The efficient operation of a lawn maintenance machine relies heavily on its intricate assembly of elements. Familiarizing oneself with the various components is crucial for both maintenance and troubleshooting. An in-depth exploration of these parts not only enhances performance but also extends the longevity of the equipment.

In this section, we will delve into the essential elements that comprise a high-performance mower. Each part plays a specific role, contributing to the overall functionality and effectiveness of the machinery. By gaining insight into how these components work together, operators can ensure optimal performance and reliability.

Additionally, understanding the configuration of these elements aids in identifying potential issues and streamlining repair processes. Knowledge of the arrangement can save time and resources, making it an invaluable asset for anyone invested in lawn care and landscaping endeavors. Join us as we uncover the intricacies of mower assembly and how they impact your lawn maintenance experience.

Understanding Scag Turf Tiger

This section explores the essential components and functionality of a high-performance lawn care machine designed for professionals. Recognizing how these machines operate and the significance of their features can enhance both maintenance efficiency and user experience.

Key Features

These powerful machines often boast advanced cutting technology, robust engines, and ergonomic designs. Durability and efficiency are paramount, ensuring reliable performance across various terrains and conditions.

Maintenance Insights

Regular upkeep is crucial to maximizing longevity and effectiveness. Understanding the maintenance requirements and having access to accurate schematics facilitates timely interventions and repairs, ultimately supporting optimal functionality.

Key Components Overview

This section provides an insightful exploration of the essential elements that contribute to the functionality and efficiency of high-performance mowing equipment. Understanding these fundamental components is crucial for proper maintenance and optimal performance.

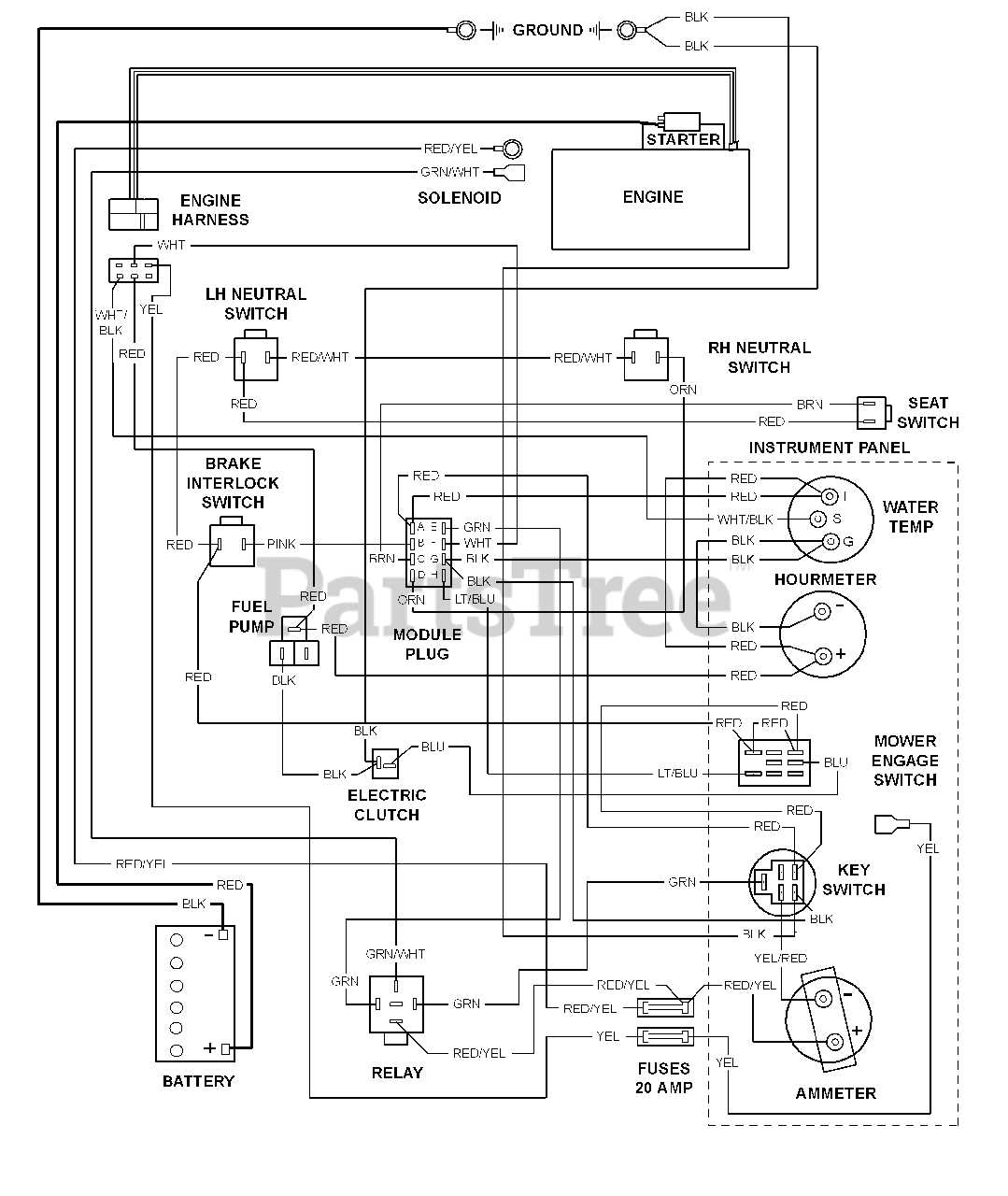

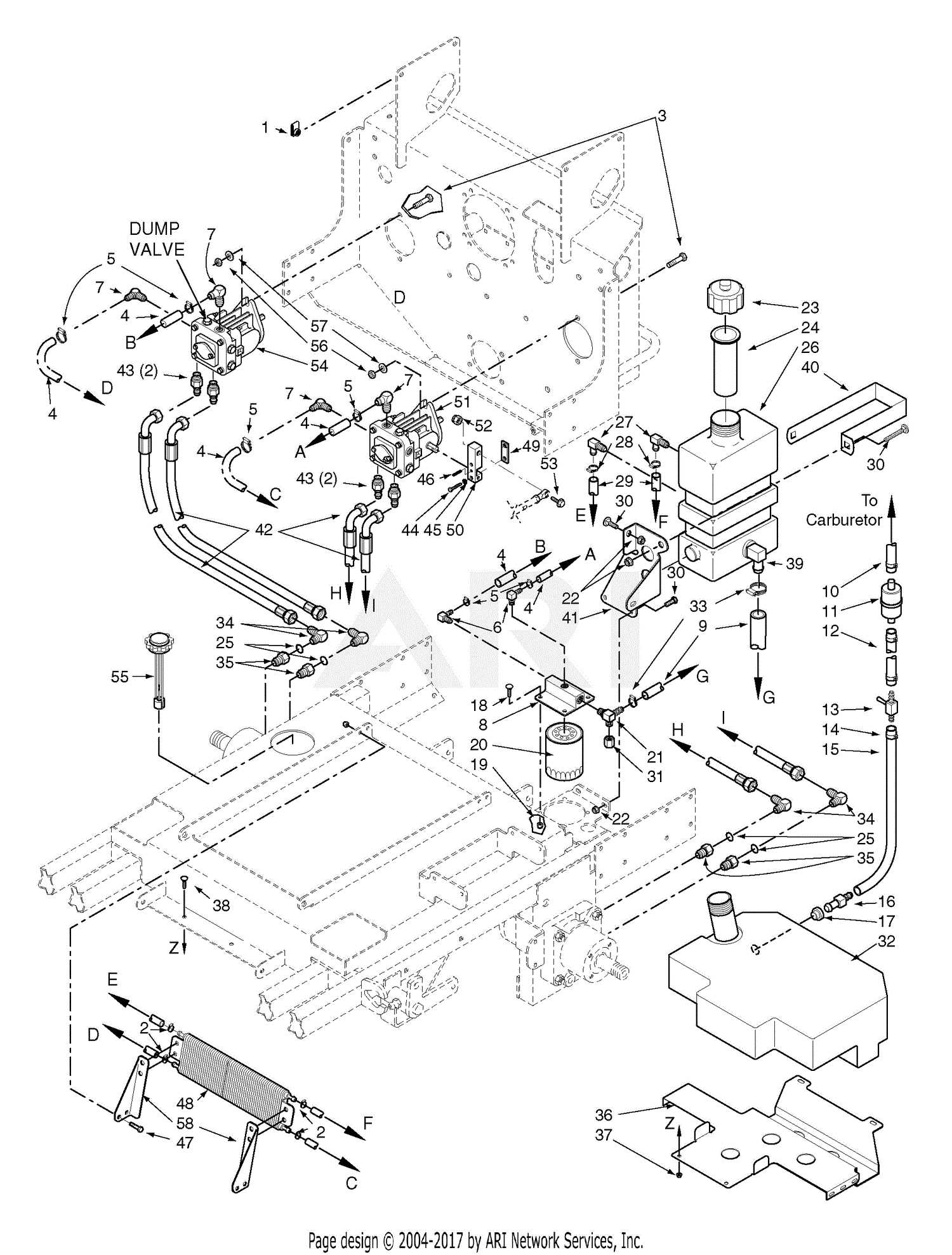

At the core of any robust machine lies the engine, a powerhouse that drives all operations. Its specifications, including horsepower and torque, greatly influence the equipment’s capabilities. Coupled with the engine, the transmission system plays a vital role in transferring power smoothly, ensuring that the equipment operates seamlessly across various terrains.

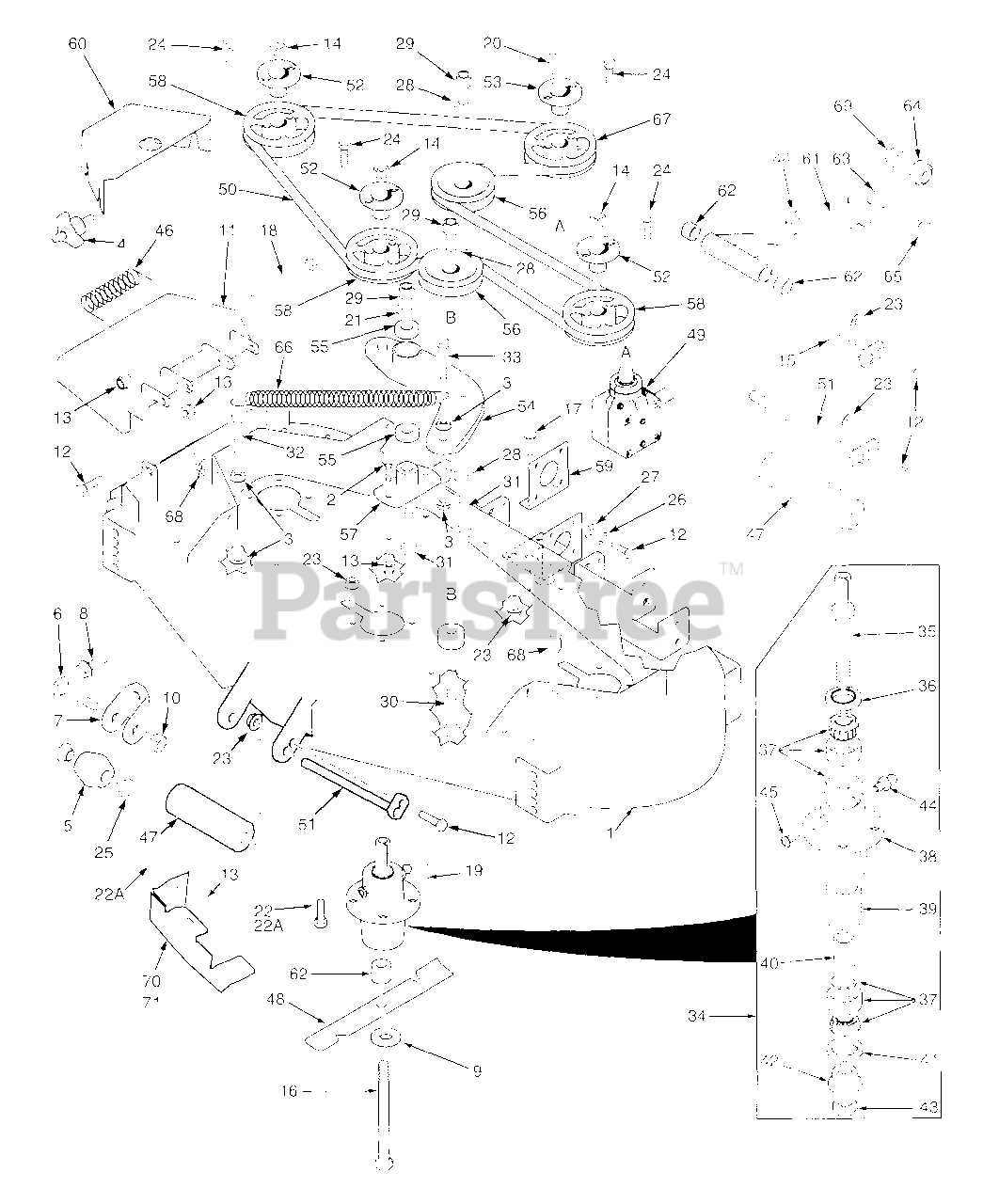

The cutting deck is another critical component, designed to achieve precise trimming results. Its design, including blade configuration and deck height adjustments, allows for adaptability to different grass types and conditions. Additionally, the wheel assembly is essential for maneuverability, providing stability and ease of control while navigating around obstacles.

Lastly, the control panel and safety features are integral to user experience and operational safety. They facilitate intuitive handling and ensure that the operator remains protected throughout the mowing process. By understanding these key elements, users can enhance their equipment’s longevity and efficiency.

Benefits of Scag Turf Tiger

This powerful machine offers a range of advantages that make it a preferred choice for landscaping professionals and homeowners alike. Its design and features enhance efficiency, reliability, and overall performance in lawn maintenance.

- Durability: Constructed with high-quality materials to withstand rigorous use.

- Efficiency: Engineered for optimal cutting speed, reducing the time spent on lawn care.

- Comfort: Ergonomically designed controls and seating for a smoother operation.

- Versatility: Compatible with various attachments for different landscaping tasks.

- Power: Equipped with robust engines that deliver consistent performance.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan and performance of your equipment. Regular attention to details can prevent costly repairs and ensure efficient operation. Here are some key practices to follow:

- Regular Cleaning: Keep the machine clean by removing debris and grass clippings after each use to prevent corrosion and buildup.

- Fluid Checks: Monitor oil levels and replace fluids as recommended to maintain optimal functionality.

- Blade Maintenance: Sharpen blades regularly to ensure clean cuts and reduce strain on the engine.

Additionally, consider the following tips:

- Inspect Belts and Cables: Regularly check for wear and tear, replacing any damaged components promptly.

- Storage Practices: Store the equipment in a dry place, ideally indoors, to protect it from the elements.

- Professional Servicing: Schedule periodic professional inspections to address potential issues before they become significant problems.

By following these maintenance tips, you can enhance the longevity and reliability of your machinery, ensuring it serves you well for years to come.

Common Repairs and Solutions

This section explores frequent maintenance tasks and effective strategies for addressing common issues faced by users of professional mowing equipment. Understanding these solutions can enhance performance and prolong the life of your machinery.

Routine Maintenance Tasks

- Regular oil changes

- Sharpening blades

- Cleaning air filters

- Inspecting belts and cables

Common Issues and Fixes

- Engine Won’t Start: Check the fuel level and battery connections.

- Uneven Cutting: Ensure blades are level and sharp.

- Excessive Vibration: Inspect for loose parts and worn-out components.

Parts Replacement Guide

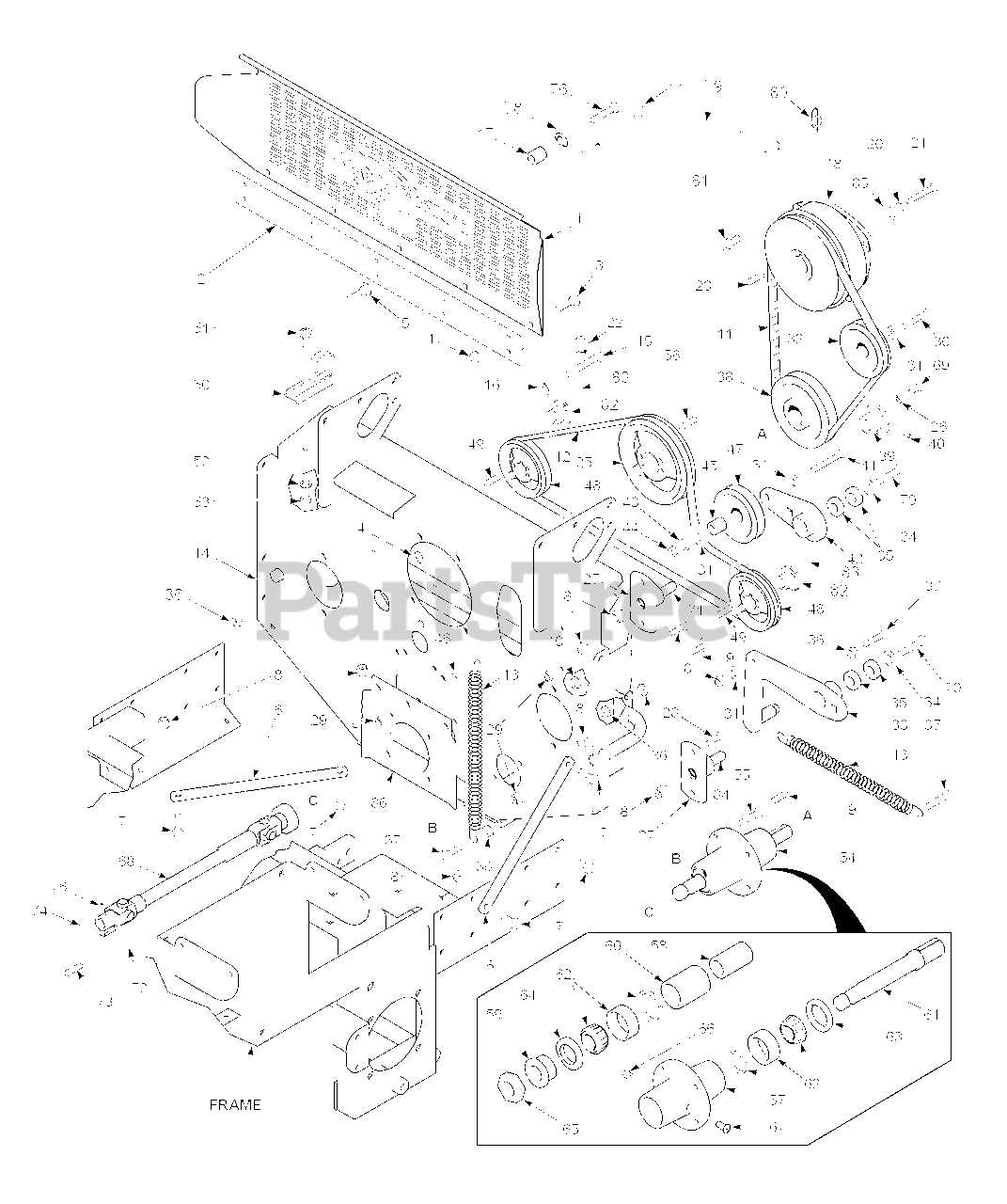

This section aims to provide valuable insights into the process of exchanging components within your machinery. Understanding how to effectively replace various elements can enhance performance and prolong the lifespan of your equipment. Following the correct procedures ensures optimal functionality and reduces the risk of future issues.

Identifying Components

Before initiating any replacement, it’s crucial to accurately identify the specific components that require attention. Consult your user manual or a reliable reference source to determine the correct specifications. Visual inspections can help pinpoint wear and tear, guiding you toward necessary replacements.

Replacement Process

Once you’ve identified the components, gather the appropriate tools and follow these general steps for a smooth exchange:

- Ensure the machinery is powered off and secure to prevent accidents.

- Carefully remove the worn or damaged element, taking note of its position and any connecting parts.

- Install the new component, ensuring it fits snugly and aligns correctly with other elements.

- Double-check all connections and fasteners for security before reactivating the machine.

Regular maintenance and timely replacements will contribute to sustained efficiency and performance in your equipment. Always prioritize safety and consult with professionals if uncertain about any steps in the process.

Tools Needed for Repairs

Proper maintenance of machinery requires a selection of essential implements. Understanding which tools are necessary can greatly enhance the efficiency of any repair task, ensuring that issues are addressed swiftly and effectively. Having the right equipment at hand not only facilitates the process but also minimizes the risk of further complications.

Essential Implements

Here is a list of indispensable tools that are commonly used for maintenance and repair tasks:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To drive screws of various sizes. |

| Pliers | For gripping, bending, and cutting wires. |

| Socket Set | To quickly remove or install fasteners. |

Additional Supplies

Besides the basic tools, certain supplies can aid in achieving the ultimate results:

| Supply | Use |

|---|---|

| Lubricants | To reduce friction and wear. |

| Cleaning Solvents | For removing grime and debris. |

| Protective Gear | To ensure safety during repairs. |

Identifying Part Numbers

Understanding the various components of machinery is essential for maintenance and repairs. Accurate identification of item numbers ensures that you obtain the correct replacements, contributing to the longevity and efficiency of the equipment. This section will guide you through the process of recognizing and locating the relevant identifiers for your machinery components.

Understanding Component Identification

Each element of the machinery is associated with a unique identifier, which simplifies the ordering process. These identifiers often include alphanumeric codes that provide vital information about the component’s specifications. Familiarity with these codes allows for more efficient troubleshooting and replacement strategies.

How to Locate Item Numbers

To find the correct identifiers, consult the user manual or manufacturer’s resources. Many manufacturers offer online databases or catalogs that include comprehensive listings of component identifiers. Additionally, visual inspection of the machinery may reveal labels or engravings that contain the necessary codes. Always ensure that the information is up to date to avoid errors during the ordering process.

Exploring Aftermarket Options

When it comes to maintaining outdoor machinery, many owners seek alternatives to original components. The aftermarket offers a wide range of solutions that can enhance performance and extend the lifespan of equipment. These options often provide cost-effective substitutes, catering to both budget-conscious consumers and those looking for specialized features.

Quality and Compatibility are crucial factors to consider when selecting replacement items. Not all alternatives are created equal, and it is essential to choose reputable manufacturers that ensure reliability and fit. Researching user reviews and expert recommendations can aid in making informed decisions.

Innovation and Technology play significant roles in aftermarket developments. Many brands incorporate advanced materials and engineering techniques to improve durability and functionality. This can lead to enhanced efficiency and overall performance, making them a viable choice for many users.

Ultimately, exploring aftermarket solutions allows operators to personalize their equipment while potentially saving money. Balancing quality, compatibility, and innovation will lead to satisfactory results and a more enjoyable experience in maintaining and using outdoor machinery.

Original Manufacturer Parts

Utilizing components directly from the original creator ensures compatibility and performance. These elements are crafted to meet specific standards, providing reliability and durability in operation. By choosing authentic options, users can maintain the integrity and efficiency of their equipment.

Investing in these genuine components often results in enhanced longevity and reduces the likelihood of malfunctions. The precision engineering behind these items guarantees a seamless fit, allowing for optimal functionality. When repairs or replacements are necessary, sticking with original solutions can significantly improve the overall user experience.

Moreover, using manufacturer-certified items often protects warranties, as many brands emphasize the importance of original replacements. This not only safeguards investments but also supports the longevity of the machinery in question. Ultimately, the choice of authentic components contributes to smoother operations and greater satisfaction for users.

Assembly Instructions for Parts

This section provides essential guidance for the proper assembly of components, ensuring optimal performance and longevity of your equipment. Following these steps meticulously will help you avoid common pitfalls and enhance overall efficiency.

Preparation Steps

Before starting the assembly process, gather all necessary tools and components. It is crucial to work in a clean and organized space to minimize distractions. Verify that all items are in good condition and ready for installation. Refer to the provided documentation for a list of required tools and a complete inventory of elements needed for assembly.

Assembly Process

Begin by laying out the primary components in the order of assembly. This systematic approach will streamline the process and reduce the risk of missing any parts. Align each piece carefully, following the manufacturer’s instructions. Fasten components securely, ensuring that they are tightly fitted but not over-tightened, which could lead to damage. Regularly check for stability as you progress, making adjustments as necessary to achieve a robust assembly.

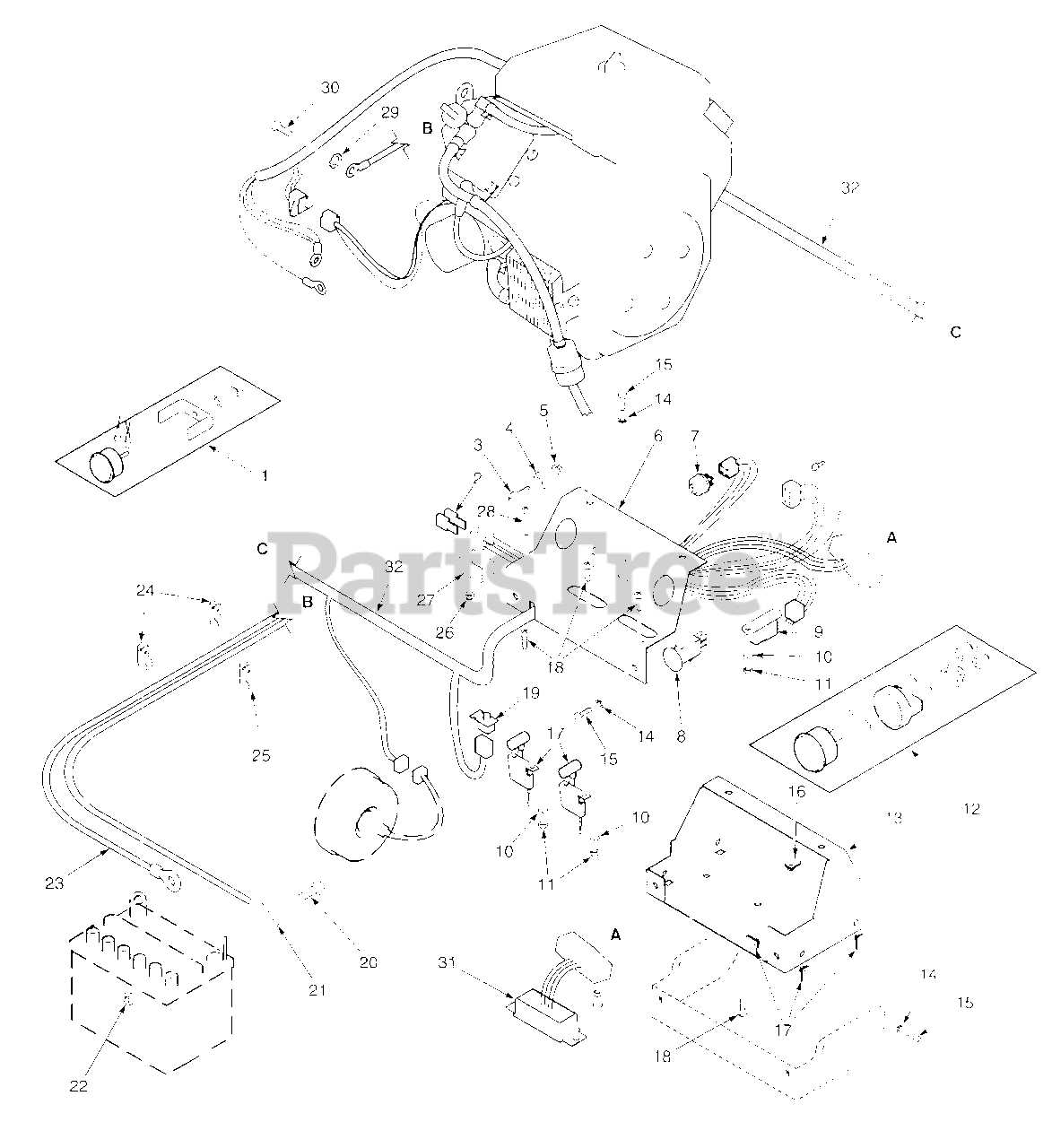

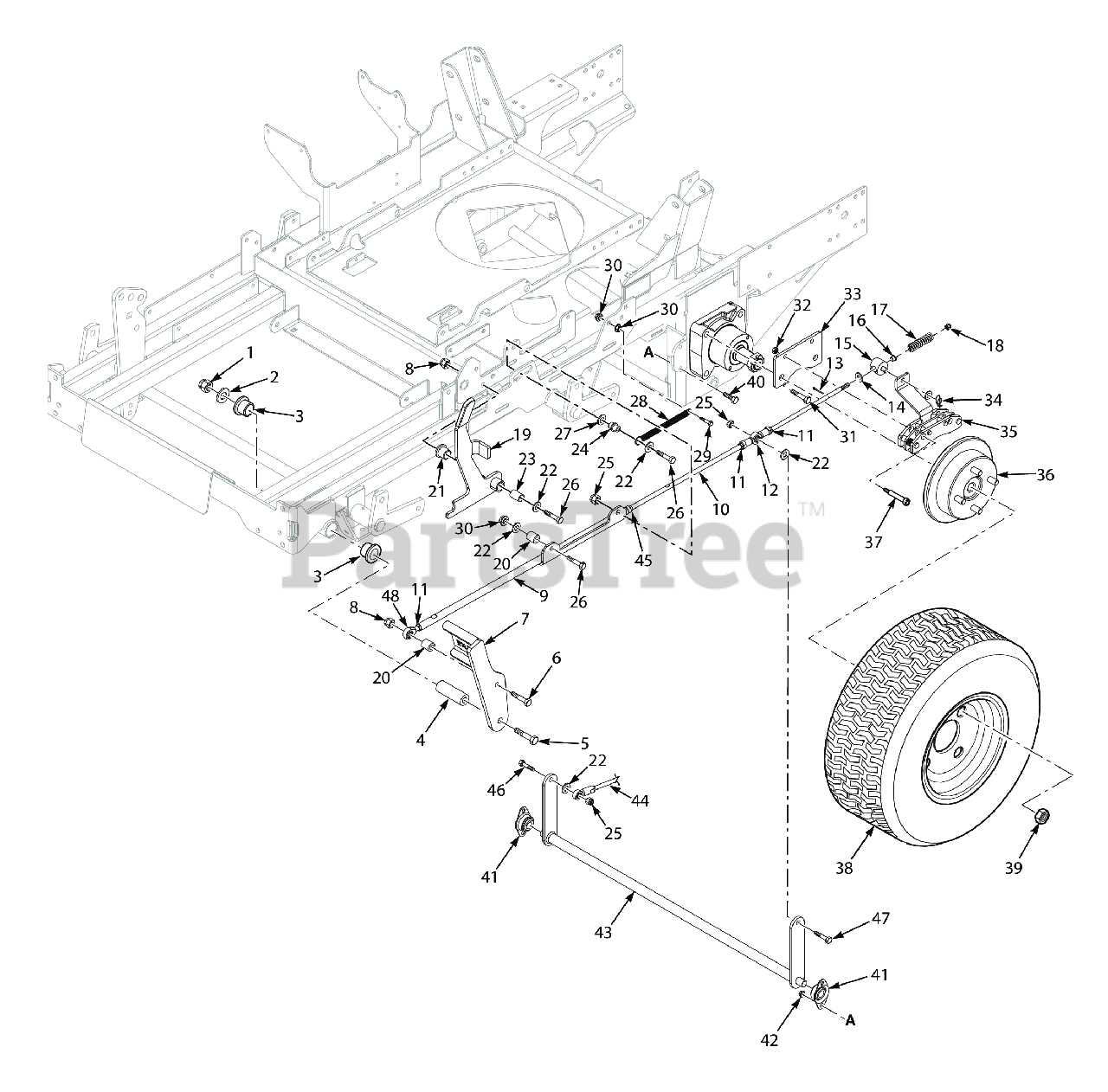

Visual Diagrams Explained

Visual representations serve as powerful tools for understanding complex systems and components. They break down intricate mechanisms into easily digestible parts, allowing for better comprehension and navigation through various elements. By providing a clear overview, these illustrations facilitate efficient maintenance and troubleshooting.

Benefits of Visual Aids

Utilizing graphic representations enhances learning and retention. They cater to different learning styles, making information accessible to a broader audience. This visual clarity often leads to quicker identification of issues, streamlining repair processes and improving overall efficiency.

Interpreting Illustrations

To effectively interpret these visuals, one must focus on key labels and connections. Understanding the relationship between various components is essential for grasping their functionality. Engaging with these illustrations allows users to delve deeper into the intricacies of the subject matter.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair of outdoor machinery. Understanding these concepts can enhance user experience and ensure optimal performance.

What are the most common issues faced? Many users report challenges with engine performance and blade effectiveness, often stemming from wear and tear over time.

How can I find the correct replacement components? It’s advisable to consult your user manual or seek guidance from authorized dealers to ensure compatibility with your model.

What maintenance practices should I follow? Regular cleaning, oil changes, and blade sharpening are essential to prolong the lifespan of your equipment.

Is professional servicing necessary? While many tasks can be performed by the owner, complex repairs may require professional expertise to ensure safety and reliability.