The effective functioning of a compact energy solution relies on its internal elements, each playing a vital role in delivering reliable performance. Knowing how these components fit together can significantly enhance your ability to maintain and troubleshoot your equipment.

In this section, we will explore the intricate layout of various essential elements that contribute to the overall efficiency of a portable power unit. By familiarizing yourself with the structure and connections of these parts, you can ensure optimal operation and longevity of your device.

Whether you are an experienced user or a newcomer to this type of machinery, having a clear visual representation of the essential components will empower you to tackle any maintenance tasks confidently. Understanding each part’s function and relationship to others is key to maximizing the utility of your portable power source.

Choosing authentic components for your equipment can significantly enhance its performance and longevity. Authentic items are designed specifically for compatibility and reliability, ensuring that your machinery operates smoothly and efficiently.

- Quality Assurance: Genuine components undergo rigorous testing to meet industry standards, providing peace of mind regarding durability and effectiveness.

- Optimal Performance: Using original items ensures that the machinery runs at peak efficiency, reducing the risk of malfunctions and enhancing overall productivity.

- Long-Term Cost Savings: While authentic items may have a higher upfront cost, their longevity often translates to fewer replacements and repairs, saving money in the long run.

- Warranty Protection: Many manufacturers offer warranties on their authentic components, safeguarding your investment against defects and failures.

- Better Compatibility: Genuine components are engineered to fit perfectly with your machinery, minimizing the risk of operational issues that can arise from using substandard alternatives.

Investing in authentic components ultimately leads to greater reliability and satisfaction in the long term, making it a wise choice for any equipment owner.

Common Issues with Generator Components

Understanding the typical problems associated with different components can significantly enhance the longevity and efficiency of portable power sources. Identifying these issues early allows for timely maintenance and repairs, ultimately saving users from more significant troubles down the line.

Frequent Component Malfunctions

Several parts can experience common malfunctions, leading to reduced performance. Here are some frequently encountered issues:

- Fuel System: Clogs or leaks in the fuel lines can hinder the flow of fuel, causing the device to operate inefficiently.

- Air Filter: A dirty air filter can restrict airflow, leading to poor combustion and decreased power output.

- Battery: Weak batteries may fail to provide adequate starting power, resulting in difficulties during startup.

- Spark Plug: Worn or fouled spark plugs can prevent ignition, leading to starting issues.

Symptoms to Watch For

Users should be vigilant about certain signs that indicate potential problems. Addressing these symptoms promptly can prevent further damage:

- Unusual noises during operation may suggest mechanical issues.

- Difficulty starting or frequent stalling can point to fuel or ignition problems.

- Reduced runtime or irregular power output may indicate electrical component failures.

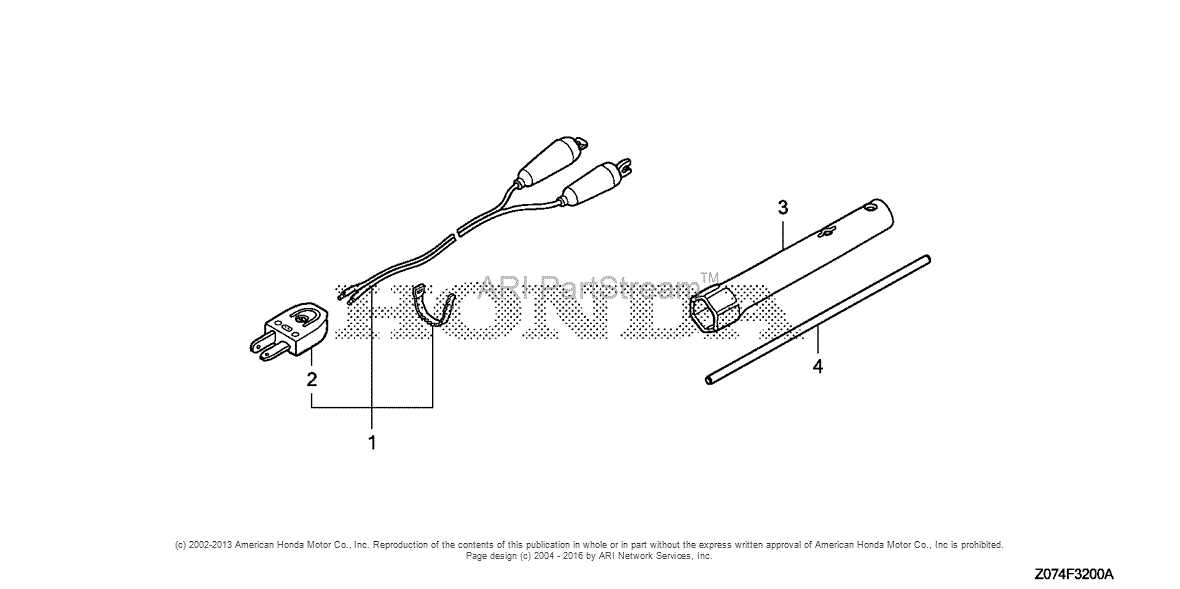

Replacement Parts for EU2000i Model

Ensuring optimal performance of your device often requires the timely substitution of essential components. Various elements may wear out over time or require updates to maintain efficiency. Identifying and acquiring the correct replacements is crucial for the longevity and functionality of your equipment.

Several key components are commonly replaced in these models. Filters, for instance, play a vital role in maintaining clean operation and should be checked regularly. Additionally, spark plugs are integral for ignition and performance, necessitating periodic replacement to prevent starting issues.

Furthermore, belts and hoses are susceptible to wear due to exposure and usage. Regular inspections can help detect early signs of degradation, allowing for timely replacements. Lastly, battery and electrical components should not be overlooked, as they ensure reliable operation and should be replaced when performance diminishes.

By staying informed about these crucial elements and their upkeep, users can significantly enhance the reliability and efficiency of their equipment. Keeping a stock of necessary components on hand can also minimize downtime during maintenance tasks.

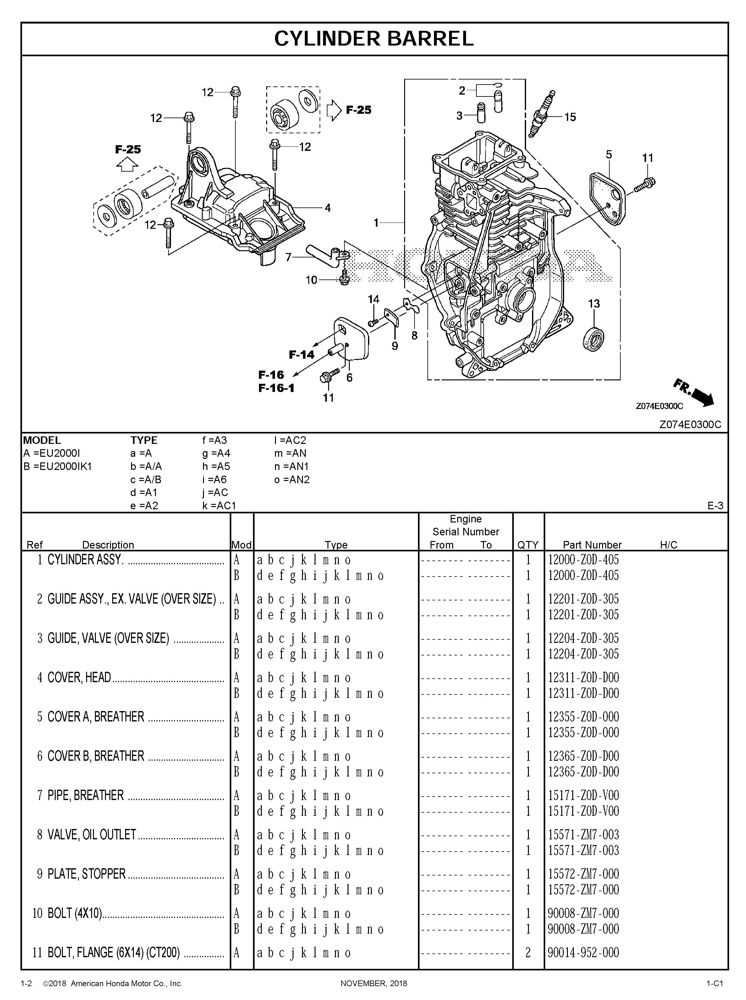

How to Identify Parts on Diagram

Understanding the components of a mechanical device is essential for effective maintenance and repairs. Familiarizing yourself with the visual representation can significantly enhance your ability to recognize each element and its function within the system.

Begin by examining the labeled sections of the visual aid. Each part is typically assigned a reference number or letter, corresponding to an index that provides further information. This index may include specifications, dimensions, and details on the role of each element.

| Label | Description |

|---|---|

| A | Power switch |

| B | Fuel tank |

| C | Air filter |

| D | Exhaust outlet |

| E | Oil filler cap |

Pay attention to the arrangement of these elements. Understanding their positioning can help in recognizing their connectivity and interactions. This knowledge is vital for troubleshooting issues and ensuring the efficient operation of the unit.

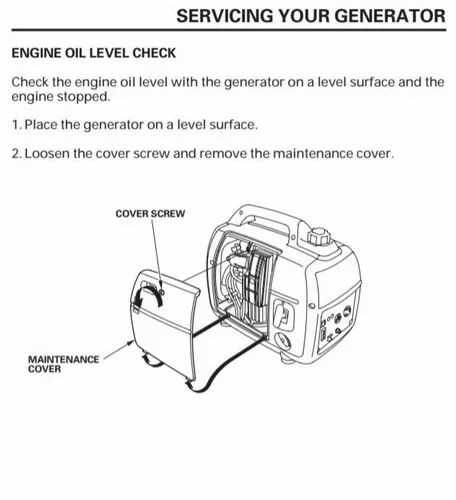

Maintenance Tips for Generator Longevity

To ensure the extended life and optimal performance of your portable energy source, implementing effective maintenance practices is essential. Regular attention to key components can prevent issues and enhance efficiency, allowing the equipment to serve its purpose reliably over time.

Regular Inspection and Cleaning

Frequent checks and cleaning of the machine are crucial for maintaining its functionality. Dust and debris accumulation can impede airflow and cause overheating. It is advisable to examine the exterior and interior components regularly and clean them as needed.

Proper Fuel Management

Using high-quality fuel and ensuring it is stored correctly can significantly impact the longevity of the unit. Old or contaminated fuel can lead to starting difficulties and operational issues. Always drain unused fuel after a period of inactivity and refill with fresh supplies when necessary.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect and Clean Air Filter | Every 50 hours | Replace if excessively dirty |

| Change Oil | Every 100 hours | Check oil level regularly |

| Check Spark Plug | Every 100 hours | Clean or replace as necessary |

| Examine Fuel System | Every 50 hours | Ensure no leaks are present |

Where to Buy Honda Parts

Finding high-quality components for your equipment can be a straightforward process when you know where to look. Numerous options are available, catering to different needs and preferences.

Online Retailers: The internet offers a plethora of websites specializing in selling replacement items. These platforms often provide detailed descriptions and images, allowing you to make informed choices. It is advisable to check customer reviews and ratings to ensure reliability.

Local Dealers: Authorized dealers in your area can be an excellent source for genuine replacements. They typically have a knowledgeable staff who can assist with locating the correct items for your equipment. Visiting in person allows you to inspect the components before purchasing.

Automotive Supply Stores: Many automotive supply chains also carry a range of components suitable for various machines. It can be beneficial to call ahead and confirm availability before making the trip.

Salvage Yards: For those on a budget, salvage yards can be a treasure trove of useful components. This option may require some effort to find the right parts, but it often yields significant savings.

By exploring these various avenues, you can secure the necessary components to keep your equipment functioning optimally.

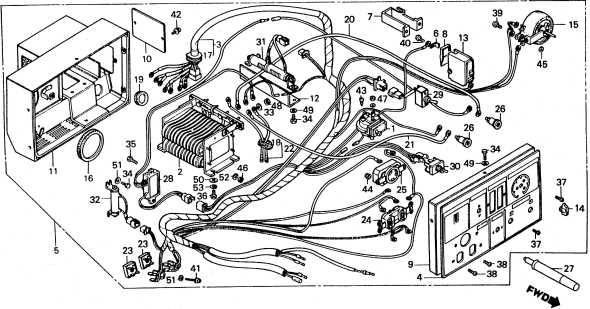

Understanding Wiring Diagrams and Symbols

Wiring illustrations are essential tools for anyone looking to comprehend electrical systems. They provide a visual representation of how components are interconnected, allowing for better troubleshooting and maintenance. By familiarizing oneself with these visuals, users can gain insight into the functionality of the electrical setup and ensure proper operation.

Key Elements of Wiring Illustrations

- Symbols: Each symbol in a wiring illustration represents a specific component, such as switches, resistors, or power sources. Understanding these symbols is crucial for deciphering the overall system.

- Connections: Lines in the illustration indicate how various parts are connected. These can represent physical wires or electrical paths, highlighting the flow of current throughout the system.

- Labels: Components are often labeled for easier identification. These labels can include information such as voltage ratings or specific functions, aiding in understanding.

Importance of Familiarity

- Enhances troubleshooting skills by providing a clear roadmap of the electrical system.

- Facilitates repairs by allowing individuals to pinpoint issues quickly.

- Improves safety by ensuring that all components are correctly identified and connected.

Frequently Asked Questions about EU2000i

This section addresses common inquiries regarding a portable power solution known for its reliability and efficiency. Users often seek clarity on various aspects, including maintenance, performance, and operational guidelines to maximize their experience with this versatile device.

What maintenance is required for optimal performance?

Regular upkeep is essential to ensure the longevity of the unit. This includes routine oil changes, air filter inspections, and fuel system checks. Keeping the equipment clean and well-maintained helps prevent operational issues and enhances overall efficiency.

How can I troubleshoot common issues?

If you encounter problems, start by checking the fuel level, ensuring that all connections are secure, and reviewing the user manual for troubleshooting tips. Simple actions such as cleaning the spark plug or replacing the air filter can often resolve minor performance issues.