This section delves into the essential elements involved in the process of temperature regulation within vehicles. By comprehensively exploring these integral components, one can gain valuable insights into how optimal climate control is achieved for a comfortable driving experience.

Each component plays a significant role in the overall functionality, ensuring that the interior environment remains pleasant regardless of external conditions. A thorough understanding of these elements not only enhances appreciation for the system’s complexity but also aids in identifying potential issues and maintenance needs.

By examining the interactions and connections among these crucial components, we can better grasp the intricacies of the cooling mechanism. This knowledge is vital for anyone looking to ensure the efficiency and longevity of the system.

The efficiency of a temperature regulation system relies on several critical components working harmoniously. Understanding these essential elements is fundamental to grasping how the entire cooling process operates, ensuring a comfortable environment regardless of external conditions.

- Compressor: This component compresses the refrigerant, raising its pressure and temperature, and plays a pivotal role in initiating the cooling cycle.

- Condenser: Located outside, this unit dissipates heat from the refrigerant, transforming it from a gas to a liquid as it cools down.

- Expansion Valve: This part regulates the flow of refrigerant into the evaporator, allowing the liquid refrigerant to expand and cool further before entering the next phase.

- Evaporator: Situated inside, it absorbs heat from the surrounding air, turning the refrigerant back into a gas and lowering the temperature of the air circulating within the space.

- Refrigerant: This fluid circulates through the system, changing states between gas and liquid, and facilitating the heat exchange necessary for cooling.

Each of these elements contributes to the overall functionality, forming an integrated system that effectively manages thermal comfort.

How Refrigerant Circulates in System

The circulation of refrigerant within a cooling mechanism is vital for its efficiency and performance. This process involves the movement of a specialized fluid through various components, facilitating heat exchange and temperature regulation. Understanding this flow is crucial for maintaining optimal functionality.

Components Involved in the Circulation

The system comprises several key elements, each playing a distinct role in the refrigerant’s journey. The process begins with the compressor, which pressurizes the refrigerant and propels it through the system.

| Component | Function |

|---|---|

| Compressor | Compresses and circulates the refrigerant. |

| Condenser | Releases heat and condenses the refrigerant into a liquid. |

| Expansion Valve | Reduces pressure, allowing the refrigerant to expand and cool. |

| Evaporator | Absorbs heat, causing the refrigerant to evaporate and cool the environment. |

Process of Circulation

The cycle initiates when the refrigerant enters the compressor as a low-pressure gas. Upon compression, its pressure and temperature increase significantly. The high-pressure gas then flows into the condenser, where it releases heat to the surroundings and transforms into a liquid state. This liquid refrigerant travels through the expansion valve, where its pressure decreases, leading to a drop in temperature. Finally, it enters the evaporator, absorbing heat from the environment and converting back into a gas, ready to return to the compressor and repeat the cycle.

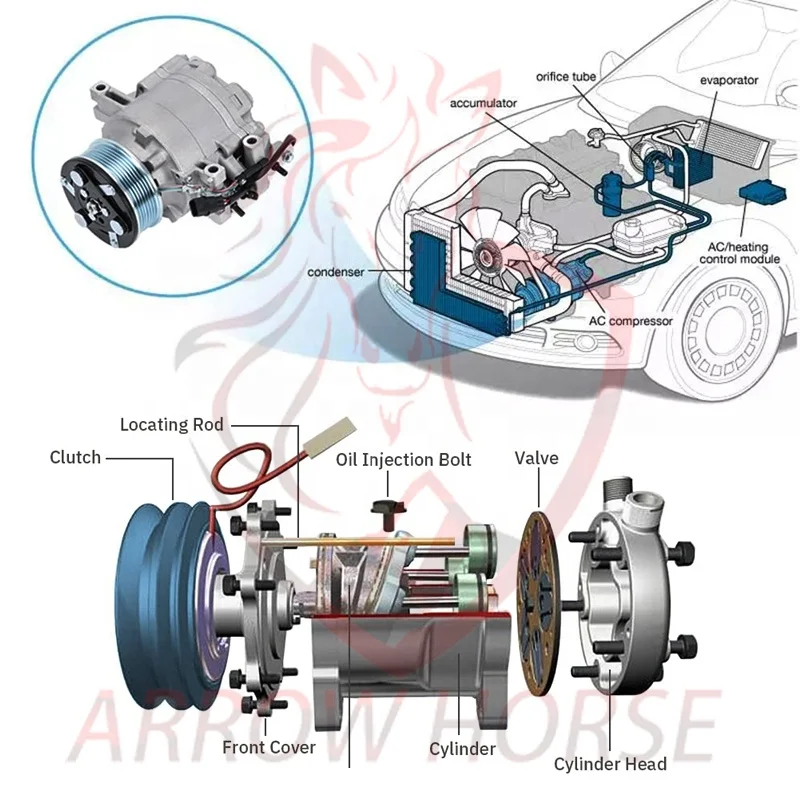

Roles of Compressor and Condenser

The efficiency of temperature regulation systems relies heavily on the functions of specific components that work in tandem to achieve optimal performance. Two critical elements in this process are the compressor and the condenser, each playing distinct yet complementary roles.

The compressor serves as the heart of the system, responsible for circulating the refrigerant throughout the entire setup. By compressing the refrigerant gas, it increases the pressure and temperature, allowing it to flow into the next stage. This component ensures that the refrigerant moves efficiently, facilitating the heat exchange necessary for effective cooling.

On the other hand, the condenser acts as a cooling agent, dissipating heat absorbed by the refrigerant as it travels through the system. As the high-pressure gas enters the condenser, it releases its heat to the surrounding environment, transforming into a liquid state. This process is vital for maintaining a consistent cycle, enabling the system to return to the compressor and repeat the cooling procedure.

In summary, the synergy between the compressor and condenser is essential for the efficient operation of temperature control mechanisms. Together, they ensure that the refrigerant undergoes the necessary transformations, maintaining a balanced and effective cooling cycle.

Evaporator Function and Importance

The evaporator plays a crucial role in the refrigeration process, serving as the component that facilitates the cooling effect within the system. By absorbing heat from the surrounding environment, it creates a comfortable atmosphere, making it essential for efficient temperature regulation.

How the Evaporator Works

The operation of the evaporator can be summarized in the following steps:

- The refrigerant enters the evaporator as a low-pressure liquid.

- As it passes through the coils, it absorbs heat from the surrounding air.

- This heat absorption causes the refrigerant to evaporate, turning it into a gas.

- The cooled air is then circulated into the interior space.

Significance of the Evaporator

The importance of the evaporator extends beyond mere temperature control:

- Enhances Comfort: By effectively lowering the ambient temperature, it ensures a pleasant environment.

- Energy Efficiency: A well-functioning evaporator contributes to the overall efficiency of the system, reducing energy consumption.

- Humidity Control: It helps to dehumidify the air, preventing excessive moisture buildup.

Expansion Valve: Purpose and Operation

The expansion valve plays a crucial role in regulating the flow of refrigerant within the cooling system. This component is designed to control the pressure and volume of the refrigerant before it enters the evaporator. By adjusting these parameters, the expansion valve ensures optimal performance and efficiency of the entire system.

When the refrigerant leaves the condenser, it is in a high-pressure state. The expansion valve reduces this pressure, transforming the refrigerant into a low-pressure mist. This change is essential for the subsequent evaporation process, where the refrigerant absorbs heat from the environment, facilitating the cooling effect. The valve functions by responding to variations in temperature and pressure, allowing it to maintain a consistent flow rate and prevent issues such as flooding or starvation of the evaporator.

In summary, the expansion valve is integral to the effective operation of the cooling mechanism. Its ability to modulate refrigerant flow enhances system efficiency and contributes to the overall comfort within the cabin.

Understanding Blower Motor Dynamics

The functionality of ventilation systems relies heavily on the motor responsible for airflow circulation. This essential component plays a pivotal role in ensuring that the environment within a vehicle remains comfortable. A thorough comprehension of its mechanics and operation can enhance both performance and efficiency.

Key Components and Functionality

The blower motor comprises several critical elements, including the motor itself, fan blades, and control mechanisms. These components work harmoniously to regulate airflow. The motor converts electrical energy into mechanical motion, enabling the fan blades to spin and move air throughout the cabin.

Impact of Performance on Comfort

Efficient operation of the blower motor directly influences the overall climate within the interior space. Variations in motor speed can alter airflow intensity, affecting how quickly the environment adjusts to desired temperature settings. Understanding these dynamics allows for better maintenance practices, ensuring optimal performance and longevity of the system.

Effects of Air Filters on Performance

The efficiency of any system that relies on airflow significantly hinges on the quality and condition of its filtration components. These elements serve a crucial role in maintaining optimal performance by ensuring that only clean, unobstructed air circulates through the system. The impact of these filters on functionality can be profound, affecting overall comfort and energy consumption.

Importance of Clean Filters

Regularly replacing or cleaning filtration devices is essential for sustaining peak performance. Clogged filters can restrict airflow, leading to increased energy expenditure and diminished effectiveness. When obstructions occur, the system must work harder to achieve the desired temperature, which can result in premature wear and tear on mechanical components.

Choosing the Right Filter

Selecting appropriate filtration solutions tailored to specific requirements can enhance efficiency significantly. High-quality filters can trap smaller particles, promoting a cleaner environment and improving system longevity. Understanding the right type and maintenance schedule is vital for maximizing performance and ensuring a consistently comfortable atmosphere.

Common Issues in AC Systems

Many individuals encounter various complications within their cooling systems, which can hinder performance and comfort. Recognizing these challenges is crucial for maintaining optimal functionality and ensuring a pleasant environment.

Here are some frequent problems associated with cooling mechanisms:

| Issue | Description |

|---|---|

| Refrigerant Leaks | Loss of refrigerant due to cracks or holes can lead to insufficient cooling. |

| Compressor Failure | The compressor may stop functioning properly, resulting in no cooling at all. |

| Blocked Condenser | Debris accumulation can obstruct airflow, decreasing efficiency. |

| Electrical Issues | Faulty wiring or blown fuses can disrupt the power supply, preventing operation. |

| Clogged Filters | Dirty filters can restrict airflow, causing the system to work harder than necessary. |

Maintenance Tips for Long Lifespan

To ensure optimal performance and longevity of your cooling system, regular care and attention are essential. Implementing a few straightforward practices can significantly extend the lifespan of the unit and enhance its efficiency.

Regular Inspections

Conducting routine checks helps identify potential issues before they escalate. Consider the following:

- Inspect for leaks in hoses and connections.

- Check for unusual noises that may indicate wear.

- Monitor the temperature output to ensure effective cooling.

Cleaning and Maintenance

Keeping components clean contributes to optimal function. Follow these steps:

- Replace or clean air filters every few months.

- Clear debris from vents and ducts to promote airflow.

- Have the system professionally serviced at least once a year.

By following these maintenance tips, you can enhance the performance of the cooling system and prolong its operational life.

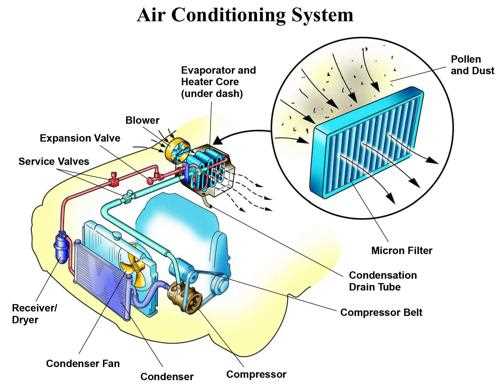

Diagram: Visual Representation of Parts

This section offers a comprehensive illustration showcasing the various components involved in the cooling mechanism of a vehicle. Understanding these elements is essential for grasping how they interact to maintain a comfortable environment within the cabin.

| Component | Description |

|---|---|

| Compressor | A pump that circulates refrigerant and increases its pressure. |

| Condenser | A heat exchanger that cools and condenses refrigerant vapor into liquid. |

| Expansion Valve | A device that regulates the flow of refrigerant into the evaporator. |

| Evaporator | A heat exchanger that absorbs heat from the cabin, cooling the air. |

| Receiver-Drier | A component that filters out moisture and impurities from the refrigerant. |