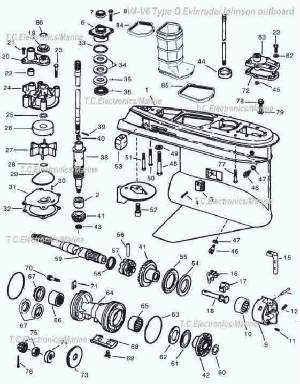

Understanding the structure of marine propulsion systems is essential for maintaining and troubleshooting any watercraft. The internal mechanisms are intricate, and their efficient operation relies on a precise arrangement of various elements. Recognizing the layout and connectivity between these components can significantly streamline any repair or upgrade process.

Whether you’re looking to maintain optimum performance or address specific issues, having a clear reference to the internal configuration is invaluable. Each element plays a vital role in ensuring smooth functioning, and an organized view of these elements helps with pinpointing potential areas of concern quickly and effectively.

In this guide, we’ll explore the internal layout of propulsion systems used in modern marine vehicles, shedding light on the interconnectivity and roles of various key elements. With this knowledge, you’ll be better equipped to ensure long-term reliability and performance on the water.

Evinrude E-TEC Components Overview

The advanced system in question integrates various essential elements that work together to deliver a smooth and reliable performance. These components are designed with precision to ensure optimal efficiency and longevity, providing seamless operation across a range of conditions. By harmonizing multiple features, the setup ensures that each element plays a vital role in maintaining overall functionality and enhancing output.

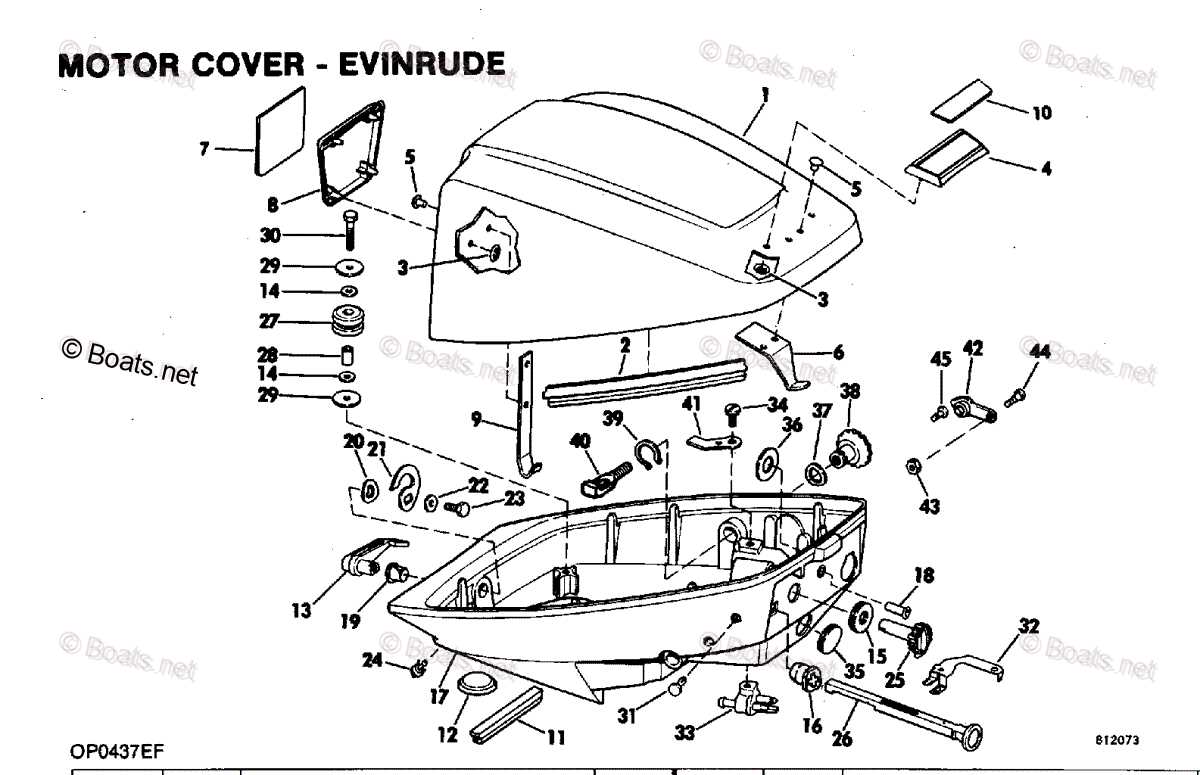

Key Mechanical Units

At the heart of this technology, key mechanical units drive the system’s capabilities. These include intricate motor mechanisms, fluid control systems, and various interconnected devices that contribute to a more powerful and controlled motion. Built for durability, these elements are fine-tuned to withstand the demands of high-performance environments, ensuring consistent operation over time.

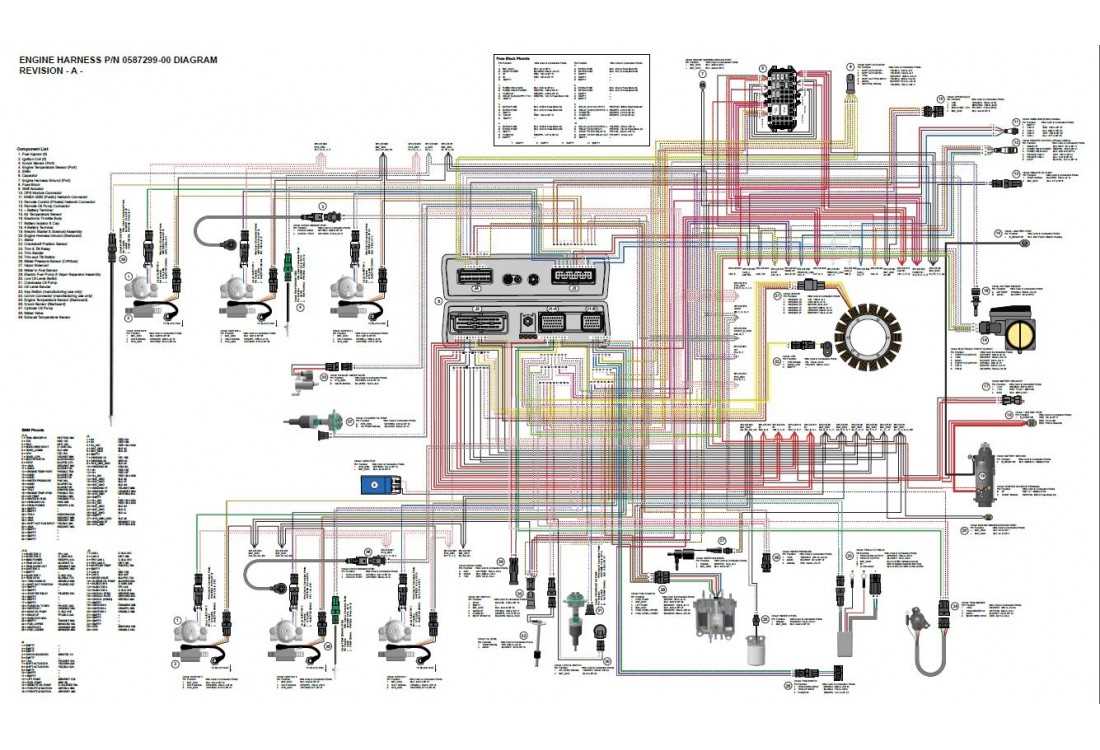

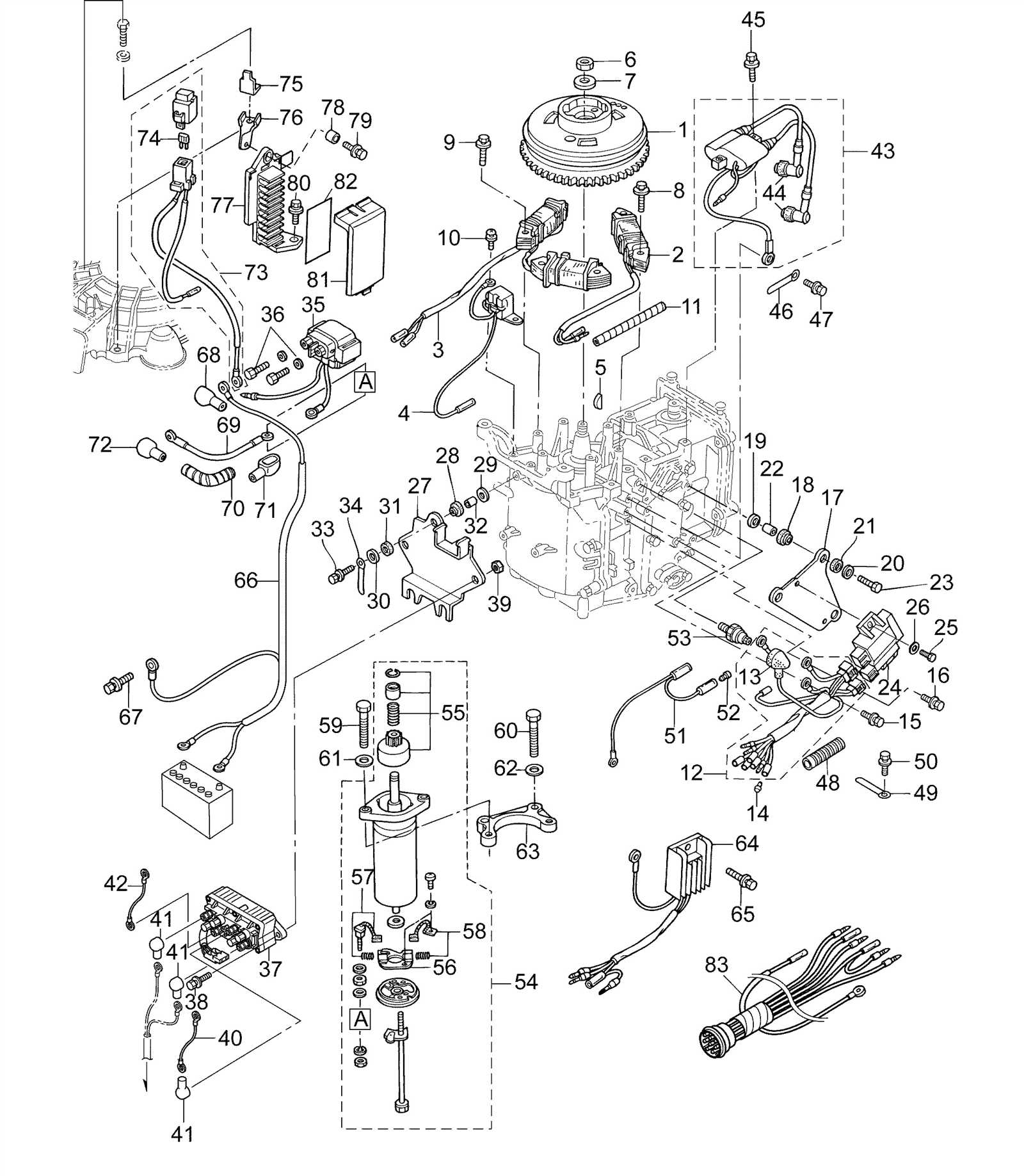

Electrical and Control Elements

Another crucial aspect involves the electrical and control features, which provide the intelligence behind the system’s operations. From power distribution units to sophisticated control modules, these components are essential

Engine Structure Breakdown for E-TEC Models

The core of modern marine power systems relies on a carefully designed mechanical layout. This section will explore the overall assembly, focusing on how each element is integrated to ensure efficient operation. Understanding the layout of these components can help in both routine maintenance and troubleshooting potential issues.

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block | Houses the cylinders where the fuel mixture is compressed and ignited. | ||||||||||||||||||||||

| Crankshaft | Converts the linear motion of pistons into rotational energy. | ||||||||||||||||||||||

| Pistons | Move up and down within the cylinder, powered by the combustion process. | ||||||||||||||||||||||

| Fuel Injectors | Deliver precise amounts of fuel to each cy

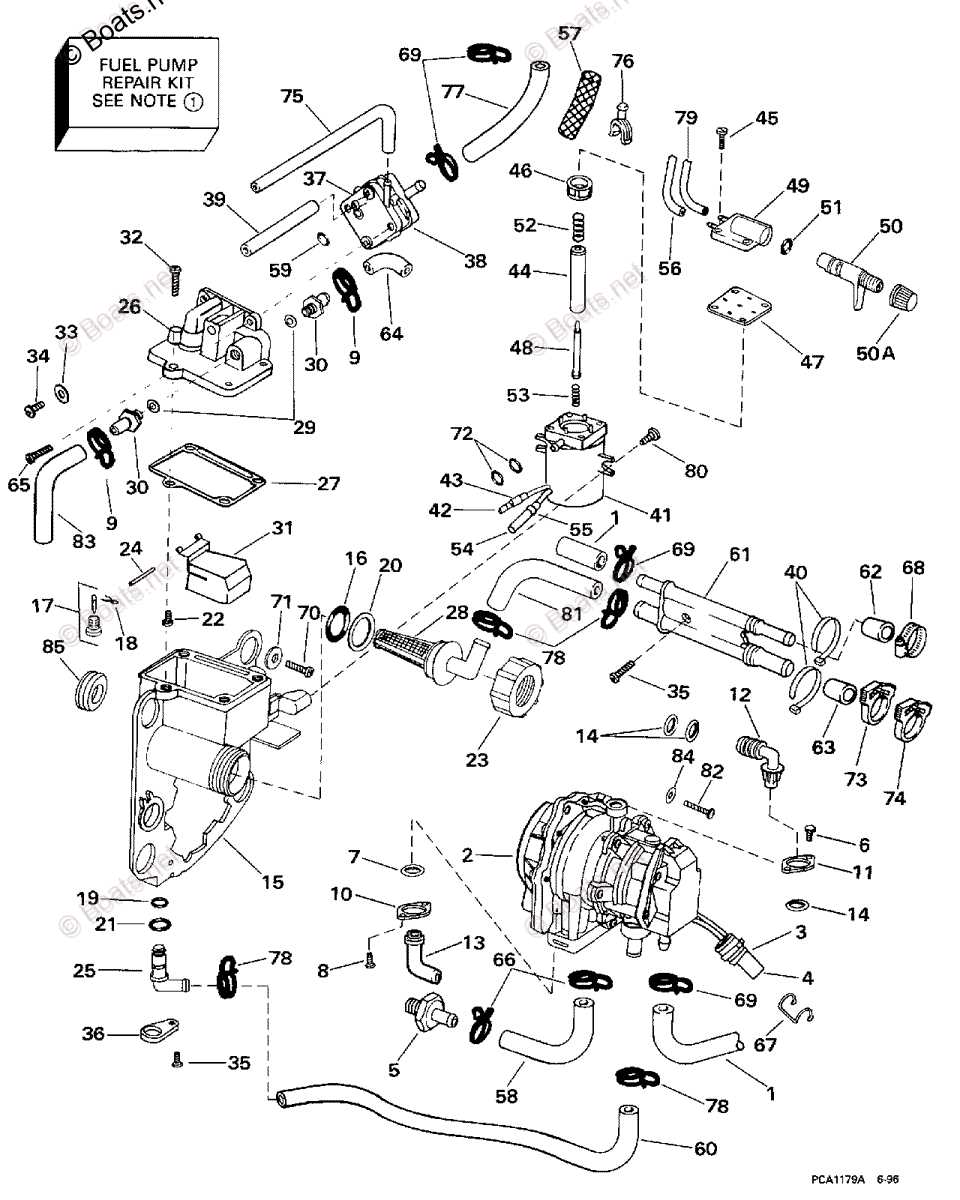

Understanding the Fuel System in Evinrude E-TEC

The fuel delivery mechanism is a crucial component in optimizing engine performance and efficiency. This system is designed to ensure that the appropriate mixture of fuel and air reaches the combustion chamber, which is vital for achieving smooth operation and reduced emissions. Understanding how this system functions can greatly enhance your maintenance and troubleshooting efforts. At the heart of this mechanism lies the fuel pump, which is responsible for transporting the fuel from the tank to the engine. This pump maintains the necessary pressure, allowing for an uninterrupted flow. Additionally, a series of filters are integrated into the system to prevent contaminants from entering the engine, thus prolonging its lifespan. Another key aspect is the fuel injectors, which precisely deliver the fuel into the combustion chamber at the right time. This precision is vital for achieving optimal combustion, resulting in improved power output and fuel efficiency. Moreover, advanced technologies, such as electronic control systems, monitor and adjust fuel delivery based on varying engine demands, ensuring consistent performance under different operating conditions. Overall, a thorough understanding of this system can empower boat enthusiasts and professionals alike, allowing for more effective maintenance and a deeper appreciation for the engineering behind modern marine engines. Electrical System Parts in Evinrude Engines

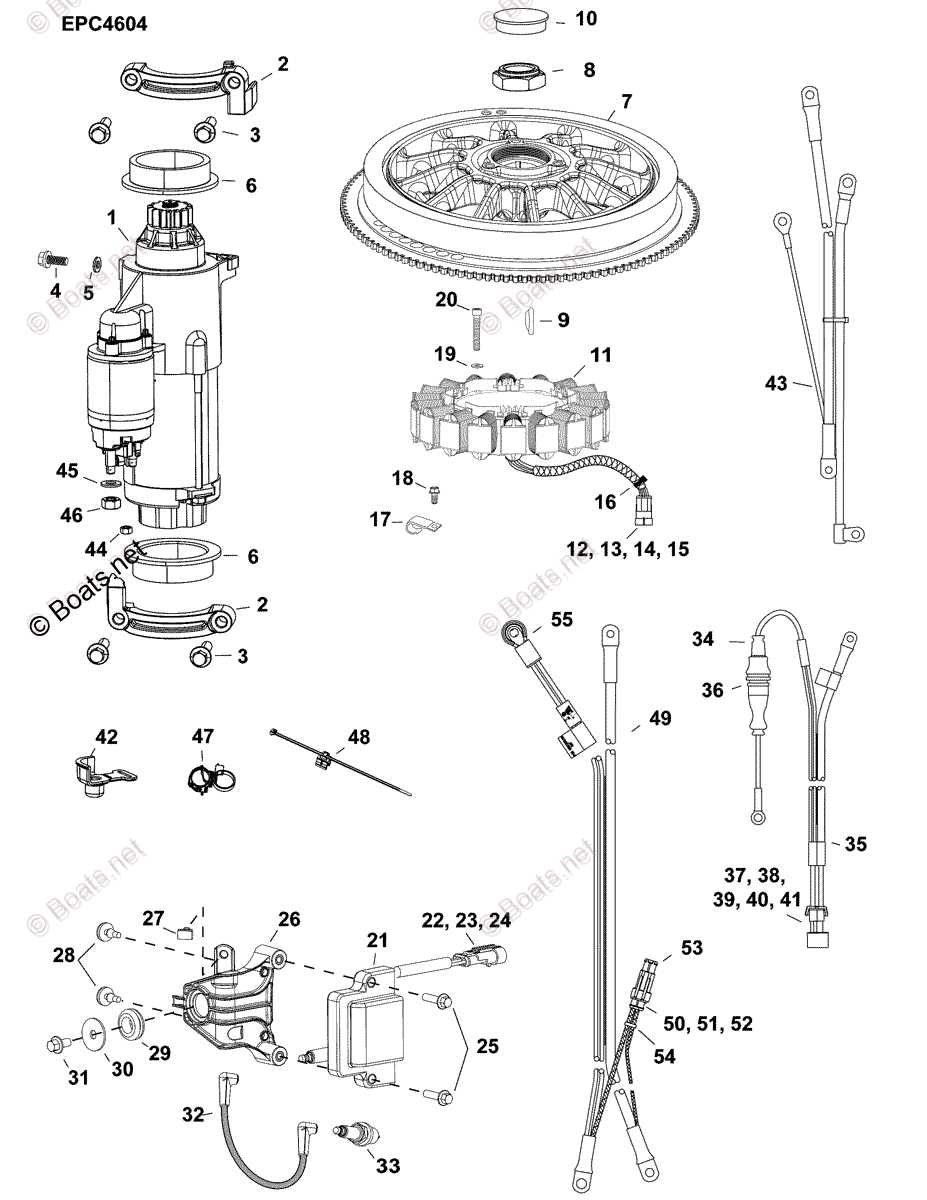

The electrical framework within marine motors plays a crucial role in ensuring efficient operation and reliability. This system encompasses a range of components that facilitate the generation, distribution, and regulation of electrical energy. Understanding the individual elements of this network is essential for optimal performance and troubleshooting. Key Components of the Electrical FrameworkVarious elements work together to maintain the functionality of the electrical system. Each component has a specific role, contributing to the overall efficiency and responsiveness of the engine. The following table outlines the primary components and their functions:

Maintenance and Troubleshooting TipsRegular inspection and maintenance of the electrical system are vital for preventing issues. Checking connections, ensuring the battery is charged, and monitoring the ignition system can help maintain optimal performance. If problems arise, consulting a professional or referring to technical resources can provide valuable guidance for effective troubleshooting. Ignition System Components of E-TEC EnginesThe ignition system is a vital component in any modern outboard motor, playing a crucial role in ensuring optimal performance and efficiency. It consists of various elements that work together to generate the spark necessary for combustion within the engine cylinders. Understanding these components can help in maintaining and troubleshooting the overall functionality of the motor. Coils serve as one of the primary components, converting low voltage from the battery into high voltage needed to create a spark. These devices are essential for starting the engine and sustaining its operation under varying conditions. Additionally, spark plugs are responsible for igniting the air-fuel mixture in the combustion chamber, ensuring smooth engine operation and efficient fuel consumption. Timing controls are equally important, regulating the exact moment the spark occurs in relation to the piston’s position. This precision is vital for maximizing power output and minimizing emissions. Furthermore, the system incorporates control modules, which manage the ignition timing and coil firing, adapting to different engine speeds and loads for enhanced performance. By understanding the intricate workings of these components, users can ensure their outboard motors remain in optimal condition, leading to improved performance and longevity. Cooling System Parts in Evinrude E-TEC

The cooling mechanism is essential for maintaining optimal engine performance and longevity. Understanding the various components involved in this system can significantly enhance maintenance and troubleshooting efforts. This section delves into the key elements that facilitate effective temperature regulation in outboard motors.

Regular inspection and maintenance of these components can prevent overheating and ensure the engine operates smoothly. Familiarity with these elements allows for better troubleshooting and enhances the overall performance of the outboard motor. Detailed View of the Exhaust SystemThe exhaust system plays a crucial role in the overall functionality of marine engines, ensuring efficient operation while minimizing harmful emissions. Understanding its components and layout is essential for maintenance and troubleshooting. This system typically consists of various elements designed to direct exhaust gases away from the engine and into the water. Below is a closer look at these components:

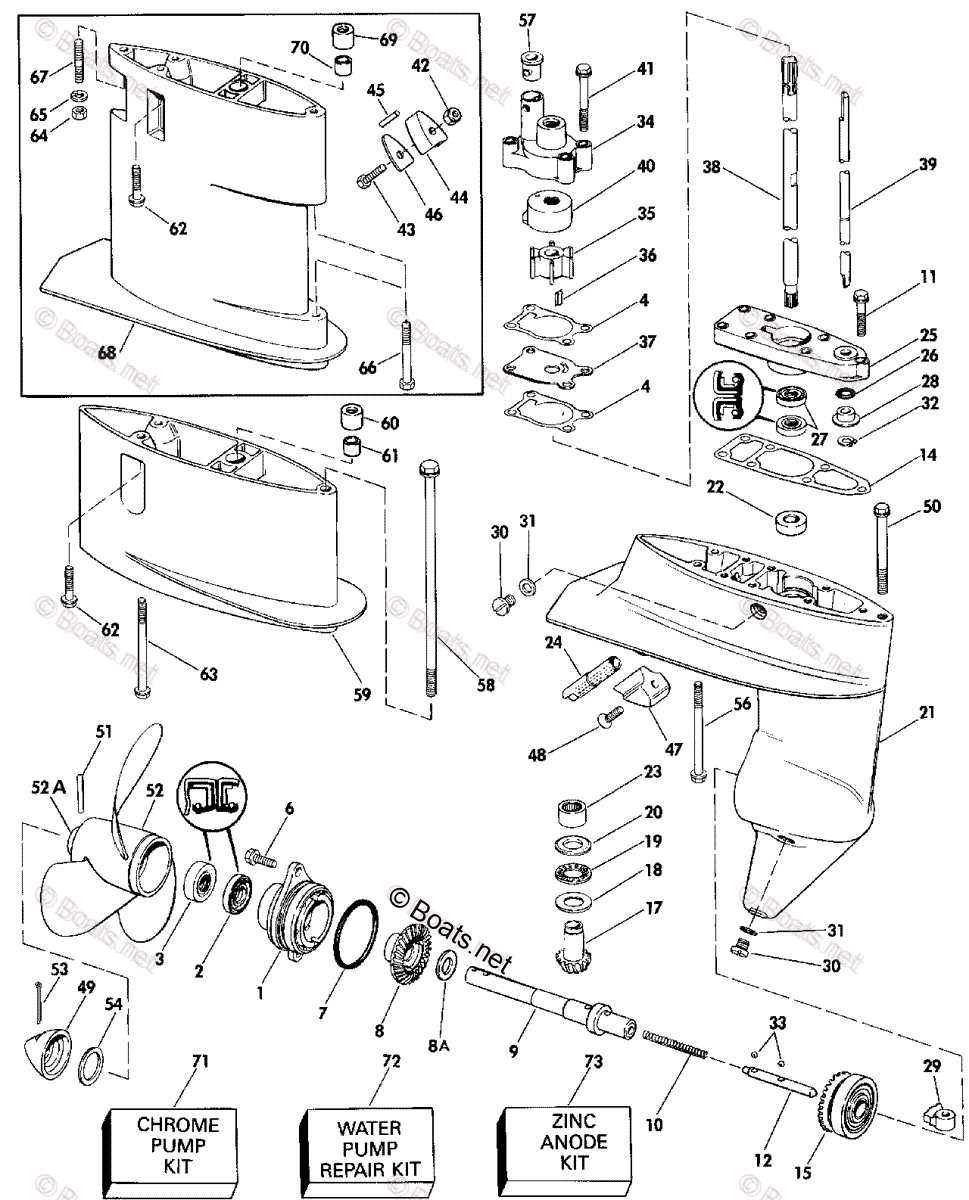

Each of these elements is critical to maintaining performance and compliance with environmental standards. Regular inspections and maintenance can help ensure that the exhaust system operates efficiently, reducing the risk of issues that could affect overall engine performance. Key Propulsion Components in Evinrude E-TECThe propulsion system of a modern marine engine encompasses several vital elements that work harmoniously to deliver power and efficiency. Understanding these components is crucial for maintaining optimal performance and ensuring a smooth boating experience. This section delves into the fundamental parts that contribute to the functionality of these advanced outboard motors. Powerhead and Fuel Delivery System

At the heart of the propulsion mechanism lies the powerhead, where the combustion process takes place. This assembly includes the cylinders, pistons, and ignition system, all designed to convert fuel into mechanical energy. Coupled with the powerhead is the fuel delivery system, which ensures that the right amount of fuel reaches the combustion chamber at the appropriate time. The synergy between these components is essential for achieving optimal power output and fuel efficiency. Lower Unit and Propeller

The lower unit serves as the connection between the powerhead and the propeller, transmitting power to the propulsion device. It houses the gear system that allows for efficient speed regulation and maneuverability. The propeller itself is a critical component that transforms the engine’s rotational force into thrust, enabling the vessel to move through water. Proper maintenance of both the lower unit and propeller is key to maximizing performance and preventing damage. Oil Distribution System for Evinrude ModelsThe lubrication mechanism in modern outboard engines plays a crucial role in ensuring smooth operation and longevity. This system is designed to efficiently deliver oil to various components, thereby minimizing friction and wear during engine performance. A well-functioning lubrication setup not only enhances efficiency but also contributes to overall engine health. At the core of this distribution network lies a series of strategically placed channels and pumps that ensure an even flow of lubricant throughout the engine. These pathways are engineered to maintain optimal pressure, allowing the fluid to reach critical areas swiftly. The integration of advanced technology in these systems enables precise control over oil delivery, adapting to the engine’s demands based on speed and load conditions. Regular maintenance of the lubrication system is essential for optimal performance. Operators should monitor oil levels and quality, ensuring that any obstructions or leaks are promptly addressed. Proper upkeep of this mechanism not only guarantees reliability but also extends the operational life of the engine. Steering Mechanism Parts in E-TEC EnginesThe steering mechanism is a crucial component in ensuring precise control and maneuverability of outboard motors. Understanding the various elements that make up this system is essential for proper maintenance and troubleshooting. Each element plays a significant role in the overall functionality of the steering, allowing for smooth and responsive operation on the water.

Each of these components contributes to the effective operation of the steering system, allowing for smooth navigation and control. Regular inspection and maintenance of these elements can enhance performance and longevity, ensuring a safer and more enjoyable experience on the water. Propeller Assembly for Evinrude OutboardsThe propeller assembly plays a crucial role in the performance and efficiency of outboard motors. This essential component converts the engine’s power into thrust, allowing the vessel to move smoothly through the water. Understanding the intricacies of this assembly can help ensure optimal operation and longevity. Components of the Propeller Assembly

The assembly typically consists of several key elements, including the propeller blades, hub, and mounting hardware. Each blade is designed to provide the necessary lift and maneuverability, while the hub connects the blades to the motor shaft, ensuring a secure attachment. Regular inspection and maintenance of these components are vital for maintaining peak performance. Installation and Maintenance TipsProper installation of the propeller assembly is essential for safe navigation. It is advisable to follow manufacturer guidelines and use the correct tools to secure the components. Regular maintenance, including cleaning and checking for signs of wear, can significantly extend the lifespan of the assembly. Pay close attention to any vibrations or unusual noises during operation, as these may indicate an issue that needs addressing. Maintenance Parts for Evinrude E-TECEnsuring the longevity and optimal performance of your marine engine involves regular attention to its essential components. This section focuses on critical elements necessary for the upkeep of your watercraft’s engine system. A well-maintained engine not only enhances performance but also increases reliability during your voyages. Key Components for Regular Maintenance

Routine inspections and timely replacements of specific elements can significantly impact the efficiency of your engine. Here are some vital components to keep an eye on:

Maintenance Schedule Recommendations

Adhering to a maintenance schedule can greatly enhance the performance of your marine engine. Regular check-ups, along with the replacement of the components listed above, will ensure smooth operation and longevity. |