Exploring the layout of lawn machinery is essential for effective maintenance and repair. Knowing the various elements and their arrangements can significantly enhance operational efficiency. This section will provide insights into the structure of a specific model, focusing on how each component interacts within the overall system.

Familiarity with the individual segments not only aids in troubleshooting but also assists in identifying suitable replacements and upgrades. By analyzing the configuration, users can make informed decisions regarding enhancements and necessary adjustments. This knowledge is vital for ensuring the longevity and performance of the equipment.

This section provides a comprehensive summary of a specific lawn maintenance vehicle designed for efficiency and versatility. The focus will be on its features, capabilities, and benefits, highlighting its importance in residential and commercial landscaping tasks.

- Engine Performance: The machine is equipped with a robust engine that ensures reliable power for various gardening activities.

- Cutting Mechanism: It offers a superior cutting system, allowing for an even and precise trim, enhancing lawn aesthetics.

- Comfort and Control: Ergonomic design elements contribute to user comfort, making long hours of operation manageable.

- Attachments and Accessories: Compatibility with various tools expands its functionality, providing options for mulching, bagging, and towing.

- Durability: Constructed with high-quality materials, it promises longevity and resilience against challenging conditions.

Understanding these elements provides insight into the overall performance and utility of this lawn care equipment, making it a valuable addition to any yard maintenance regimen.

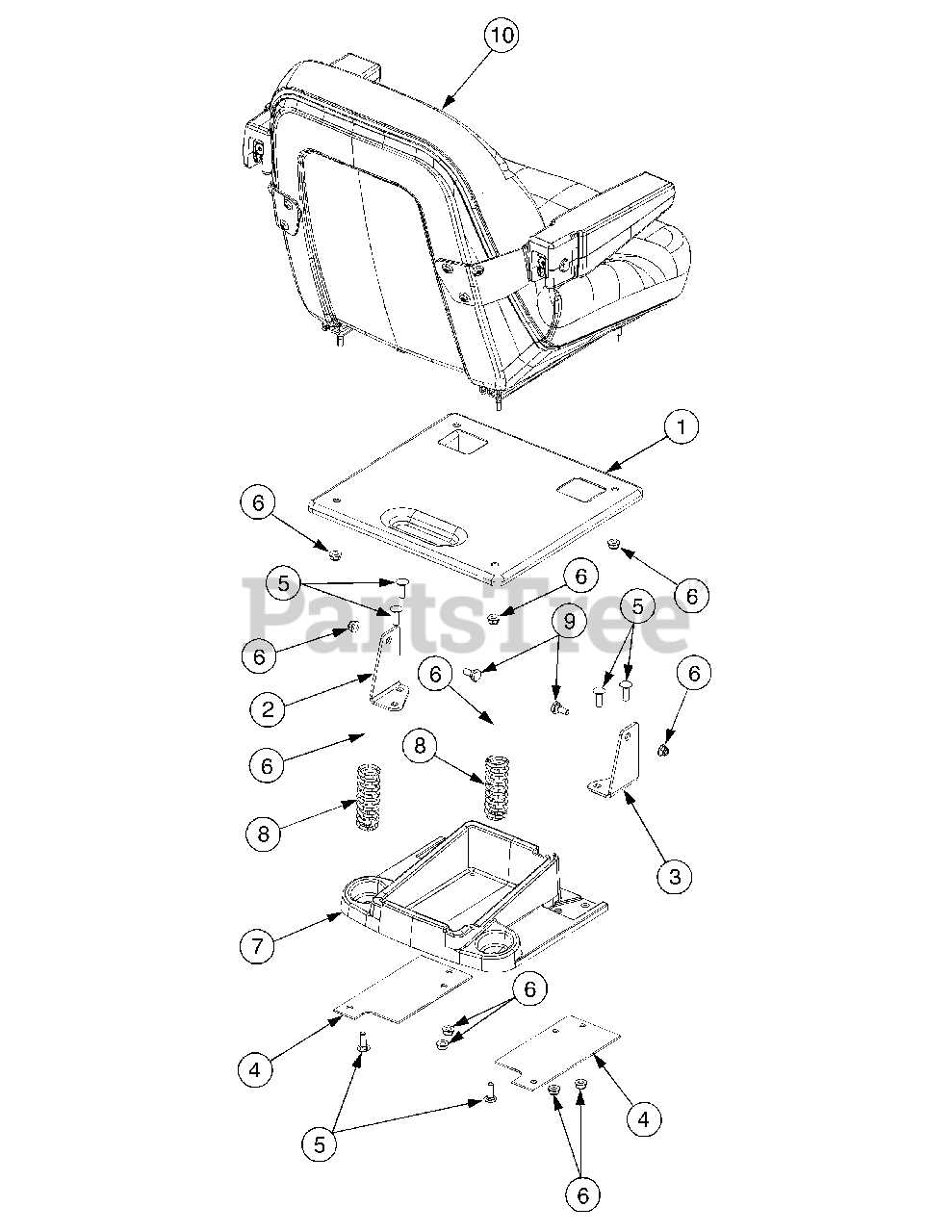

Understanding Parts Diagram Importance

Grasping the significance of a schematic representation is crucial for efficient maintenance and repair of machinery. Such illustrations serve as valuable tools, providing clarity on how components interact within a system. They allow users to identify individual elements quickly, facilitating smoother troubleshooting and assembly processes.

Benefits of Visual Aids

Visual representations enhance comprehension by breaking down complex systems into manageable sections. This not only aids in identifying necessary replacements but also minimizes the likelihood of errors during repairs. Additionally, a clear layout assists in locating specific elements, saving time and effort in the long run.

Enhancing User Confidence

When individuals understand the layout and function of each element, their confidence in performing repairs increases significantly. Familiarity with the arrangement fosters a sense of ownership and competence, ultimately leading to more effective maintenance practices. Empowered users are more likely to tackle challenges independently, enhancing their overall experience with the equipment.

Key Components of GT2550

This section explores essential elements that contribute to the functionality and efficiency of the machinery. Understanding these components allows for better maintenance and enhances overall performance.

Engine and Transmission

- Power unit: Delivers the necessary energy for operation.

- Transmission system: Ensures smooth power transfer to the wheels.

Chassis and Wheels

- Frame structure: Provides durability and stability during use.

- Wheel assembly: Facilitates mobility and supports the load.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention. Implementing a few essential practices can significantly extend the lifespan and performance of your machinery.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Regularly replace oil to maintain engine efficiency. |

| Blade Sharpening | Every season | Keep blades sharp for cleaner cuts and reduced strain on the engine. |

| Air Filter Cleaning | Every month | Inspect and clean air filters to ensure optimal airflow. |

| Tire Pressure Check | Monthly | Maintain proper tire pressure for better traction and efficiency. |

| Fuel Stabilization | As needed | Use fuel stabilizers to prevent degradation during off-seasons. |

Common Issues with Cub Cadet

Many users experience a variety of challenges with their lawn maintenance equipment. Understanding these common issues can lead to effective solutions and improved performance.

Engine Problems

One frequent concern involves engine difficulties. Symptoms may include difficulty starting, unusual noises, or stalling during operation. Regular maintenance and checks can help mitigate these issues.

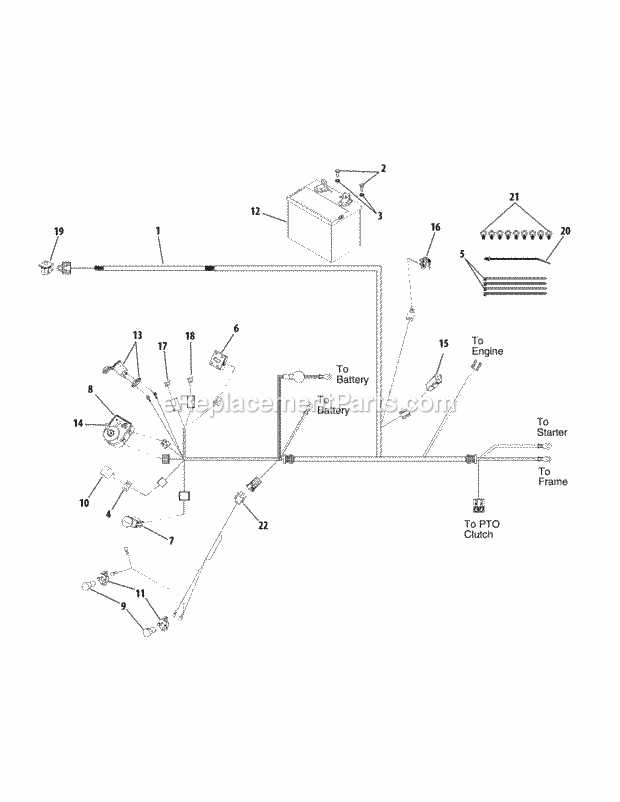

Electrical System Failures

Another common problem pertains to the electrical components. Issues such as blown fuses or malfunctioning batteries can hinder functionality. Ensuring connections are secure and inspecting wiring can prevent disruptions.

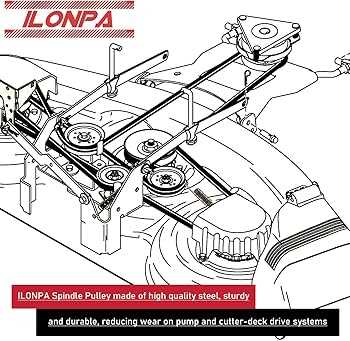

Replacing Worn-Out Parts

Maintaining optimal performance of your equipment involves timely replacement of aged components. Over time, various elements can become less effective, leading to decreased efficiency and potential breakdowns. Recognizing when to replace these elements is crucial for ensuring longevity and functionality.

Identifying Signs of Wear

Understanding the indicators of wear can help in making informed decisions regarding replacements. Common signs include unusual noises, reduced performance, and visible damage. Regular inspections are essential for early detection of issues.

Replacement Process Overview

The process of replacing aged components typically involves several steps. Begin by gathering the necessary tools and new components. Follow the manufacturer’s guidelines for disassembly, and ensure that all connections are secure when installing new items. Testing the equipment post-replacement is vital to confirm everything is functioning correctly.

| Component | Replacement Frequency | Common Symptoms |

|---|---|---|

| Belt | Every 100 hours | Slipping, fraying |

| Blades | Seasonally | Dull cutting, uneven cuts |

| Filters | Every 50 hours | Clogging, reduced airflow |

Where to Find Replacement Parts

Locating suitable components for your machinery is essential for maintaining its performance and longevity. Several resources can help you secure the necessary items, ensuring that your equipment operates smoothly.

Online Retailers

Numerous websites specialize in offering a wide range of components. Here, you can compare prices, check availability, and read customer reviews to make informed decisions.

Local Dealers

Your nearby dealers often carry an inventory of essential items. Visiting them can provide personalized service and expert advice on what you need.

| Resource Type | Advantages |

|---|---|

| Online Retailers | Wide selection, competitive prices, customer reviews |

| Local Dealers | Personalized service, expert advice, immediate availability |

Comparing OEM and Aftermarket Parts

When considering replacement components for equipment, users often face a choice between original and alternative options. Understanding the benefits and drawbacks of each can significantly impact performance and longevity.

Advantages of OEM Components

- Precision fit and compatibility with the equipment.

- Manufactured to meet stringent quality standards.

- Typically backed by a warranty from the manufacturer.

Benefits of Aftermarket Options

- Often more affordable than original versions.

- Variety of choices available, catering to different preferences.

- Potential for enhanced performance features.

Ultimately, the decision should consider factors such as budget, specific requirements, and the intended use of the equipment.

Step-by-Step Repair Guide

This guide offers a comprehensive approach to addressing common issues encountered with your machine. By following these detailed instructions, you can efficiently troubleshoot and resolve problems, ensuring optimal performance.

1. Gather Necessary Tools: Before starting, ensure you have all required tools at hand, including wrenches, screwdrivers, and replacement components.

2. Safety First: Disconnect the power source to avoid any accidents. Always wear protective gear during the repair process.

3. Identify the Problem: Carefully assess the situation to pinpoint the specific malfunction. This step is crucial for effective repairs.

4. Disassemble Carefully: Follow the manufacturer’s guidelines to dismantle components without causing damage. Take notes or pictures for easier reassembly.

5. Replace or Repair Parts: Depending on your assessment, replace damaged parts or make necessary repairs. Ensure all new components meet the required specifications.

6. Reassemble the Unit: Carefully put all components back together, ensuring everything is secure and correctly aligned.

7. Test the Machine: Reconnect the power source and perform a test run to verify that the repair was successful.

Safety Precautions During Repairs

When undertaking maintenance or repairs on machinery, adhering to safety guidelines is essential to prevent accidents and injuries. Proper precautions ensure a secure working environment and promote efficient operation.

Here are some key safety measures to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, such as gloves, goggles, and ear protection, to safeguard against potential hazards. |

| Disconnect Power Source | Before starting any repair work, ensure that the machine is completely powered off and disconnected to prevent accidental starts. |

| Work in a Well-Ventilated Area | Ensure that the workspace is well-ventilated to avoid inhaling harmful fumes or dust during repairs. |

| Keep Workspace Organized | Maintain a clean and organized area to prevent tripping hazards and to easily locate tools and parts when needed. |

| Read Manufacturer’s Instructions | Familiarize yourself with the equipment’s manual and follow the guidelines for safe handling and maintenance. |

Using the Diagram Effectively

Utilizing a visual representation of components can greatly enhance your understanding of mechanical assemblies. By closely examining the layout, you can identify various elements and their relationships, facilitating easier maintenance and repairs.

| Component | Description |

|---|---|

| Assembly | A collection of parts working together for a specific function. |

| Connection | Points where different elements join, crucial for functionality. |

| Alignment | Proper positioning of elements to ensure optimal performance. |

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair of outdoor equipment, offering insights to assist users in navigating their challenges.

What should I do if a component fails?

In the event of a malfunction, it’s essential to identify the specific issue. Refer to your user guide for troubleshooting steps, and consider consulting a professional if needed.

Where can I find replacement components?

Replacement items can typically be sourced from authorized dealers or online marketplaces. Always ensure that the parts are compatible with your model.

How often should maintenance be performed?

Regular upkeep is vital for optimal performance. It’s recommended to follow the maintenance schedule outlined in your manual to ensure longevity.

Resources for Further Information

For those seeking additional insights and knowledge regarding maintenance and repair of garden machinery, various resources are available. These materials can enhance understanding and assist in effective troubleshooting.

Online Forums and Communities

Participating in online communities can provide valuable advice from fellow enthusiasts. Engaging with forums dedicated to gardening equipment allows users to exchange tips and experiences, making it easier to resolve specific issues.

Manufacturer Manuals and Guides

Official documentation from manufacturers often includes comprehensive instructions and technical details. These guides are essential for understanding machinery functionalities and ensuring optimal performance.