In the realm of agricultural machinery, the significance of effective cutting equipment cannot be overstated. These tools are essential for maintaining fields and ensuring optimal crop yields. To keep such machinery functioning at its best, a thorough understanding of its various components is crucial.

The intricacies of these machines often involve numerous elements, each playing a vital role in overall performance. Whether it’s the drive system, the cutting mechanism, or the support structure, knowing how these parts interact can greatly enhance operational efficiency.

For enthusiasts and operators alike, having a clear visual reference of these components can simplify maintenance and repair tasks. By familiarizing oneself with the layout and function of each element, one can ensure longevity and reliability in their equipment.

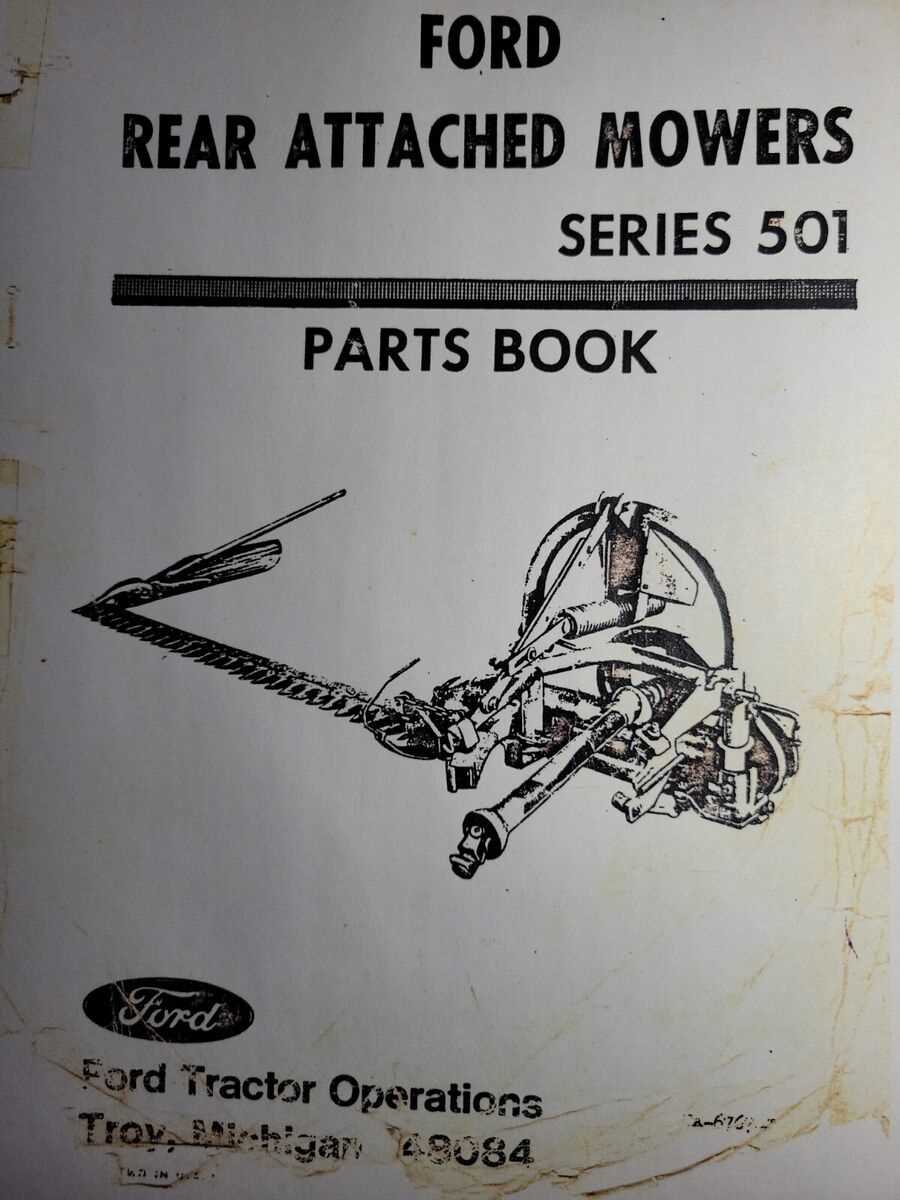

Understanding the Ford 501 Sickle Bar Mower

This section explores the intricacies of a classic cutting implement designed for agricultural use, highlighting its components, functionality, and maintenance practices.

Key features of this implement include:

- Efficient cutting mechanism

- Durable construction materials

- Compatibility with various tractors

To maximize performance, consider the following maintenance tips:

- Regularly inspect blades for sharpness

- Lubricate moving parts to reduce wear

- Check for proper alignment to ensure efficient operation

Understanding these elements will ultimately enhance the longevity and effectiveness of the cutting equipment in various farming tasks.

Key Components of the Mower

Understanding the essential elements of a cutting machine is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity. Below, we explore the primary features that contribute to the functionality of this agricultural equipment.

| Component | Description |

|---|---|

| Cutter Head | The primary unit responsible for the actual cutting action, featuring sharp blades designed for precision. |

| Drive Mechanism | This system transmits power from the engine to the cutting unit, ensuring smooth operation. |

| Mounting Frame | The structure that supports all components, providing stability and durability during use. |

| Safety Guards | Protective features that help prevent accidents and injuries while the machine is in operation. |

| Adjustable Hitch | This element allows for easy connection to various tractors, ensuring compatibility and efficient use. |

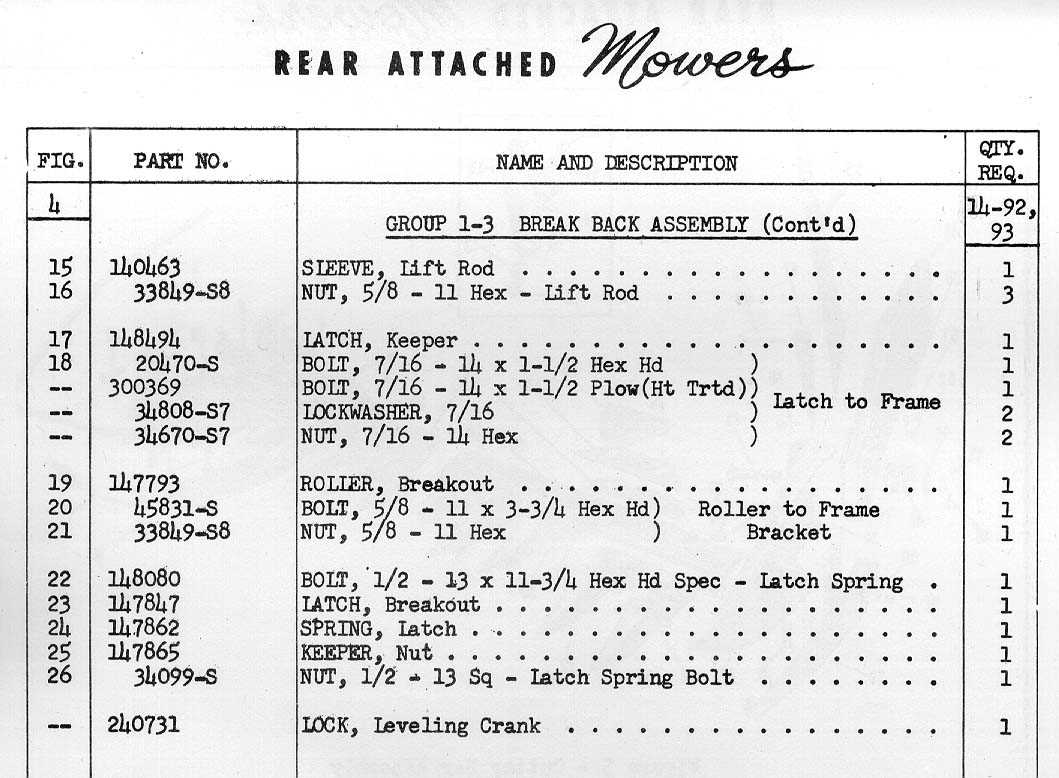

Importance of the Parts Diagram

Understanding the layout and components of machinery is crucial for efficient maintenance and operation. A visual representation of these elements helps users identify each piece, ensuring they can address issues swiftly and accurately.

Enhanced Maintenance

By utilizing a clear illustration, operators can easily locate specific components that require attention. This clarity minimizes downtime and promotes effective repairs, leading to increased productivity.

Efficient Troubleshooting

Having a comprehensive visual guide allows users to diagnose problems quickly. Identifying malfunctioning elements is simplified, enabling targeted interventions that ultimately enhance the longevity of the equipment.

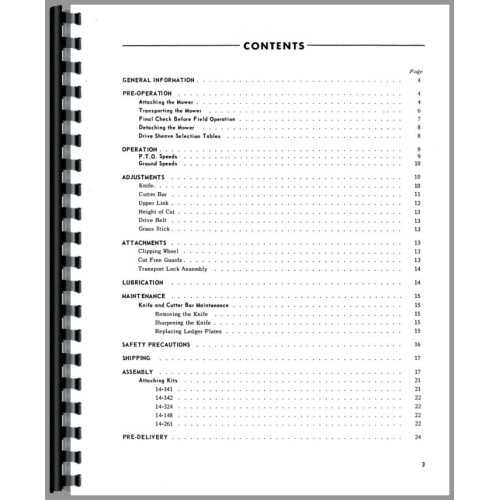

How to Read the Diagram Effectively

Understanding a technical illustration is crucial for successful maintenance and repair. It provides a visual representation that simplifies the identification of components and their relationships. By approaching it methodically, you can enhance your efficiency and accuracy.

First, familiarize yourself with the legend or key, which often explains symbols and colors used throughout the illustration. This will be your guide to deciphering various elements.

Next, break down the image into sections. Focus on one area at a time to avoid feeling overwhelmed. This segmented approach allows you to delve deeper into specific functions and assemblies.

Finally, refer to the illustration while handling actual components. This hands-on method reinforces your understanding and helps you make connections between theory and practice, leading to ultimate proficiency.

Common Replacement Parts for Ford 501

When maintaining agricultural machinery, understanding the essential components that often require replacement is crucial for optimal performance. Various elements contribute to the overall functionality of the equipment, ensuring efficiency and longevity in the field.

Blades are vital for achieving a clean cut, and regular inspection can prevent issues caused by wear and tear. Drive belts also play a critical role in power transmission; replacing them as they fray or lose tension is necessary for smooth operation. Additionally, bearings are integral for maintaining proper alignment and reducing friction, making them a common point of replacement.

Another important aspect is the gearbox, which should be checked periodically for any signs of leakage or damage. Ensuring that all components are functioning well will enhance the machinery’s efficiency and extend its lifespan.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By following a few straightforward practices, you can enhance performance and prevent potential issues down the line.

- Routine Cleaning: Remove debris and buildup after each use. This prevents rust and wear, allowing components to function smoothly.

- Inspect Blades: Regularly check cutting edges for dullness or damage. Sharpening or replacing them as needed ensures clean cuts and reduces strain on the machinery.

- Lubrication: Apply lubricant to moving parts according to the manufacturer’s guidelines. This minimizes friction and extends the life of mechanical components.

- Tighten Fasteners: Periodically check bolts and screws for tightness. Vibrations during operation can loosen connections, leading to misalignment or failure.

- Monitor Fluid Levels: Keep an eye on oil and hydraulic fluid levels. Maintaining proper levels ensures optimal operation and prevents overheating.

Implementing these practices not only enhances functionality but also contributes to a safer operating environment. Regular attention to these areas will pay off in improved efficiency and reduced downtime.

Identifying Worn-Out Components

Understanding when machinery parts have deteriorated is crucial for maintaining optimal performance and preventing further damage. Recognizing signs of wear can help ensure longevity and efficiency in operation. This section will outline key indicators that may suggest components are in need of replacement or repair.

Common Signs of Wear

Several symptoms can indicate that a component is worn out. Regular inspections can help identify these issues before they lead to significant problems.

| Indicator | Description |

|---|---|

| Excessive Noise | Unusual sounds during operation may indicate friction or misalignment in parts. |

| Vibration | Increased vibration can signal imbalance or degradation of components. |

| Visual Damage | Cracks, rust, or missing pieces can directly affect performance and should be addressed immediately. |

| Decreased Efficiency | Lower output or increased fuel consumption may point to worn components that are no longer functioning properly. |

Regular Maintenance Practices

To effectively identify worn-out components, implementing routine maintenance is essential. This includes periodic inspections, cleaning, and timely lubrication. Keeping a maintenance log can also help track performance over time, making it easier to spot potential issues.

Tools Required for Repairs

When undertaking maintenance or fixing machinery, having the right instruments is essential for efficiency and effectiveness. This section outlines the necessary tools that facilitate a smooth repair process.

Essential Hand Tools

- Wrenches (various sizes)

- Socket set

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Hammer

Specialized Equipment

- Torque wrench

- Grease gun

- Multimeter

- Cutting tools (saw or snips)

- Safety gear (gloves and goggles)

Equipping yourself with these tools ensures that you can delve into repairs effectively, achieving the ultimate results with minimal hassle.

Where to Source Genuine Parts

Finding authentic components for your equipment is essential for maintaining its performance and longevity. Reliable sources ensure that you receive high-quality items that meet the original specifications, thus safeguarding your investment.

Authorized Dealers: Begin your search with authorized distributors who specialize in specific machinery. They often carry a comprehensive inventory and can provide expert guidance.

Manufacturer Websites: Visit the official site of the machinery manufacturer. Many offer online catalogs and direct purchasing options for genuine components.

Reputable Online Retailers: Explore established e-commerce platforms that focus on equipment parts. Look for sellers with positive reviews and clear return policies to guarantee satisfaction.

Local Repair Shops: Don’t overlook local mechanics or repair shops. They may have direct access to authentic items and can offer installation services, saving you time and effort.

Always verify the authenticity of components before purchasing to ensure optimal performance and durability.

Upgrading Your Mower with New Parts

Enhancing your cutting equipment can significantly improve its performance and longevity. By integrating fresh components, you not only boost efficiency but also ensure a smoother operation, ultimately leading to better results in the field. Regular updates are essential to maintain optimal functionality and to keep your machine in peak condition.

Consider assessing the existing elements of your equipment before making any upgrades. Evaluate the wear and tear on various components, as this will guide your decisions on which upgrades are necessary. Investing in high-quality replacements can lead to improved durability and enhanced productivity.

Furthermore, researching compatible enhancements is crucial. Many manufacturers offer advanced options that can elevate the capabilities of your machinery. Explore innovative designs that incorporate the latest technology, providing you with the ultimate cutting experience.

In conclusion, regularly updating your equipment with new components not only optimizes performance but also prolongs the life of your machinery. Embrace the opportunity to improve your tools, ensuring they meet the demands of your tasks effectively.

Understanding the Mower’s Mechanics

The intricate workings of a cutting implement are essential for efficient operation and maintenance. By exploring the key components and their functions, one can appreciate how each part contributes to the overall effectiveness of the machine.

Mechanics play a crucial role in determining performance. At the heart of the device is the drivetrain, which transmits power from the engine to the cutting mechanism. This system includes gears and pulleys, all designed to optimize energy transfer.

Additionally, the cutting assembly features a series of blades that work in unison to ensure a clean cut. Understanding how these blades interact with the ground and each other can greatly enhance maintenance practices and operational efficiency.

Furthermore, adjustability is vital. Many implements allow for height and angle adjustments, enabling users to tailor performance to specific conditions. This adaptability not only improves results but also extends the lifespan of the equipment.

Ultimately, a deeper knowledge of these mechanics empowers users to troubleshoot issues and enhance the machine’s longevity, leading to a more productive experience.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines ensures that repairs are conducted efficiently while minimizing risks. Proper preparation and awareness of potential hazards are essential components of a safe working environment.

Here are some key safety measures to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and appropriate footwear to protect against sharp edges and flying debris. |

| Disconnect Power Sources | Ensure that any power supply is turned off and disconnected before starting any maintenance to avoid accidental activation. |

| Maintain a Clean Workspace | A clutter-free area reduces the risk of tripping and allows for better focus on the task at hand. |

| Use Tools Properly | Familiarize yourself with the correct use of tools to prevent misuse that can lead to injuries. |

| Have Emergency Supplies | Keep a first aid kit and fire extinguisher accessible in case of emergencies. |

Implementing these precautions fosters a safer atmosphere, enabling effective and secure completion of repair tasks.

FAQs About the Ford 501 Mower

This section addresses common inquiries related to a specific model of agricultural equipment. Users often seek clarity on various aspects, from maintenance to compatibility, ensuring optimal performance and longevity.

What maintenance is required for optimal performance?

Regular upkeep includes checking and lubricating moving components, inspecting blades for wear, and ensuring all connections are secure. Scheduled maintenance can significantly enhance efficiency and extend the lifespan of the equipment.

Are there compatible accessories available?

Many aftermarket options exist that can improve functionality. It’s advisable to consult a trusted supplier to identify compatible enhancements that align with your specific needs, ensuring seamless integration with the equipment.

Always refer to the manufacturer’s guidelines for detailed instructions on maintenance and compatible accessories. Proper care and informed choices will lead to a better operating experience.