The efficiency of modern farming relies heavily on the proper functioning of specialized equipment. Each machine is designed with precision, ensuring seamless operation during critical tasks in the field. Understanding how these machines are constructed and the role of each element within them can significantly impact their maintenance and performance.

For agricultural professionals, keeping their equipment in top shape is essential for productivity. Recognizing the vital mechanisms and ensuring they are in proper condition is a crucial part of maintaining such machinery. Regular upkeep and awareness of the internal systems allow farmers to optimize their workflow and minimize downtime.

In this article, we will delve into the key features and components that make these machines function effectively. By understanding the detailed structure, operators can ensure their equipment remains reliable throughout the farming seasons.

Understanding the Functionality of Round Balers

Agricultural machinery plays a crucial role in modern farming, especially in managing and collecting fodder materials. Efficient equipment designed for compressing and packing hay or straw into manageable bundles is essential for simplifying tasks and improving productivity. To fully grasp how these machines work, it’s important to break down their core features and operational principles.

The mechanism that drives these machines ensures that harvested material is collected, processed, and shaped into compact forms. Below is a closer look at how these functions are achieved:

- Collection: The equipment gathers loose materials from the field, drawing them into the main chamber.

- Compression: The material is tightly pressed into a specific shape for easy storage and transport.

- Binding: Once compressed, the bundle is secured using durable ties or wraps to maintain its form.

- Ejection: The completed package is released from

Key Components of a Hay Baler

A hay baler is designed to collect and compress cut grass, straw, or other crop residues into compact bundles for easier storage and transportation. It consists of several critical elements that work together to ensure the efficient gathering and packing of hay. Understanding these key mechanisms allows for better maintenance and optimal performance.

Pickup Mechanism

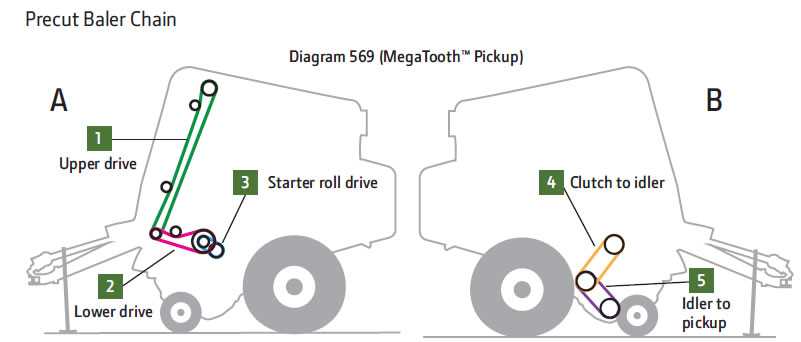

The pickup component is responsible for lifting the cut material from the ground and feeding it into the machine. This part typically uses rotating tines or teeth to grab the hay, ensuring that the material is consistently and smoothly moved into the baler.

Compression Chamber

Once the hay is collected, it is transferred to the compression chamber. Here, the material is pressed tightly to form solid, uniform bales. This section ensures the baler produces densely packed hay, allowing for efficient use of storage space and easier handling during

How the Pickup Mechanism Works

The pickup mechanism is designed to efficiently gather materials from the ground and feed them into the processing chamber. This system is crucial for maintaining a smooth and continuous flow of input without unnecessary stops. Its operation relies on synchronized movement between several components, ensuring that the material is evenly collected and delivered for further handling.

Key Elements of the Pickup System

The system consists of rotating tines, which are responsible for lifting the material from the ground. These tines are positioned in a way that maximizes the collection area, ensuring minimal waste. As the tines rotate, they sweep the material upwards, directing it towards the inlet. This consistent motion is essential for maintaining efficiency during operation.

Smooth Flow of Material

Once the material is lifted, it is transported further into the machine by a series of conveyors or belts. These mechanisms are designed to prevent blockages and ensure that the material moves continuously. Proper alignment of the pickup mechanism is critical to avoid jams and maintain a steady pace. In addition,

Role of the Bale Chamber in Operations

The bale chamber plays a critical function in agricultural machinery, contributing significantly to the formation of compact and consistent materials. By acting as the central processing area, this chamber ensures that the material is efficiently compressed and shaped into manageable units for storage and transportation. Its design and operation directly affect the quality and density of the final product, making it an essential component in the overall workflow.

Material Compression and Shaping

Within the chamber, the raw material is tightly compressed, ensuring that the mass is both stable and easy to handle. The system works in stages, gradually reducing the volume of the material until it reaches the desired density. This process not only optimizes storage but also enhances the durability and integrity of the units produced.

Impact on Efficiency

Maintenance Tips for Long-Lasting Equipment

Ensuring the longevity of agricultural machinery requires consistent care and a proactive approach to maintenance. Regular attention to crucial components, combined with timely checks, helps avoid unnecessary breakdowns and keeps the equipment running efficiently for years to come.

- Regular Inspection: Conduct frequent visual checks for any signs of wear, rust, or damage. Early detection of issues can prevent costly repairs down the road.

- Lubrication: Make sure all moving parts are adequately lubricated. Proper lubrication reduces friction, which extends the lifespan of critical components.

- Cleaning: Keep the machinery clean, removing dirt, debris, and other residues th

Common Issues in Baler Mechanics

Understanding the frequent challenges encountered in compression machinery is essential for effective maintenance and optimal performance. These issues can significantly affect productivity and operational efficiency. Below are some of the most prevalent problems faced by operators.

Mechanical Failures

Mechanical failures can lead to unexpected downtime and costly repairs. Common failures include:

- Broken belts causing operational interruptions

- Worn-out bearings affecting movement

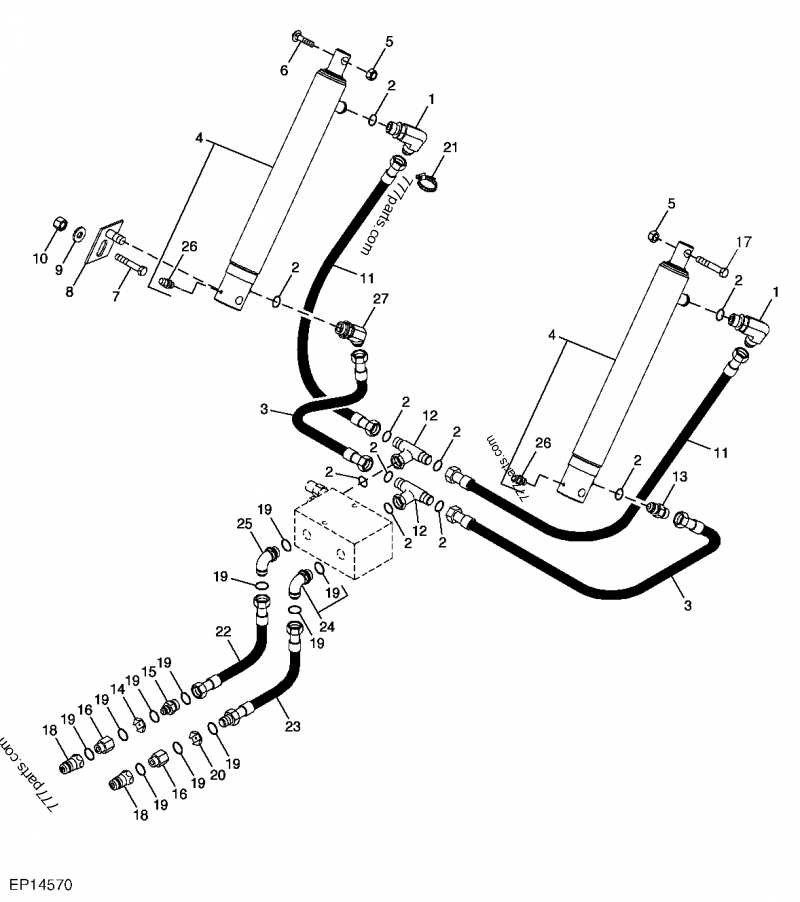

- Malfunctioning hydraulic systems leading to pressure loss

Material Blockages

Blockages in the feed system can disrupt the workflow and result in inefficiencies. Key causes include:

- Debris accumulation within the feeding mechanism

- Incorrect moisture content in materials leading to clumping

- Improper loading techniques that hinder smooth processing

Efficient Usage of Baler Belts

The effective operation of agricultural machinery significantly relies on the performance and maintenance of its components. Among these, the belts play a crucial role in ensuring smooth functioning and optimal productivity. Understanding how to maximize their utility is essential for achieving better results in field operations.

Regular Inspections are vital for maintaining the integrity of the belts. Frequent checks can help identify signs of wear or damage early on, preventing unexpected breakdowns and costly repairs. It’s advisable to inspect the belts for cracks, fraying, or any misalignment that may hinder performance.

Proper tension adjustment is also crucial for optimal operation. Belts that are either too loose or too tight can lead to inefficient performance and potential damage. Maintaining the right tension helps ensure that the machinery operates smoothly, reducing the risk of slippage and improving overall efficiency.

Finally, keeping the belts clean and free from debris is essential. Regular cleaning can prevent the accumulation of materials that may cause excessive wear or hinder movement. Implementing these practices can significantly enhance the longevity and effectiveness of the belts, contributing to improved operational success.

The Importance of Proper Bale Tension

Maintaining adequate pressure during the wrapping process is crucial for achieving optimal results in agricultural operations. Proper tension ensures that the bales are compact and uniform, which directly influences their quality and durability.

When tension is insufficient or excessive, several issues may arise:

- Inadequate Compression: Low tension can lead to loosely packed bales, making them susceptible to spoilage and degradation.

- Overcompression: Excessive tension may cause damage to the materials, leading to tears or breaks that compromise the integrity of the bale.

- Moisture Retention: Improper tension can affect how moisture is retained, impacting the preservation of the contents.

- Operational Efficiency: Incorrect tension levels can hinder the performance of the machinery, leading to increased wear and maintenance costs.

To ensure the best results, operators should regularly monitor and adjust the tension settings based on the specific requirements of the materials being processed. This practice not only enhances the quality of the bales but also maximizes efficiency in the overall operation.

Guide to Replacing Worn Parts

Maintaining machinery is essential for ensuring optimal performance and longevity. When components begin to show signs of wear, it is crucial to address these issues promptly to avoid more significant problems. This section provides insights into the process of identifying and replacing degraded elements, ensuring your equipment operates smoothly.

Identifying Worn Components

Recognizing the signs of wear is the first step in maintenance. Look for the following indicators:

- Unusual noises during operation

- Decreased efficiency or performance

- Visible damage or deterioration

- Leaking fluids or other materials

Replacement Process

Once you have identified the components that require replacement, follow these steps for effective replacement:

- Gather necessary tools and new components.

- Ensure the machine is powered off and secure.

- Carefully remove the damaged component.

- Install the new part, ensuring proper alignment and secure fittings.

- Conduct a thorough inspection to confirm the installation.

- Test the machinery to ensure everything is functioning as expected.

Optimizing Performance for Different Crop Types

Enhancing efficiency in harvesting various types of vegetation requires understanding the unique characteristics of each crop. Tailoring machinery settings and adjustments can significantly impact the quality of the harvest and overall productivity.

Understanding Crop Variability: Different types of crops exhibit distinct growth patterns, moisture content, and structural integrity. For instance, some grasses may be more pliable, while others might be tougher and denser. Adjusting equipment to accommodate these differences ensures optimal performance and reduces wear and tear.

Machinery Adjustments: Fine-tuning parameters such as speed, pressure, and cutting height is essential. For softer crops, a gentler approach may be needed to prevent damage, while denser materials might require more robust settings to ensure thorough processing. Regularly consulting equipment manuals can provide guidance on specific adjustments for various vegetation types.

Monitoring Conditions: External factors such as weather and soil conditions also play a vital role in crop performance. Keeping an eye on moisture levels and timing the harvest correctly can enhance yield quality. Utilizing sensors and technology can aid in monitoring these factors in real-time, allowing for quick adjustments to machinery settings as needed.

Safety Measures When Operating Balers

Ensuring safety while handling agricultural machinery is paramount for preventing accidents and injuries. Proper awareness and adherence to safety protocols can significantly mitigate risks associated with operation. This section outlines essential precautions and guidelines to follow when engaging with these powerful machines.

Pre-Operational Checks

Before commencing work, conducting thorough inspections is vital. Here are key areas to evaluate:

- Inspect all moving parts for wear and damage.

- Ensure that safety guards are in place and functional.

- Verify that the machine is free from debris and blockages.

- Check fluid levels, including oil and hydraulic fluids.

Operational Guidelines

During operation, following specific guidelines can enhance safety:

- Always wear appropriate personal protective equipment (PPE), including gloves and safety goggles.

- Maintain a safe distance from the machinery’s moving parts while in use.

- Be aware of the working environment and potential hazards, such as uneven terrain.

- Never attempt to clear jams or blockages while the machine is running.