris. Utilize appropriate cleaning tools and solutions to ensure that all components are properly cared for. Regular cleaning not only maintains aesthetic appeal but also promotes longevity.

Inspection and Replacement

Conducting periodic inspections allows you to identify wear and tear before it leads to major issues. Check for any signs of damage or deterioration in essential components. If you notice any abnormalities, promptly replace the affected parts to prevent further complications. Staying ahead of maintenance needs can save you time and resources in the long run.

How to Identify Replacement Parts

Recognizing the appropriate components for your equipment is essential for maintaining optimal functionality. This process involves understanding the characteristics and specifications of the elements that may require substitution. Accurate identification can prevent operational issues and enhance the overall performance of your tools.

Understanding Component Types

Begin by familiarizing yourself with the various types of elements within your equipment. Each type serves a distinct purpose, and knowing their functions will assist in determining which may need replacement. Consult the manufacturer’s documentation or online resources to gain insights into the different categories and their specific roles.

Using Reference Guides

Utilizing reference materials is a practical approach to pinpointing the correct replacements. These guides often include detailed illustrations and descriptions, making it easier to compare your existing components. By cross-referencing these visuals with your equipment, you can identify worn or damaged items more effectively.

Tools Required for Repairs

Proper maintenance and repair tasks necessitate specific instruments to ensure efficiency and effectiveness. Having the right tools on hand not only streamlines the process but also enhances the overall quality of the work performed.

Here is a list of essential instruments needed for carrying out repair activities:

- Adjustable wrench

- Screwdriver set (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Utility knife

- Measuring tape

- Hex keys (Allen wrenches)

In addition to these basic tools, you may also find the following items useful for specific repair tasks:

- Torque wrench

- Rubber mallet

- Wire cutters

- Safety goggles

- Gloves

Having these instruments readily available will facilitate a smoother repair process, allowing for effective troubleshooting and resolution of issues.

Assembling the Paint Crew System

This section focuses on the assembly process of the application system designed for efficient and uniform coating. Understanding the components and their interactions is crucial for achieving optimal results during usage.

Step-by-Step Assembly Process

Begin by organizing all components in a designated area to ensure a smooth assembly. Each element plays a vital role in the overall functionality, so it’s important to follow the instructions carefully. Start with the base unit, attaching it securely to provide a stable foundation. Next, integrate the delivery mechanisms, ensuring they align correctly to facilitate consistent application.

Final Checks and Adjustments

Once the assembly is complete, perform thorough checks to confirm that all connections are secure and that there are no obstructions in the system. Adjust any components as necessary to ensure optimal performance. Regular maintenance and inspection of the assembled unit will enhance its longevity and reliability.

Safety Precautions During Use

Ensuring safety while operating equipment is paramount to prevent accidents and injuries. Proper practices not only safeguard the user but also enhance the overall efficiency of the task at hand.

Always wear appropriate protective gear, including goggles, gloves, and masks, to shield yourself from harmful substances and potential splashes. It is essential to prioritize your well-being during any operation.

Before commencing work, thoroughly inspect the tools to confirm they are in good working condition. Check for any wear or damage that could lead to malfunction or safety hazards. Ensuring that everything is functioning correctly can prevent unforeseen incidents.

Maintain a clean workspace by removing any clutter that may pose a risk of tripping or accidents. A tidy environment promotes focus and minimizes distractions, leading to safer operations.

Finally, be mindful of your surroundings and ensure adequate ventilation, especially when using substances that emit fumes. Proper airflow can significantly reduce the risk of inhalation hazards, contributing to a safer work atmosphere.

Comparing Models of Wagner Equipment

When evaluating various models of painting machinery, it is essential to consider their distinct features and functionalities. Each variant offers unique capabilities designed to meet specific user needs, making the selection process crucial for achieving optimal results in different applications.

Some models may prioritize portability, enabling users to easily transport equipment to various job sites. Others might focus on power output, providing enhanced performance for larger tasks or more demanding environments. Additionally, the range of attachments and accessories available can significantly influence versatility and overall efficiency.

Understanding the specifications and intended uses of each machine allows for informed decision-making. Users can better assess which model aligns with their requirements, ensuring they choose the most suitable option for their projects. By comparing these machines thoughtfully, individuals can enhance productivity and achieve superior outcomes in their work.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their functionality. Understanding these elements can enhance user experience and ensure optimal performance of the equipment.

Common Queries

Many users often seek clarification on various aspects of components. Below are some typical questions that arise:

| Question | Answer |

|---|---|

| What should I do if a component is damaged? | It is advisable to replace the damaged component to maintain efficiency and safety. |

| How can I identify the right component for my equipment? | Refer to the user manual or consult customer support for assistance in selecting the appropriate item. |

| Are there any specific maintenance tips for the components? | Regular cleaning and inspection can help extend the lifespan of the components. |

Support Resources

For further assistance, users are encouraged to access online resources or contact customer service for expert guidance on their inquiries.

Where to Find Replacement Diagrams

Locating accurate illustrations for component replacements is essential for ensuring the longevity and efficiency of your equipment. Various resources can assist you in acquiring these valuable visuals, enabling you to make informed decisions during maintenance or repairs.

Consider the following avenues to find the necessary replacement illustrations:

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | Official sites often provide downloadable resources and manuals, including detailed visuals for various models. |

| Online Forums | Community-driven platforms can offer insights, shared experiences, and sometimes access to user-uploaded diagrams. |

| Retailers | Authorized sellers may have access to specific resources or can direct you to where you can find them. |

| Repair Shops | Local or online repair specialists often have diagrams and manuals they can share or sell. |

Utilizing these resources will facilitate the identification of accurate illustrations, ultimately streamlining the process of replacing necessary components.