In any mechanical system, the arrangement and relationship between various elements play a crucial role in ensuring functionality and efficiency. Grasping how these components interact can significantly enhance maintenance and repair processes. This section aims to provide clarity on these intricate layouts, offering insights that can be applied across various applications.

By exploring the intricacies of assembly configurations, one can uncover vital information about compatibility and performance. Knowledge of how each piece contributes to the overall mechanism not only aids in troubleshooting but also elevates the user’s understanding of the equipment’s capabilities.

In this discussion, we will delve into the essential features of these configurations, highlighting the ultimate significance of comprehending each element’s purpose. Whether for personal use or professional applications, a thorough grasp of these layouts is indispensable for anyone looking to optimize their operational efficiency.

Understanding Tb475ss Components

This section explores the essential elements that contribute to the functionality of a specific machine model. Each component plays a vital role, ensuring that the overall system operates smoothly and efficiently.

Key Elements

Components can be classified based on their functions, with each serving a unique purpose. Understanding these classifications helps in maintenance and troubleshooting.

| Component | Function |

|---|---|

| Engine | Drives the overall performance. |

| Transmission | Facilitates gear changes. |

| Hydraulic System | Controls movement and power. |

| Chassis | Provides structural support. |

Importance of Maintenance

Regular upkeep of these elements is crucial for longevity and efficiency. Identifying and understanding each part’s role allows for better management of the machine’s performance.

Overview of Tb475ss Parts

This section provides a comprehensive look at the components that contribute to the overall functionality of the machinery. Understanding these elements is essential for maintenance, repair, and optimal performance.

- Engine assembly: Vital for power generation.

- Transmission unit: Ensures smooth power transfer.

- Hydraulic system: Facilitates movement and operation.

- Electrical components: Crucial for functionality and safety.

- Chassis structure: Provides support and stability.

Each component plays a critical role in the seamless operation of the equipment, and knowing their functions can help in troubleshooting and enhancing performance.

Importance of Accurate Diagrams

Precise representations of components are crucial in various fields, ensuring clarity and efficiency in assembly and maintenance processes. These visual tools not only guide users but also minimize errors that could arise from misinterpretation. Accurate schematics enhance communication among team members, fostering collaboration and productivity.

Enhancing Efficiency

When individuals rely on detailed illustrations, the time spent on assembling or repairing equipment significantly decreases. By providing a clear roadmap, these visual aids help streamline workflows and enable quicker decision-making, ultimately leading to increased operational effectiveness.

Reducing Errors

Inaccurate representations can lead to costly mistakes, resulting in wasted resources and potential safety hazards. Employing reliable visuals helps to mitigate these risks by offering a trustworthy reference that users can depend on, ensuring that tasks are completed correctly the first time.

Common Issues with Tb475ss Units

Every mechanical unit can encounter challenges over time, affecting its overall performance and reliability. Understanding these common problems can help users troubleshoot effectively and ensure longevity. Addressing these issues promptly not only enhances functionality but also prevents further complications.

One frequent concern involves overheating, which can result from inadequate cooling systems or blocked vents. Regular maintenance and cleaning can mitigate this risk, ensuring optimal airflow.

Another issue relates to power supply failures, often due to worn-out cables or connectors. Inspecting these components regularly can help identify potential faults before they lead to significant malfunctions.

Leaking fluids is also a prevalent problem, usually indicating worn seals or gaskets. Timely replacement of these parts can prevent further damage and maintain efficiency.

By being aware of these common issues, users can take proactive measures to enhance the durability and effectiveness of their units.

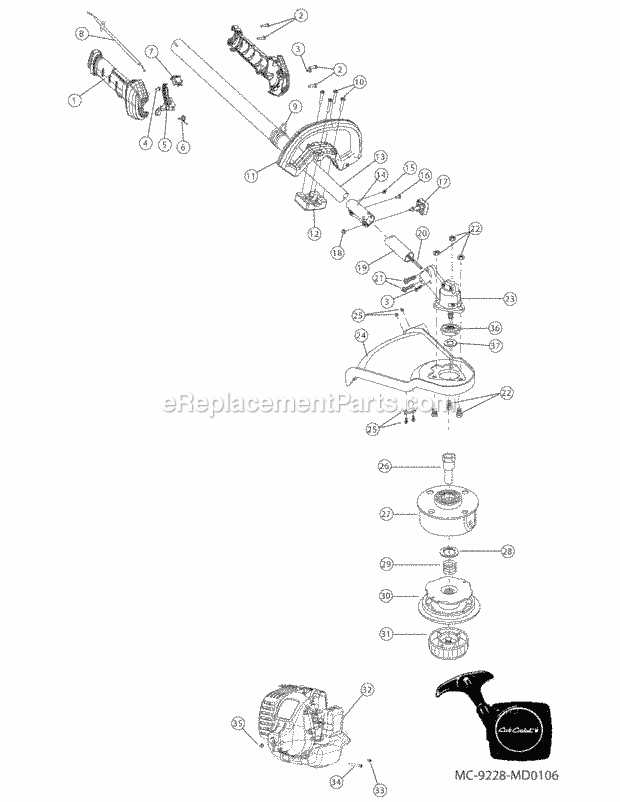

Step-by-Step Diagram Analysis

This section focuses on the meticulous breakdown of visual schematics to enhance understanding and facilitate effective maintenance. By examining each component methodically, we can gain insights into their functions and interrelationships, ultimately leading to more informed decision-making during repairs and upgrades.

Understanding Component Functions

To start, it is essential to identify each element represented in the schematic. Recognizing the purpose of every part not only aids in troubleshooting but also assists in the assembly and disassembly processes. For instance, valves control flow, while connectors establish essential links between sections. A thorough grasp of these functions will empower technicians to address issues swiftly and accurately.

Interpreting Connections and Relationships

Next, analyzing the connections between various elements reveals the operational dynamics of the entire system. Observing how different pieces interact can highlight potential points of failure or inefficiency. Diagrams often illustrate these links through lines and symbols, making it easier to trace pathways and understand the flow of operation. By following these connections, one can identify not only how to repair faults but also how to optimize overall performance.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective assembly and maintenance. These illustrations provide a detailed overview of individual elements and their relationships within a larger system. By mastering the interpretation of these visuals, you can enhance your ability to identify and locate each piece accurately.

Here are some essential tips for interpreting these visuals:

- Familiarize Yourself with Symbols: Each representation uses specific symbols and notations. Learn what each symbol signifies to avoid confusion.

- Identify the Legend: Most visuals include a legend or key. This section clarifies the meaning of different icons and line types.

- Follow the Layout: Components are often arranged systematically. Understanding the flow can help you trace connections and functionalities.

- Take Note of Labels: Labels often provide crucial information about each element, including part numbers and descriptions.

- Cross-Reference with Manuals: Use user manuals or assembly guides alongside the visual for comprehensive understanding.

By applying these strategies, you can efficiently navigate these visual aids, making your tasks smoother and more informed.

Essential Tools for Repair

Having the right equipment is crucial for any repair task. Whether tackling mechanical issues or performing maintenance, specific instruments can significantly enhance efficiency and effectiveness. This section outlines the fundamental tools needed for successful repairs.

Basic Hand Tools

- Wrenches: Ideal for gripping and turning fasteners.

- Screwdrivers: Essential for removing and inserting screws.

- Pliers: Versatile tools for gripping, bending, and cutting.

Power Tools

- Drills: Useful for creating holes and driving screws with ease.

- Impact Wrenches: Provide high torque for loosening stubborn bolts.

- Grinders: Perfect for shaping and finishing materials.

Equipping yourself with these tools will ultimately streamline your repair projects and yield professional results.

Finding Quality Replacement Parts

When it comes to maintaining machinery or equipment, sourcing high-quality components is essential for optimal performance and longevity. The market is filled with options, making it crucial to discern which offerings meet the necessary standards of reliability and durability.

Research is your best ally in this quest. Start by seeking reputable suppliers known for their commitment to quality. Reviews and testimonials from other users can provide invaluable insights into the effectiveness of specific items.

Additionally, consider the materials used in the components. Higher-grade materials often translate to better performance and a longer lifespan. Don’t hesitate to reach out to manufacturers for specifications and certifications that verify the quality of their products.

Finally, ensure that you’re not only looking for affordable options but also weighing the long-term value of your investment. A well-chosen component can save time and money in repairs down the line.

Manufacturer Specifications and Guidelines

This section aims to provide a comprehensive overview of the essential requirements and recommendations set forth by the manufacturer. Adhering to these standards ensures optimal performance, safety, and longevity of the equipment. It is crucial for users to familiarize themselves with these guidelines to maintain functionality and prevent potential issues.

Key Requirements

The manufacturer outlines specific criteria that must be met for proper operation. These include recommended materials, operating conditions, and maintenance schedules. Users should consult the provided documentation to understand the necessary precautions and optimal usage practices. Regular adherence to these specifications is vital for achieving the best results and avoiding unnecessary wear and tear.

Maintenance Recommendations

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires regular attention and care. By implementing a few straightforward practices, you can significantly enhance performance and reliability over time. These strategies focus on routine inspections, timely servicing, and mindful usage, ultimately preserving your investment.

Regular Cleaning: Keeping the equipment clean is vital. Accumulated dirt and debris can hinder functionality and lead to premature wear. Schedule frequent cleanings, paying special attention to hard-to-reach areas where buildup can occur.

Routine Inspections: Conduct periodic checks to identify any signs of wear or damage early. Look for unusual noises, vibrations, or leaks, and address them promptly to prevent more significant issues down the line.

Proper Lubrication: Adequate lubrication minimizes friction between moving parts, reducing wear and tear. Use the recommended lubricants and adhere to suggested intervals for application to maintain smooth operation.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions for maintenance schedules and operational practices. Adhering to these recommendations ensures optimal performance and longevity.

Mindful Operation: Train all operators on best practices for using the machinery. Gentle handling and avoiding overloading can greatly reduce stress on components, leading to longer service life.

By integrating these maintenance strategies into your routine, you will not only enhance the efficiency of your equipment but also prolong its operational life, ensuring reliability for years to come.

Expert Recommendations for Repairs

When tackling maintenance tasks, following expert guidance can significantly enhance the success of your endeavors. Skilled professionals emphasize a few key practices that can streamline the repair process and ensure longevity of the equipment.

- Thorough Diagnosis: Always begin with a detailed assessment to identify the root cause of the issue.

- Quality Components: Use high-quality replacements to avoid future complications and enhance performance.

- Documentation: Keep a record of previous repairs and modifications to inform future maintenance.

- Safety Precautions: Always prioritize safety by wearing appropriate gear and following proper protocols.

Implementing these strategies will not only facilitate effective repairs but also contribute to the overall reliability of the machinery.

Where to Source Parts Online

Finding components for machinery or equipment can be challenging, but the internet provides a plethora of resources to streamline this process. Whether you’re looking for replacements or upgrades, numerous platforms cater to various needs and budgets. Understanding where to search can save time and ensure you acquire quality items.

Popular Online Marketplaces

Many people turn to well-known e-commerce sites, which offer a wide array of options from multiple sellers. These platforms often feature user reviews and ratings, helping buyers make informed choices. Additionally, they typically provide buyer protection policies, enhancing the purchasing experience.

Specialized Retailers

For more specific requirements, specialized retailers can be invaluable. These sites focus on particular industries or types of machinery, offering expert advice and detailed catalogs. Often, they carry hard-to-find items that general marketplaces may lack, ensuring you get precisely what you need.