The intricacies of agricultural machinery often hold the key to optimizing performance and efficiency on the farm. Knowledge of each component’s function and layout can significantly enhance maintenance and repair efforts. This understanding not only aids in troubleshooting but also extends the lifespan of the equipment.

In this section, we will explore a detailed overview of the various elements involved in a specific piece of farming equipment. By dissecting the essential mechanisms, users can gain insights into how each part interacts within the system. This comprehension is vital for anyone looking to ensure their machinery operates at its ultimate capacity.

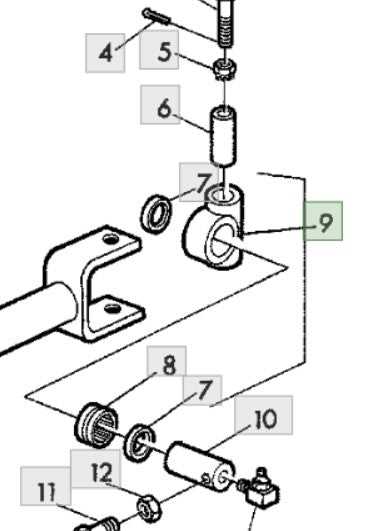

Moreover, visual representations of the components allow for a clearer understanding of their arrangement and functionality. Whether you are a seasoned operator or a newcomer to agricultural practices, having access to these schematics can serve as an invaluable resource for efficient equipment management.

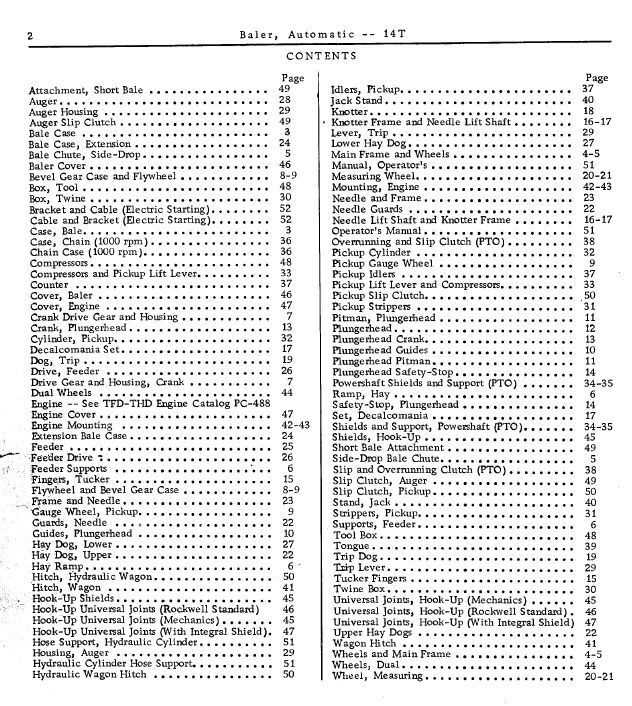

Overview of John Deere 14T Baler

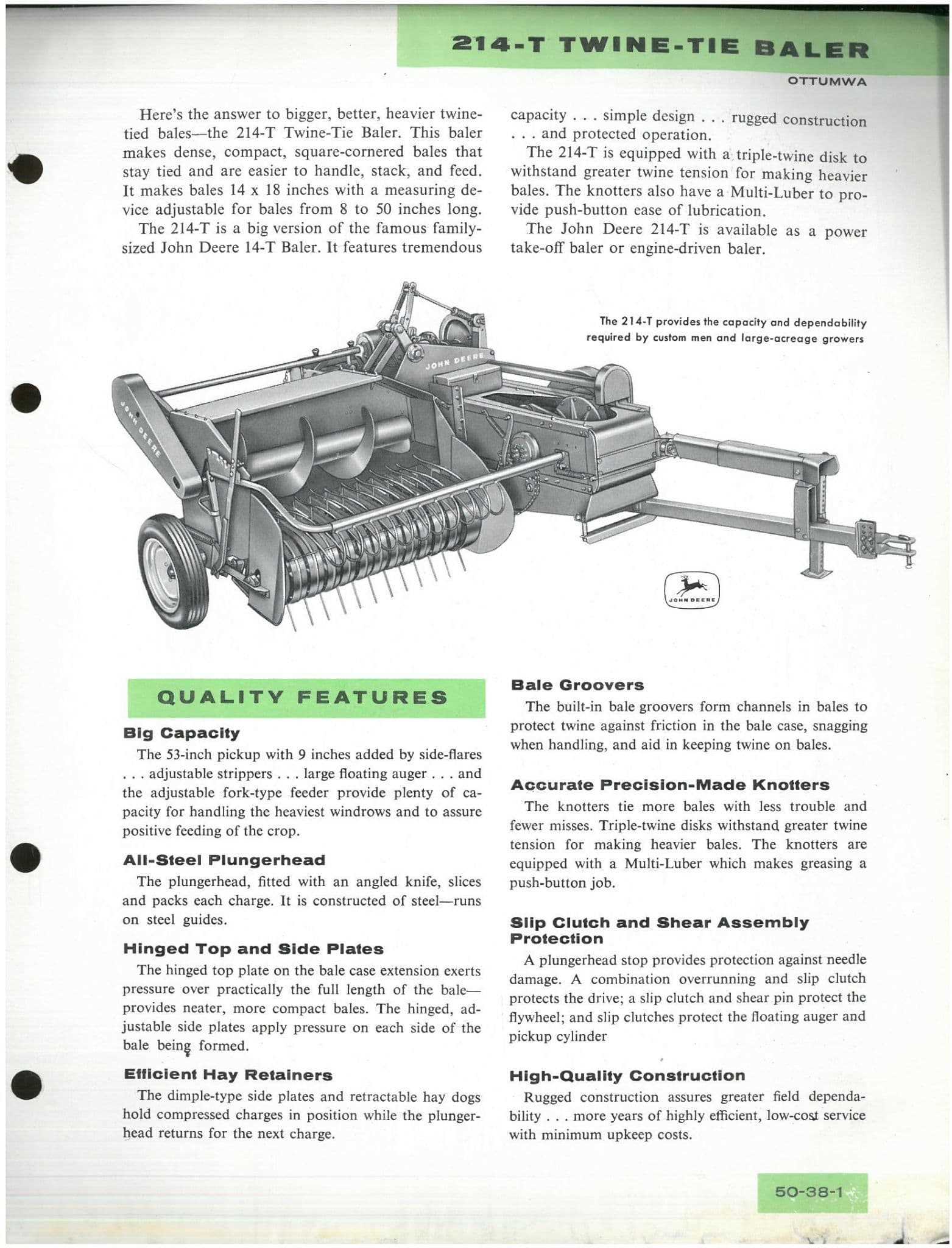

This section provides a comprehensive look at a popular agricultural machine renowned for its efficiency in handling forage. Designed to streamline the process of creating compact bundles, this implement has become a staple for many farmers, offering reliability and ease of use in various conditions.

Key Features

Equipped with advanced mechanisms, this machine enhances productivity while minimizing operator fatigue. The design incorporates durable materials, ensuring longevity and optimal performance throughout the harvesting season.

Maintenance Considerations

Regular upkeep is essential to maintain functionality and prevent costly repairs. Simple procedures, such as lubrication and inspection of critical components, can significantly extend the lifespan of this machinery and improve its overall efficiency.

Key Components of the Baler

The efficient operation of a forage packaging machine relies on several essential elements, each playing a pivotal role in ensuring optimal performance and durability. Understanding these fundamental components is crucial for effective maintenance and troubleshooting.

Core Mechanisms

Among the main mechanisms, the gathering system is responsible for collecting and directing the crop material into the processing chamber. The cutting apparatus allows for the precise sizing of materials, while the compression mechanism forms tightly packed bundles for easy handling and transport.

Support Structures

Supporting these mechanisms are structural components that provide stability and alignment. The frame serves as the backbone, while the wheel assembly ensures mobility across different terrains. These parts must be robust to withstand the rigors of field operations.

| Component | Function |

|---|---|

| Gathering System | Collects and directs crop material |

| Cutting Mechanism | Sizes material for processing |

| Compression Unit | Forms compact bundles |

| Frame | Provides structural support |

| Wheel Assembly | Facilitates mobility |

Importance of Maintenance Practices

Regular upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Effective maintenance practices not only enhance operational efficiency but also prevent unexpected breakdowns, which can lead to costly downtime. Understanding the significance of these practices can empower operators to make informed decisions regarding their equipment management.

Benefits of Consistent Maintenance

- Enhanced Performance: Well-maintained machinery operates more smoothly, increasing productivity during harvesting seasons.

- Cost Efficiency: Routine checks and repairs can prevent more extensive and expensive damage in the long run.

- Safety: Regular inspections reduce the risk of accidents caused by equipment failure, ensuring a safer working environment.

- Longevity: Proper care extends the lifespan of machinery, maximizing investment returns over time.

Key Maintenance Practices

- Conduct regular inspections to identify wear and tear.

- Lubricate moving components to reduce friction and prevent rust.

- Replace worn or damaged parts promptly to avoid further issues.

- Keep machinery clean to prevent debris build-up that can hinder performance.

Identifying Common Wear Parts

In the world of agricultural machinery, recognizing components that are prone to deterioration is crucial for maintaining optimal performance. These elements often experience significant stress during operation, leading to a need for regular inspection and timely replacement to ensure efficiency and prevent costly downtime.

Key Components to Monitor

- Cutting Blades: Essential for effective material processing, these elements can dull or chip over time.

- Drive Belts: These components are vital for transferring power; wear can lead to slippage or breakage.

- Rollers: Responsible for material movement, they may suffer from wear patterns affecting functionality.

- Chains: Used for mechanical power transfer, these can stretch or become damaged, impacting overall operation.

Signs of Wear

- Increased noise during operation.

- Difficulty in processing material smoothly.

- Visible signs of damage or wear on surfaces.

- Frequent need for adjustments or repairs.

Regular checks on these critical components can greatly enhance machinery longevity and performance, ensuring that operations run smoothly and efficiently.

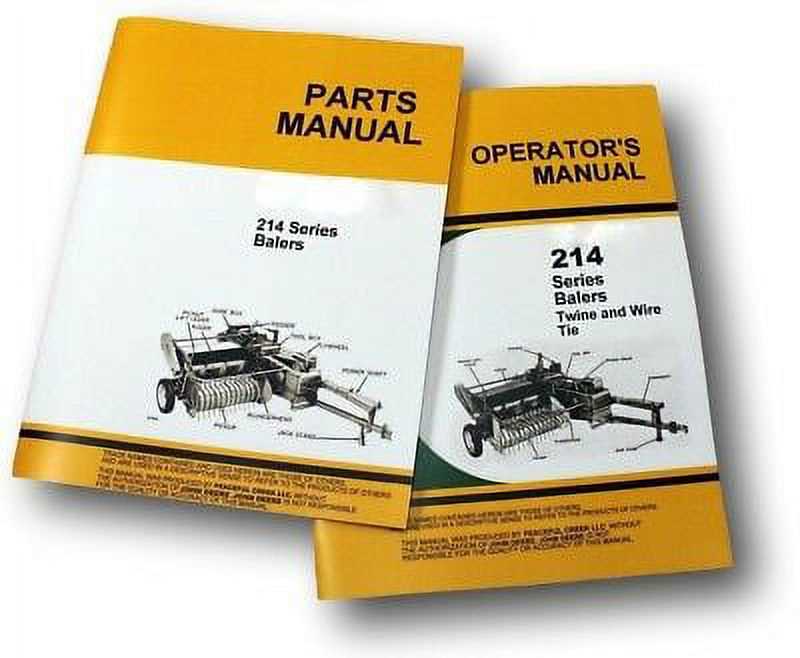

How to Access Parts Diagram

Finding detailed illustrations of components for agricultural machinery is essential for efficient maintenance and repairs. Accessing these visuals can streamline the process of identifying and obtaining the necessary elements for your equipment.

Here are steps to access these essential resources:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Search for your specific model or equipment type.

- Look for downloadable files, which may include manuals and visual aids.

- If available, utilize the online parts catalog for interactive access.

Additionally, you can consider the following options:

- Consult local dealers for printed materials or brochures.

- Join forums or online communities dedicated to agricultural machinery.

- Check third-party websites that specialize in equipment resources.

Replacing Worn Components Safely

Ensuring the longevity and efficiency of machinery involves timely replacement of degraded elements. Addressing wear and tear proactively not only enhances performance but also mitigates safety risks during operation. Proper techniques and precautions are vital for effective and secure replacements.

Preparation Steps

Before initiating the replacement process, it is essential to gather the necessary tools and safety gear. A well-organized workspace minimizes distractions and promotes efficiency. Ensure that all equipment is powered down and adequately secured to prevent accidental activation during maintenance.

Executing the Replacement

When removing old components, employ appropriate methods to avoid damaging surrounding structures. Utilize manufacturer guidelines for reference on installation techniques. After installing the new elements, double-check connections and alignments to ensure optimal functionality. Finally, conduct a thorough inspection before resuming regular operations, confirming that everything is secure and functioning correctly.

Troubleshooting Common Issues

This section aims to assist operators in identifying and resolving frequent problems that may arise during the operation of agricultural machinery. By understanding typical symptoms and their potential causes, users can effectively maintain performance and enhance productivity.

Identifying Symptoms

Recognizing early signs of malfunction is crucial. Common indicators include unusual noises, inefficient operation, or inconsistent output. Documenting these symptoms can help in diagnosing the underlying issue.

Common Causes and Solutions

| Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Unusual noises | Worn components | Inspect and replace worn parts |

| Inefficient operation | Incorrect settings | Check and adjust operational parameters |

| Inconsistent output | Blockages | Clear any debris and obstructions |

Recommended Tools for Repairs

Having the right equipment is essential for effective maintenance and restoration tasks. Proper tools not only enhance efficiency but also ensure that repairs are conducted safely and accurately. Below is a list of recommended instruments to consider when undertaking repairs.

Essential Hand Tools

Common hand tools such as wrenches, screwdrivers, and pliers are indispensable for various tasks. Ensure you have a full set of sizes to accommodate different fasteners and components. Additionally, a sturdy hammer and a reliable tape measure will assist in making precise adjustments.

Specialized Equipment

For more intricate work, specialized devices like torque wrenches and diagnostic tools are beneficial. A torque wrench ensures that components are tightened to the manufacturer’s specifications, while diagnostic tools help in troubleshooting any operational issues effectively.

Understanding Hydraulic System Components

Hydraulic systems play a crucial role in facilitating smooth operation and enhancing performance in various machinery. They utilize fluid pressure to transmit force, allowing for efficient movement and control of different elements within the system. Understanding the key components of these systems is essential for maintaining and troubleshooting machinery effectively.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure by moving fluid from the reservoir. |

| Actuator | Converts hydraulic energy into mechanical motion. |

| Reservoir | Holds hydraulic fluid and ensures a steady supply to the system. |

| Valves | Regulate fluid flow and pressure, directing it to various components. |

| Hoses and Fittings | Transport hydraulic fluid between components, ensuring a secure connection. |

Ordering Parts from Authorized Dealers

Acquiring components from certified suppliers is crucial for maintaining the efficiency and reliability of agricultural machinery. Authorized dealers offer genuine items that meet the manufacturer’s standards, ensuring optimal performance and longevity.

Benefits of Using Authorized Suppliers

- Access to high-quality components

- Expert assistance and support

- Warranty protection on purchased items

- Up-to-date product information and availability

Steps to Place an Order

- Identify the required components based on your equipment’s needs.

- Visit the official website of an authorized dealer or contact them directly.

- Provide the necessary details, including model specifications and quantities.

- Confirm your order and payment method.

- Track the shipment and ensure proper installation upon arrival.

Upgrades and Modifications Available

Enhancing the functionality and efficiency of agricultural machinery can significantly improve productivity and longevity. Various upgrades and modifications can be implemented to tailor equipment to specific operational needs, ensuring optimal performance in diverse conditions.

Performance Enhancements

To boost efficiency, consider installing advanced feed systems or improved drivetrains. These modifications can lead to smoother operations and reduced wear on components, ultimately extending the lifespan of the equipment.

Safety Features

Integrating additional safety features, such as enhanced lighting systems or protective guards, is crucial. These upgrades not only ensure compliance with safety regulations but also enhance operator confidence and minimize risk during operation.