The intricate design of a pressure cleaning machine often involves various elements that work in harmony to deliver powerful performance. Understanding the layout and functionality of these individual segments can significantly enhance the user’s experience, making maintenance and repairs more manageable.

Each section of this cleaning apparatus has a specific role, contributing to the overall efficiency and effectiveness of the device. By familiarizing oneself with the arrangement of these components, users can quickly identify issues and implement solutions, ensuring their machine operates at peak capacity.

Exploring the schematic representation of these crucial elements not only aids in troubleshooting but also fosters a deeper appreciation for the engineering behind these high-performance tools. Grasping the relationship between different sections empowers users to make informed decisions regarding upkeep and enhancements.

Understanding the Karcher K5 Parts

When it comes to high-pressure cleaning machines, having a solid grasp of their components is essential for effective maintenance and optimal performance. Each element plays a vital role, contributing to the overall efficiency and longevity of the device. Familiarity with these elements ensures that users can troubleshoot issues and perform necessary repairs with confidence.

Below is a breakdown of key components typically found in such equipment:

| Component | Function |

|---|---|

| Motor | Drives the pump and generates the pressure needed for cleaning. |

| Pump | Increases the water pressure and delivers it through the nozzle. |

| Nozzle | Controls the water spray pattern and intensity for various cleaning tasks. |

| Hose | Connects the machine to the water source and allows for movement during operation. |

| Filter | Prevents debris from entering the pump and damaging internal components. |

Understanding these fundamental components can greatly enhance user experience and maintenance efficiency, ensuring that the cleaning device remains in excellent working condition for years to come.

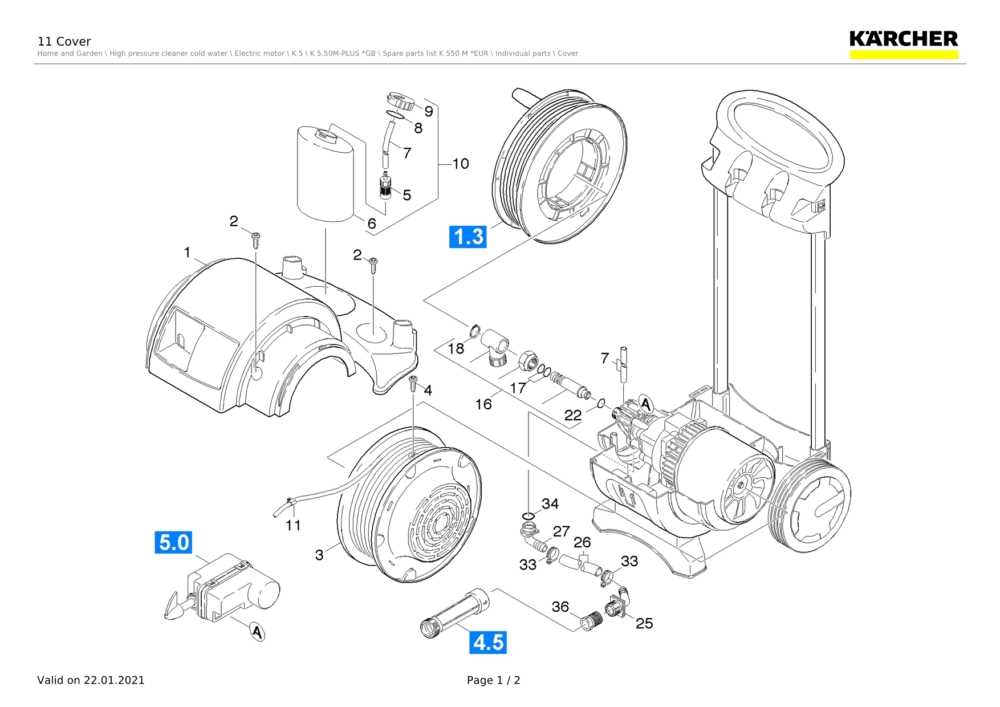

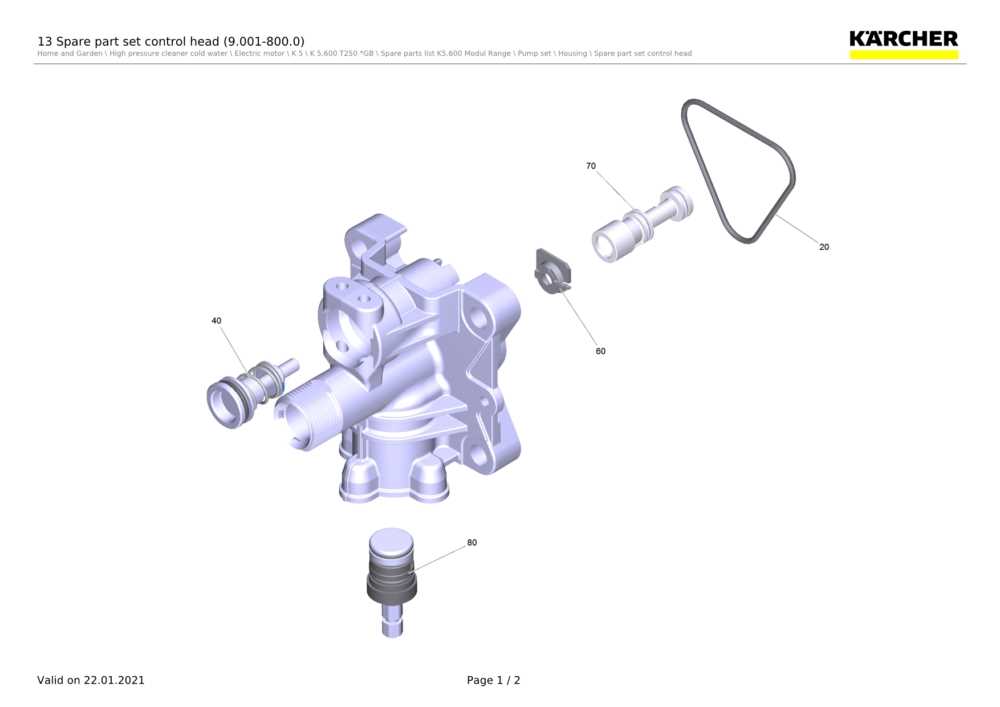

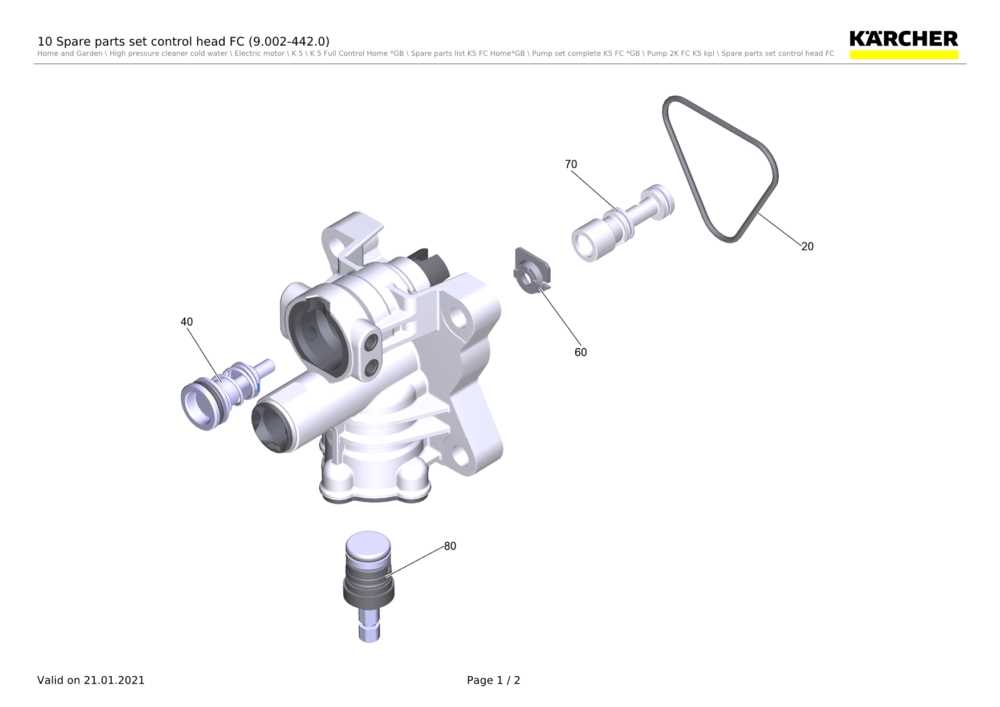

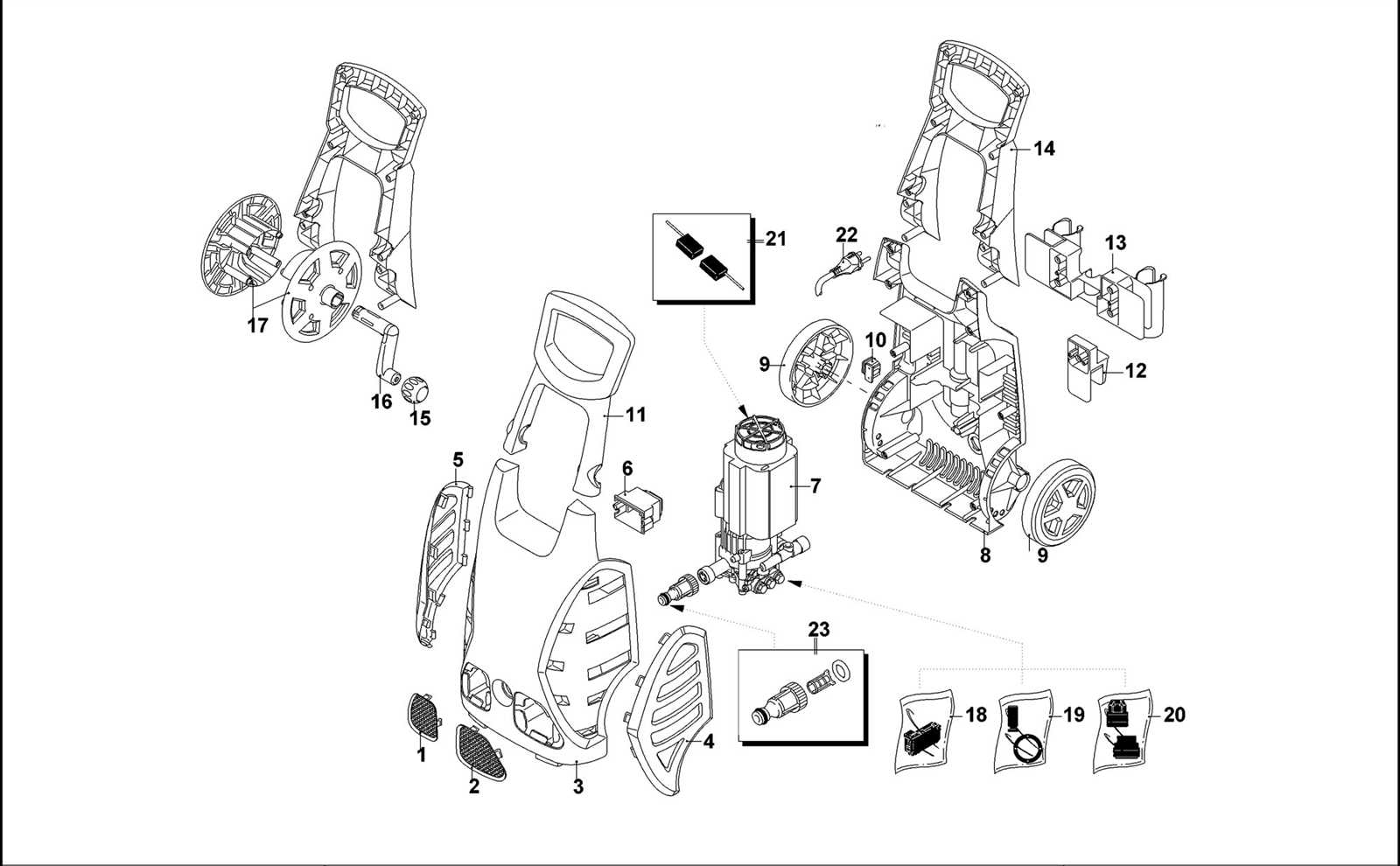

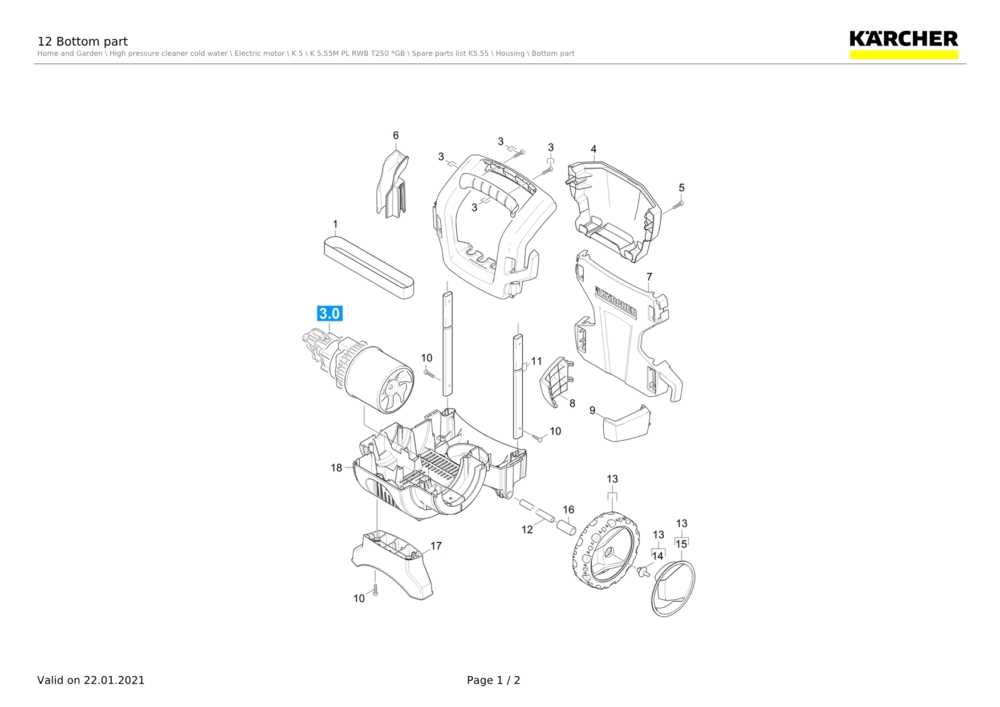

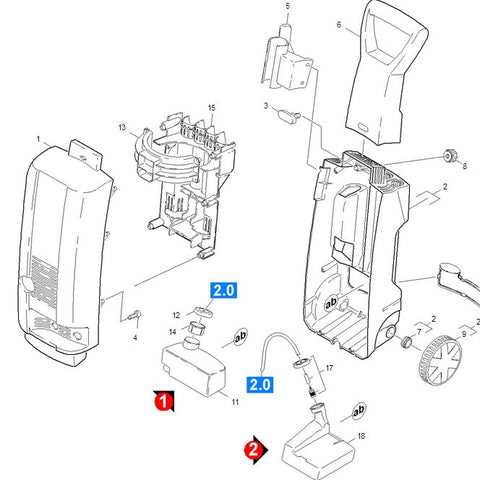

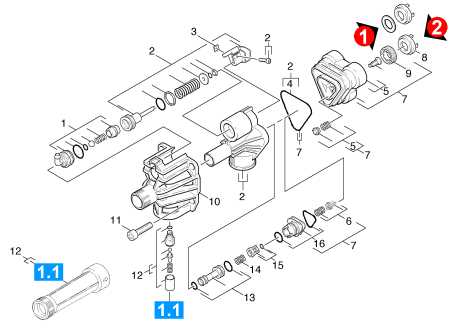

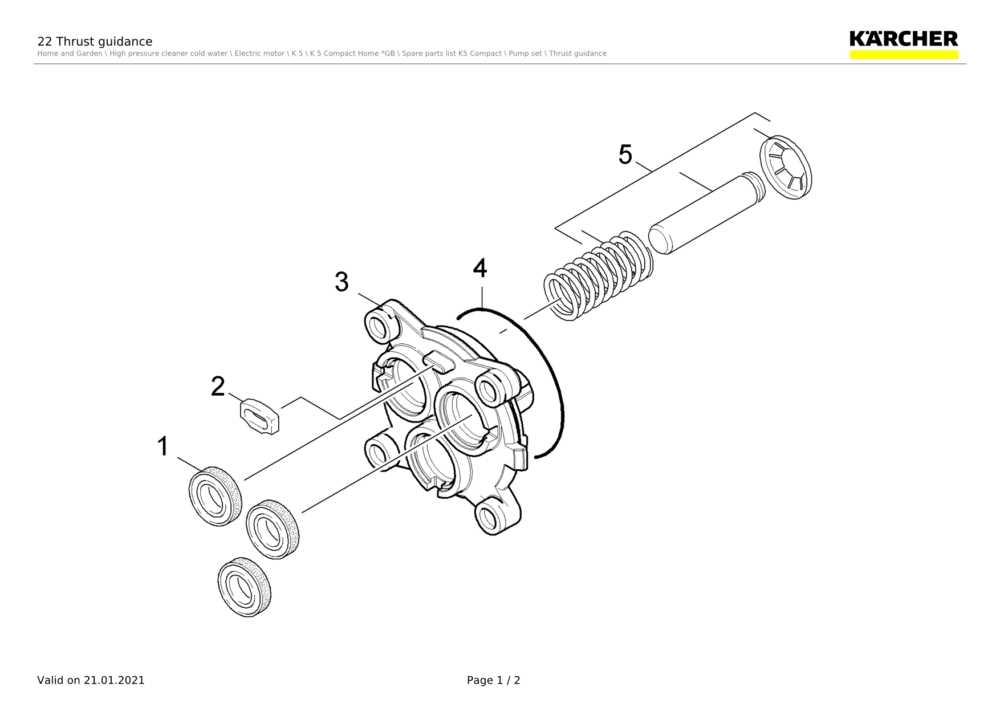

Importance of a Parts Diagram

Understanding the layout and components of any machinery is crucial for maintenance and repair. A visual representation of individual elements allows users to identify and source necessary components efficiently.

- Enhances troubleshooting by clearly showing how each element connects.

- Facilitates ordering the correct replacements without confusion.

- Assists in understanding the assembly and disassembly processes.

- Promotes better maintenance practices through increased awareness of the system.

Ultimately, a comprehensive visual reference serves as an invaluable resource for both novices and experienced technicians, ensuring that repairs are carried out smoothly and effectively.

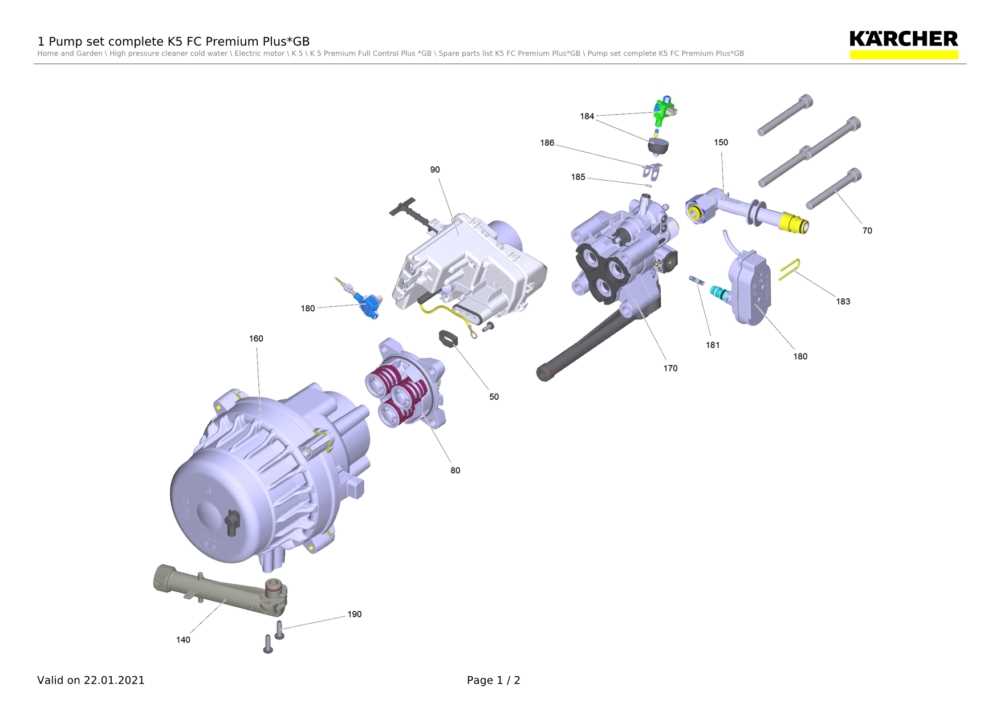

Main Components of Karcher K5

The efficiency of this cleaning device relies heavily on its core elements, which work together to deliver optimal performance. Understanding these components can enhance your maintenance and usage experience.

- Motor: The powerhouse that drives the unit, providing the necessary force for water pressure.

- Pump: Essential for creating high pressure, enabling effective cleaning of various surfaces.

- Water Inlet: The entry point for water, crucial for maintaining a steady flow to the pump.

- Pressure Hose: Connects the unit to the nozzle, allowing the pressurized water to reach the target area.

- Nozzle: Directs the water spray, with different types available for varied cleaning tasks.

These key components form the foundation of the device, ensuring reliability and effectiveness in various cleaning scenarios.

How to Read the Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. This guide will help you navigate through the essential elements and symbols typically found in such illustrations, enabling you to identify and manage individual pieces with confidence.

Key Elements to Look For

Begin by familiarizing yourself with the common symbols and lines used in these illustrations. Each component is often labeled clearly, while lines may indicate connections or flow. Understanding these markers can significantly enhance your ability to interpret the schematic.

Using the Reference Table

| Symbol | Description |

|---|---|

| Circle | Represents a connection point. |

| Arrow | Indicates the direction of flow or movement. |

| Square | Denotes a key component or assembly. |

By mastering these basics, you’ll be better equipped to delve into the intricate details of your equipment and tackle any issues that may arise.

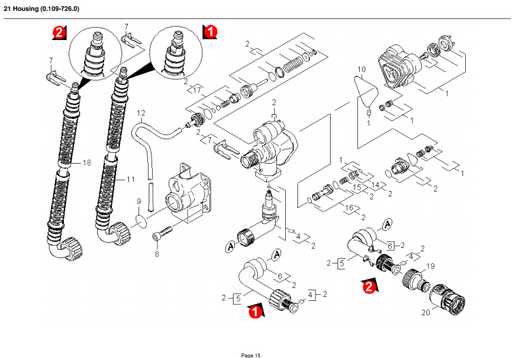

Common Replacement Parts

Maintaining your pressure cleaning equipment is essential for optimal performance and longevity. Various components may wear out or become damaged over time, necessitating their replacement to ensure efficient operation. Understanding these essential elements can help you make informed decisions when it comes to upkeep.

Essential Components

Among the crucial elements are seals and O-rings, which prevent leaks and maintain pressure. Additionally, nozzles play a significant role in directing water flow effectively, while hoses need regular inspection for wear and tear.

Performance Enhancements

Replacing worn-out filters is vital for ensuring clean water flow and protecting internal mechanisms. Furthermore, upgrading to more efficient spray wands can enhance your cleaning experience. Regularly checking these items will lead to improved performance and reliability.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan and performance of your cleaning equipment. Implementing a few straightforward practices can significantly enhance efficiency and reliability, ensuring that your device remains in optimal condition for years to come.

- Regular Cleaning: Keep the exterior and accessible components free of dirt and debris. This prevents buildup that can affect functionality.

- Check for Wear: Periodically inspect hoses, connectors, and other attachments for signs of damage. Replace any worn parts promptly to avoid larger issues.

- Fluid Levels: Ensure that all necessary fluids are at the recommended levels. Regularly topping off lubricants can prevent mechanical strain.

- Follow Usage Guidelines: Adhere to the manufacturer’s recommendations regarding operation limits. Avoid overexerting the machine to maintain its integrity.

- Store Properly: When not in use, keep the equipment in a dry, sheltered space. Protect it from extreme temperatures and moisture that can lead to corrosion.

Incorporating these simple practices into your routine can lead to improved functionality and a longer lifespan for your cleaning equipment, making maintenance an essential aspect of ownership.

Identifying Issues through Diagrams

Visual representations play a crucial role in diagnosing problems within complex systems. By analyzing these illustrations, one can pinpoint malfunctioning components, understand their interrelations, and streamline the troubleshooting process. This approach not only enhances clarity but also fosters effective communication among users and technicians.

Benefits of Visual Analysis

Utilizing visual aids simplifies the identification of discrepancies. Users can quickly grasp the layout and functionality of different elements, allowing for efficient diagnosis. This method ultimately reduces the time spent on resolving issues, leading to enhanced productivity.

Enhancing Troubleshooting Skills

Engaging with these visual tools empowers individuals to develop better troubleshooting skills. By understanding the systematic layout, users become adept at recognizing patterns and anomalies, which is essential for effective maintenance. Ultimately, this fosters a deeper connection with the equipment and encourages proactive care.

Ordering Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is essential for optimal performance and longevity. Genuine replacements ensure that your device operates efficiently and safely, reducing the risk of malfunction or damage. Utilizing high-quality parts can significantly enhance the overall user experience and maintain the integrity of the machinery.

To begin the ordering process, it’s crucial to identify the specific components needed for your model. Consulting the manufacturer’s resources can provide clarity on the correct items required. Many suppliers offer comprehensive catalogs and online platforms where you can easily find and order these essential elements.

When placing an order, consider checking for authorized dealers or official distributors. This guarantees that you receive the correct components designed specifically for your equipment. Additionally, purchasing through reputable sources often comes with warranties and customer support, ensuring peace of mind with your investment.

Before finalizing your order, verify the details such as part numbers and descriptions. Taking the time to ensure accuracy can save you from potential issues down the line. Once you’ve confirmed everything, proceed with your purchase, and look forward to the improved functionality that genuine components can provide.

Tools Needed for Repairs

To successfully carry out maintenance or fix any equipment, having the right tools at your disposal is essential. The correct instruments not only streamline the process but also ensure that repairs are conducted safely and effectively. This section outlines the essential tools that will aid in troubleshooting and restoring functionality.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening or tightening nuts and bolts, ensuring secure connections. |

| Screwdriver Set | Essential for removing or fastening screws, available in various sizes and types. |

| Pliers | Versatile tool for gripping, twisting, and cutting wires or small components. |

| Multimeter | A device for measuring electrical voltage, current, and resistance, useful for diagnostics. |

| Socket Set | Includes various sizes of sockets for quickly tightening or loosening bolts. |

| Cleaning Supplies | Brushes, cloths, and cleaning solutions to maintain and prepare surfaces before repairs. |

DIY Repair Guidelines

When it comes to maintaining and fixing your equipment, a hands-on approach can save both time and money. Understanding the essential components and how they work together enables you to tackle common issues effectively. Whether you’re dealing with leaks, performance drops, or general wear and tear, these guidelines will help you navigate repairs with confidence.

Identifying Issues

Begin by observing the symptoms your device is exhibiting. Look for signs such as unusual noises, loss of pressure, or leaks. Documenting these issues can help in pinpointing the exact component that may require attention.

Tools and Materials

Gather the necessary tools before starting your repair. Basic items like screwdrivers, wrenches, and replacement seals will likely be essential. Additionally, having a repair manual or online resources can greatly assist in understanding the assembly and disassembly process.

Always prioritize safety when working on machinery. Ensure the unit is powered off and disconnected before beginning any repairs. By taking a methodical approach, you can restore functionality and prolong the life of your equipment.

When to Seek Professional Help

Recognizing when to call in an expert can be crucial for maintaining equipment efficiently. Sometimes, what seems like a minor issue may require specialized knowledge or tools to resolve safely and effectively.

Here are some scenarios to consider:

- If you notice persistent leaks or unusual noises.

- When standard troubleshooting methods fail to resolve the problem.

- If you lack the necessary tools or skills to address the issue.

- When repairs seem complex or beyond your understanding.

- If there are safety concerns, such as electrical issues.

Ultimately, seeking help from a professional can save time and prevent further damage.

Exploring Upgrades and Accessories

Enhancing your cleaning equipment with the right additions can significantly improve its performance and versatility. By exploring various upgrades and accessories, users can tailor their machines to meet specific needs and tackle a broader range of tasks efficiently. From enhancing functionality to increasing convenience, the right enhancements can transform your experience.

Popular Upgrades

- Pressure Nozzles: Different spray patterns allow for targeted cleaning, making it easier to tackle tough stains or delicate surfaces.

- Extended Hoses: Longer hoses provide greater reach, enabling users to clean hard-to-access areas without moving the main unit.

- Surface Cleaners: These attachments speed up the cleaning of large flat surfaces, providing a uniform finish without streaks.

Useful Accessories

- Foam Sprayers: Ideal for applying detergents evenly, making pre-treatment more effective.

- Brushes: Various brush types cater to different surfaces, enhancing the cleaning process.

- Storage Solutions: Organizers and holders help keep accessories tidy and readily accessible, improving efficiency during use.

Comparative Analysis with Other Models

This section explores the distinctions and similarities among various high-pressure cleaning devices, focusing on their performance, durability, and user-friendliness. By examining these aspects, we can gain insights into how one model stacks up against others in the market.

Performance is a crucial factor when comparing these machines. While some devices excel in water pressure and flow rate, others may offer superior cleaning efficiency due to advanced nozzle designs or integrated technologies. Evaluating these metrics allows users to identify which model best meets their cleaning requirements.

Another essential aspect is durability. Different models often feature varying materials and construction quality, impacting their longevity. Some manufacturers utilize robust components, ensuring a longer lifespan, while others might compromise on build quality for a lower price point. This comparison helps potential buyers understand the long-term value of their investment.

Lastly, user-friendliness can significantly influence user experience. Features such as ergonomic designs, ease of assembly, and accessibility of controls vary widely across models. Understanding these differences can aid consumers in selecting a device that is not only effective but also easy to operate and maintain.