The intricate world of machinery often requires a detailed examination of its individual elements. By breaking down complex systems into their fundamental parts, we can enhance our comprehension and maintenance strategies. This approach not only fosters a deeper understanding but also aids in troubleshooting and repairs.

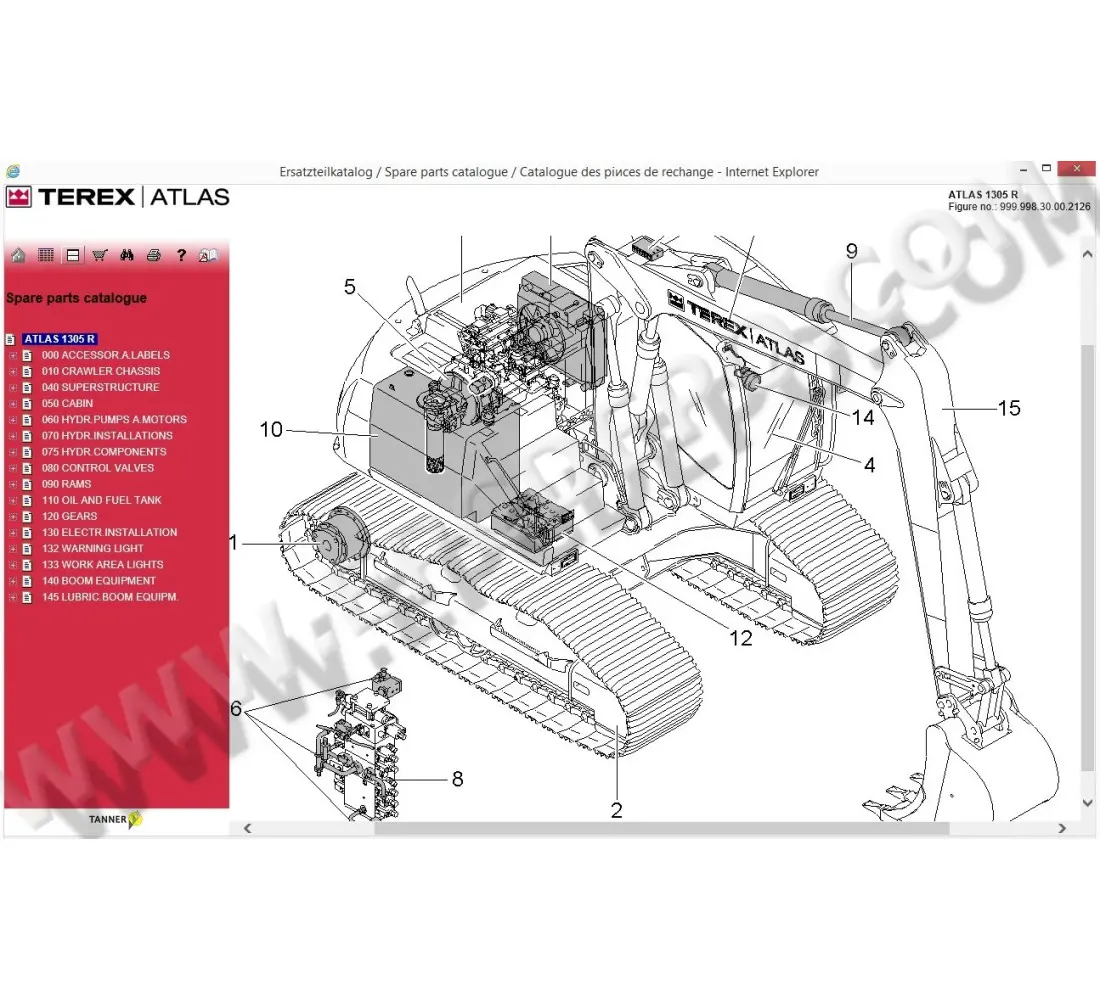

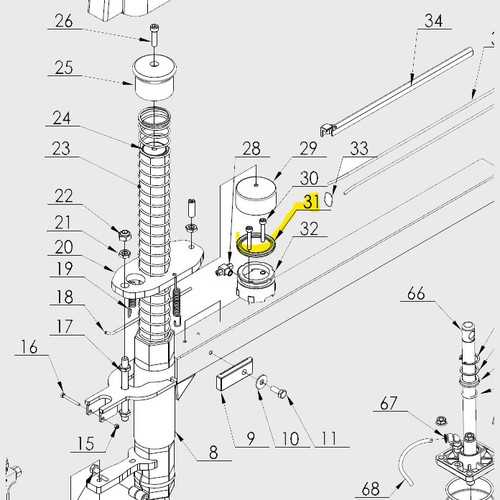

For enthusiasts and professionals alike, having access to comprehensive visual representations can be the ultimate tool. These illustrations serve as essential guides, highlighting the relationships and functions of various components. With the right resources, one can easily navigate through the myriad of elements that contribute to a machine’s overall functionality.

In this exploration, we will delve into the essential features and benefits of these visual aids. Whether you are looking to optimize performance or engage in restoration projects, understanding each segment is crucial for effective operation and longevity.

Understanding Atlas TC289 Components

Gaining insight into the various elements of complex machinery is crucial for effective maintenance and operation. Each component plays a vital role, contributing to the overall functionality and efficiency of the system. By familiarizing oneself with these integral parts, users can enhance performance and troubleshoot issues more effectively.

Core Components are essential for the machinery’s operation. These pieces work in harmony to ensure smooth performance. Understanding their roles can aid in identifying potential problems and facilitating timely interventions.

Secondary Elements also deserve attention, as they support and optimize the main components. While they may seem less critical, their proper functioning is necessary to prevent unexpected failures and prolong the lifespan of the system.

Finally, Maintenance Practices should be prioritized to ensure all elements are functioning at their best. Regular inspections and timely replacements of worn parts can greatly impact reliability and efficiency. Familiarity with the machinery’s makeup empowers users to take proactive steps in preserving its performance.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They simplify the identification and organization of individual elements, enhancing maintenance and repair processes. By providing clarity, these illustrations serve as a vital tool for technicians and engineers alike.

Facilitating Communication

Using clear visuals aids in conveying technical information between team members. When everyone can reference the same graphical materials, misunderstandings are minimized, leading to improved collaboration and efficiency.

Streamlining Repairs

Having a comprehensive visual reference allows for quicker troubleshooting and efficient replacement of elements. Technicians can pinpoint issues faster, reducing downtime and ensuring optimal performance of the machinery.

Key Features of TC289 Model

This model stands out due to its innovative design and exceptional functionality. Users can expect a combination of reliability and advanced engineering that enhances performance across various applications. The thoughtful integration of components ensures efficiency and ease of use, making it a preferred choice for many professionals.

Innovative Design

Ergonomics plays a vital role in the overall user experience, as the model is crafted to minimize fatigue during extended use. The layout of essential controls is intuitive, allowing operators to focus on their tasks without distraction.

Advanced Performance

Equipped with a high-efficiency engine, this model delivers optimal power while maintaining fuel economy. Coupled with a robust build, it is designed to withstand rigorous conditions, ensuring longevity and dependable service in diverse environments.

Identifying Essential Components

Understanding the critical elements of machinery is vital for effective maintenance and operation. Familiarity with these components enables users to troubleshoot issues, enhance performance, and ensure longevity. Recognizing the various pieces that make up the system helps streamline repairs and replacements.

Key components typically include:

- Engine: The powerhouse that drives the entire unit.

- Transmission: Responsible for transferring power to the wheels, crucial for movement.

- Chassis: The frame that supports all other parts and provides structural integrity.

- Hydraulic System: Facilitates various functions, from lifting to steering, essential for maneuverability.

- Electrical System: Powers all electronic components, crucial for operational efficiency.

By focusing on these fundamental elements, operators can gain deeper insights into functionality and maintenance requirements. A systematic approach to understanding these parts contributes to optimal performance and reliability.

Furthermore, it’s beneficial to familiarize oneself with auxiliary components, such as:

- Filters: Essential for maintaining fluid cleanliness and preventing damage.

- Belts and Hoses: Vital for the operation of various systems, often requiring regular inspection.

- Valves: Control the flow of fluids, critical for hydraulic and pneumatic systems.

- Wiring Harness: Connects electrical components and ensures proper functionality.

Ultimately, a comprehensive understanding of these elements is indispensable for anyone involved in the operation or maintenance of machinery. This knowledge not only aids in immediate repairs but also enhances overall efficiency and safety.

Common Issues with Atlas TC289

This section explores frequent challenges encountered with a specific model in the equipment category. Understanding these problems can aid in effective troubleshooting and maintenance, ensuring optimal performance and longevity.

Frequent Mechanical Problems

Mechanical issues are often reported, ranging from minor glitches to significant malfunctions. Regular inspections can help identify these concerns early, minimizing downtime.

| Issue | Description | Solution |

|---|---|---|

| Hydraulic Leaks | Fluid loss can lead to reduced performance. | Inspect seals and connections; replace damaged components. |

| Electrical Failures | Malfunctions in the electrical system may cause operational issues. | Check wiring and connections; test electrical components. |

Maintenance Tips

Regular maintenance is crucial to prevent these issues. Adhering to a consistent schedule can significantly enhance reliability and efficiency.

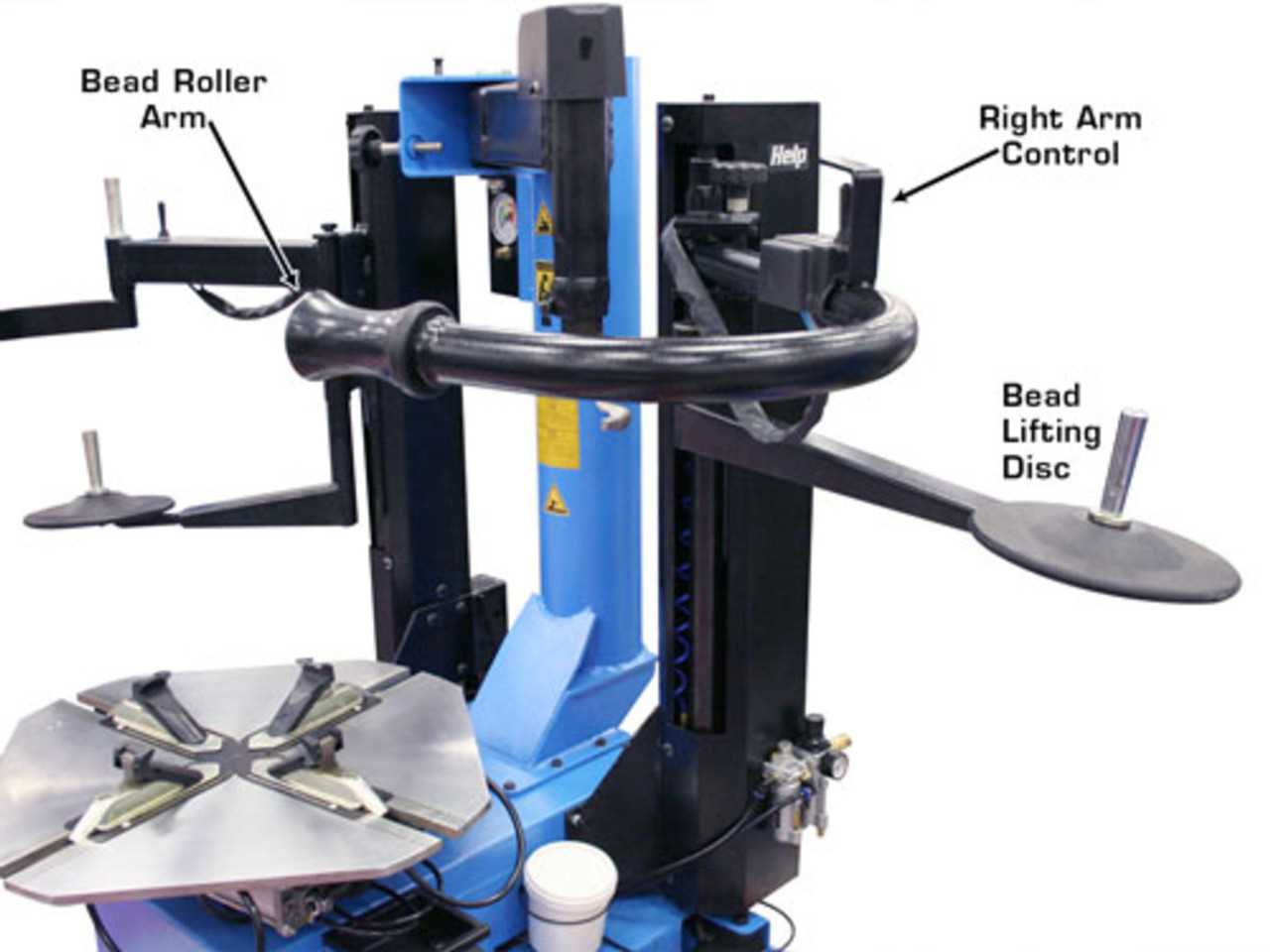

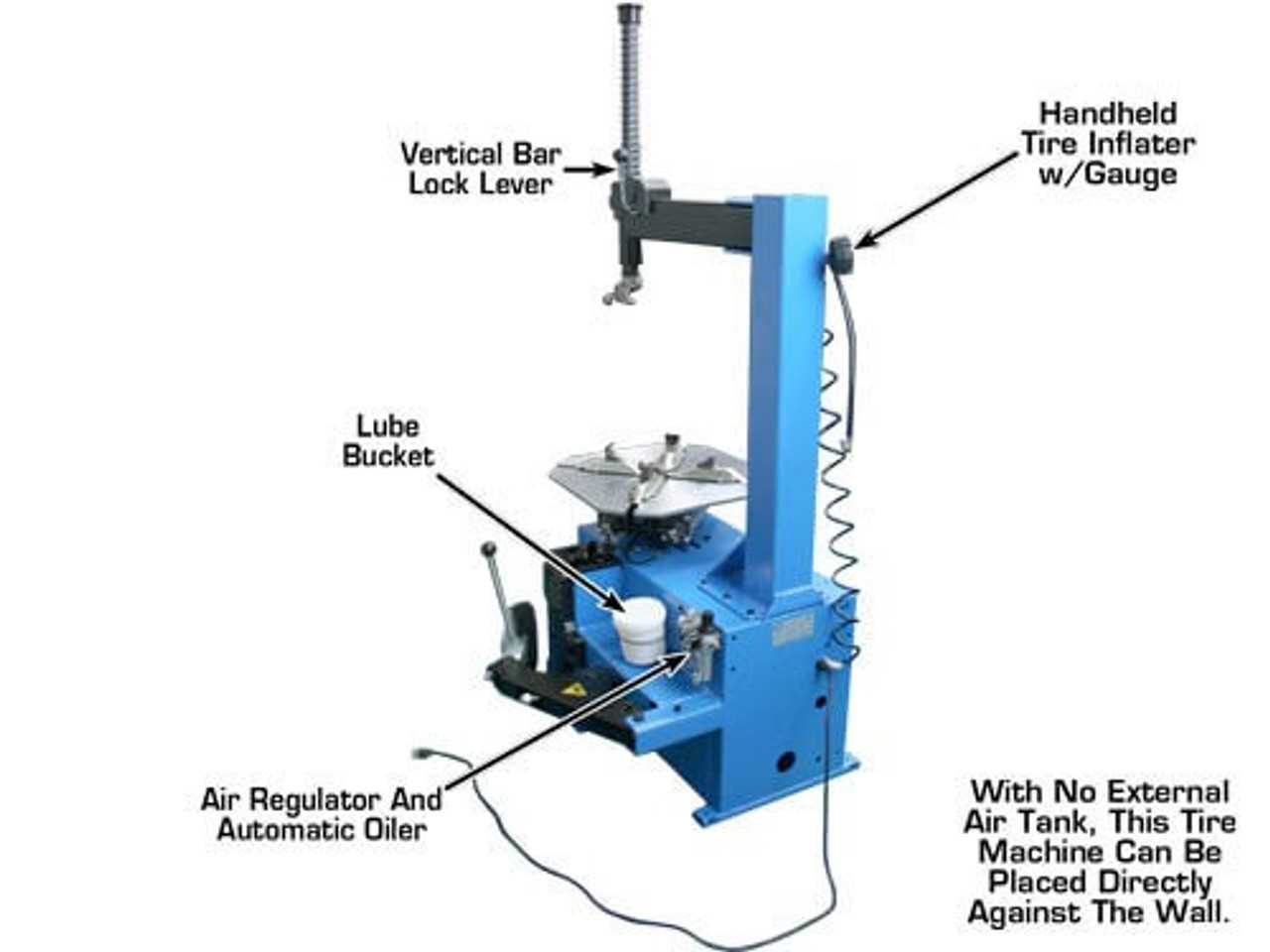

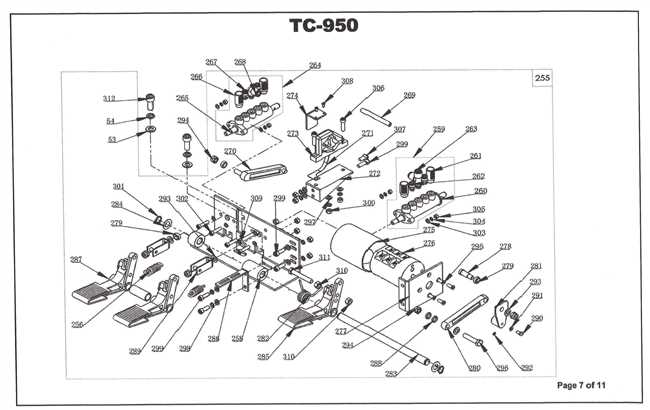

How to Use the Diagram

This section aims to guide users on effectively navigating and interpreting visual representations of components. Understanding these visuals is essential for identifying and managing various elements within a system, ensuring smoother operation and maintenance.

Identifying Key Components

Start by familiarizing yourself with the layout, noting where each item is situated. This will help you quickly locate essential parts when troubleshooting or performing replacements.

Following Connections and Relationships

Pay attention to the lines and arrows that indicate relationships between elements. Recognizing how components interact will enhance your understanding of the overall system functionality.

Maintenance Tips for TC289 Parts

Proper upkeep of equipment components is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances functionality but also prevents unexpected failures and costly repairs. By following a few essential guidelines, users can keep their machinery running smoothly and efficiently.

First and foremost, routine inspections should be conducted to identify any signs of wear or damage. Look for cracks, rust, or loose fittings that could lead to bigger issues if left unattended. Addressing minor concerns early can save time and resources in the long run.

Cleaning components regularly is equally important. Dust, grime, and debris can accumulate and affect performance. Utilize appropriate cleaning solutions and tools, ensuring that all residues are thoroughly removed without damaging sensitive parts.

Lubrication plays a critical role in maintaining functionality. Apply suitable oils or greases to moving elements to reduce friction and prevent overheating. It’s essential to adhere to the manufacturer’s recommendations regarding types and frequencies of lubrication.

Lastly, keeping detailed records of maintenance activities can provide valuable insights over time. This documentation helps track performance, identify recurring issues, and plan for future servicing needs. By implementing these practices, users can significantly enhance the reliability and efficiency of their machinery.

Replacement Parts Availability

Ensuring a steady supply of components is crucial for maintaining equipment efficiency and longevity. Various sources offer access to essential items, catering to different needs and preferences. Whether for immediate repairs or future upgrades, understanding where to find quality replacements can significantly enhance operational reliability.

Numerous suppliers, including specialized distributors and online platforms, provide a range of options. These sources typically offer detailed inventories, enabling users to easily locate the specific components required. Additionally, some manufacturers may facilitate direct purchasing, further simplifying the acquisition process.

It’s advisable to verify the quality and compatibility of any component before making a purchase. Checking reviews, seeking recommendations, and consulting technical specifications can help ensure that the right choice is made. This diligence not only minimizes the risk of issues but also optimizes performance over time.

Moreover, considering the availability of aftermarket alternatives can lead to more economical solutions. Many companies produce compatible items that often meet or exceed original standards, providing cost-effective choices for maintenance and repairs. Exploring these options can be beneficial for both budget-conscious individuals and organizations.

In summary, navigating the landscape of component availability requires careful consideration and research. By leveraging multiple sources and being informed about options, users can secure the necessary items to keep their systems running smoothly.

Compatibility with Other Models

This section explores how various components can interchange between different machines, enhancing versatility and maintenance efficiency. Understanding these relationships can significantly aid in repairs and upgrades.

Key Compatible Models

- Model A – shares several critical components.

- Model B – offers a similar design, allowing for easy swaps.

- Model C – utilizes many of the same mechanisms, ensuring seamless integration.

Benefits of Compatibility

- Reduced inventory costs due to fewer unique parts.

- Increased availability of replacement components.

- Simplified repair processes through shared resources.

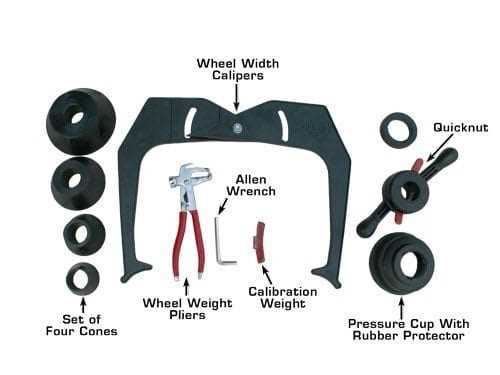

Tools Needed for Repairs

When it comes to maintaining machinery, having the right equipment is essential for efficient and effective repairs. This section outlines the fundamental implements required to ensure smooth operations and successful restoration of components.

Essential Hand Tools

Basic hand tools are indispensable for any repair job. A set of screwdrivers, including both flathead and Phillips, will tackle most fastening needs. Wrenches of various sizes are necessary for loosening and tightening bolts, while a reliable hammer can assist in adjustments and aligning parts. Additionally, a good quality pliers set is crucial for gripping and manipulating smaller components.

Power Tools and Accessories

In many situations, power tools significantly expedite the repair process. A drill is vital for creating holes or driving screws efficiently. A grinder can help shape and smooth metal surfaces, while a saw may be necessary for cutting through tougher materials. Having the right accessories, such as drill bits and blades, ensures versatility and readiness for various tasks.

Visual Reference for Assembly

This section aims to provide a comprehensive guide for assembling components effectively. By utilizing clear illustrations and detailed annotations, users can easily understand how each element interacts within the larger framework. The goal is to facilitate a smooth assembly process, minimizing confusion and enhancing efficiency.

Clarity is essential in assembly tasks, and visual aids serve as valuable tools for this purpose. They offer an ultimate reference point, allowing individuals to verify their progress at each stage. Engaging with these resources will lead to a more successful and informed assembly experience.

Where to Find Diagrams Online

Locating visual schematics for various machinery and equipment can significantly enhance repair and maintenance processes. Numerous online resources offer access to detailed illustrations that aid in understanding component layouts and assembly instructions. Here are some effective methods to find these valuable resources.

1. Manufacturer Websites

Many manufacturers provide downloadable resources directly on their official sites. This often includes:

- Technical manuals

- Service guides

- Visual representations of products

Check the support or resources section for these documents.

2. Online Forums and Communities

Engaging with online forums dedicated to specific machinery can yield helpful information. Users often share:

- Links to helpful resources

- Personal scans of manuals

- Advice on finding specific illustrations

Participating in these communities can lead to valuable insights and connections.

Expert Recommendations for Users

When navigating the complexities of machinery maintenance and repair, gaining insights from experienced professionals can significantly enhance user experience. Understanding how components work together, recognizing potential issues, and knowing the best practices for upkeep are essential for ensuring longevity and optimal performance.

Regular Inspection: Schedule routine evaluations to identify wear and tear early. This proactive approach can prevent minor issues from escalating into major problems.

Consult Documentation: Refer to comprehensive guides and manuals that provide detailed information about each component’s function and assembly. These resources are invaluable for both troubleshooting and performing maintenance tasks.

Quality Components: Invest in high-quality replacement elements. Opting for superior parts ensures reliability and performance, reducing the likelihood of future failures.

Seek Professional Advice: Don’t hesitate to reach out to experts when uncertain. Their specialized knowledge can offer clarity and save time and resources in the long run.

Stay Updated: Keep abreast of any advancements or updates in technology related to your equipment. This knowledge can provide insights into improved practices and tools that enhance efficiency.

Documentation of Maintenance: Maintain a detailed log of all service activities. This practice aids in tracking performance trends and assists in planning future maintenance tasks effectively.

Implementing these strategies will not only enhance the operational efficiency of your machinery but also contribute to a safer and more productive work environment.