In the realm of modern agriculture, machinery plays a pivotal role in enhancing productivity and efficiency. A thorough comprehension of the individual elements that comprise these machines is essential for maintenance and repair. This section delves into the intricacies of the layout of components, providing valuable insights for operators and technicians alike.

By familiarizing oneself with the arrangement and functions of various parts, users can ensure that their equipment remains in optimal condition. Proper knowledge not only aids in troubleshooting but also facilitates timely interventions that can prevent costly downtime. As we explore the essential components of specific machinery, the importance of clarity in their organization becomes evident.

Understanding how each piece interacts within the larger system allows for better decision-making during repairs and upgrades. Whether it involves routine maintenance or major overhauls, having a detailed visual representation of these elements serves as an invaluable resource. This exploration aims to equip users with the necessary tools to navigate the complexities of their machinery confidently.

Understanding John Deere 240 Components

When operating machinery, it’s crucial to grasp the various elements that contribute to its functionality. Each component plays a significant role, ensuring optimal performance and longevity. By familiarizing oneself with these essential parts, users can enhance their maintenance practices and troubleshooting skills.

Key Components: The engine serves as the heart, providing the necessary power for operation. The transmission allows for smooth movement and speed adjustments, while the hydraulic system facilitates various tasks by controlling attachments. Additionally, the electrical system is vital for ignition and overall control.

Maintenance Tips: Regular checks on oil levels, filter conditions, and wear signs on components can prevent unexpected breakdowns. Keeping the machine clean and free from debris also aids in its efficiency and durability.

Essential Parts of John Deere 240

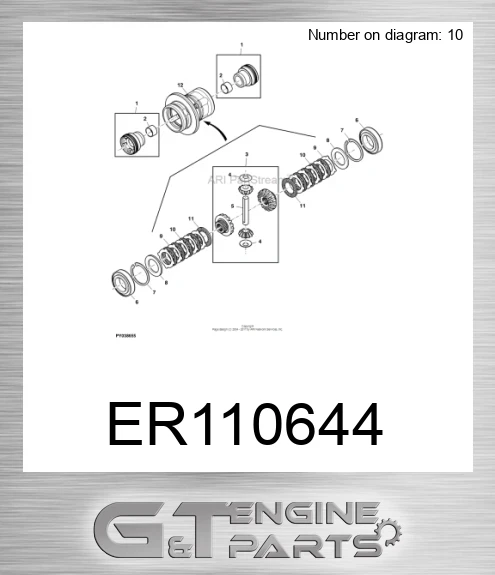

This section explores crucial components essential for optimal functionality and performance. Understanding these elements can significantly enhance the efficiency and longevity of the machinery, ensuring smooth operations across various tasks.

The powerhouse of the machine, responsible for providing the necessary energy to drive all operations, is vital for seamless performance.

The mechanism that facilitates the transfer of power from the engine to the wheels, allowing for controlled movement and speed variations, is essential for maneuverability.

This system plays a pivotal role in enabling various attachments to function effectively, enhancing versatility in different applications.

The structural framework supports all components, ensuring stability and durability during operation, which is critical for maintaining overall integrity.

User interfaces that allow operators to manage and adjust settings efficiently are crucial for maximizing productivity and ease of use.

Common Issues with John Deere 240

Understanding typical challenges can greatly enhance the experience of using this equipment. Users often encounter various operational difficulties that may arise from wear and tear, improper maintenance, or environmental factors.

Frequent Problems

- Starting issues due to battery failure or electrical problems.

- Overheating from coolant leaks or blocked radiators.

- Poor performance linked to fuel system malfunctions.

Maintenance Tips

- Regularly check and replace fluids as necessary.

- Inspect belts and hoses for wear.

- Keep the air filter clean to ensure optimal performance.

Maintenance Tips for John Deere 240

Proper upkeep is essential for enhancing the performance and longevity of your equipment. Regular attention to key components can prevent costly repairs and ensure efficient operation. Below are some effective strategies to maintain your machine in optimal condition.

Regular Inspections

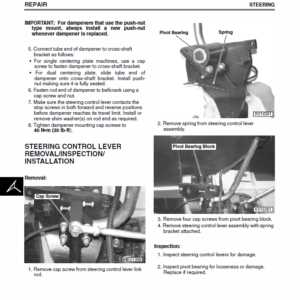

Conduct frequent evaluations of critical areas such as the engine, hydraulic system, and belts. Look for signs of wear or leaks, as these can indicate potential issues. Timely identification of problems allows for prompt solutions and minimizes downtime.

Fluid Changes and Filters

Changing fluids and filters on a consistent schedule is vital. Fresh oil and coolant contribute to smoother functioning and reduce the risk of overheating or mechanical failure. Always use high-quality products recommended for your specific model.

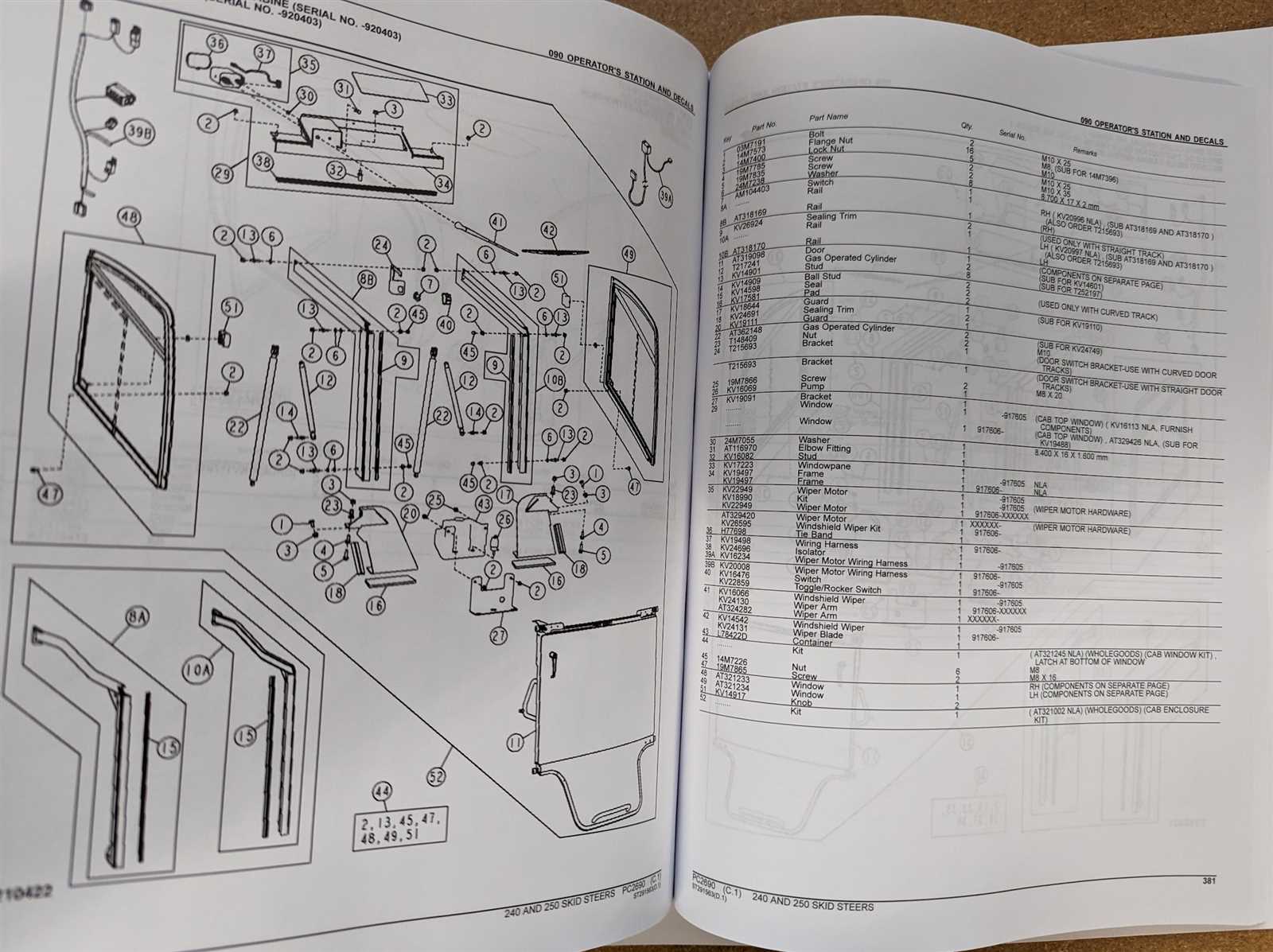

How to Access the Parts Diagram

To effectively obtain the visual representation of components for your equipment, follow these straightforward steps. This guide ensures that you can easily navigate through resources to find the necessary illustrations.

| Step | Action |

|---|---|

| 1 | Visit the official website of the manufacturer. |

| 2 | Navigate to the support or resources section. |

| 3 | Enter the model number of your machinery. |

| 4 | Locate the visual guide or reference for components. |

| 5 | Download or print the diagram for future use. |

By following these steps, you will have access to the ultimate resource for understanding your equipment’s assembly.

Importance of Accurate Parts Identification

Precise identification of components is crucial for efficient machinery maintenance and repair. Understanding the specific attributes of each element can lead to enhanced performance and longevity.

Benefits of accurate component recognition include:

- Reduced downtime through swift repairs

- Minimized risk of errors during maintenance

- Improved compatibility with existing machinery

- Enhanced safety for operators

Inaccurate identification can result in:

- Increased operational costs due to improper replacements

- Potential damage to equipment from mismatched parts

- Delays in service due to the need for re-ordering

Ultimately, a thorough understanding of each component fosters better decision-making, ensuring machinery operates at its peak efficiency.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward process if you know where to look. Whether you’re in need of specific items for repairs or maintenance, various resources are available to assist you in your search. Understanding these options will streamline the process and ensure you obtain quality replacements for your equipment.

Here are some effective sources to consider:

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides detailed listings and options for original equipment, ensuring compatibility and quality. |

| Local Dealerships | Authorized dealerships usually stock essential items and can offer expert advice on the best solutions for your needs. |

| Online Retailers | Many e-commerce platforms specialize in machinery components, allowing you to compare prices and availability easily. |

| Salvage Yards | For those on a budget, salvage yards can be treasure troves of used components at a fraction of the cost of new ones. |

| Forums and Community Groups | Engaging with online communities can provide insights and recommendations on where to find specific items, often from experienced users. |

Utilizing these avenues will enhance your chances of finding the right components efficiently and effectively.

Differences Between John Deere Models

Understanding the variations among different models of agricultural machinery is essential for making informed decisions. Each model brings unique features and specifications tailored to specific tasks, influencing efficiency and performance in the field.

Key Variations

- Engine Power: Different models may offer various horsepower options, impacting productivity.

- Size and Weight: Dimensions can affect maneuverability and suitability for diverse terrains.

- Transmission Types: Options range from manual to automatic, influencing ease of operation.

Feature Highlights

- Hydraulic Systems: Some models feature advanced hydraulics for better implement control.

- Cab Comfort: Variations in cab design enhance operator comfort and visibility.

- Technology Integration: Certain models come equipped with precision agriculture technology for data-driven farming.

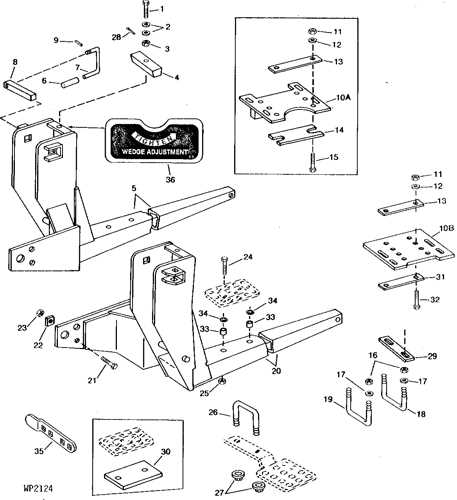

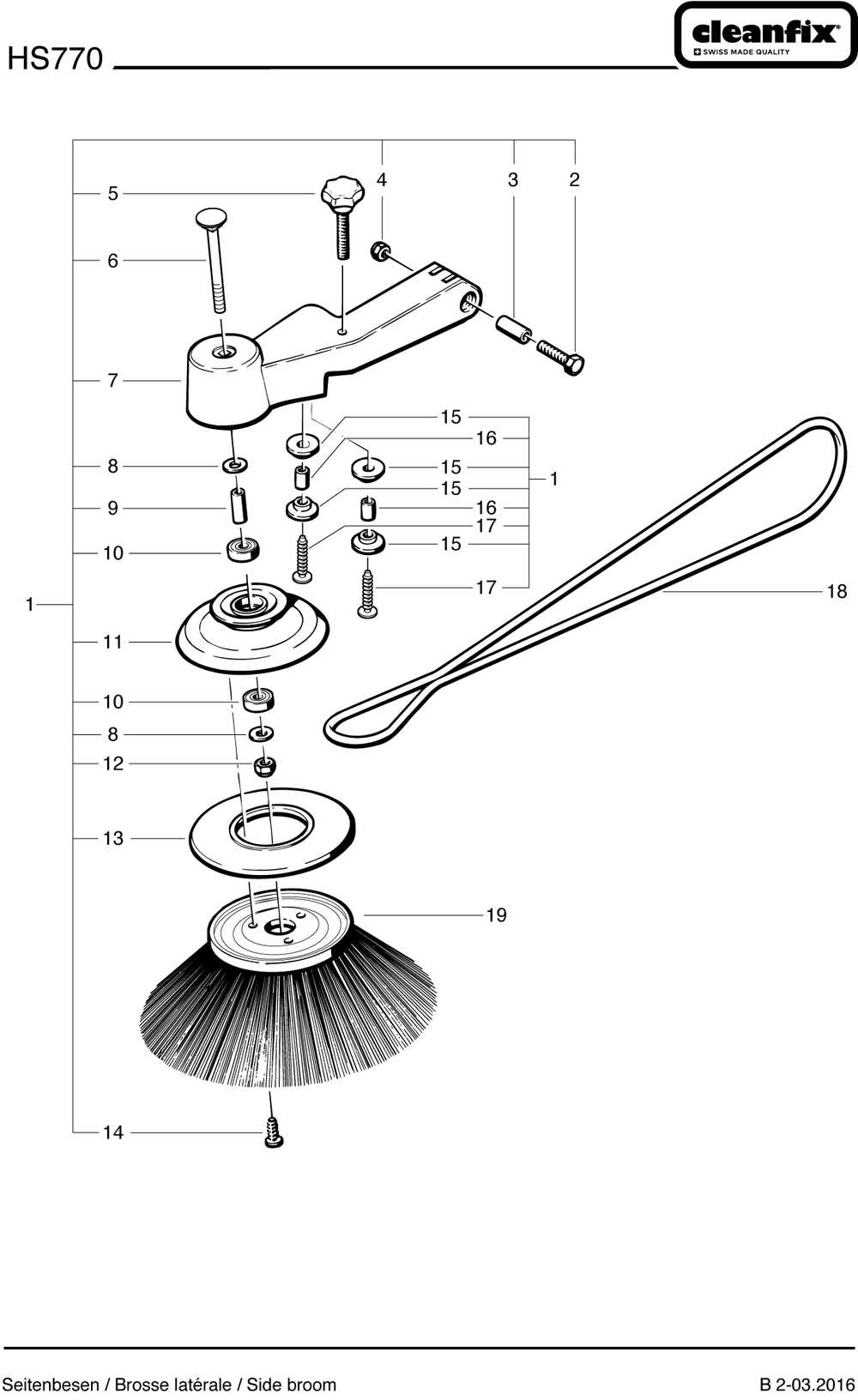

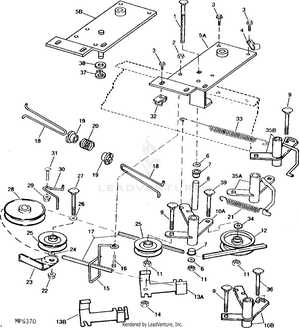

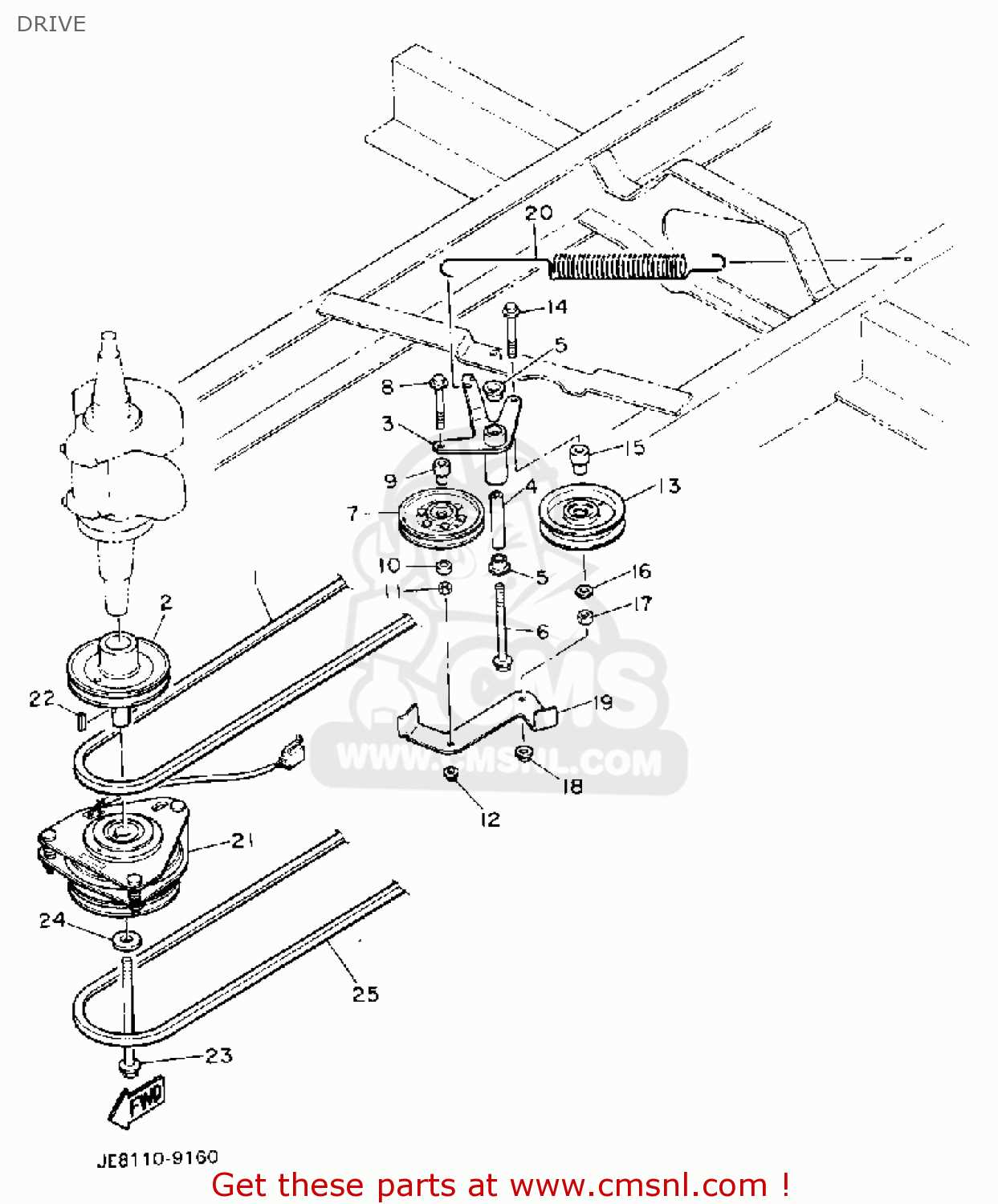

Using the Parts Diagram Effectively

Utilizing a visual reference for components can significantly enhance the maintenance and repair process. By understanding how to navigate this resource, users can quickly identify necessary elements, streamline troubleshooting, and facilitate more efficient repairs.

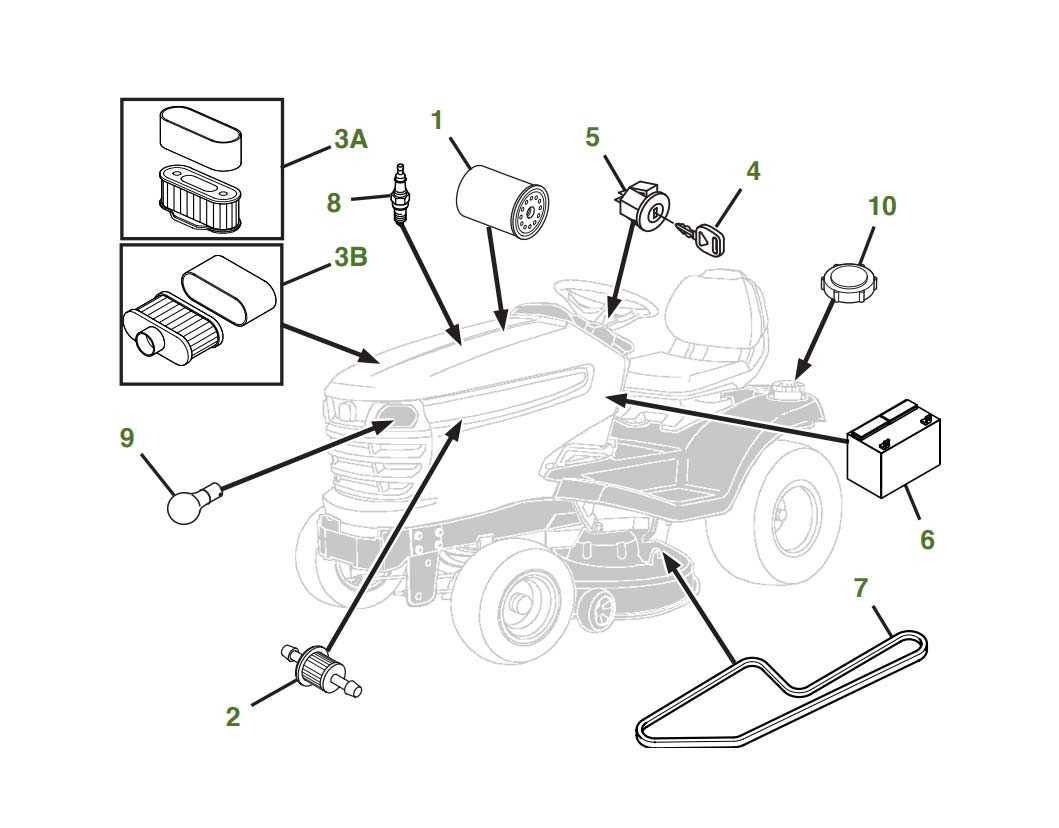

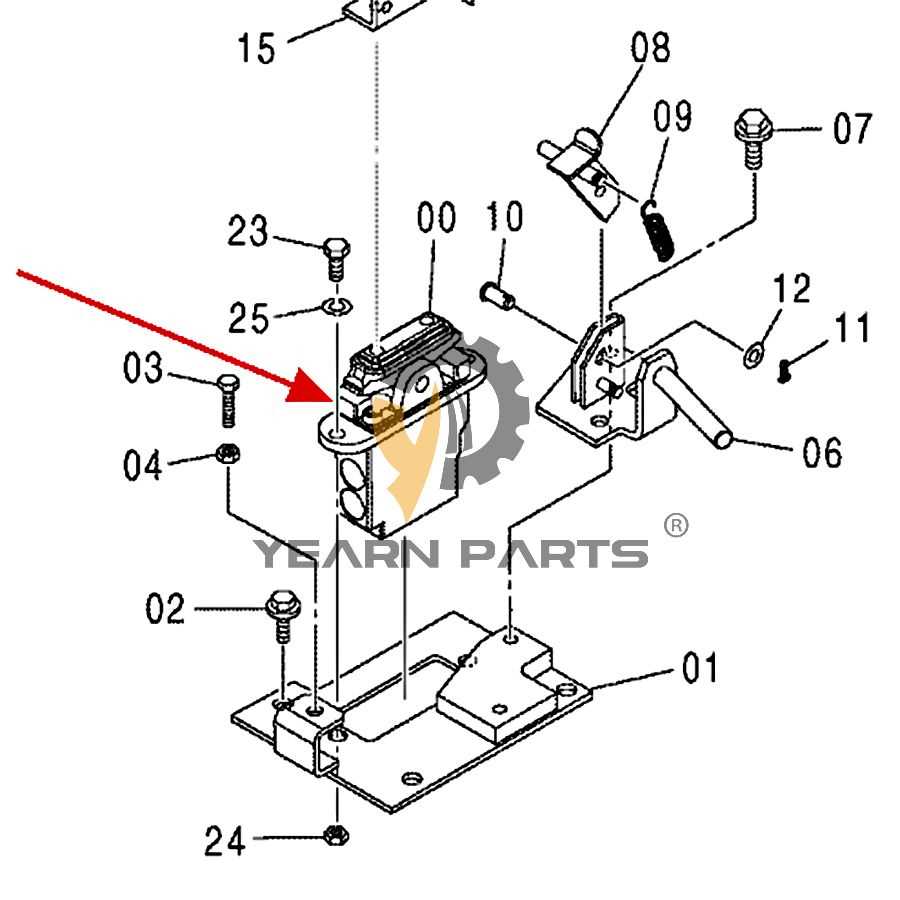

Identifying Key Components

Begin by familiarizing yourself with the layout of the visual reference. Each section typically corresponds to a specific assembly, allowing for easy navigation. Pay attention to labels and numbers, which guide you in pinpointing individual items. This knowledge not only helps in finding replacements but also aids in understanding the overall assembly structure.

Organizing Your Search

When looking for specific elements, it can be beneficial to categorize your search. Break down your needs into groups based on function or assembly type. This structured approach can reduce confusion and save time during the repair process. Below is an example of how to organize your search effectively:

| Category | Components | Notes |

|---|---|---|

| Engine | Fuel Pump, Filter, Gaskets | Check for wear and tear |

| Transmission | Gears, Bearings, Seals | Inspect for noise or slippage |

| Hydraulics | Pumps, Valves, Hoses | Look for leaks or blockages |

Expert Advice on Repairs and Parts

When it comes to maintaining your machinery, understanding the components and their functions is crucial for effective repairs. This section offers insights into best practices for troubleshooting and sourcing essential components.

- Always refer to manufacturer resources for accurate specifications.

- Invest in quality tools to ensure efficient disassembly and reassembly.

- Document your repair process to help with future maintenance.

For anyone looking to enhance their knowledge and skills in repairs, consider the following recommendations:

- Join local repair workshops or online forums for shared expertise.

- Keep a log of common issues and solutions encountered during repairs.

- Stay updated on new technologies and parts for better performance.

Taking these steps will ultimately lead to improved efficiency and longevity of your equipment.

Tools Needed for John Deere Repairs

When it comes to maintenance and restoration tasks, having the right equipment is essential for efficiency and effectiveness. Whether you are performing routine checks or tackling more complex repairs, the selection of tools can significantly impact the quality of your work and the longevity of the machinery.

Essential Tools for Maintenance

For everyday upkeep, a basic set of hand tools is indispensable. This includes wrenches, screwdrivers, and pliers, which are crucial for accessing various components. Additionally, a reliable jack and jack stands are important for safely lifting and supporting the equipment during repairs.

Specialized Equipment for Repairs

Some repairs may require specialized tools to ensure precision and ease of use. Items such as torque wrenches are vital for maintaining the correct tension on bolts, while multimeters are essential for diagnosing electrical issues. Investing in a quality toolbox to organize these instruments will streamline your workflow and keep everything accessible.

Upgrades and Modifications for Performance

Enhancing the efficiency and capability of your machinery can significantly impact productivity and overall performance. By implementing specific upgrades and modifications, you can achieve better functionality and responsiveness, tailored to your operational needs.

Consider the following enhancements to optimize your equipment:

- Engine Tuning: Adjusting fuel mixtures and ignition timing can lead to improved horsepower and torque.

- Exhaust Systems: Upgrading to a high-flow exhaust can reduce back pressure, enhancing engine efficiency.

- Transmission Improvements: Installing a performance transmission can provide smoother shifting and quicker response times.

- Suspension Upgrades: Enhanced suspension systems improve stability and handling, especially in rugged terrains.

- Wheel and Tire Choices: Opting for specialized tires can improve traction and handling under various conditions.

Additionally, consider the following modifications:

- Implementing advanced hydraulic systems for better control and power.

- Upgrading lighting systems for improved visibility during low-light conditions.

- Integrating precision guidance technology to enhance accuracy in operations.

Each of these upgrades can contribute to a more effective and responsive machine, ensuring that it meets the demands of your tasks with greater ease and efficiency.

Customer Reviews of John Deere 240 Parts

This section explores the feedback from users regarding components for a popular machinery model. Insights from various customers can guide potential buyers in making informed decisions and understanding the reliability and performance of these essential items.

Overall Satisfaction

Many users express positive experiences, highlighting durability and functionality:

- High-quality materials

- Easy installation process

- Improved machine performance

Common Concerns

Some reviewers note areas for improvement:

- Occasional shipping delays

- Incompatibility with certain models

- Limited customer support options