Understanding the intricate workings of agricultural equipment is essential for ensuring efficiency and longevity in farming operations. This guide aims to provide an in-depth look into the structure and key elements that make up a widely-used tool in the field. Whether you’re a seasoned farmer or a newcomer to the world of machinery, grasping how each component interacts is crucial for smooth operation and effective maintenance.

When operating large-scale equipment, knowledge of its construction and individual elements becomes invaluable. Knowing how to locate and identify specific elements can drastically improve the maintenance process, helping to prevent potential breakdowns and ensure optimal performance in the field. Additionally, being familiar with the design layout allows operators to quickly troubleshoot and address issues as they arise.

In the following sections, we will delve into the various mechanisms that make up this essential farming tool. We will explore each element’s purpose and how they work together to produce efficient and reliable results, ensuring your equipment remains in top condition throughout the seasons.

Hesston 1150 Haybine Parts Overview

This section provides a comprehensive examination of the essential components and their roles in the overall operation of the machine. Understanding the key elements and how they interact with one another is crucial for ensuring smooth functionality and long-term reliability of the equipment.

Key Mechanical Components

- Cutter Bar Assembly: The cutting mechanism, vital for the efficiency of the unit, ensures clean and precise cuts.

- Reel System: Responsible for directing the crop toward the cutting area, enhancing the overall performance.

- Drive Belts: These transfer power between various systems, ensuring synchronized movement and functionality.

Operational Features

The machine’s effectiveness relies on several integrated systems working in harmony. From the power transfer mechanisms to the hydraulic systems, each part plays a pivotal role

Main Components of Hesston 1150 Haybine

The machine designed for efficient cutting and conditioning of crops consists of several key elements working together to ensure smooth operation. Each of these units plays a vital role in delivering high-quality results during fieldwork, contributing to the overall performance and longevity of the equipment.

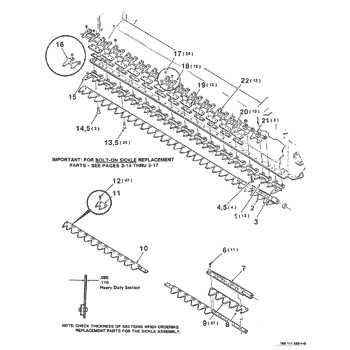

Cutting Mechanism

The cutting mechanism is responsible for shearing through the crop. It includes sharp blades arranged in a way that ensures even and precise cutting, reducing crop damage. These components require regular maintenance to maintain their effectiveness.

- Blades: Designed for clean cuts.

- Knife drive: Powers the movement of the blades.

- Guards: Protect the blades from debris.

Conditioning System

The conditioning system is essential for preparing the crop for drying. It crimps or crushes the stems, speeding up the drying process. This unit can be adjusted de

Understanding the Cutting Mechanism

The cutting mechanism is a critical component in agricultural machinery, designed to efficiently trim and process crops. This system ensures precise cuts while maintaining the integrity of the harvested material, allowing for optimal performance in various conditions. By understanding how each part interacts, operators can improve the overall efficiency and longevity of their equipment.

Main Components

- Blades: These are the sharp edges responsible for cutting the crop. Regular sharpening and replacement are essential for smooth operation.

- Knife drive: This element moves the blades back and forth, enabling continuous cutting action. A properly functioning drive ensures consistent performance.

- Guard system: Guards are positioned to protect the blades and provide a guide for the crop during cutting. These need to be aligned correctly to prevent blockages.

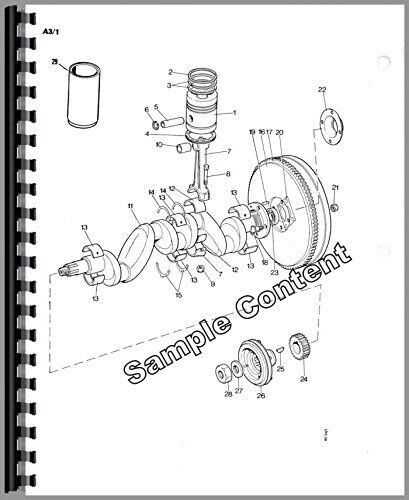

The drive mechanism is a key component that ensures smooth operation and efficient power transmission. The arrangement of belts within this system plays a crucial role in distributing power to various sections, contributing to the machine’s overall functionality and performance. Proper alignment and maintenance of these elements are essential for optimal operation.

Main Components of the Drive System

- Power source connection

- Primary and secondary pulleys

- Transmission shafts

- Tensioners and idlers

Belt Types and Their Functions

- Main drive belt: Responsible for transferring power from the engine to the primary moving parts.

- Auxiliary belts: Assist in driving secondary components such as rollers and conditioning elements.

- Tension belts: Ensure

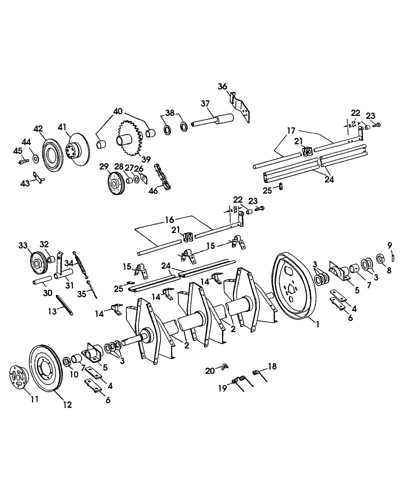

Roller and Conditioner Assembly Details

The roller and conditioner mechanism is essential for effective crop processing, ensuring that the material is properly conditioned before being moved further through the machine. The system consists of several critical components that work together to optimize the handling of crops by breaking down the stems and preparing them for the next phase of processing.

- Rollers: These are designed to crush and crimp the crop, allowing for quicker drying. Their surface texture and material composition are key factors in achieving optimal performance.

- Conditioning Mechanism: Located in direct contact with the rollers, this component enhances the conditioning process by increasing the contact surface with the crop. The spacing and alignment of this part are adjustable for different types of crops.

- Support Bearings: The

Hydraulic Systems and Functions

Hydraulic systems are essential components in machinery, providing the power to perform a variety of tasks efficiently. These systems convert mechanical energy into fluid pressure, enabling the operation of various mechanisms. Their role is to ensure smooth movement and control in equipment, making the work process more efficient and reliable.

The core of such systems involves fluid transmission, where pressurized liquid is circulated through lines, valves, and cylinders to generate force. This flow is controlled through valves that regulate the direction and speed, ensuring that the machinery responds precisely to operator commands. By adjusting pressure and flow, these systems offer a high degree of flexibility and power in handling different tasks.

Furthermore, the integration of hydraulic functions in machinery allows for better load management, precision in movement, and increased operational efficiency. Components like pumps, actuators, and reservoirs work together to maintain consistent performance, even under heavy workloads. Proper maintenance and regular checks of hydraulic lines and connections are vital to ensure optimal functionality and avoid malfunctions.

Sickle Bar and Knife Mechanism Explained

The cutting system of agricultural machines involves a series of components working together to efficiently trim crops. This mechanism relies on precise coordination between the blade and its moving parts to deliver clean, uniform cuts.

Core Components of the Mechanism

- Sickle Bar: The backbone of the cutting system, holding the blades in place. It serves as the structural support, ensuring the stability of the entire mechanism.

- Knives: These are the sharp, reciprocating blades that move back and forth to slice through crops. They are mounted along the sickle bar and work in tandem with the guards.

- Guards: Positioned ahead of the knives, these parts guide the crops into the cutting zone and protect the blades from damage.

How It Works

- As

Wheel and Axle Setup

The wheel and axle configuration is crucial for ensuring smooth operation and stability during movement. This section will focus on the proper arrangement and alignment of the wheels and axles to guarantee efficient handling and minimize wear. Attention to detail is key to maintaining longevity and safety during use.

Axle Positioning

Proper axle positioning is fundamental to maintaining balance. The axle should be securely mounted to ensure equal distribution of weight across both sides. It’s important to periodically check the alignment to prevent any shifting that could cause imbalance or uneven tire wear.

Wheel Alignment

Ensuring the wheels are aligned correctly not only extends the life of the tires but also enhances maneuverability. A misaligned wheel setup can lead to irregular wear, which reduces efficiency and increases the risk of damage to the overall system. Regular inspections are recommended.

Component Maintenance Frequency Action Axle Every 6 months Troubleshooting Common Part Failures

When operating agricultural machinery, it is crucial to recognize and address frequent component malfunctions that can hinder performance. Understanding the common issues that may arise allows for timely interventions, ensuring smooth operation and prolonging the lifespan of the equipment.

One of the most prevalent problems involves the wear and tear of cutting elements. Over time, blades can become dull or damaged, resulting in ineffective cutting. Regular inspections are essential to identify any signs of wear. If the cutting action appears inconsistent, consider sharpening or replacing the blades to restore efficiency.

Another common failure relates to the drive system. If you notice unusual noises or a lack of power during operation, it may indicate issues with belts or gears. Inspecting these components for signs of fraying or misalignment can help pinpoint the problem. Replacing worn belts promptly can prevent further damage to the drive mechanism.

Hydraulic system failures are also a significant concern. Low fluid levels or leaks can lead to insufficient pressure, affecting overall performance. Regularly checking hydraulic fluid levels and inspecting hoses for leaks can help maintain optimal functionality. If any hydraulic components show signs of malfunction, such as slow response times, prompt servicing is recommended.

Lastly, ensure that all electrical connections are secure and free from corrosion. Electrical failures can disrupt various functions of the equipment. Regularly inspecting wiring and connectors can prevent unexpected breakdowns and enhance reliability.

Regular Maintenance and Replacement Tips

Maintaining agricultural equipment is essential for optimal performance and longevity. Regular upkeep not only enhances efficiency but also prevents unexpected breakdowns. Implementing a systematic approach to maintenance can save both time and costs in the long run.

Routine Inspections: Conduct periodic checks of the machinery to identify wear and tear. Focus on components such as belts, blades, and hydraulic systems. Early detection of issues can prevent more significant problems later on.

Cleaning and Lubrication: Keep the equipment clean to avoid buildup that may hinder its operation. Regularly lubricate moving parts to reduce friction and wear. Use the appropriate lubricants recommended by the manufacturer for best results.

Replacement of Worn Parts: Replace any components that show signs of significant wear. This includes cutting edges, filters, and seals. Utilizing quality replacement parts is crucial for maintaining performance and ensuring safety.

Storage Considerations: Proper storage during off-seasons helps protect machinery from environmental damage. Cover the equipment to shield it from moisture and debris, which can lead to rust and deterioration.

Consultation with Professionals: When in doubt, consult with a professional mechanic or technician. Their expertise can provide valuable insights into the specific needs of your equipment, ensuring it runs efficiently and effectively.

Where to Find Genuine Hesston Parts

When it comes to sourcing authentic components for your agricultural machinery, it’s crucial to ensure quality and compatibility. Reliable suppliers can make a significant difference in the longevity and performance of your equipment.

Authorized Dealers: The most dependable option is to purchase from authorized dealers. These retailers specialize in original equipment and offer a range of products tailored for your machinery. They are knowledgeable about the specific needs of each model, ensuring you receive the right items.

Manufacturer Websites: Visiting the official website of the manufacturer can provide access to a wealth of information. Many manufacturers offer online catalogs and resources where you can find authentic components directly from the source.

Reputable Online Retailers: Various online platforms specialize in agricultural equipment. Look for sites that emphasize genuine merchandise and have positive customer reviews. Always verify the authenticity of the products before making a purchase.

Local Farm Supply Stores: Your local farm supply store may also carry genuine components. These establishments often have knowledgeable staff who can assist you in finding the right items for your equipment.

Parts Expos and Trade Shows: Attending agricultural expos and trade shows can be an excellent way to discover authentic components. These events allow you to connect with manufacturers and dealers directly, often featuring exclusive deals and promotions.