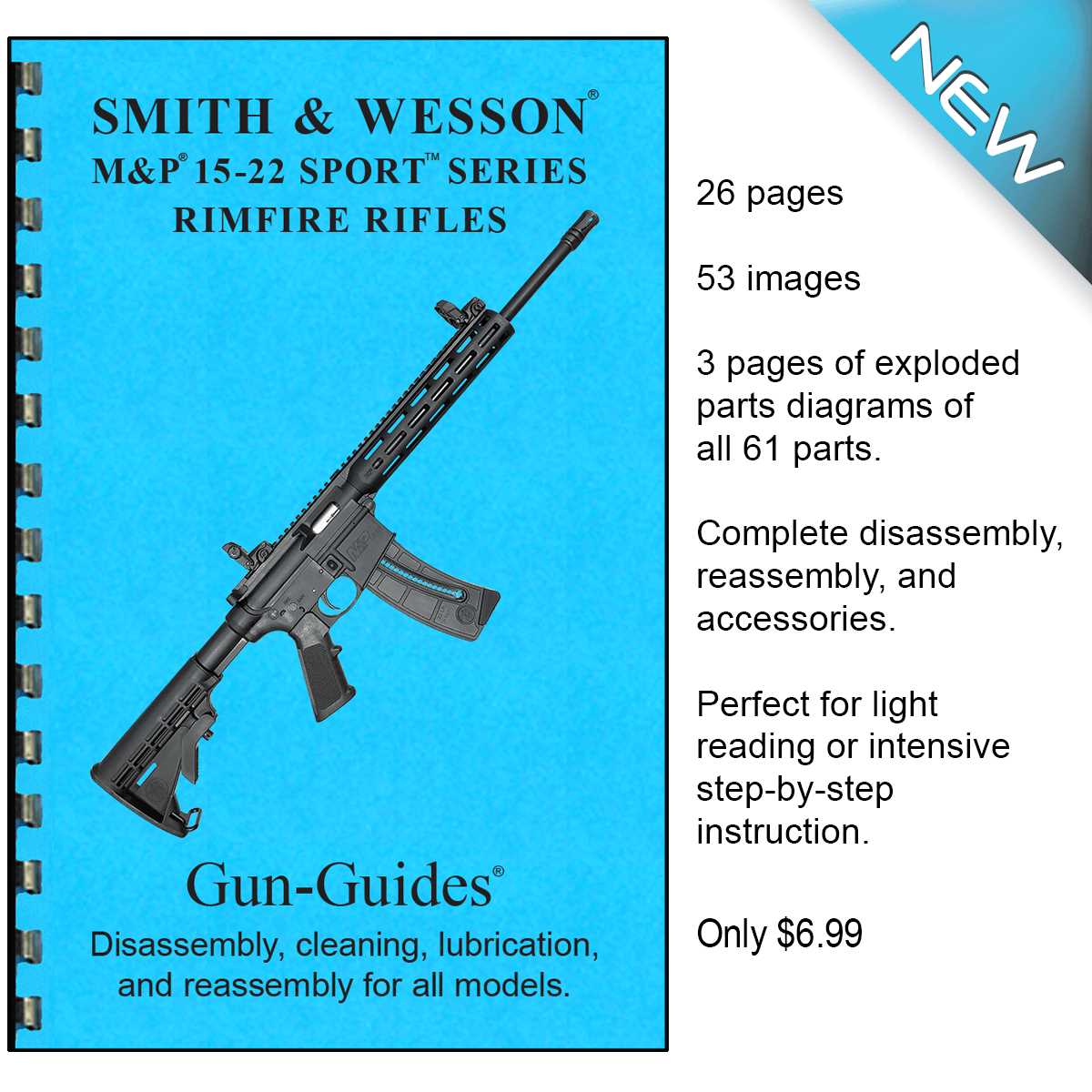

The M4 is widely recognized for its versatility and detailed construction. This model boasts a carefully designed framework, crafted for both performance and precision. Its build allows for seamless customization, making it a popular choice for enthusiasts who value adaptability and detailed engineering.

Every component within the M4 model plays a crucial role in ensuring reliability and ease of use. From the outer framework to the intricate internal mechanisms, each piece is designed to work in harmony, creating a balanced and efficient operation. Understanding how these elements connect provides insight into its sophisticated design.

By exploring the full structural layout of the M4, you can appreciate the thoughtful engineering behind it. From its core framework to smaller elements, every detail contributes to an efficient and reliable operation. With a clear understanding of its composition, users can enhance their experience and make informed decisions about potential upgrades.

M4 Airsoft Gun: Key Components Overview

The M4 platform is known for its versatility and adaptability, thanks to the thoughtful arrangement of its essential features. Each element plays a crucial role in ensuring smooth performance, allowing for precise adjustments and modifications. Understanding the primary mechanisms involved helps in grasping how this equipment functions effectively in various conditions.

Barrel Assembly: This component directs the projectile with accuracy and stability. It includes several sections that manage the overall velocity and precision of each shot.

Stock: Adjustable and ergonomic, this part offers support and balance, making it comfortable to handle for extended periods.

Receiver: Housing vital internal systems, the receiver ensures seamless coordination between different parts, enabling smooth operation and reliability under stress.

Handguard: Designed to provide a comfortable grip, this feature also allows for additional accessories to be attached, enhancing flexibility in performance.

Barrel System Breakdown for M4 Airsoft

The barrel assembly is a crucial component for ensuring accuracy and stability in shooting performance. Understanding how each element contributes to the overall function can significantly enhance both control and precision. In this section, we will explore the key elements that make up this part of the setup.

Inner Barrel

The inner barrel directly influences the trajectory and range. It channels the projectile with minimal friction, ensuring smooth delivery. Choosing the right length and material is vital for achieving the desired balance between accuracy and velocity.

Outer Barrel

The outer barrel provides structural support, keeping everything aligned and steady. It’s responsible for protecting the inner mechanisms from external damage, ensuring that performance remains consistent over time.

- Secures internal components

- Contributes to overall stability

- Available in various lengths and materials

The proper integration of these elements ensures optimal functionality, making it essenti

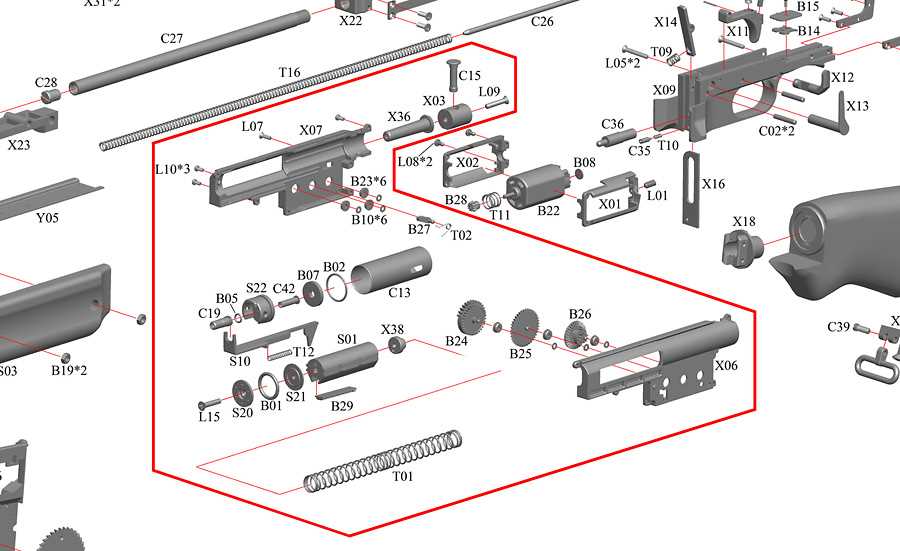

Exploring the Gearbox Mechanism in M4 Models

The internal workings of M4 models rely on a complex system that transforms energy into motion, ensuring smooth operation. Central to this system is a well-engineered mechanism responsible for managing the intricate movements needed for functionality. This part is crucial in maintaining balance and performance, allowing the entire structure to operate efficiently.

Let’s break down the key components of this mechanism:

- Motor: Powers the system by generating the necessary force for movement.

- Gears: These transfer and regulate the force from the motor to ensure consistency.

- Piston: Moves in response to the gears, playing a critical role in the cyclical operation.

- Cylinder: Houses the piston and creates the pressure needed for movement.

- Spring: Provides the necessary tension to maintain the cycle of motion.

Each of these elements must work in harmony to deliver consistent, reliable performance. When well-maintained, the mechanism ensures longevity and precision, allowing for smooth transitions in motion without unne

Understanding the Role of the Hop-Up Chamber

The hop-up chamber is a key component that significantly impacts the performance of a projectile system. It fine-tunes the motion of the projectile by applying a specialized adjustment that enhances precision and stability. This mechanism ensures consistent trajectory, improving accuracy over longer distances.

At its core, the chamber works by adjusting the interaction between the projectile and the internal mechanics. The process involves introducing a controlled amount of rotation, which counters external factors like gravity, helping to maintain a more direct flight path.

- Increased accuracy by optimizing trajectory

- Ability to maintain stable performance over extended ranges

- Adjustable settings for fine-tuning performance based on conditions

Overall, the hop-up chamber is essential for achieving greater consistency and range in each shot, making it a crucial element in the performance of the overall system.

Battery and Wiring Setup in Airsoft M4

One of the essential elements for powering an electric model is its battery system and wiring layout. Proper energy management not only ensures smooth operation but also enhances the longevity and performance of the device. Understanding how to connect the power source and maintain the wiring is crucial for an efficient setup.

Choosing the Right Power Source

When selecting a power source, it’s important to consider the capacity and voltage that best fit your needs. Common options include NiMH and Lipo varieties, each offering different levels of energy output. Ensuring the right fit for your equipment will help maximize efficiency and prevent potential issues.

Wiring Connections

The wiring system plays a key role in transferring power to the internal components. Maintaining secure connections and using quality wires can prevent overheating and provide stable energy flow. Always inspect your wiring for any signs of wear or damage to ensure consistent performance.

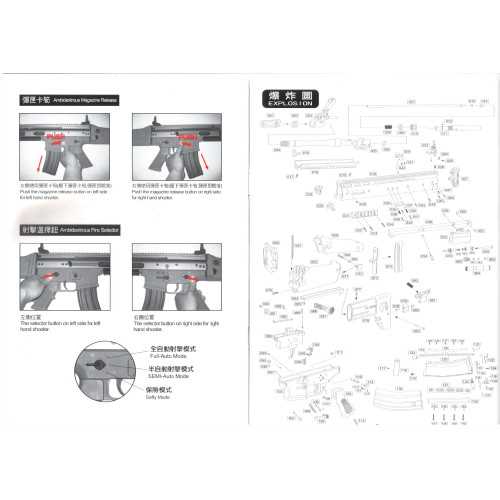

Magazine Types Compatible with M4 Airsoft

Understanding the various types of magazines that work with the M4 platform is crucial for enhancing your shooting experience. Each variant offers distinct advantages, catering to different preferences and gameplay styles. Knowing these options allows users to optimize their setup for performance and efficiency.

Standard magazines are often the most commonly used, featuring a typical capacity that strikes a balance between size and usability. These are ideal for players seeking a reliable and straightforward solution during engagements. Alternatively, high-capacity variants provide increased ammo storage, enabling longer play sessions without frequent reloads. They are particularly popular among those who prefer a more aggressive style of play.

For those looking to achieve a competitive edge, mid-capacity magazines offer a blend of the benefits found in both standard and high-capacity types. These magazines maintain a manageable profile while allowing for sufficient rounds, making them an excellent choice for players who prioritize stealth and efficiency. Additionally, specialized magazines, such as drum types, cater to specific needs and can provide substantial ammo reserves for prolonged skirmishes.

Stock Customization for Enhanced Stability

Customization of the rear assembly can significantly improve the overall steadiness of your setup, allowing for more precise handling and better performance. By modifying the back end, enthusiasts can achieve a tailored fit that enhances control and comfort during use.

Upgrading the rear assembly involves selecting components that align with personal preferences and operational needs. Options may include adjustable cheek rests, padded buttstocks, or specialized mounting systems that contribute to stability. Each of these enhancements plays a crucial role in creating a more balanced experience.

Furthermore, personalized modifications can lead to improved ergonomics. By ensuring that the rear assembly fits snugly against the shoulder, users can reduce fatigue and increase accuracy. This attention to detail not only enhances the functionality of the equipment but also elevates the user’s confidence and performance in various scenarios.

Trigger Assembly and Functionality Explained

The trigger assembly serves as a crucial component in the operation of various mechanisms, acting as the interface between the user and the device. This assembly is responsible for initiating the firing sequence, ensuring precision and reliability during use. Understanding its structure and functionality is essential for anyone interested in optimizing performance and maintenance.

Components of the Trigger Assembly

The trigger assembly typically consists of several key components, each playing a vital role in the overall mechanism. These parts work together seamlessly to ensure that the action is initiated smoothly and effectively.

| Component | Description |

|---|---|

| Trigger | The primary lever that the user interacts with to activate the mechanism. |

| Hammer | A component that strikes the firing mechanism upon activation of the trigger. |

| Spring | Provides tension to return the trigger to its original position after activation. |

| Sear | Holds the hammer in a cocked position until the trigger is pulled. |

Operation Mechanism

When the trigger is pulled, it engages the sear, releasing the hammer. This action causes the hammer to move forward rapidly, striking the firing mechanism. The tension from the spring ensures the trigger resets quickly, allowing for repeated activation. This precise coordination between components is what enables consistent performance.

Front and Rear Sights Adjustments

Fine-tuning the alignment of the front and rear aiming devices is essential for achieving precision during usage. Proper adjustment allows for accurate targeting, enhancing the overall experience. Understanding how to adjust these components can significantly improve your effectiveness and confidence.

Understanding Sight Alignment

Achieving optimal sight alignment involves positioning the front element precisely within the rear aperture. The objective is to ensure that the target is in line with both sights, allowing for clear visibility and accuracy. Misalignment can lead to inconsistent results, making adjustments crucial.

Adjustment Procedures

To modify the elevation and windage of the sights, follow these guidelines:

| Adjustment Type | Adjustment Method | Tools Required |

|---|---|---|

| Elevation | Turn the elevation knob clockwise to raise the point of impact and counterclockwise to lower it. | Elevation tool or flathead screwdriver |

| Windage | Adjust the windage knob to the right to shift the point of impact right, and to the left to move it left. | Windage tool or flathead screwdriver |

Regularly checking and fine-tuning these settings ensures that your aim remains true, allowing for improved performance in various situations.

Motor and Piston Performance in M4 Airsoft

The efficiency and responsiveness of the drive system are crucial for optimal functionality. Understanding how the components work together can significantly impact the overall effectiveness and user experience. The interaction between the motor and the piston is vital, as it directly influences the speed and power of the system.

Motor quality plays a pivotal role in determining performance. Higher-quality motors can provide increased torque and speed, leading to faster cycle rates. This allows for quicker firing sequences, which can enhance precision and responsiveness during operation. Additionally, the type of motor–be it standard or high-torque–can affect how well it manages the energy output and maintains stability under different conditions.

Piston design also contributes significantly to overall performance. A well-engineered piston can maximize air compression and improve shot consistency. Lightweight materials can facilitate faster cycling, while reinforced structures ensure durability. Furthermore, the relationship between the piston and the gearbox is critical; a properly aligned setup reduces friction and wear, extending the lifespan of both components.

In conclusion, optimizing motor and piston interaction is essential for achieving superior functionality. Focusing on component quality and design can lead to enhanced performance, making a substantial difference in usage scenarios.

Receiver Construction and Durability Insights

The integrity and resilience of the receiver assembly are crucial factors that contribute to the overall performance and longevity of the mechanism. This component serves as the backbone, housing essential mechanisms while ensuring smooth operation under various conditions. Understanding its construction and the materials utilized provides valuable insights into its reliability and effectiveness in different scenarios.

Manufacturers often employ a combination of materials to enhance strength and reduce weight. Commonly used substances include high-grade polymers and aluminum alloys, each offering unique benefits. The choice of material affects not only the durability but also the operational efficiency of the unit.

| Material | Strength | Weight | Durability |

|---|---|---|---|

| Polymer | Moderate | Lightweight | Good |

| Aluminum Alloy | High | Moderate | Excellent |

| Steel | Very High | Heavy | Exceptional |

Additionally, construction techniques play a vital role in enhancing the assembly’s durability. Processes such as machining, molding, and heat treatment are employed to ensure precision and resilience. These techniques contribute to the overall quality and reliability, making the assembly capable of withstanding rigorous usage and environmental factors.