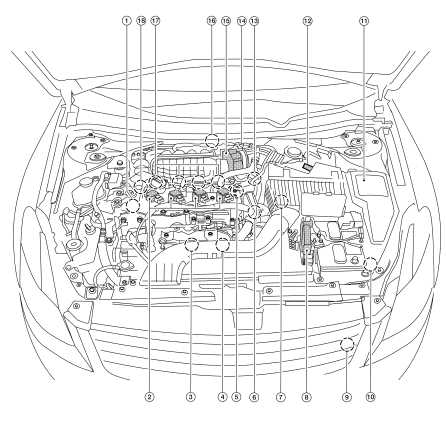

Every vehicle relies on a sophisticated system under the hood to ensure smooth operation. Whether you’re a car enthusiast or someone interested in learning more, understanding the various elements involved in powering a car is essential. Each part works in harmony to deliver the performance that drivers expect, contributing to the overall efficiency and longevity of the vehicle.

The intricate structure beneath the hood includes numerous crucial components, all playing vital roles in the car’s overall performance. These parts, when properly maintained, help ensure that the vehicle runs optimally, minimizing breakdowns and improving fuel efficiency. For those seeking to gain a deeper understanding of this mechanical network, knowing what each component does and how they interact is the first step toward mastering vehicle maintenance.

In this guide, we will explore the layout of the key components responsible for transforming fuel into motion. Whether you’re planning to troubleshoot an issue or just increase your knowledge, a clear visual representation of how everything fits together can be incredibly helpful. Let’s dive into the core aspects of this vital system, breaking down each section to give you a comprehensive overview.

Nissan Altima Engine Overview

The heart of this vehicle has been engineered with precision and efficiency, ensuring a blend of power and fuel economy. Its design incorporates advanced technology aimed at providing smooth performance, with an emphasis on durability and low emissions. Drivers can rely on this system to offer consistent and responsive driving experiences, adapting to various road conditions and driving styles.

Main Components

The key mechanical components play a crucial role in the operation, each part carefully integrated to optimize function and longevity. These elements are designed to work together, enhancing overall efficiency while minimizing wear and tear.

| Component | Description |

|---|---|

| Cylinder Block | Foundation of the system, housing critical elements like cylinders and passages for coolant and oil. |

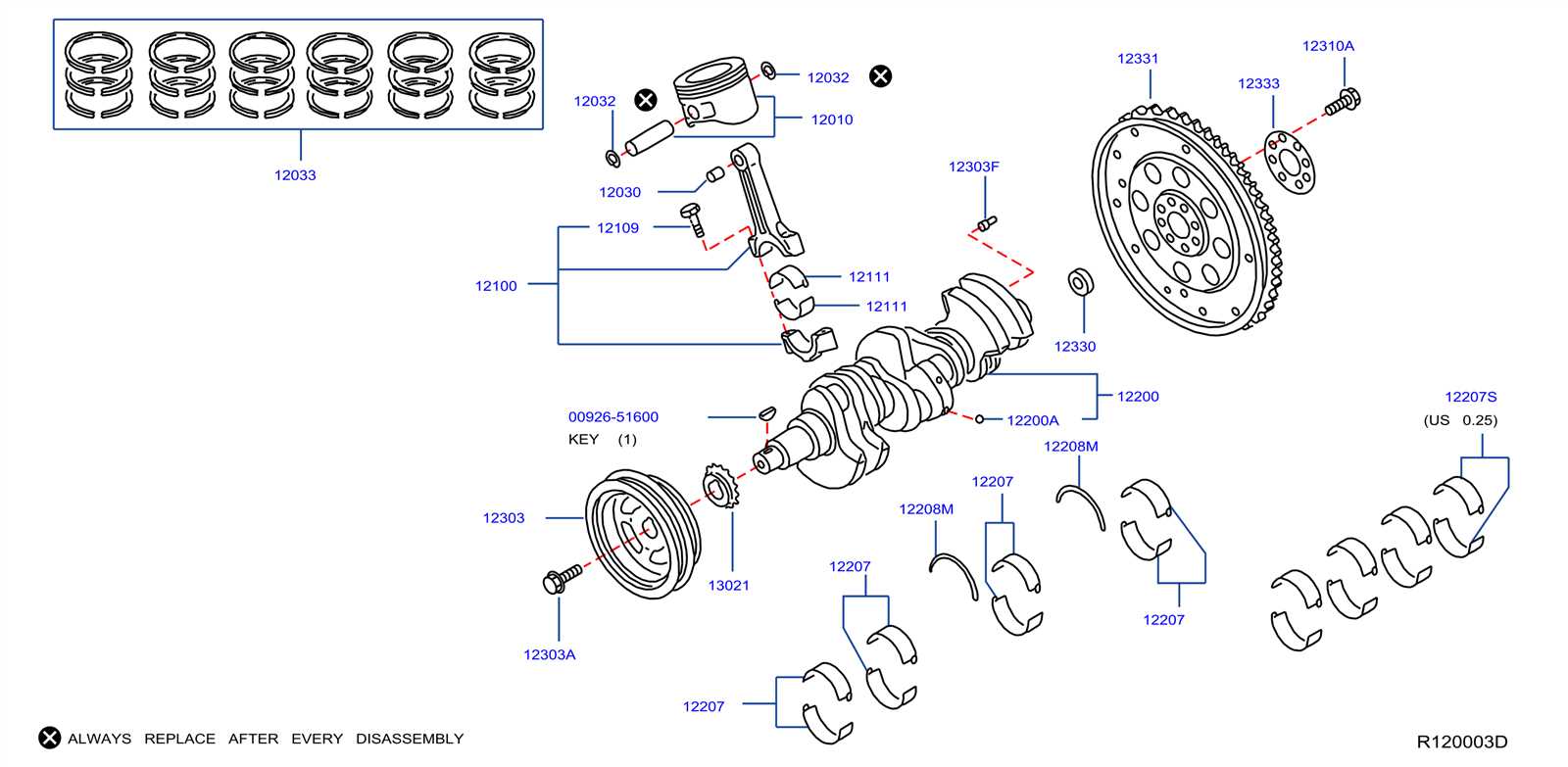

| Crankshaft | Converts linear motion into rotational energy, driving other key systems in the vehicle. |

| Pistons | Move within the cylinders to compress air and fuel, initiating combustion. |

| Camshaft | Controls the opening and closing of the valves, timed precisely with the movement of other components. |

Performance Benefits

The design also focuses on maximizing performance while maintaining optimal fuel efficiency. Thanks to various enhancements, the powertrain can deliver reliable speed, acceleration, and long-term reliability, ensuring a smooth and comfortable ride in different environments.

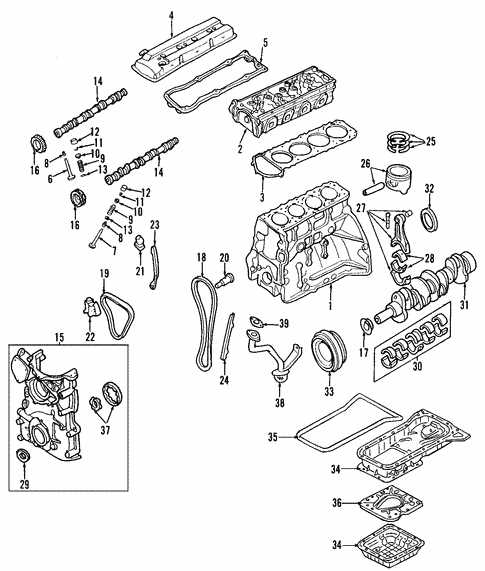

Main Components of the Altima Engine

The power system of the vehicle is built from several essential elements that work together to ensure efficient operation. Each piece plays a specific role, contributing to the overall performance, durability, and reliability of the automobile. Understanding these key elements provides insight into how the system functions as a whole.

First, we have the combustion chamber, where fuel and air combine to produce the energy needed to drive the car. This process is critical, as it transforms chemical energy into mechanical motion. The next important element is the crankshaft, which converts the up-and-down motion of the pistons into rotational energy, ultimately powering the wheels.

Another crucial part is the intake system, responsible for bringing air into the combustion process. This system ensures the proper mix of air and fuel for optimal performance. In addition, the exhaust system plays a vital role in removing gases produced during combustion, keeping the system running smoothly.

The cooling system prevents overheating by circulating coolant, maintaining a stable temperature during operation. Lastly, the lubrication system reduces friction between moving components, preventing wear and tear, and extending the lifespan of the mechanical assembly.

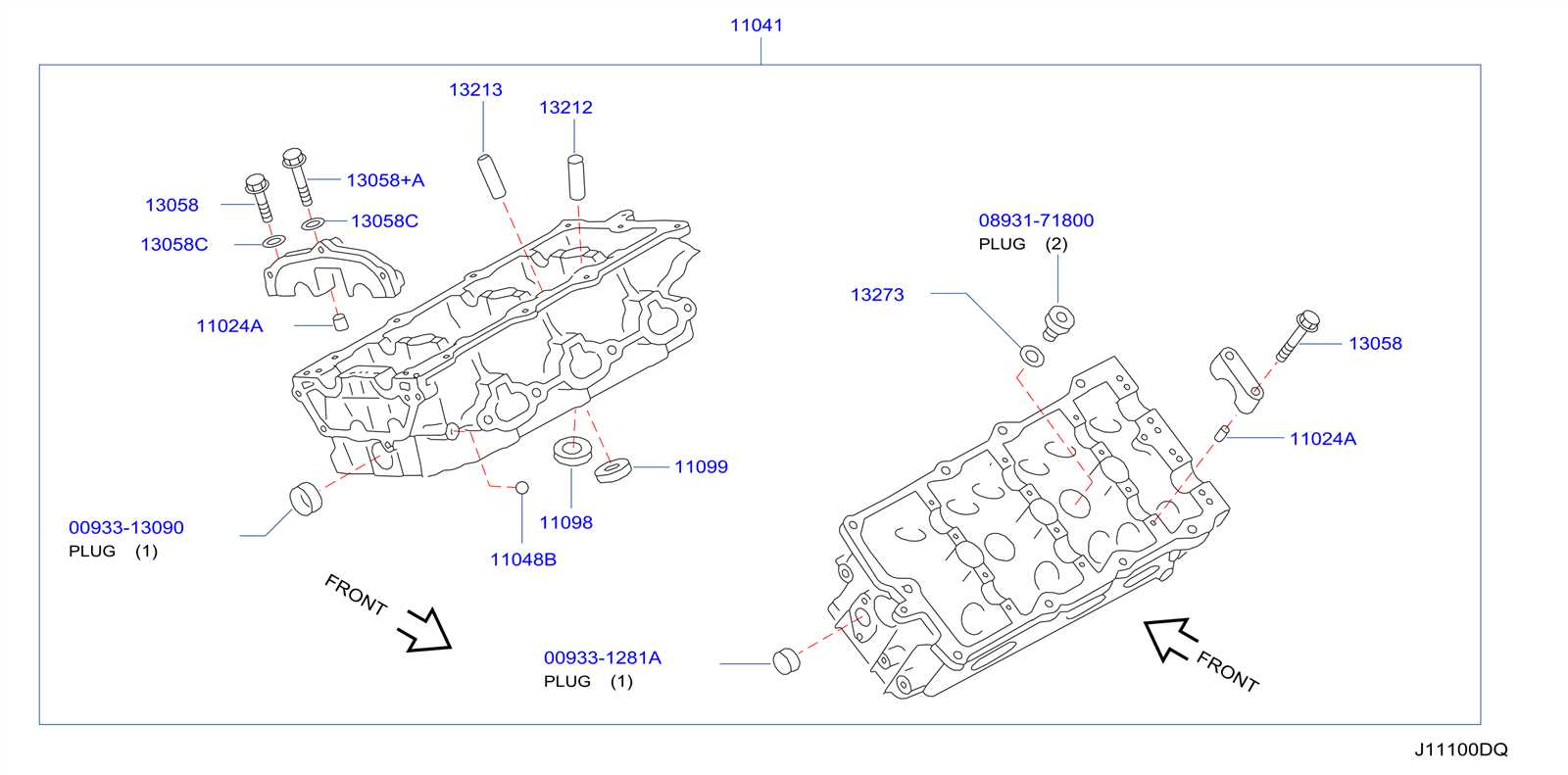

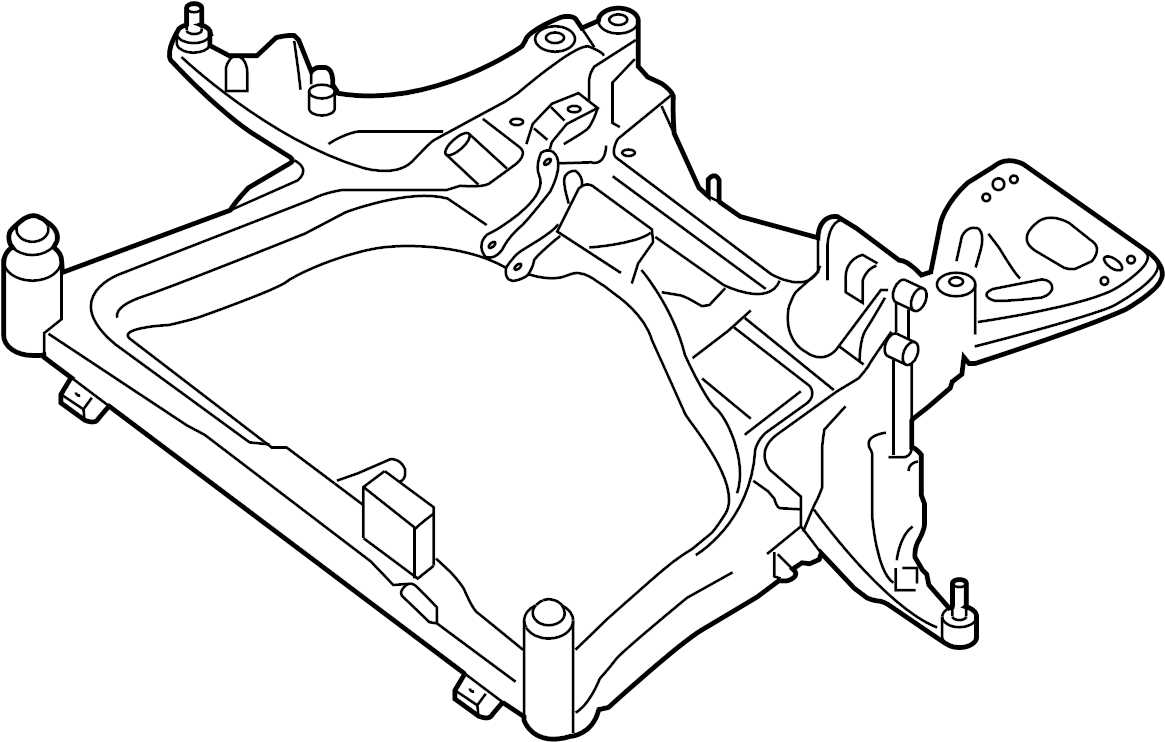

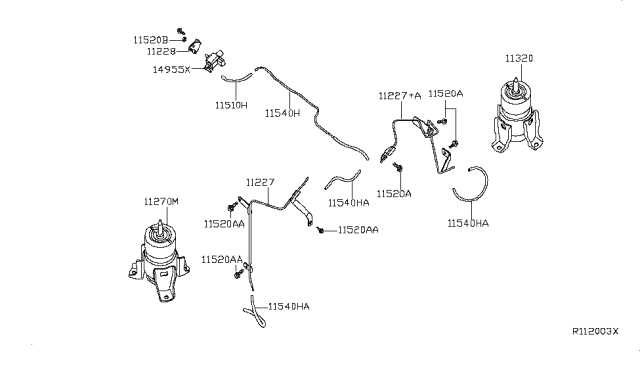

Detailed Breakdown of Engine Block

The heart of any vehicle’s power system is the central component that holds key mechanical elements responsible for generating motion. Understanding the various elements within this structure provides insight into how mechanical force is produced and maintained. Each section within this block is meticulously designed to ensure efficiency and performance, playing a crucial role in the overall functioning of the machine.

Main Components Overview

At the core of this system are multiple sections working together in harmony. These sections include cavities, connecting shafts, and multiple fasteners, each contributing to the power output and smooth operation. These parts must be robust and precision-engineered, as they endure significant forces during operation.

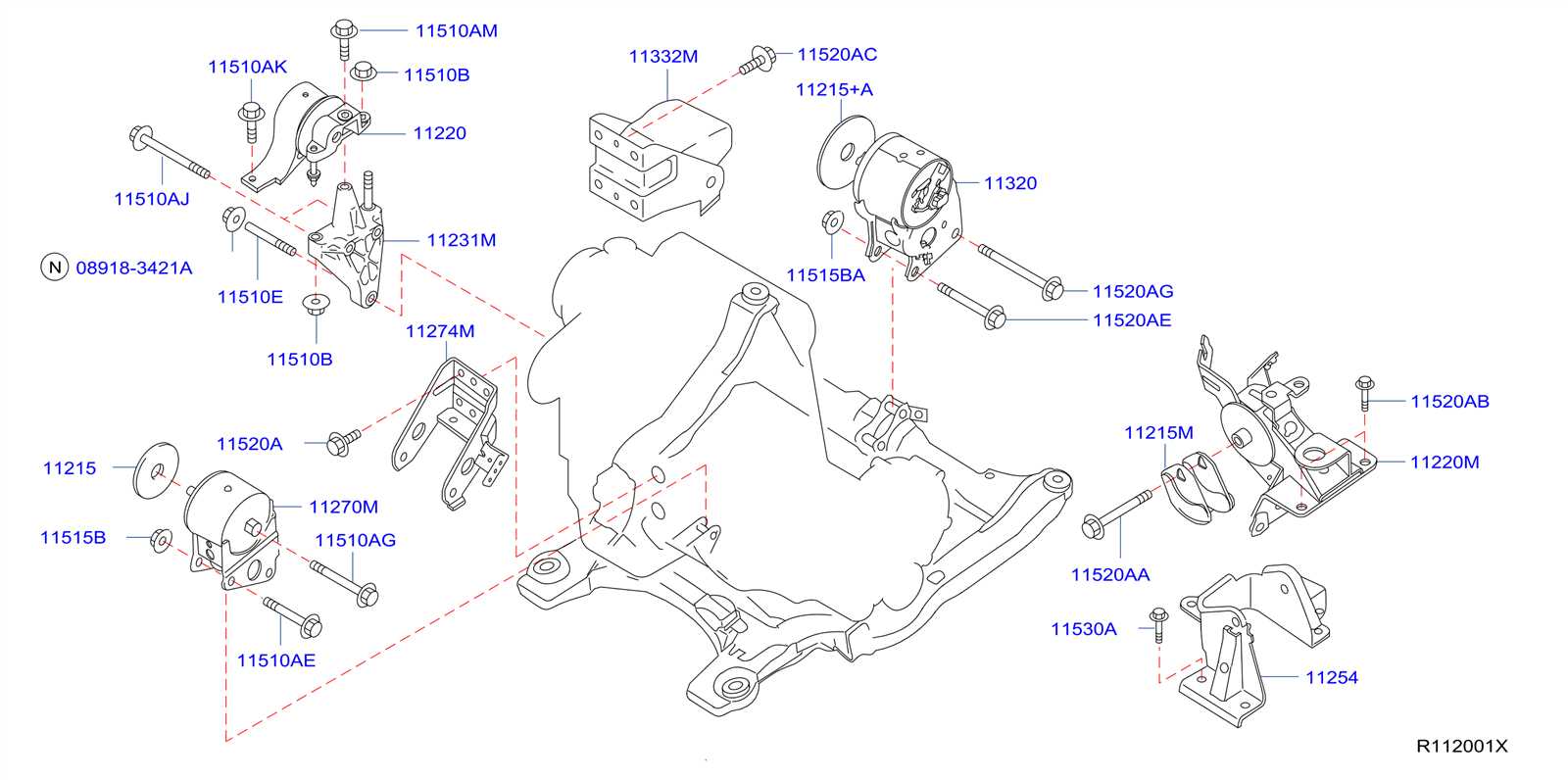

Internal Systems and Their Roles

The central component hosts various internal systems, including channels for fluid circulation and mechanical joints for movement transmission. These systems facilitate cooling, lubrication, and proper alignment of internal mechanisms, which are essential for maintaining optimal functionality.

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Housing | Provides structural integrity and holds critical components in place. | ||||||||||||

| Cooling Passages | Allow fluid circulation to regulate temperature during operation. | ||||||||||||

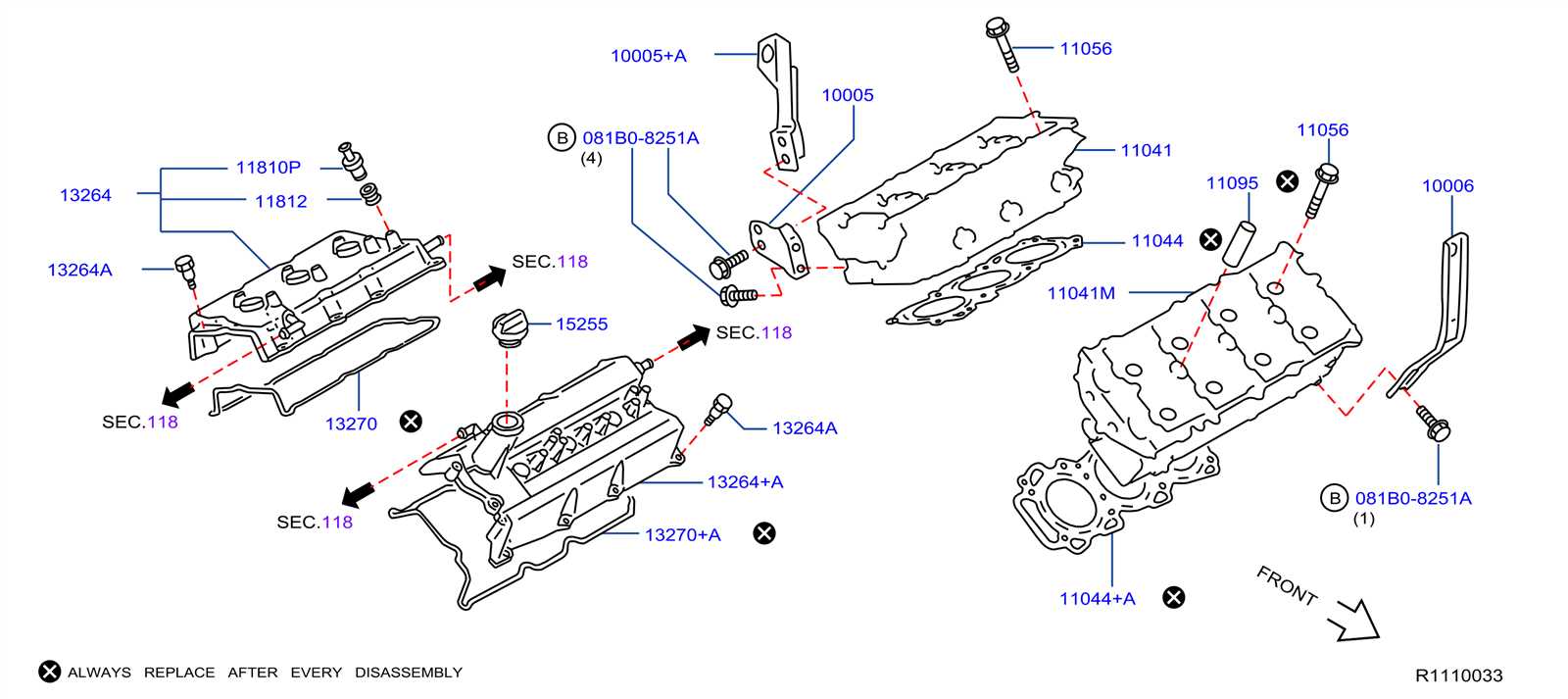

| Mounting Points | Ensure proper alignment and secure attachment to the surrounding structure.Function of the Cylinder Head in the Altima

The cylinder head plays a critical role in the overall performance of a vehicle’s power system. It forms the top section of the combustion chamber and is responsible for sealing the cylinders. This component ensures that fuel combustion occurs effectively, impacting both power output and efficiency. Key Responsibilities of the Cylinder Head: It houses essential elements like valves and spark plugs, which regulate the intake of air and fuel, and the release of exhaust gases. Additionally, it maintains pressure within the system, which is vital for optimal combustion. Precision in Manufacturing is crucial to ensure the smooth operation of this part. Its ability to handle high temperatures and pressure contributes to long-term reliability and prevents issues like overheating or loss of compression. Understanding the Altima’s Fuel System

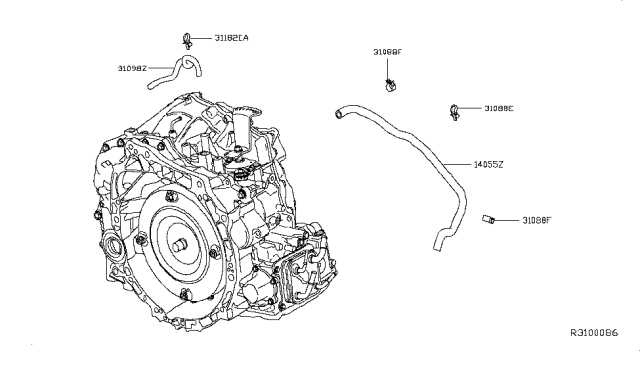

The fuel system in a vehicle plays a critical role in ensuring proper functionality by delivering the necessary energy for the car’s performance. This system consists of various interconnected components that work together to transport, regulate, and control the flow of fuel. Maintaining efficiency in this area is key to the overall reliability and smooth operation of the vehicle. Key Components of the Fuel System

The primary elements involved in the fuel delivery process include the fuel tank, pump, filter, and injectors. Each part has a specific function. The pump draws the fuel, the filter removes impurities, and the injectors ensure precise delivery into the combustion chamber. The coordination between these elements is essential for optimal performance. Common Issues and Maintenance

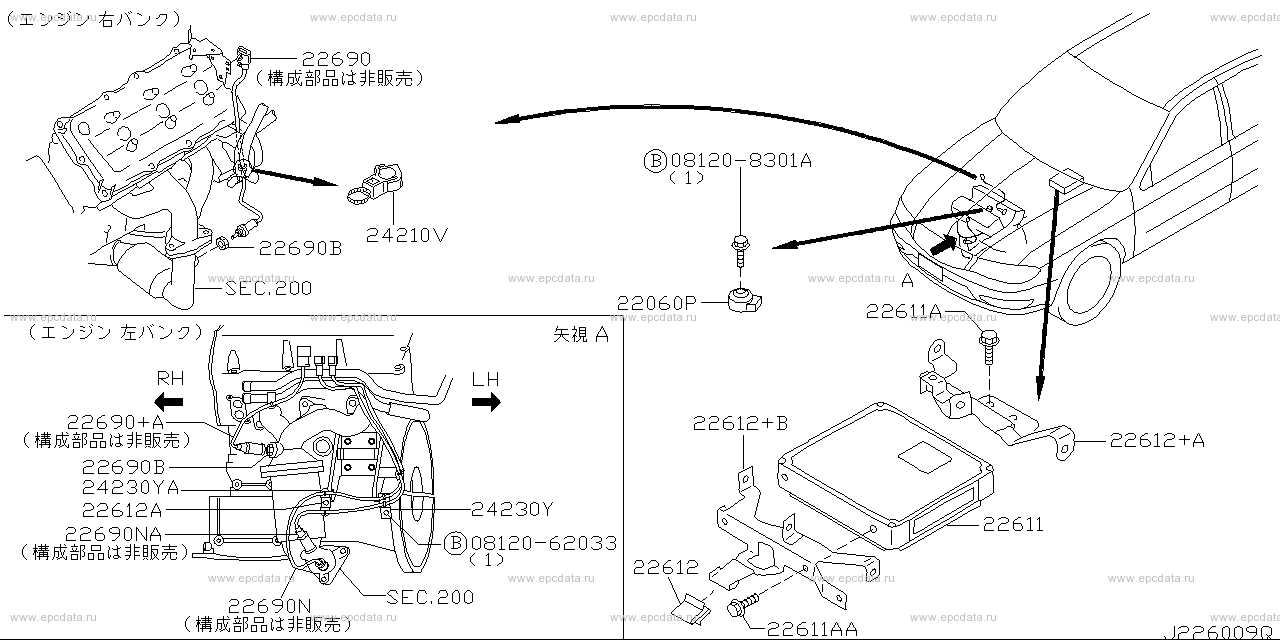

Regular inspection of the fuel system can prevent issues such as clogged filters or faulty pumps. Keeping this system in good condition not only improves efficiency but also reduces emissions and enhances the vehicle’s longevity. Proper care can make a significant difference in overall performance. How the Ignition System OperatesThe ignition system is a crucial component in the operation of a vehicle’s combustion process. It is responsible for initiating the burning of fuel by producing a high-voltage spark that ignites the air-fuel mixture within the cylinders. Understanding its functionality is essential for maintaining optimal performance and efficiency. Key Components

Operating Sequence

This sequence is repeated continuously, enabling the vehicle to operate efficiently. Regular maintenance of the ignition components is vital to ensure reliable performance and prevent misfires. Overview of the Exhaust System in AltimaThe exhaust mechanism plays a crucial role in managing emissions and enhancing overall performance. This system ensures that harmful gases are efficiently expelled while maintaining optimal engine operation. Understanding its components and functionality is vital for effective maintenance and troubleshooting.

Regular inspections of this system can help prevent performance issues and prolong the lifespan of the vehicle, ensuring a smooth and efficient ride. The Role of the Timing ChainThe timing chain serves a crucial function in coordinating the movements of various mechanical components within a vehicle’s power unit. This essential element ensures that the rotation of the crankshaft and the camshaft are synchronized, allowing for optimal performance and efficiency. Importance of SynchronizationEffective synchronization is vital for maintaining proper valve operation. When the timing chain operates accurately, it minimizes the risk of misalignment, which can lead to severe damage and decreased performance. A well-functioning chain supports smooth combustion cycles and enhances overall power delivery. Maintenance and LongevityRegular inspection and maintenance of the timing chain can prevent premature wear and potential failure. Signs of wear include unusual noises or performance issues, signaling the need for timely replacement. Ensuring the longevity of this component is essential for maintaining peak performance and avoiding costly repairs. Altima Engine Cooling System ExplainedThe cooling system plays a crucial role in maintaining optimal temperatures within a vehicle’s powertrain. It ensures that components function efficiently, preventing overheating and potential damage. Key components of this system include:

Understanding how each part contributes to temperature regulation is essential:

Regular maintenance and checks can enhance the longevity and performance of this critical system. Air Intake Components in Nissan Altima

The air intake system plays a crucial role in ensuring optimal performance and efficiency of a vehicle’s power unit. It facilitates the flow of fresh air into the combustion chamber, which is essential for the combustion process. Understanding the elements involved in this system can greatly enhance maintenance and troubleshooting efforts. Main Components

Regular inspection and replacement of these components are vital for sustaining performance. A clean air filter can significantly improve fuel efficiency, while a well-maintained manifold ensures balanced airflow, optimizing engine functionality. The oil reservoir plays a crucial role in maintaining the overall health and efficiency of a vehicle’s internal combustion system. It serves as a storage unit for lubricating fluid, ensuring that all moving components are adequately greased during operation. First and foremost, this component provides a reliable supply of lubricant to reduce friction, which is essential for optimal performance and longevity. By minimizing wear on parts such as pistons and crankshafts, it helps prevent premature failure and costly repairs. Additionally, the oil reservoir facilitates the cooling of the lubricating fluid, allowing it to effectively dissipate heat generated by the various mechanical processes. This temperature regulation is vital in preventing overheating and ensuring that the system operates smoothly. Furthermore, it serves as a filtration point, capturing contaminants and debris that could potentially harm internal components. Regular maintenance of this unit is necessary to ensure that it functions at its best, ultimately contributing to the reliability and efficiency of the entire mechanism. When it comes to the internal mechanisms of a vehicle, various challenges can arise that affect performance and reliability. Understanding these common problems is crucial for maintenance and can help in preventing costly repairs. One of the most prevalent concerns involves wear and tear on crucial components. Over time, essential elements may degrade, leading to decreased efficiency and potential breakdowns. Regular inspections can identify these issues early on. Another common issue is the occurrence of fluid leaks, which can compromise the overall functionality of the system. Additionally, overheating can result from blockages or malfunctioning cooling mechanisms, necessitating immediate attention to avoid severe damage. Regular upkeep of your vehicle’s power unit is essential for optimal performance and longevity. Following a structured maintenance routine can prevent issues and enhance efficiency, ensuring a smoother driving experience. |