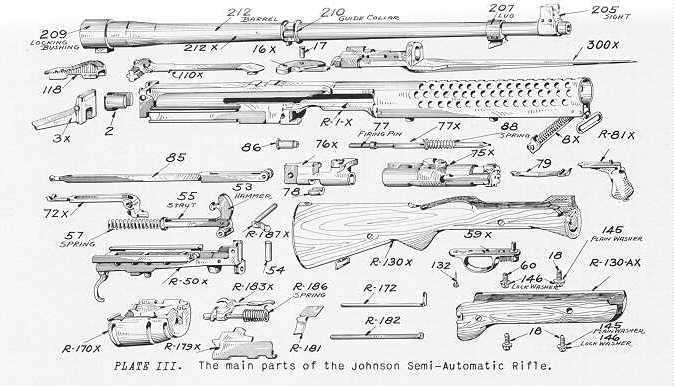

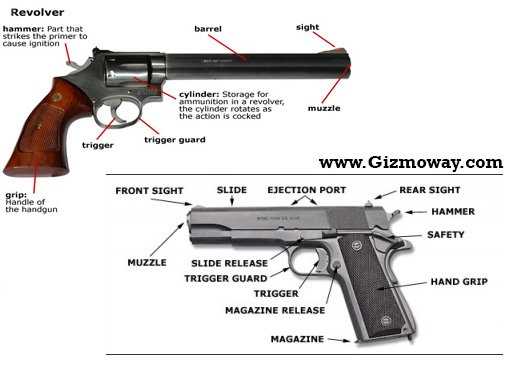

The intricate design of a traditional handgun reveals a fascinating interplay of various elements that contribute to its functionality. Each segment plays a crucial role in ensuring reliability and performance, making it essential for enthusiasts and practitioners to familiarize themselves with these components. Analyzing the structure of such a weapon not only enhances appreciation for its craftsmanship but also aids in maintenance and troubleshooting.

At the core of this mechanical marvel lies a series of interconnected mechanisms, each with a specific purpose. From the trigger assembly to the firing mechanism, understanding these elements provides insights into how they work together seamlessly. This knowledge is invaluable for those looking to deepen their expertise or engage in hands-on repairs and modifications.

Moreover, a clear visual representation of these components can serve as an excellent educational tool. It allows individuals to visualize the relationship between each element, facilitating a better grasp of their functions and interactions. Whether for practical use or academic interest, exploring the anatomy of this iconic firearm opens the door to a deeper appreciation of its enduring legacy.

Understanding Revolver Mechanics

Grasping the intricacies of this firearm type involves exploring its unique components and how they function together. Each element plays a crucial role in the overall operation, ensuring reliability and precision.

- Trigger mechanism

- Cylinder rotation

- Firing pin engagement

- Barrel alignment

Key aspects to consider include:

- Action Types: Variants include single-action and double-action, affecting firing sequences.

- Locking Mechanism: Ensures secure alignment before discharge.

- Safety Features: Important for preventing accidental discharges.

By delving into these elements, one can achieve a deeper appreciation for how each function contributes to the ultimate performance of the firearm.

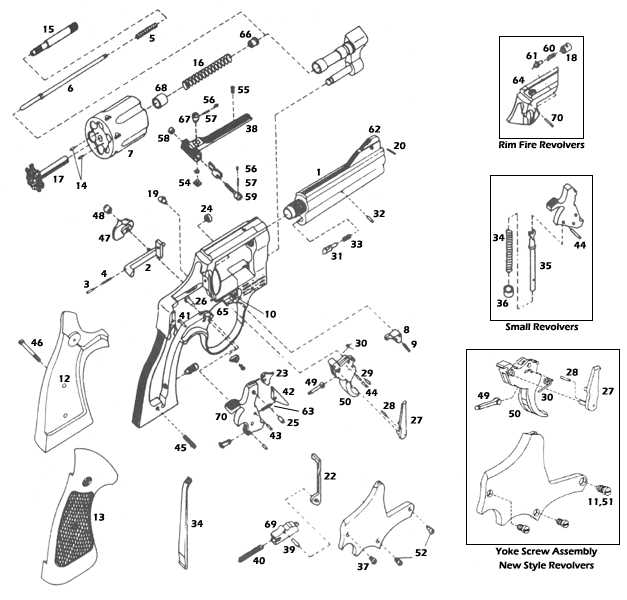

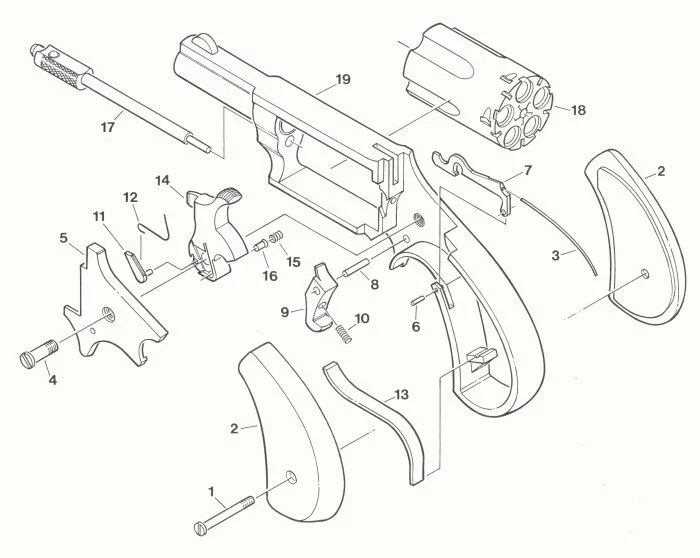

Components of a Revolver

Understanding the fundamental elements of a wheel-lock firearm reveals the intricate mechanics that enable its operation. Each component plays a crucial role in functionality, contributing to both performance and safety. From the trigger mechanism to the cylinder, these features work in harmony to achieve reliable discharge.

The frame serves as the backbone, providing structure and support. Attached to it, the barrel channels the projectile, ensuring accuracy. The rotating cylinder holds the cartridges, facilitating a seamless transition during firing.

Moreover, the hammer mechanism is vital for initiating ignition, while the trigger allows the shooter to engage the system. Other components, such as the extractor, assist in cartridge removal, enhancing efficiency after each shot. Together, these elements create a cohesive unit, showcasing remarkable engineering.

Functionality of the Cylinder

The cylinder serves a crucial role in the operation of certain firearms, housing the ammunition and facilitating the firing mechanism. Its design allows for quick rotation, enabling each chamber to align with the barrel, thus ensuring accurate shot placement. Understanding this component’s functionality is essential for grasping the overall performance of the firearm.

Mechanics of Rotation

The cylinder rotates in synchronization with the trigger pull, allowing for seamless transitions between chambers. This mechanism ensures that each round is positioned correctly for ignition, contributing to both reliability and efficiency.

Loading and Ejecting Ammunition

Loading and ejecting cartridges is a critical process managed by the cylinder. It is designed to accommodate smooth insertion and removal, providing ease of use while maintaining safety during operation.

| Function | Description |

|---|---|

| Rotation | Aligns each chamber with the barrel for firing. |

| Loading | Facilitates the insertion of rounds into chambers. |

| Ejection | Allows for the removal of spent cartridges after firing. |

Role of the Trigger Assembly

The trigger assembly plays a crucial part in the operation of firearm mechanisms, acting as the bridge between the user’s intent and the firing process. It ensures that the weapon is discharged with precision and control, providing both safety and functionality.

Key Functions

- Initiates the firing sequence.

- Controls the release of the hammer or striker.

- Provides feedback to the shooter.

- Ensures safety features are engaged.

Components Involved

- Trigger: The part directly interacted with by the shooter.

- Sear: Engages and disengages the firing mechanism.

- Spring: Provides the necessary tension for operation.

Understanding the intricacies of the trigger assembly allows for better maintenance and improved handling, ultimately enhancing performance and safety in various situations.

Exploring the Hammer Mechanism

The hammer mechanism plays a crucial role in the operation of many firearms, serving as a key element that activates the ignition process. Understanding its function is essential for grasping how these devices operate safely and effectively. This section delves into its components, interactions, and significance within the overall system.

Components of the Hammer System

The mechanism consists of several critical components that work together to ensure proper functioning. Each part must interact flawlessly to achieve the desired outcome during firing.

| Component | Function |

|---|---|

| Hammer | Strikes the firing pin to initiate ignition. |

| Sear | Holds the hammer back until the trigger is pulled. |

| Trigger | Releases the sear to allow the hammer to fall. |

| Firing Pin | Punctures the primer to ignite the cartridge. |

Importance in Firearm Functionality

The hammer mechanism’s design directly influences the reliability and safety of the firearm. A well-engineered system minimizes the risk of misfires and ensures smooth operation, making it an ultimate focus for enthusiasts and professionals alike.

Importance of the Barrel Design

The configuration of the tube that directs the projectile is crucial for ensuring accuracy, stability, and overall performance. Its design directly influences the effectiveness of the firearm and the experience of the user. Understanding its significance can lead to enhancements in both functionality and safety.

A well-engineered tube not only maximizes projectile velocity but also minimizes recoil, making it easier to handle. The materials and geometry involved play a vital role in how effectively the energy is transferred and how the firearm behaves during operation.

| Design Element | Impact on Performance |

|---|---|

| Length | Affects accuracy and muzzle velocity. |

| Inner Diameter | Influences projectile fit and gas seal. |

| Twist Rate | Determines stability of the projectile in flight. |

| Material | Impacts durability and weight. |

Ultimately, the design of this component is foundational to ensuring optimal operation and user satisfaction. Recognizing its role can lead to advancements in technology and improved designs for future models.

Safety Features in Revolvers

Understanding the protective mechanisms in firearms is essential for responsible usage. These features are designed to minimize the risk of accidental discharge and enhance user control. Below are key elements that contribute to safe handling.

Key Safety Mechanisms

- Transfer Bar: Prevents the firing pin from striking the cartridge unless the trigger is fully pulled.

- Hammer Block: Keeps the hammer from making contact with the firing pin unless intentionally released.

- Safety Notch: Allows the hammer to rest without engaging a cartridge, reducing the chance of unintentional firing.

User Responsibility

While mechanical safety features are crucial, user education and awareness are equally important. Following best practices can further ensure a secure experience:

- Always keep the muzzle pointed in a safe direction.

- Verify that the firearm is unloaded when not in use.

- Engage safety mechanisms whenever the weapon is not actively being fired.

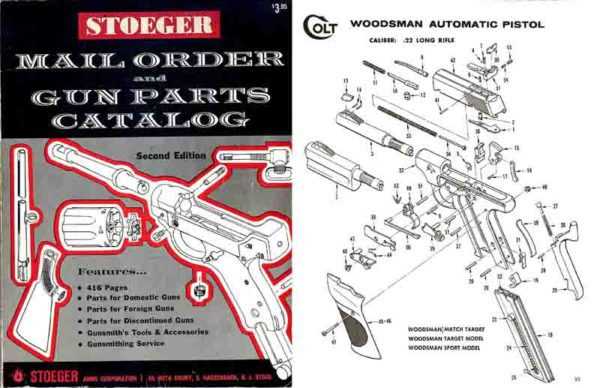

Comparing Different Revolver Models

When exploring various firearm types, it’s essential to understand the distinctions between models, as each design offers unique characteristics and performance features. By examining aspects such as construction, firing mechanisms, and usability, enthusiasts can appreciate how these variations impact handling and accuracy.

For instance, some designs emphasize lightweight materials for enhanced portability, while others prioritize robustness for increased durability. Additionally, the choice of caliber can significantly affect the shooting experience, influencing recoil and precision. Comparing these elements can help potential users make informed decisions based on their needs.

Furthermore, the historical evolution of these firearms has led to innovative designs that incorporate modern technology, enhancing functionality. By delving into these advancements, one can gain insight into how tradition meets innovation, ultimately shaping user preference and application.

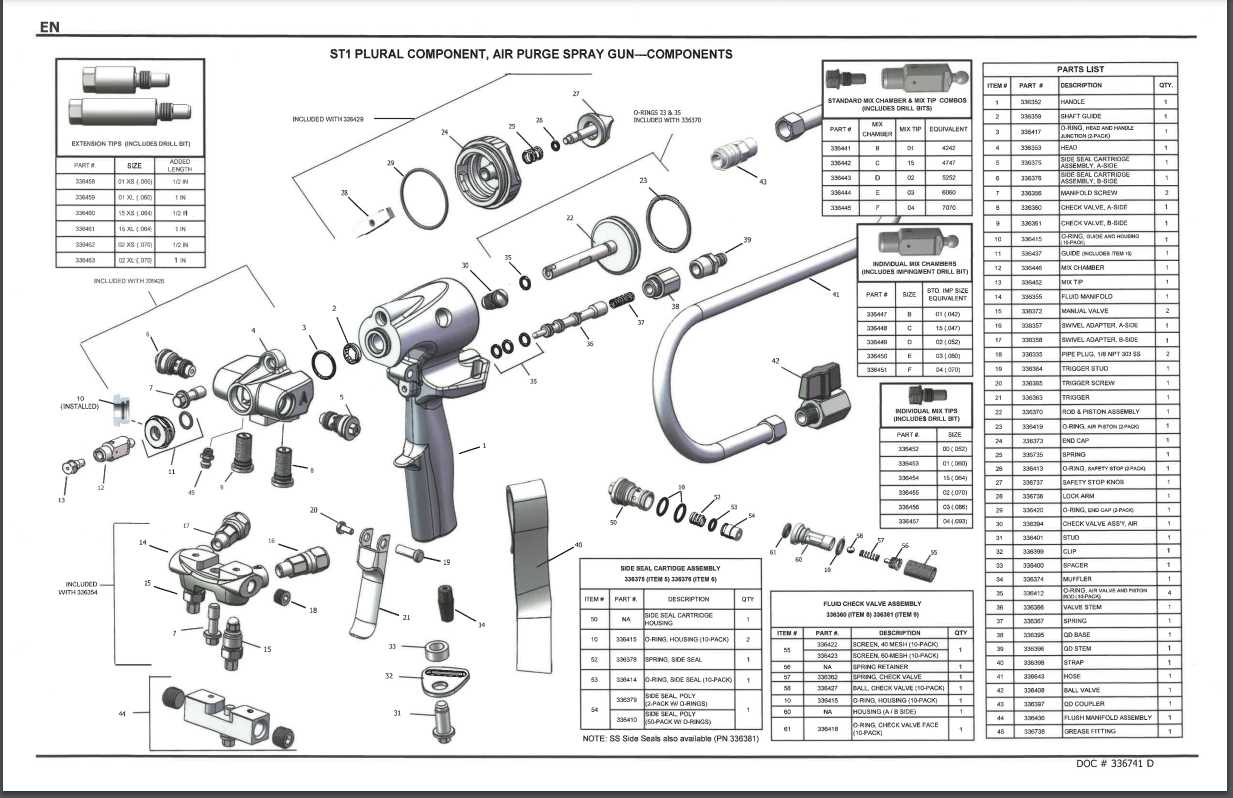

Assembly and Disassembly Process

This section outlines the essential steps involved in the careful reassembly and disassembly of a specific firearm mechanism. Understanding this process is crucial for maintenance, repair, and overall familiarity with the equipment. Each stage requires precision and attention to detail to ensure functionality and safety.

Before starting, gather the necessary tools and a clean workspace. Follow these key steps:

- Preparation:

- Ensure the mechanism is unloaded.

- Gather required tools such as screwdrivers, wrenches, and cleaning materials.

- Set up a well-lit, organized workspace.

- Disassembly:

- Carefully remove any external components, taking note of their arrangement.

- Unscrew and detach internal mechanisms systematically.

- Store removed elements in labeled containers to avoid confusion.

- Inspection:

- Examine each component for wear, damage, or dirt accumulation.

- Clean parts as needed with appropriate solvents and tools.

- Reassembly:

- Refer to the original configuration for correct placement of each element.

- Carefully align and secure components, ensuring they fit snugly.

- Test the mechanism to verify proper function before full reassembly.

- Final Check:

- Perform a thorough function check after reassembly.

- Ensure all fasteners are tight and components are correctly positioned.

Following these steps meticulously not only enhances the lifespan of the firearm but also guarantees safe and effective operation.

Common Revolver Maintenance Tips

Regular upkeep is essential for ensuring the longevity and reliability of your firearm. By following a few straightforward practices, you can enhance performance and safety, ultimately protecting your investment. Here are some key suggestions to keep in mind.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean Barrel | After each use | Use a quality cleaning rod and solvent. |

| Check Lubrication | Monthly | Apply light oil to moving components. |

| Inspect Cylinder | Every outing | Look for residue buildup and wear. |

| Examine Grips | Quarterly | Ensure they are secure and comfortable. |

| Test Functionality | Before each use | Check all mechanisms and safety features. |

Impact of Material on Performance

The choice of materials used in mechanical devices significantly influences their efficiency, durability, and overall effectiveness. Various components can be constructed from a range of substances, each contributing unique properties that affect how well the device operates.

Key aspects to consider include:

- Weight: The density of materials affects the overall weight, impacting handling and ease of use.

- Strength: Some materials offer superior tensile and compressive strength, enhancing longevity under stress.

- Corrosion Resistance: Materials with high resistance to corrosion ensure better performance over time, especially in adverse conditions.

- Thermal Conductivity: The ability of materials to conduct heat can influence the device’s performance during extended use.

- Cost Efficiency: Economic factors often dictate material choices, balancing performance and affordability.

In conclusion, selecting appropriate materials is crucial for optimizing the functionality and lifespan of any mechanical system. A thoughtful approach can lead to significant improvements in both reliability and performance.

Historical Evolution of Revolver Design

The development of multi-chambered firearms has significantly influenced both military and civilian applications throughout history. Understanding this progression offers insight into the technological advancements that shaped their functionality and reliability.

Initially, these firearms were simplistic in design, often requiring manual loading and single shots. Over time, innovations introduced various features:

- Single-action mechanisms: Enabled quicker firing through mechanical advantages.

- Double-action systems: Allowed for easier operation, improving user efficiency.

- Cylinder rotation: Advanced designs facilitated faster reloading and increased capacity.

As manufacturing techniques evolved, so did the materials used, leading to enhanced durability and performance. Key historical milestones include:

- Early 19th century: Introduction of percussion caps and rifled barrels.

- Mid-19th century: Adoption of metal cartridges, revolutionizing ammunition.

- 20th century: Emergence of modern materials and precision engineering.

This historical journey reflects not only advancements in technology but also shifts in societal needs and preferences, ultimately culminating in the sophisticated models available today.

Future Trends in Revolver Technology

The evolution of firearm design continues to shape the landscape of personal defense and sport shooting. As advancements in materials, manufacturing processes, and technology emerge, we can anticipate significant changes that will enhance performance, safety, and user experience.

Innovative Materials and Manufacturing Techniques

One of the most promising directions is the integration of advanced materials such as carbon fiber and polymer composites. These materials offer lightweight durability and resistance to corrosion, which can lead to a more ergonomic and resilient design. Furthermore, additive manufacturing techniques are set to revolutionize production, allowing for greater customization and complex geometries that were previously unattainable.

Smart Technology Integration

Another exciting trend is the incorporation of smart technology into traditional designs. Features such as biometric locks, built-in sensors, and connectivity options could enhance safety and user control. These innovations can provide users with critical information about their firearm’s status and even connect to mobile devices for enhanced functionality.

As these advancements unfold, the landscape of personal defense tools will likely become more efficient, reliable, and user-friendly, reflecting the ongoing demand for innovation in the industry.