In the realm of electromechanical systems, a variety of crucial elements work in harmony to convert electrical energy into mechanical movement. These intricate assemblies play a significant role in numerous applications, from automotive engineering to home appliances, making their understanding essential for both enthusiasts and professionals alike.

Each component within these assemblies serves a specific function, contributing to the overall efficiency and effectiveness of the device. By exploring the layout and interaction of these elements, one gains insight into how electrical impulses can create controlled motion, leading to practical solutions in everyday technology.

Familiarity with these mechanisms not only aids in troubleshooting and maintenance but also inspires innovation in design. A closer examination of the configuration of these components reveals the sophistication behind seemingly simple operations, showcasing the blend of creativity and engineering that defines modern advancements.

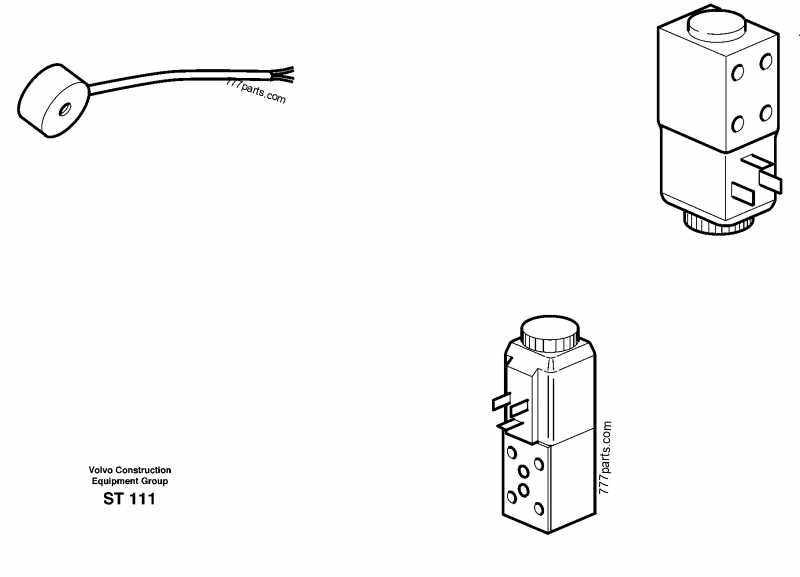

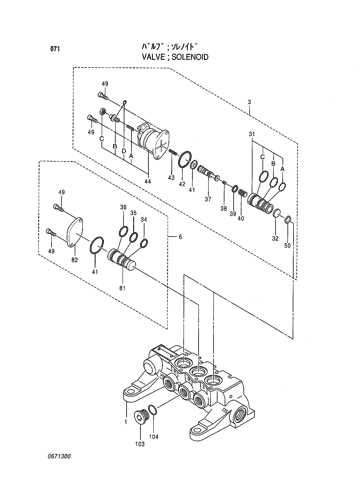

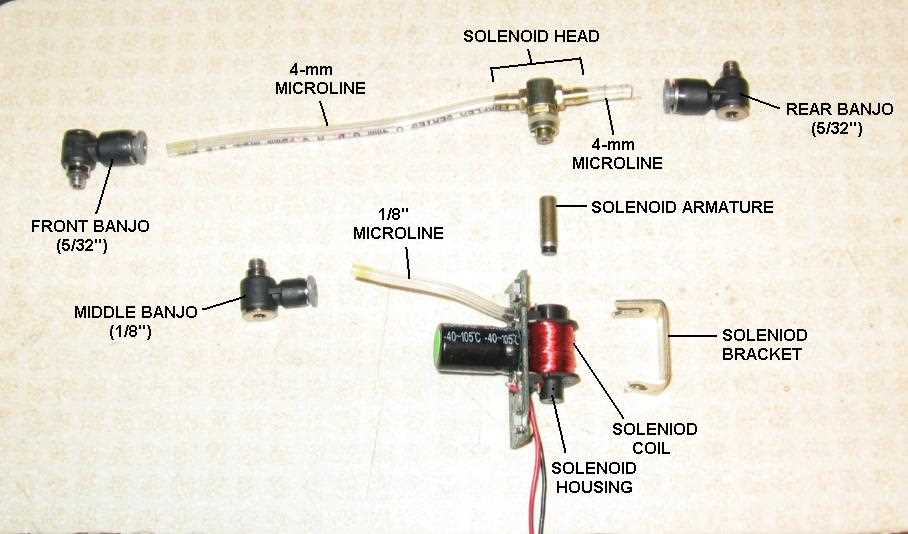

Understanding Solenoid Components

Exploring the essential elements of electromagnetic devices reveals a fascinating interplay of mechanics and electricity. Each component plays a vital role in the overall functionality, contributing to the precision and efficiency of the system.

Key Elements of Electromagnetic Devices

- Coil: This is the winding of conductive material that generates a magnetic field when an electric current flows through it.

- Core: Typically made from ferromagnetic material, it enhances the magnetic field produced by the coil, increasing the device’s strength.

- Housing: The outer casing protects internal components and ensures durability in various environments.

- Armature: A movable element that responds to the magnetic field, translating electrical energy into mechanical motion.

- Terminal Connections: These allow for the input of electrical power, facilitating the operation of the device.

Functionality and Interactions

Understanding how these elements interact is crucial for grasping the overall operation. The coil generates a magnetic field, which pulls the armature toward the core, enabling motion. The efficiency of this process depends on the materials used and the design of each component.

- The quality of the winding affects the strength of the generated magnetic field.

- Material selection for the core influences responsiveness and efficiency.

- Proper sealing and housing design prevent environmental damage and ensure longevity.

What Is a Solenoid?

A solenoid is an electromechanical device that converts electrical energy into linear motion. It consists of a coil of wire, which generates a magnetic field when an electric current flows through it, allowing for various applications in automation and control systems. The operation is based on principles of electromagnetism, making it essential in numerous technologies.

| Component | Description |

|---|---|

| Coil | A winding of wire that generates a magnetic field when energized. |

| Plunger | A movable rod that is driven by the magnetic field. |

| Housing | The casing that encloses the coil and plunger for protection. |

| Terminal | Connection points for electrical supply. |

Key Functions of Solenoid Parts

This section explores the essential roles of the components involved in the electromagnetic actuator mechanism. Each element contributes uniquely to the overall functionality, ensuring efficient operation and reliable performance in various applications.

Electromagnetic Activation

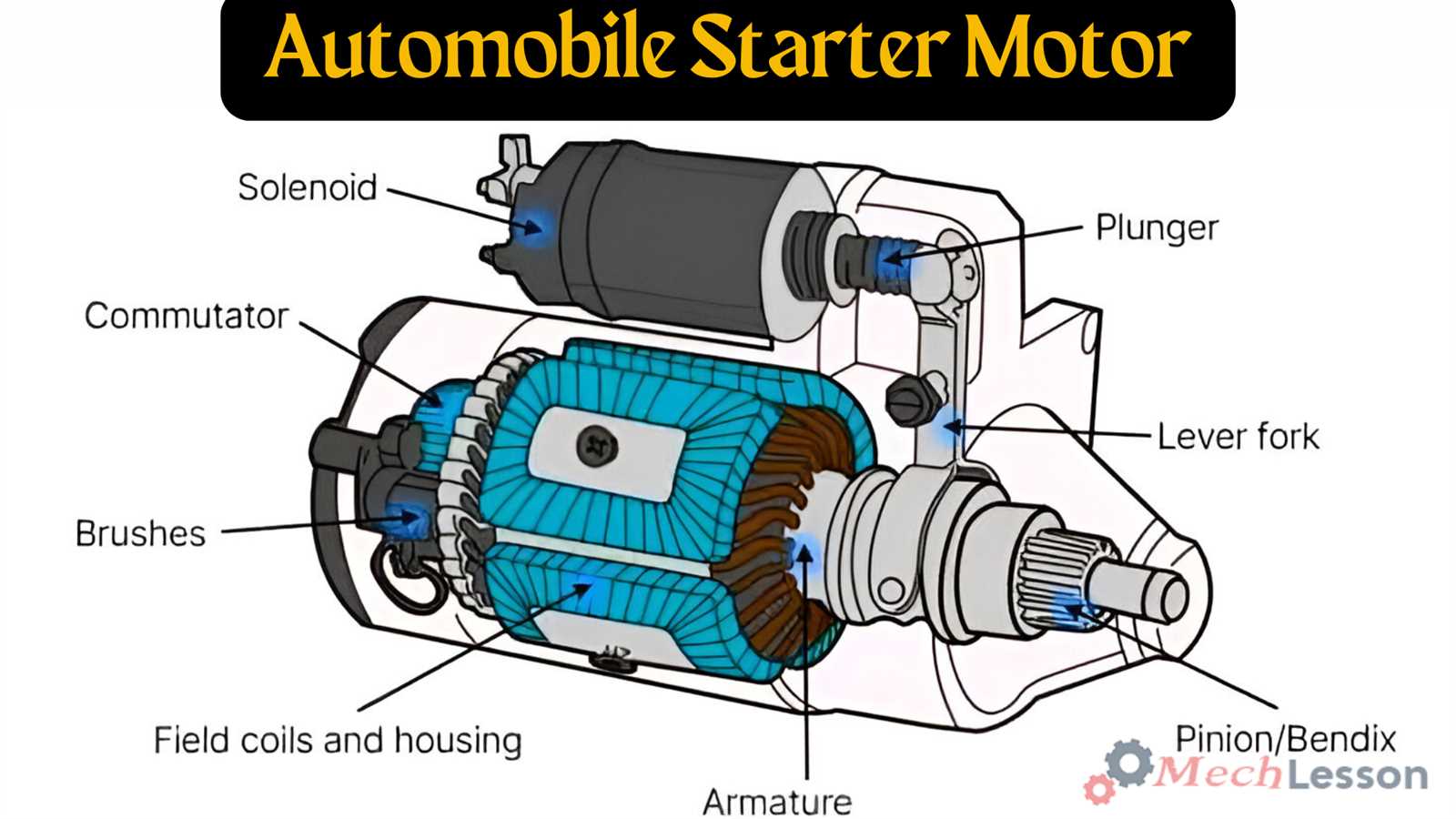

The primary function is to convert electrical energy into mechanical movement. When current flows through the coil, a magnetic field is generated, which subsequently pulls or pushes the movable core. This transformation enables the device to perform tasks such as switching or locking with precision.

Control and Efficiency

Another crucial aspect involves the regulation of movement. The design allows for quick actuation, facilitating rapid response times in systems where speed is vital. Additionally, energy consumption is optimized, minimizing waste and enhancing overall efficiency, making it suitable for both industrial and consumer applications.

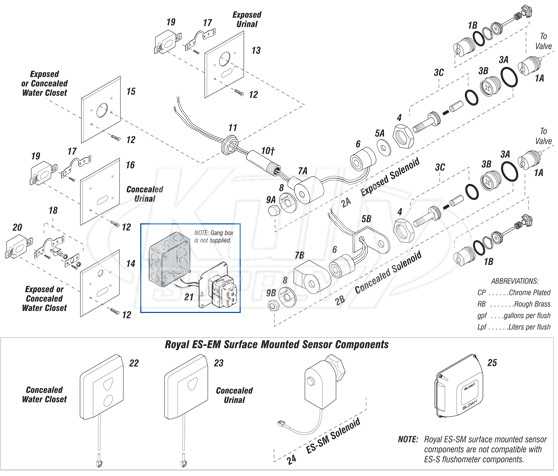

Common Applications of Solenoids

Electromechanical devices play a crucial role in various industries, providing reliable control for numerous systems. Their versatility allows for seamless operation in both simple and complex applications.

Automotive Uses

- Locking mechanisms for doors and trunks

- Engine management systems

- Transmission control

Industrial Applications

- Actuators in assembly lines

- Control valves in hydraulic systems

- Automation in manufacturing processes

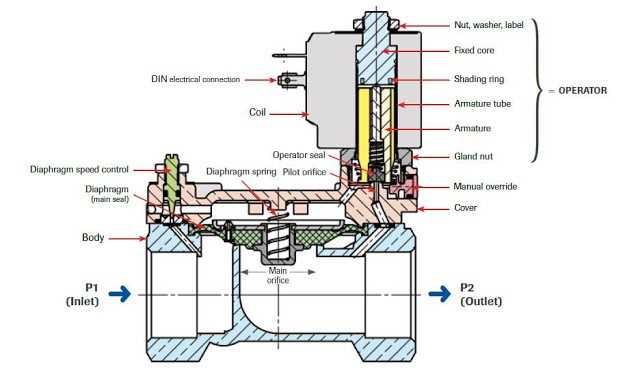

Main Parts of a Solenoid Explained

The fundamental components of this electromagnetic device work in harmony to convert electrical energy into mechanical motion. Understanding each element is essential for grasping how this mechanism operates effectively in various applications.

Coil: The coil is a tightly wound wire, typically made of copper, which creates a magnetic field when an electric current flows through it. The strength of this field is directly proportional to the number of turns and the current intensity.

Core: At the center of the coil lies the core, often made of ferromagnetic material. This component enhances the magnetic field generated by the coil, significantly increasing the device’s efficiency and responsiveness.

Armature: The armature is a movable element that is attracted towards the core when the magnetic field is activated. Its movement is responsible for performing the intended mechanical work, such as opening or closing a switch.

Spring: A spring is often incorporated to return the armature to its original position once the current ceases. This ensures that the device can reset and be ready for the next cycle of operation.

Housing: The outer casing provides protection and structural support to the internal components. It also aids in the efficient distribution of magnetic forces, ensuring optimal performance.

By examining these essential elements, one can appreciate how they collectively function to achieve precise control in various mechanical systems.

How Solenoids Work Internally

Understanding the inner workings of electromagnetic devices reveals the fascinating interplay between electricity and magnetism. At their core, these devices transform electrical energy into mechanical motion, leveraging the principles of electromagnetism to achieve this conversion effectively.

The Electromagnetic Principle

When an electric current flows through a coil of wire, it generates a magnetic field around it. This phenomenon is fundamental to the operation of these devices. The strength and direction of the magnetic field can be manipulated by adjusting the current, allowing precise control over the resulting mechanical action. A core, often made of ferromagnetic material, is typically placed within the coil to enhance the magnetic field, making the entire system more efficient.

Mechanical Movement

The interaction between the magnetic field and the core creates a force that can move an armature or plunger. This movement can be linear or rotational, depending on the design. The rapid switching of current allows for quick responses, making these devices essential in various applications, from automotive to industrial machinery. Additionally, the construction often includes return springs to ensure that the mechanical component returns to its original position when the current is removed, completing the cycle.

Electrical Connections in Solenoid Systems

The functionality of electromagnetic devices relies heavily on the integrity and design of their electrical interfaces. Properly configured connections ensure that power is delivered efficiently, allowing for reliable operation. These interfaces play a crucial role in the performance and longevity of the system.

Key considerations include the choice of materials for conductors, as well as the methods of insulation and protection against environmental factors. Quality components help minimize resistance and heat generation, which can compromise efficiency.

Additionally, the layout of wiring is vital for preventing interference and ensuring that signals are transmitted effectively. Correct termination techniques also contribute to the overall reliability, as poor connections can lead to erratic behavior or complete system failure.

Ultimately, meticulous attention to electrical connections not only enhances the functionality of these devices but also supports their safe and efficient operation across various applications.

Materials Used in Solenoid Manufacturing

In the production of electromagnetic devices, the choice of materials plays a critical role in determining performance, durability, and efficiency. Various substances are employed to construct the components that enable the effective functioning of these devices. Each material is selected based on its specific properties and suitability for the intended application.

- Conductors: Typically, copper is the primary choice due to its excellent electrical conductivity. Other options may include aluminum and silver, depending on cost and performance requirements.

- Magnetic Cores: Soft iron and various alloys are often used for cores. These materials enhance magnetic fields and improve efficiency. Specialized ferrites may also be utilized for specific applications.

- Insulation: To prevent short circuits, high-quality insulating materials are essential. Common choices include varnishes, plastics, and composite materials, which offer thermal stability and electrical resistance.

- Enclosures: The external casing is often made from steel or durable plastics, providing protection against environmental factors while ensuring structural integrity.

Each of these materials contributes to the overall functionality and reliability of the device, making their selection crucial for optimal performance in various applications.

Common Issues with Solenoid Parts

Understanding the typical challenges that can arise with electromagnetic devices is crucial for effective troubleshooting and maintenance. These complications can significantly impact functionality and performance, often leading to operational failures.

Frequent Problems

- Electrical malfunctions due to wiring issues.

- Mechanical wear affecting movement.

- Corrosion causing connection failures.

- Overheating resulting from excessive current.

Preventive Measures

- Regular inspections to identify early signs of wear.

- Ensuring proper electrical connections to avoid shorts.

- Maintaining a clean environment to prevent corrosion.

- Monitoring operating conditions to prevent overheating.

Maintenance Tips for Solenoid Devices

Ensuring the longevity and efficient operation of electromagnetic components requires regular upkeep and attention. Proper maintenance not only enhances performance but also minimizes the risk of failure. Here are essential practices to keep these devices functioning optimally.

Routine Checks

Regular inspections are crucial. Look for signs of wear, corrosion, or loose connections. Ensure that all mounting hardware is secure, and clean any debris that may accumulate around the unit.

Lubrication and Cleaning

Maintaining cleanliness and appropriate lubrication is vital. Use suitable cleaning agents and avoid harsh chemicals that can cause damage. Apply lubricant to moving parts as recommended by the manufacturer to ensure smooth operation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for corrosion or damage. |

| Cleaning | Quarterly | Use soft cloth and appropriate cleaner. |

| Lubrication | Every 6 months | Refer to manufacturer’s guidelines. |

Choosing the Right Solenoid for Your Needs

Selecting the appropriate electromagnetic device for your application is crucial for achieving optimal performance and efficiency. Various factors must be considered, including operational requirements, environmental conditions, and energy consumption. Understanding these elements will help in making an informed decision.

Key Factors to Consider

When evaluating options, pay attention to the following aspects:

| Factor | Description |

|---|---|

| Voltage | Determine the necessary voltage level for your system. |

| Force | Assess the required force output to perform your tasks effectively. |

| Response Time | Consider the speed at which the device must operate. |

| Durability | Evaluate the environmental conditions the device will face. |

Final Thoughts

Choosing the right device involves careful consideration of various specifications to ensure compatibility with your needs. By analyzing each factor, you can make an informed choice that aligns with your project’s requirements.

Innovations in Solenoid Technology

Recent advancements in electromagnetic devices have transformed various industries, enhancing performance, efficiency, and reliability. These innovations are driven by the need for more compact solutions, improved energy consumption, and greater durability, leading to a new era in automation and control systems.

Key Developments

- Miniaturization: The trend towards smaller devices allows for integration in tighter spaces, making them ideal for modern applications.

- Smart Technology: Integration with IoT devices enables remote monitoring and control, enhancing functionality.

- Energy Efficiency: New materials and designs reduce power consumption, contributing to sustainable practices.

Applications of New Technologies

- Automotive industry, where compact solutions improve engine control and safety mechanisms.

- Home automation, providing convenience and enhanced security through smarter locking systems.

- Industrial automation, streamlining processes and increasing productivity with advanced control systems.

The continuous evolution of these electromagnetic devices is setting the stage for future innovations, promising even greater enhancements in functionality and application versatility.

Future Trends in Solenoid Design

The evolution of electromagnetic devices is paving the way for innovative designs that enhance efficiency, performance, and integration into modern systems. As technology advances, new materials and techniques are being explored to create components that are not only more powerful but also more sustainable.

Several key trends are emerging in this field:

- Miniaturization: The push for smaller, more compact devices is driving the design of components that occupy less space while maintaining functionality. This trend supports the development of portable and lightweight applications.

- Smart Integration: The incorporation of smart technologies, such as sensors and IoT connectivity, is becoming increasingly common. This allows for real-time monitoring and adaptive responses in various applications.

- Material Innovation: Researchers are investigating advanced materials that offer improved thermal and electrical properties. This includes the use of composites and nanomaterials to enhance performance.

- Energy Efficiency: There is a growing emphasis on reducing power consumption. Designs that utilize low-energy mechanisms without compromising strength or reliability are gaining traction.

- Customization: Tailored solutions are becoming more prevalent, enabling manufacturers to meet specific industry needs. This flexibility is essential in a market that demands diverse applications.

As these trends continue to unfold, the landscape of electromagnetic device design will transform, leading to more innovative solutions that address the challenges of tomorrow.