The intricate design of mechanical systems often necessitates a clear representation of their various elements. An effective visualization aids in comprehending how individual components interact and function within a larger assembly. This understanding is crucial for both enthusiasts and professionals alike, ensuring efficient maintenance and repair processes.

Detailed illustrations serve as invaluable resources, offering insights into the arrangement and connectivity of each segment. By examining these visuals, one can identify specific features, enhance troubleshooting skills, and facilitate informed decisions regarding repairs or upgrades. Overall, such resources are essential for achieving optimal performance and longevity in any mechanical device.

In addition to fostering a deeper understanding, these representations also empower users to become more hands-on with their equipment. Whether for routine maintenance or extensive modifications, having access to comprehensive layouts makes it easier to navigate complexities and enhance functionality. Engaging with these resources transforms the maintenance experience, making it both efficient and enlightening.

This section provides a comprehensive look at a specific vehicle model known for its performance and reliability. It covers essential aspects of the vehicle, including its key features, capabilities, and significance in the automotive world.

- Performance Features: A discussion on engine specifications, transmission options, and overall driving experience.

- Design Aspects: Insights into the exterior and interior design, focusing on aesthetics and functionality.

- Technological Advancements: An overview of modern technologies integrated into the vehicle, enhancing safety and convenience.

- Market Position: An analysis of how this vehicle stands against competitors in its class, including customer preferences.

This section aims to equip readers with a foundational understanding of the vehicle, paving the way for deeper exploration into its components and maintenance.

Importance of Parts Diagrams

Understanding the layout and function of various components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, allowing users to identify individual elements and their relationships with one another. This clarity promotes efficient troubleshooting and enhances the overall lifespan of equipment.

These visual aids provide numerous benefits:

- Enhanced Clarity: Clear illustrations help users quickly locate and comprehend each component’s role.

- Improved Efficiency: By simplifying the identification process, users can perform repairs and replacements more swiftly.

- Facilitated Communication: Shared visuals can bridge gaps between technicians and non-experts, ensuring everyone is on the same page.

- Training Support: New users can reference these guides to learn about the system’s structure and functionality.

- Accurate Ordering: When parts need to be replaced, visual references ensure correct identification, reducing the likelihood of errors.

In conclusion, utilizing these representations is essential for anyone involved in the upkeep of machinery. Their role in streamlining processes and fostering understanding cannot be overstated.

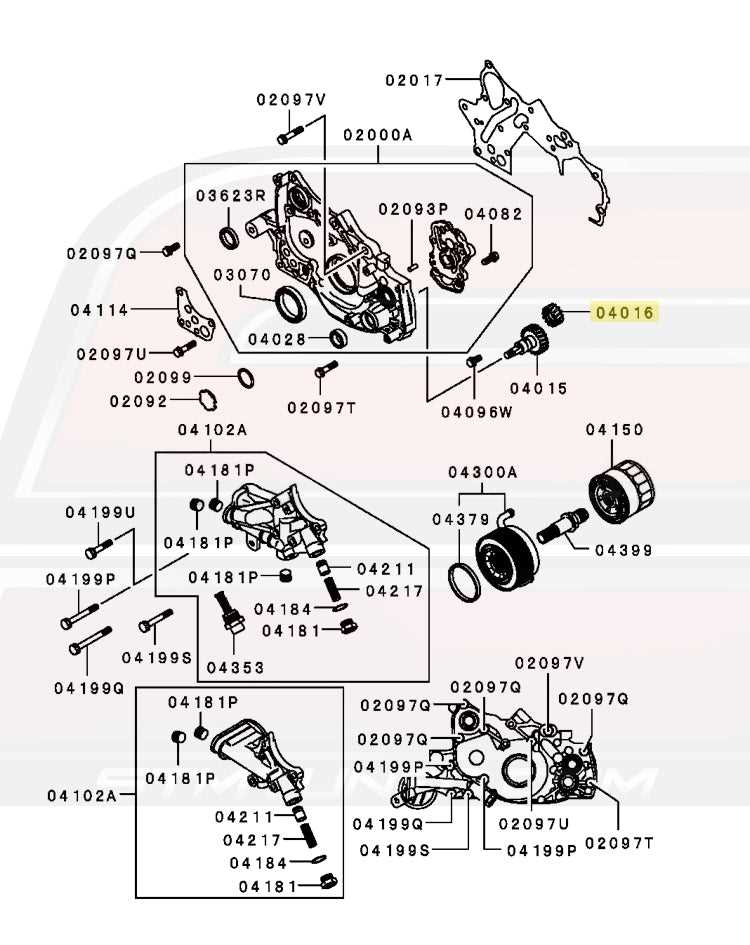

Key Components of GT600

This section delves into the essential elements that contribute to the overall functionality of this model. Understanding these critical parts helps users appreciate how the system operates efficiently and how various components work together to ensure optimal performance.

Powertrain Elements

The powertrain is a fundamental aspect of this machinery, consisting of the engine, transmission, and associated systems. These components play a crucial role in delivering the required power and torque, facilitating smooth operation across various conditions. The integration of advanced technologies in these parts enhances fuel efficiency and overall performance.

Chassis and Suspension

The chassis and suspension systems are vital for stability and handling. The design of these elements ensures that the vehicle can absorb shocks and maintain traction on different surfaces. A well-engineered chassis contributes to the overall safety and comfort of the ride, providing a solid foundation for all other components.

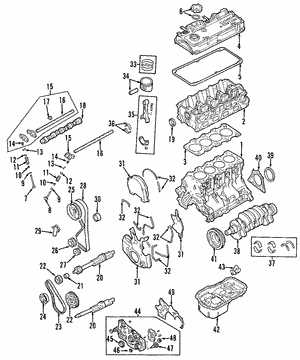

Understanding the Diagram Layout

Grasping the arrangement of technical illustrations is essential for effective comprehension of complex machinery. These visual representations serve as a valuable tool for identifying various components and their interconnections. By familiarizing oneself with the structure of these illustrations, individuals can enhance their understanding of how different parts function together.

Key Elements of the Illustration

Each visual guide typically includes several key elements that contribute to its informative value. Labels, symbols, and color coding are commonly employed to signify different components and their functions. Understanding these features allows users to quickly locate and interpret the information necessary for troubleshooting or maintenance.

Interpreting Connections and Relationships

Recognizing how components relate to one another is crucial for effective operation and repair. Arrows and lines often indicate connections, helping to illustrate how energy or information flows between parts. A thorough understanding of these relationships aids in diagnosing issues and planning maintenance tasks efficiently.

Identifying Essential Parts

Understanding the key components of any machinery is crucial for effective maintenance and optimal performance. Recognizing these fundamental elements enables users to troubleshoot issues efficiently and ensures the longevity of the equipment. Each segment plays a vital role in the overall functionality, and being familiar with their characteristics can significantly enhance operational efficiency.

To begin with, it’s important to familiarize oneself with the primary elements that constitute the machine. These include the engine, transmission, and electrical systems, each of which contributes uniquely to the unit’s operation. Knowing how these components interact allows for better diagnosis when problems arise and assists in making informed decisions regarding repairs and replacements.

Furthermore, understanding the layout and arrangement of these components can aid in identifying potential wear and tear areas. Regular inspections of these crucial sections can prevent unexpected breakdowns and promote a smoother operational process. This knowledge empowers users to take proactive measures, ensuring that the equipment remains in peak condition.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires regular attention and care. By following a few essential maintenance practices, you can enhance its durability and efficiency over time. This section highlights key strategies to keep your machinery in optimal condition.

Regular Inspections: Conducting frequent checks on your device is vital. Look for signs of wear and tear, and address any issues promptly. Early detection can prevent more significant problems and costly repairs.

Proper Lubrication: Maintaining adequate lubrication is crucial for the smooth operation of moving parts. Use the recommended lubricants to minimize friction and reduce the risk of overheating. Always consult the manufacturer’s guidelines for specific requirements.

Cleaning and Dust Removal: Keeping your equipment clean can significantly impact its performance. Regularly remove dust and debris that may accumulate in crevices and on surfaces. This practice not only improves efficiency but also prevents potential blockages or overheating.

Timely Replacement of Worn Components: Identifying and replacing components that show signs of wear is essential for maintaining functionality. Establish a schedule for replacing parts based on usage and condition to ensure reliability.

Adhering to Operating Guidelines: Following the operational guidelines provided by the manufacturer is fundamental. Proper usage techniques can prolong the life of your equipment and enhance its performance, ultimately leading to fewer issues down the line.

Common Issues with GT600 Parts

When dealing with the components of a specific model, various challenges may arise that can affect performance and reliability. Understanding these potential problems is crucial for maintenance and ensuring longevity. Below are some common concerns associated with these elements.

Frequent Problems Encountered

- Worn-out seals leading to fluid leaks

- Corrosion on electrical connections, causing failures

- Misalignment of moving parts resulting in excessive wear

Preventative Measures

- Regular inspections to identify early signs of wear

- Utilizing protective coatings to reduce corrosion

- Following manufacturer recommendations for component replacement

Where to Find Replacement Parts

Locating suitable components for your vehicle can often be a challenging task. Various options are available to ensure you find the right items to maintain optimal performance. By exploring different sources, you can discover quality alternatives that fit your needs.

One effective method is to check online marketplaces, where numerous sellers offer a wide range of components. These platforms often provide user reviews and ratings, helping you make informed decisions. Additionally, specialized websites dedicated to automotive supplies can be a treasure trove of resources, showcasing both new and refurbished items.

Local retailers and automotive supply shops are also valuable resources. Visiting these establishments allows you to consult with knowledgeable staff who can guide you in selecting the appropriate components. Furthermore, many shops maintain partnerships with manufacturers, ensuring access to reliable replacements.

Another option is to connect with online forums or communities dedicated to vehicle enthusiasts. Engaging with other users can lead to recommendations for reputable suppliers or individuals selling components directly. This network can provide insights into the best places to find what you need.

Comparing GT600 to Similar Models

This section provides an overview of how a specific vehicle compares to its counterparts within the same category. By examining various features, specifications, and performance metrics, we can better understand the strengths and weaknesses of this model in relation to others that share similar characteristics.

When assessing vehicles of this type, it is essential to consider factors such as engine performance, fuel efficiency, and technological advancements. While some models may excel in power and handling, others might offer superior comfort or safety features. Analyzing these aspects helps potential buyers make informed decisions based on their unique preferences and requirements.

Additionally, the availability of upgrades and modifications can significantly influence a model’s appeal. Some competitors may provide a wider range of aftermarket options, enhancing customization and overall driving experience. By comparing these elements, enthusiasts and consumers alike can identify which model aligns best with their expectations and lifestyle.

Tools for Part Replacement

When it comes to replacing components in machinery, having the right tools is essential for ensuring a smooth and efficient process. The selection of instruments can greatly impact the ease of disassembly and reassembly, leading to successful maintenance and functionality.

Proper preparation and knowledge of the necessary tools can save time and prevent damage to delicate elements. Below is a list of common tools used in component replacement:

| Tool Type | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing screws of various sizes. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

| Torque Wrench | Ensures proper tension on bolts for safety. |

| Jack and Stands | For safely lifting and supporting equipment during work. |

| Cleaning Supplies | For removing dirt and debris from components. |

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling a complex mechanical system. By following these detailed instructions, you will gain insights into the order of operations and key components necessary for successful construction.

Preparation Before Assembly

- Gather all necessary tools and equipment.

- Ensure all components are clean and free from damage.

- Review the assembly sequence to familiarize yourself with the process.

Assembly Steps

- Begin by securing the base structure in a stable position.

- Attach the primary frame elements according to the outlined order.

- Integrate secondary components, ensuring proper alignment and fit.

- Install any necessary fasteners, making sure they are tightened adequately.

- Conduct a thorough inspection of the assembled unit for any potential issues.

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users regarding their recent purchases. Feedback from customers is crucial as it provides valuable information about the performance and reliability of the items, assisting potential buyers in making informed decisions.

Overall Satisfaction

Many users express a high level of satisfaction with their acquisitions, noting the quality and effectiveness of the components. Positive remarks often emphasize durability and ease of installation, which contribute to a seamless experience.

Areas for Improvement

While most feedback is favorable, some customers mention specific aspects that could be enhanced. Suggestions for improvement typically involve more detailed instructions and increased availability of certain components. Constructive criticism helps manufacturers understand consumer needs better.

Expert Recommendations for Users

When it comes to maintaining and enhancing your vehicle’s performance, expert guidance can be invaluable. Understanding essential components and their functions ensures that you can make informed decisions regarding repairs and upgrades. Below are some key suggestions to help you navigate this process effectively.

Regular Maintenance Checks

Conducting routine inspections is crucial for identifying potential issues before they escalate. Consider the following points:

- Inspect fluid levels regularly to ensure optimal operation.

- Check for signs of wear and tear on key components.

- Clean air filters and replace them as necessary.

Utilizing Quality Components

When it comes time to replace any elements, prioritizing quality can significantly impact your vehicle’s longevity and efficiency. Here are some recommendations:

- Opt for OEM (Original Equipment Manufacturer) products when possible.

- Research reliable aftermarket options that meet or exceed original specifications.

- Consult with professionals to ensure compatibility and performance.