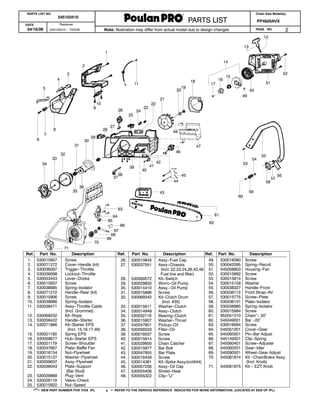

Understanding the intricacies of a technical illustration that delineates the inner workings of a certain machine involves delving into the minute details of its structural anatomy. This visual representation not only serves as a guide but also acts as a comprehensive map, elucidating the interconnections and functionalities of the various elements within.

Within this exploration, we navigate through the interlinked components that collaborate harmoniously to ensure the optimal operation of the apparatus in question. Each segment depicted plays a crucial role, contributing to the overall performance and efficiency, thereby underscoring the significance of a detailed breakdown.

Poulan Pro 220 Overview

This model represents a reliable and powerful solution for those in need of a durable tool capable of handling various outdoor tasks. Its design prioritizes efficiency, combining user-friendly controls with a robust engine, making it suitable for both light and more demanding applications. This device ensures optimal performance, even during extended use, thanks to its balanced construction and high-quality components.

| Feature | Details |

|---|---|

| Engine | Strong and reliable power output for diverse operations |

| Weight | Designed to reduce fatigue during prolonged tasks |

| Maintenance | Easy access to key components for simplified servicing |

| Durability | High-quality materials ensure long-lasting operation |

Understanding Parts Diagrams

When working with mechanical equipment, visual guides are essential for identifying individual components and their connections. These illustrations offer a clear representation of how various elements interact, simplifying maintenance, repair, and replacement tasks.

How to Read Technical Illustrations

Technical illustrations often include numbered elements, each corresponding to a list of components. These numbers make it easier to locate specific items and understand their role in the system.

- Examine the layout carefully to identify key areas.

- Follow the numbering system to trace the sequence of assembly or disassembly.

- Use the reference list to match numbers with detailed descriptions of each component.

Benefits of Using Visual Guides

Using these visual references provides multiple advantages, such as reducing errors during repairs, saving time, and ensuring the proper installation of components.

- Enhanced accuracy in identifying individual parts.

- Clearer understanding of the assembly structure.

- Efficient troubleshooting of mechanical issues.

Common Issues with Poulan Pro 220

Over time, various technical challenges may arise with this specific type of tool. These challenges can stem from wear and tear or improper maintenance, leading to performance decline. Addressing these issues promptly helps to prolong the tool’s lifespan and ensure smooth operation.

Starting problems are among the most frequent issues. Often, the device may fail to start due to fuel-related concerns, such as stale gasoline or a clogged filter. Regularly checking and replacing fuel can prevent these occurrences.

Another common complication involves power loss during use. This issue may result from a dirty air filter, which restricts airflow. Cleaning or replacing the filter restores optimal performance.

Lastly, chain tension may loosen over time, affecting precision. Adjusting the chain regularly ensures better efficiency and safety during operation.

Key Components of the Chainsaw

A chainsaw is comprised of various critical mechanisms that work together to ensure efficient cutting performance and safety. Understanding the essential elements is important for maintenance and repair tasks, ensuring the tool operates smoothly and lasts longer.

| Component | Description |

|---|---|

| Engine | The motor powers the entire tool, converting fuel or electricity into mechanical motion to drive the chain around the guide bar. |

| Guide Bar | A metal bar that provides support for the moving chain, guiding it in a straight path during operation. |

| Chain | A loop of sharp teeth that rotates around the guide bar, cutting through wood or other materials. |

| Clutch | This part engages and disengages the engine from the chain, allowing control over when the chain

Maintenance Tips for LongevityTo ensure the extended lifespan of your equipment, regular upkeep is essential. Proper attention to key components can prevent wear and improve performance over time. Following simple yet effective steps can make a significant difference in how long your device remains functional. Clean Thoroughly: After each use, make sure to clean all accessible areas. Dirt, dust, and debris can accumulate and cause internal issues if not addressed regularly. Inspect Moving Parts: Periodically check moving elements for any signs of wear or looseness. Tightening or replacing parts as needed can help maintain efficiency and reduce the risk of breakdowns. Lubricate Appropriately: Applying the correct lubricant to moving mechanisms is crucial to prevent friction damage. Be sure to use the right type and quantity of lubrication for optimal results. Replace Worn Out Components: If any component shows signs of significant wear, it’s important to replace it promptly. Delaying replacement can lead to further damage and costly repairs. By consistently following these maintenance practices, you’ll maximize the durability and performance of your equipment. Where to Find Replacement PartsLocating the right components for your equipment can be essential for maintaining its functionality and longevity. Whether it’s a minor repair or a full replacement, sourcing these items from reliable suppliers ensures that your machine continues to perform at its best. There are several common places to look for replacements:

Before purchasing, it’s important to check the compatibility and authenticity of the item to avoid potential issues during installation. Tools Needed for RepairsWhen working on maintenance tasks, having the right set of tools is essential for ensuring a smooth and efficient process. Each tool serves a specific function, allowing for precise adjustments, disassembly, and reassembly of various components. By preparing the appropriate equipment in advance, you can avoid delays and potential mistakes during the repair process. Commonly required tools include screwdrivers, wrenches, and pliers, which help handle fasteners and secure fittings. A socket set is also crucial for dealing with bolts and nuts of different sizes. Additionally, specialized equipment like torque wrenches and measuring tools may be necessary for more complex adjustments and calibration. Other useful items include cleaning supplies, such as brushes and compressed air, which help maintain the working condition of different elements during repairs. By keeping all necessary instruments at hand, you ensure that repair tasks proceed efficiently and safely. Step-by-Step Repair GuideMaintaining equipment efficiently requires understanding the basic procedures for resolving common issues. Proper care and timely fixes extend the life of your machine, ensuring optimal performance without the need for extensive overhauls. Step 1: Inspect the Device Begin by conducting a thorough inspection. Look for any signs of wear, loose components, or obvious blockages. Identifying the issue visually can help pinpoint what needs immediate attention. Step 2: Disassemble Carefully If a deeper issue is suspected, carefully disassemble the necessary sections. Keep track of screws and small parts to avoid losing any important components. A methodical approach to disassembly will help simplify the reassembly process. Step 3: Clean and Replace Once the parts are separated, clean any areas that may have accumulated dirt or debris. Replace any damaged or worn-out sections to ensure the equipment runs smoothly once reassembled. Always use compatible replacements to maintain functionality. Step 4: Reassemble and Test Reassemble the machine by following the reverse order of the disassembly. Ensure that all connections are secure and parts are fitted correctly. Once reassembled, run a test Safety Precautions While OperatingProper safety measures are essential when handling any equipment. Taking precautions ensures both personal safety and the optimal functioning of the device. Below are key guidelines to follow when using machinery in any environment.

Frequently Asked QuestionsThis section addresses common inquiries users may have regarding the equipment. The answers provided will help you understand essential aspects of handling, maintenance, and troubleshooting. How do I maintain the equipment for optimal performance?

What should I do if the machine fails to start?

|