In the realm of agricultural equipment, comprehending the intricacies of machinery is essential for optimal performance. This guide delves into the essential elements that make up various models, focusing on the visual representation of individual components and their interconnections. Such insights not only aid in maintenance but also enhance the overall operational efficiency of the equipment.

Accurate visualization of equipment elements allows operators and technicians to identify and troubleshoot issues more effectively. By examining the layout and relationships between different components, one can gain a deeper understanding of the machinery’s functionality. This knowledge empowers users to perform repairs and replacements with confidence, ensuring longevity and reliability in their agricultural tasks.

Whether you are a seasoned expert or a novice in the field, familiarity with these crucial details can significantly improve your ability to manage and maintain your equipment. With a comprehensive overview, you will be better equipped to make informed decisions, ultimately leading to enhanced productivity and reduced downtime in your agricultural endeavors.

Overview of John Deere SB14

The equipment in question is a robust and reliable machine designed to tackle a variety of tasks with efficiency. Its construction allows for heavy-duty work, providing users with durability and consistency. The tool is often used in outdoor environments, where its performance remains strong despite challenging conditions. It offers an optimal balance between power and control, making it suitable for different kinds of operations.

This model is engineered to ensure ease of maintenance and repair, with components that are accessible and designed to minimize downtime. The machine’s versatility and adaptability contribute to its widespread use, offering practical solutions for a range of needs. Its efficient design helps users handle complex tasks with ease, ensuring high productivity throughout its operation.

Understanding Parts and Components

When analyzing machinery, it’s crucial to have a clear grasp of the various elements that work together to ensure smooth operation. Each unit plays a vital role in maintaining overall functionality, whether it’s for propulsion, control, or another key function. Knowing how these elements interconnect allows for more efficient maintenance and troubleshooting.

Key systems within any mechanical equipment are designed to work in harmony, with each piece contributing to the performance and durability of the machine. By familiarizing yourself with these individual components, you can gain deeper insight into how the entire system functions and how to keep it running effectively.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding and maintaining complex machinery. These illustrations help ensure that every component is properly identified and correctly assembled, reducing the chances of mistakes during repairs or maintenance.

Having a detailed overview of each element and its connection to other parts allows users to quickly troubleshoot issues and avoid unnecessary replacements. Properly labeled images are essential for both professionals and those with less technical experience, ensuring that the right tools and steps are applied for efficient operation and longevity of the equipment.

How to Read the Parts Diagram

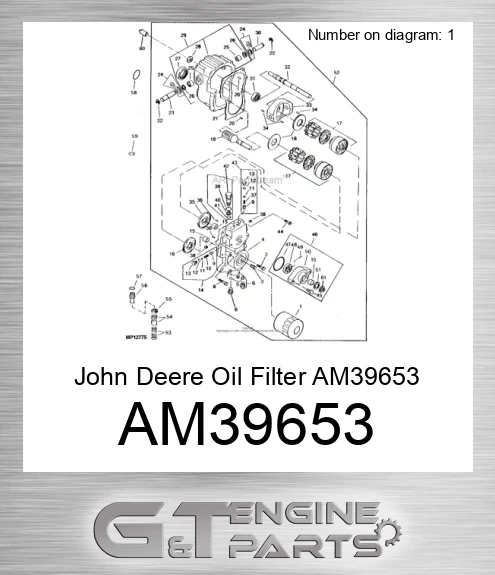

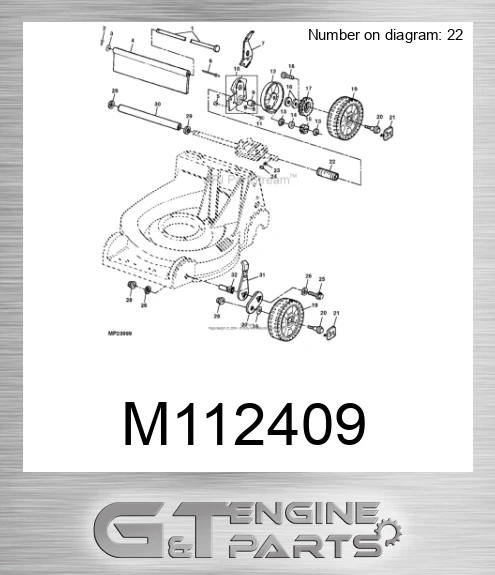

Understanding a component layout chart is essential when it comes to identifying individual elements in any mechanical system. These charts are detailed representations that showcase the arrangement and interconnections of various components, allowing for easier maintenance and replacement processes.

Each component is typically marked with a unique identifier, often accompanied by a corresponding list explaining the function, size, or specifications of the part. These identifiers help users pinpoint the exact element they need to address, whether it’s for repair or regular upkeep.

| Component Identifier | Description | Quantity |

|---|---|---|

| 1 | Main assembly unit | 1 |

| 2 | Supporting bracket | 2

Common Issues with SB14 Parts

In machinery of this type, components may encounter wear and tear due to extensive use, environmental conditions, or inadequate maintenance. Over time, mechanical elements can show signs of degradation, leading to inefficiencies or malfunctions. Recognizing potential weak points early can help avoid serious breakdowns. One frequent challenge involves the operation of moving sections. These areas are prone to friction, which can cause loosening or breakage. Additionally, bolts and fasteners can suffer from rust or loosening due to vibration. Another typical concern is related to the wear of rubberized elements. Hoses, seals, and other flexible materials may crack or leak, impacting the overall functionality of the equipment. Where to Find Replacement PartsWhen it comes to keeping your machinery in top condition, finding suitable components is essential. These elements are often specific to each model, and sourcing them requires attention to detail. Thankfully, there are numerous reliable options available to obtain high-quality replacements.

By exploring these options, you can ensure that your equipment remains operational with minimal downtime. Maintaining Your SB14 EquipmentProper care and upkeep are essential to ensure the longevity and performance of your agricultural machinery. Routine inspections and servicing help avoid potential issues and keep your equipment running efficiently. By following a regular maintenance schedule, you can maximize the productivity and durability of your machine. Lubrication: Regular lubrication of moving parts is crucial to prevent wear and tear. Ensure all mechanisms are well-oiled according to the manufacturer’s recommendations. Belt and Chain Inspection: Periodically check the belts and chains for signs of wear. If you notice any cracks, fraying, or excessive stretching, it’s time to replace them to avoid operational failures. Blade Sharpening: Keeping the blades sharp is essential for optimal performance. Dull blades can lead to inefficient operation and increase the strain on the equipment. Cleaning: After each use, remove any dirt, debris, and buildup from the machine to prevent corrosion and damage. Regular cleaning also improves visibility for any potential issues that may arise during operation. By adhering to these maintenance tips, your equipment will continue to function effectively, ensuring smooth and reliable performance for yo Safety Tips for SB14 UsersWhen operating any type of machinery, it’s important to prioritize safety to avoid accidents and ensure smooth operation. Proper precautions and adherence to guidelines will help users maintain a safe working environment, reducing the risk of injury and damage. General Precautions

Operating Safely

By following these essential safety tips, users can confidently operate their equipment while minimizing the chances of accidents and ensuring a productive work environment. Comparing SB14 with Other ModelsWhen evaluating this specific equipment, it is essential to consider how it stands against other machines in the same category. Understanding the unique features, performance capabilities, and design improvements across different models allows for a more informed choice when selecting the right tool for the job. By analyzing various aspects, such as efficiency, durability, and ease of maintenance, one can identify the strengths and weaknesses that set it apart from its counterparts. Other similar devices might offer alternative configurations or additional functions that could be more suited to specific tasks. However, this model’s particular balance of functionality and reliability often makes it a competitive option. Comparing multiple machines side by side reveals subtle differences in construction quality, fuel efficiency, and operating costs, helping users make well-rounded decisions based on their needs. Upgrades and Modifications AvailableTo enhance the functionality and extend the lifespan of agricultural equipment, several upgrades and modifications are available. These improvements are designed to boost performance, improve efficiency, and adapt the machinery to various needs and conditions. Below are some key areas where enhancements can be applied. Performance EnhancementsMany upgrades focus on optimizing operational efficiency. These improvements can include stronger components, advanced mechanical systems, or improved functionality to ensure smooth operation in diverse conditions.

Durability Improvements

Several modifications are available to increase the durability of critical components, reducing wear and tear. These adjustments help minimize downtime and extend the equipment’s operational life.

Implementing these upgrades and modifications can significantly improve the machine’s capabilities, ensuring it meets the demands of modern agricultural tasks. Customer Reviews and FeedbackFeedback from users is essential for understanding the quality and effectiveness of any equipment. By examining the experiences shared by customers, potential buyers can gain valuable insights that assist in making informed decisions. Reviews often highlight the strengths and weaknesses of products, offering a balanced perspective on their performance and reliability. Positive ExperiencesMany users appreciate the robust design and functionality of their equipment. Customers frequently mention how easy it is to operate and maintain, contributing to a smoother workflow. Durability and efficiency are often praised, with users noting significant improvements in productivity after incorporating this machinery into their routines. Areas for ImprovementWhile feedback is largely positive, some users have expressed concerns regarding specific aspects. Common issues include the availability of accessories and the need for clearer guidance on certain features. Addressing these concerns could enhance user satisfaction and overall experience, leading to even greater success in the market. Resources for Further AssistanceFor individuals seeking additional guidance on equipment maintenance and troubleshooting, a variety of valuable resources are available. These materials can enhance understanding and provide practical solutions to common challenges faced by users. Online Forums and CommunitiesEngaging with fellow enthusiasts and professionals can offer insights and support. Consider exploring the following platforms:

Manufacturer SupportDirect assistance from manufacturers can be beneficial. Resources may include:

Utilizing these resources can help ensure optimal performance and longevity of your equipment. |