The intricacies of a rolling mechanism reveal a fascinating interplay of elements that contribute to its functionality. Each component serves a unique purpose, ensuring smooth operation and durability. This section aims to provide insight into these essential elements, enabling enthusiasts to appreciate their design and interconnection.

By exploring the various segments involved, readers can uncover the ultimate framework that supports performance and reliability. From the core structure to the peripheral fittings, every piece plays a critical role in enhancing the overall experience of movement.

As we delve into this exploration, we will examine the distinct characteristics and relationships among these components. Understanding how they work together not only enriches knowledge but also aids in making informed decisions for maintenance and upgrades.

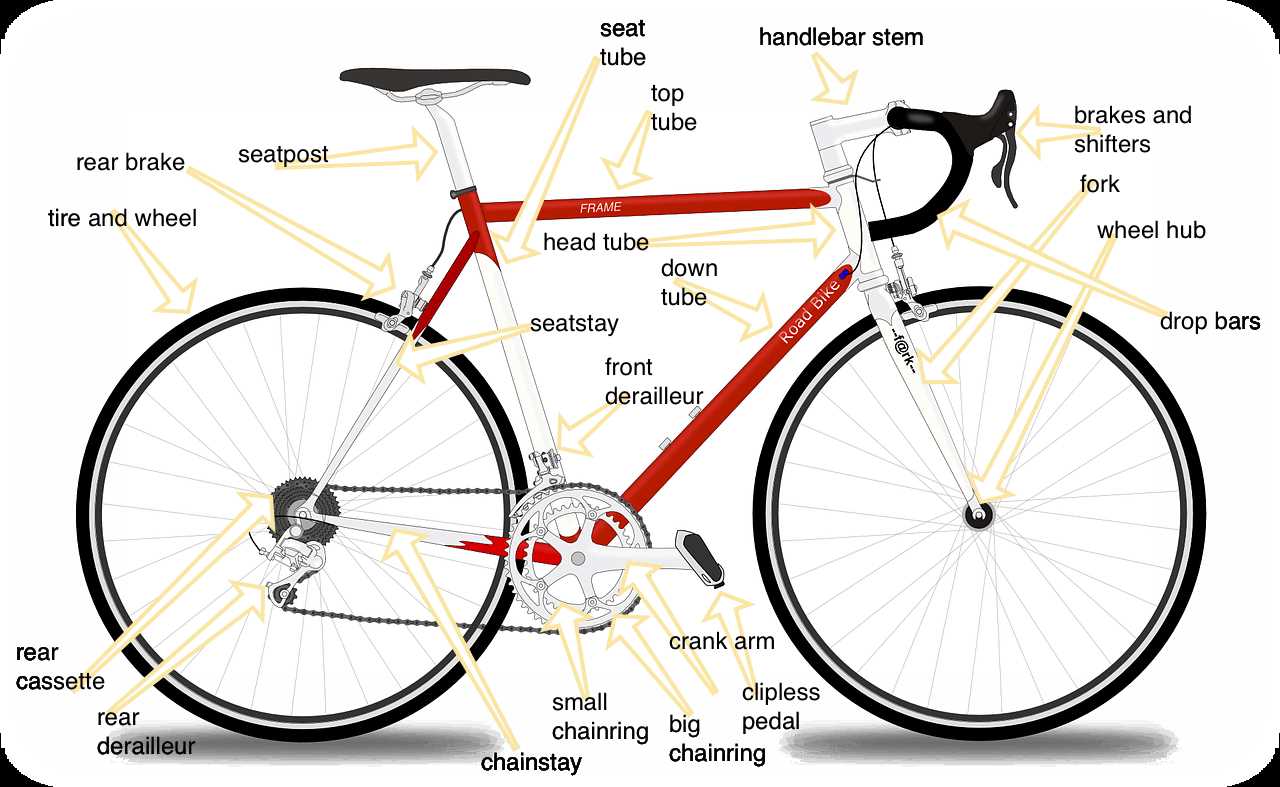

Understanding Bike Hub Components

Delving into the intricacies of a bicycle’s wheel assembly reveals a fascinating interplay of elements that ensure smooth movement and durability. Each component plays a crucial role in the overall performance, providing strength and functionality to enhance the riding experience.

Key Elements

- Shell: The outer casing that provides structural integrity.

- Axle: A central rod that connects and allows rotation of the wheel.

- Bearings: Small spheres or rollers that facilitate smooth rotation by reducing friction.

- Freewheel or Freehub: The mechanism that allows the rider to coast without pedaling.

- Spokes: Thin rods that connect the rim to the central structure, offering support and stability.

Functionality and Maintenance

Understanding the purpose of each element is vital for effective upkeep. Regular inspection and maintenance can significantly prolong the lifespan of these components. Here are some tips:

- Check for any signs of wear or damage.

- Ensure bearings are properly lubricated.

- Tighten spokes to maintain wheel integrity.

- Inspect the freewheel for smooth engagement.

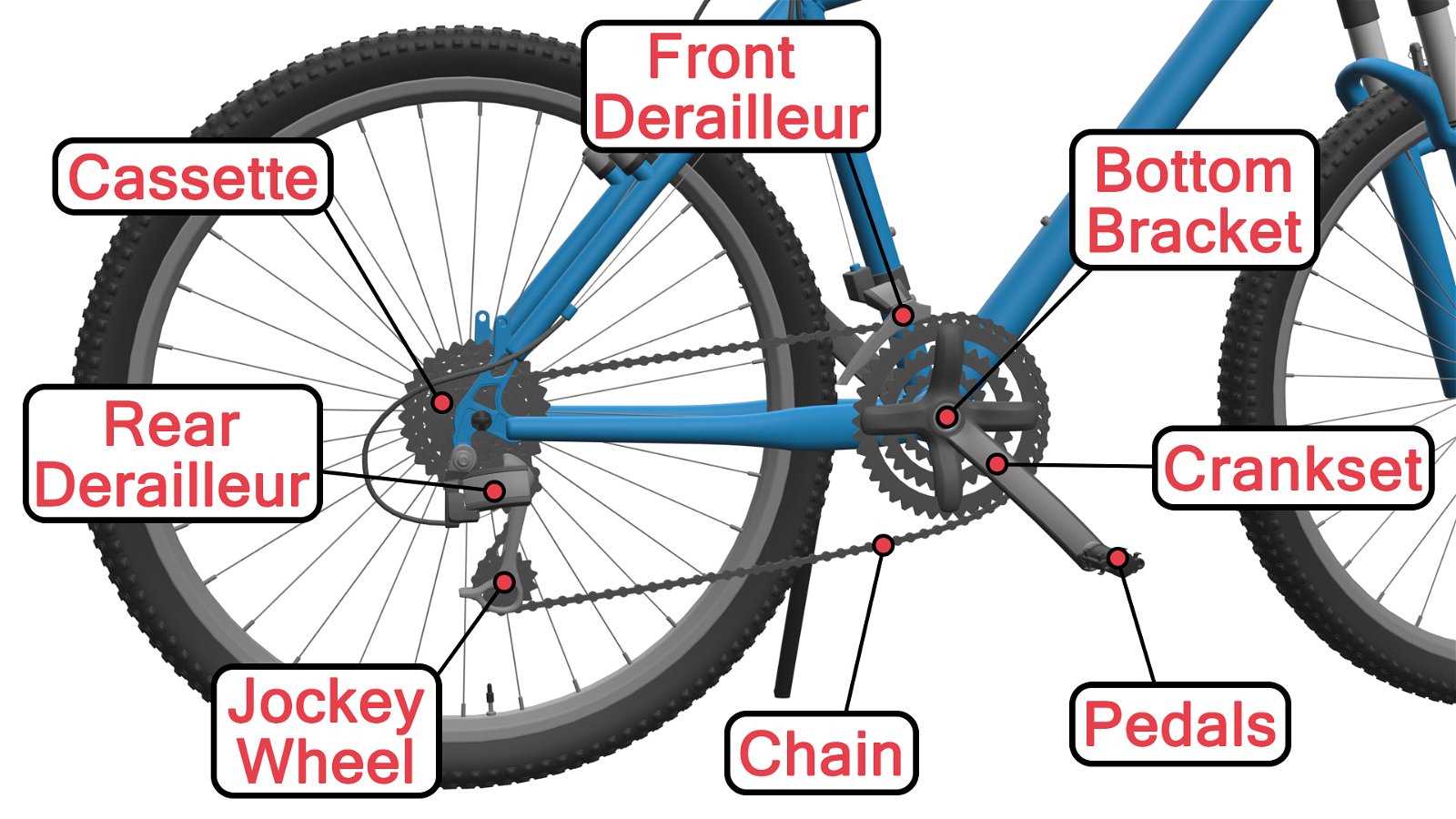

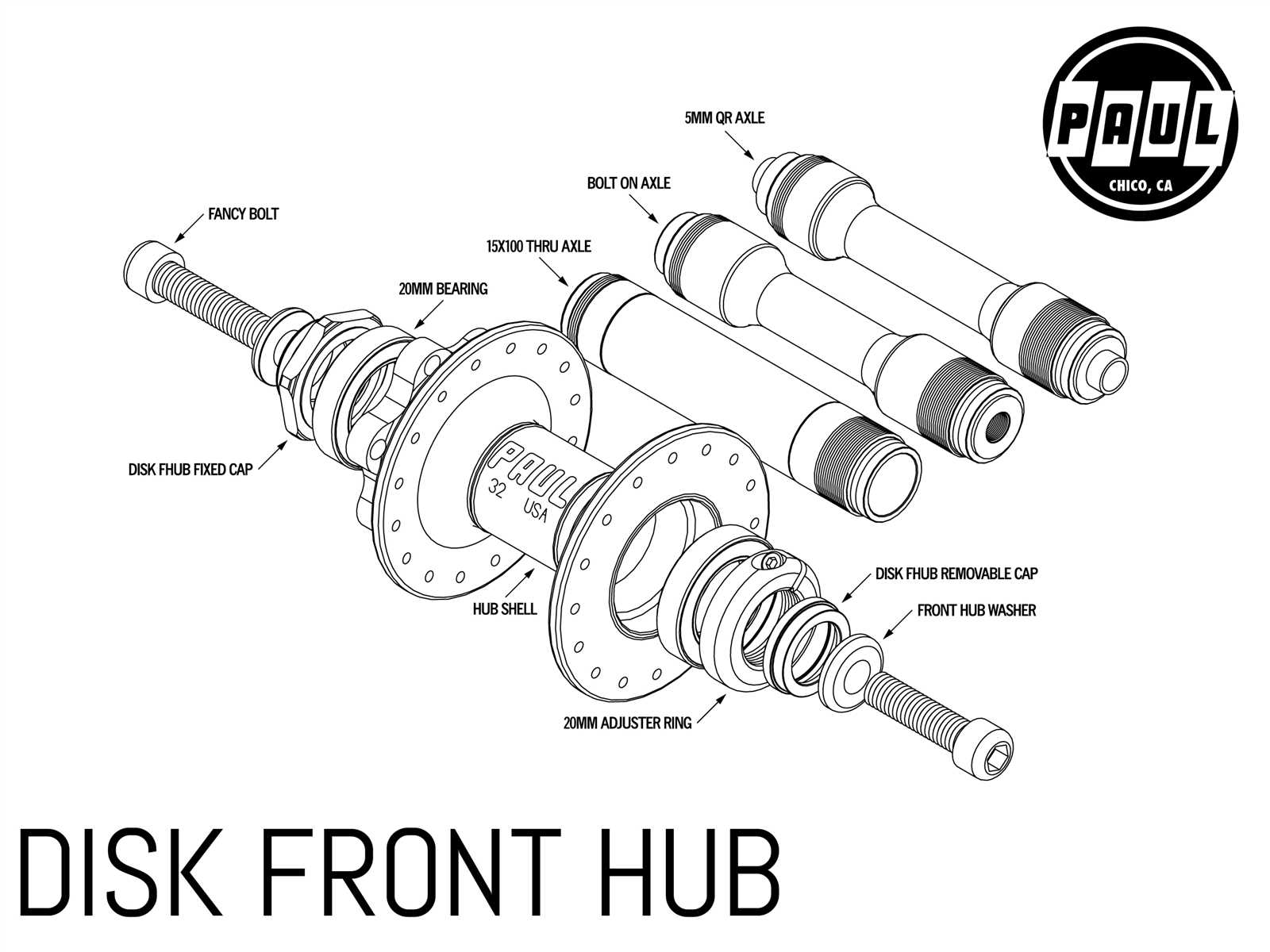

Types of Bike Hubs Explained

Understanding the various types of wheel mechanisms can significantly enhance your riding experience. Each design serves a unique purpose, affecting performance, maintenance, and overall ride quality. Let’s explore the most common variations and their characteristics.

Types of Mechanisms

- Quick Release: This design allows for easy wheel removal and installation, ideal for casual cyclists.

- Thru-Axle: Common in modern models, offering increased stability and strength, particularly for mountain biking.

- Single Speed: Simplifies maintenance with fewer components, perfect for urban commuting.

- Freehub: Facilitates multiple gear ratios, enhancing versatility for varied terrain.

Choosing the Right Mechanism

Selecting the appropriate design depends on your riding style and preferences. Consider factors such as terrain, maintenance ease, and performance to make the ultimate choice.

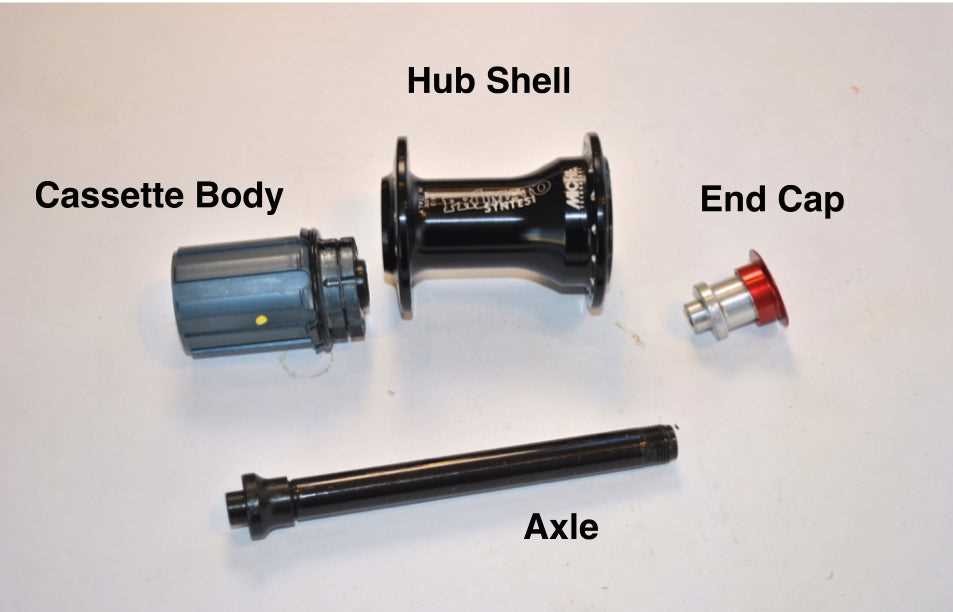

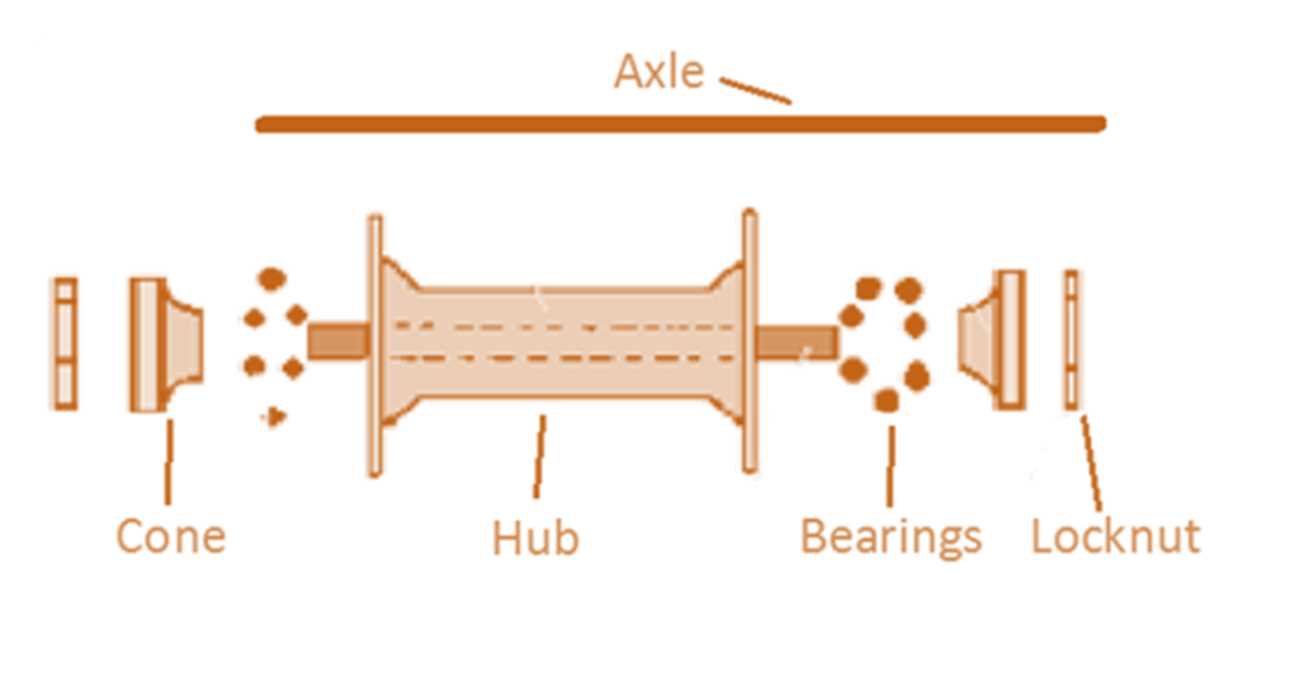

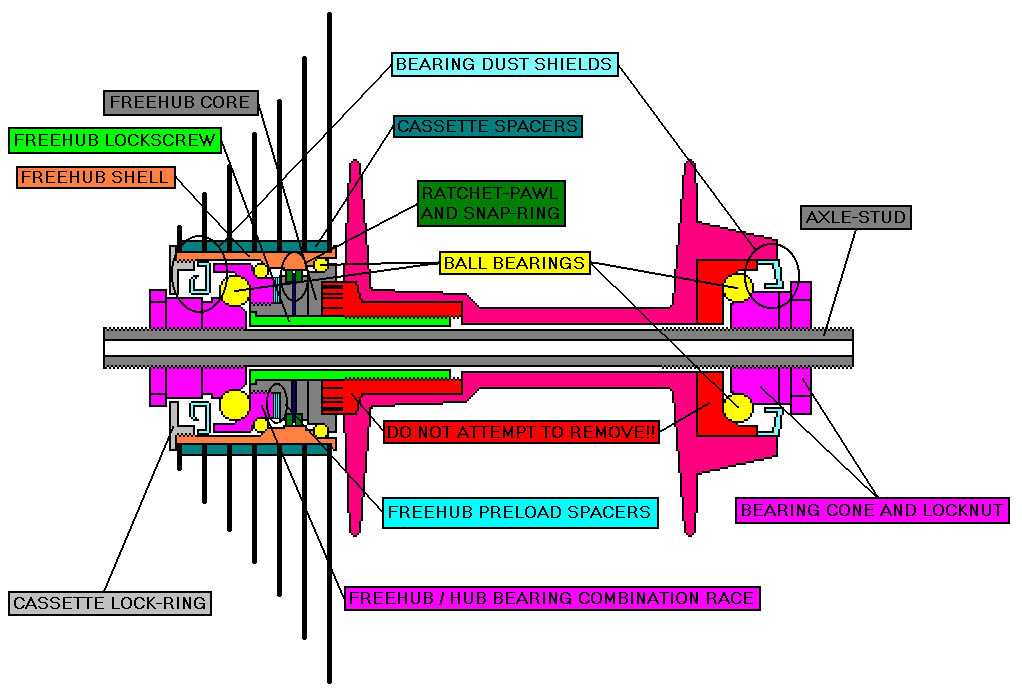

Key Parts of a Bicycle Hub

The central mechanism of a two-wheeled vehicle plays a crucial role in its overall performance. Understanding the essential components that contribute to its functionality can greatly enhance your riding experience. Each element is designed to work in harmony, ensuring smooth motion and stability.

Axle is the core element that supports the wheel and allows it to rotate freely. It connects to the frame and is critical for maintaining alignment.

Bearings facilitate smooth rotation by reducing friction between moving parts. These small yet vital elements are essential for efficient performance, especially under load.

Shell encases the internal components, providing protection and structural integrity. Its design can vary, influencing both aesthetics and functionality.

Freehub is a key feature in modern setups, allowing for the engagement of the drivetrain. This mechanism enables the rider to coast without pedaling, a significant advantage in various terrains.

Spokes connect the wheel rim to the core assembly, distributing forces evenly and providing necessary strength. Their configuration is important for overall durability and responsiveness.

Nipples are small components that adjust spoke tension, crucial for wheel trueness. Properly tuned, they enhance the ride quality and extend the lifespan of the entire system.

Each of these components plays a unique role in the mechanics of the vehicle, working together to create a reliable and efficient mode of transportation.

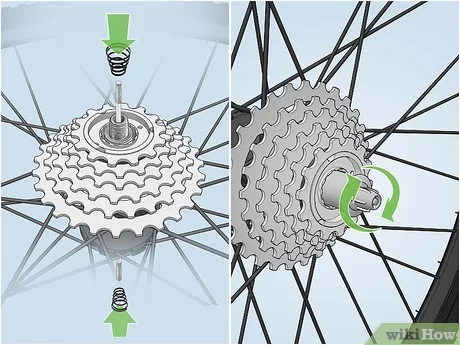

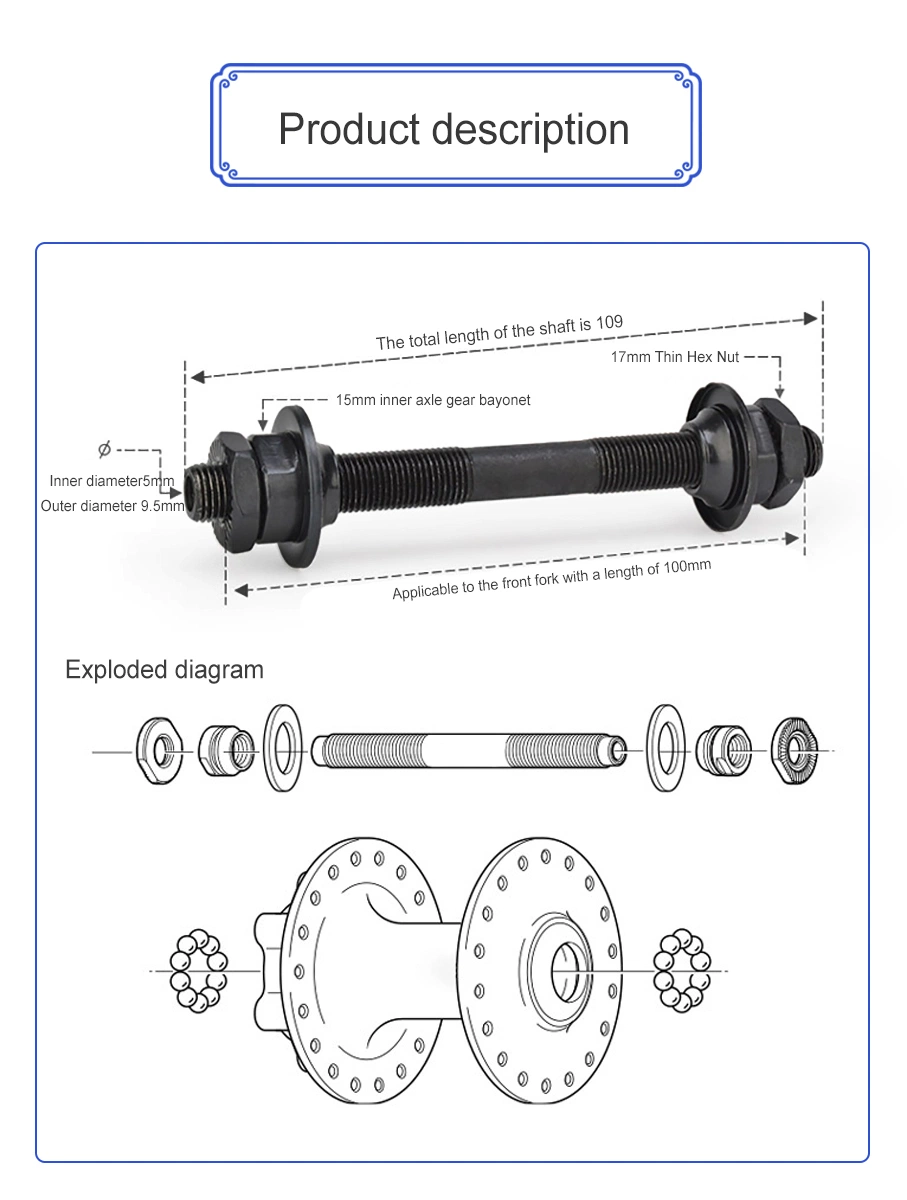

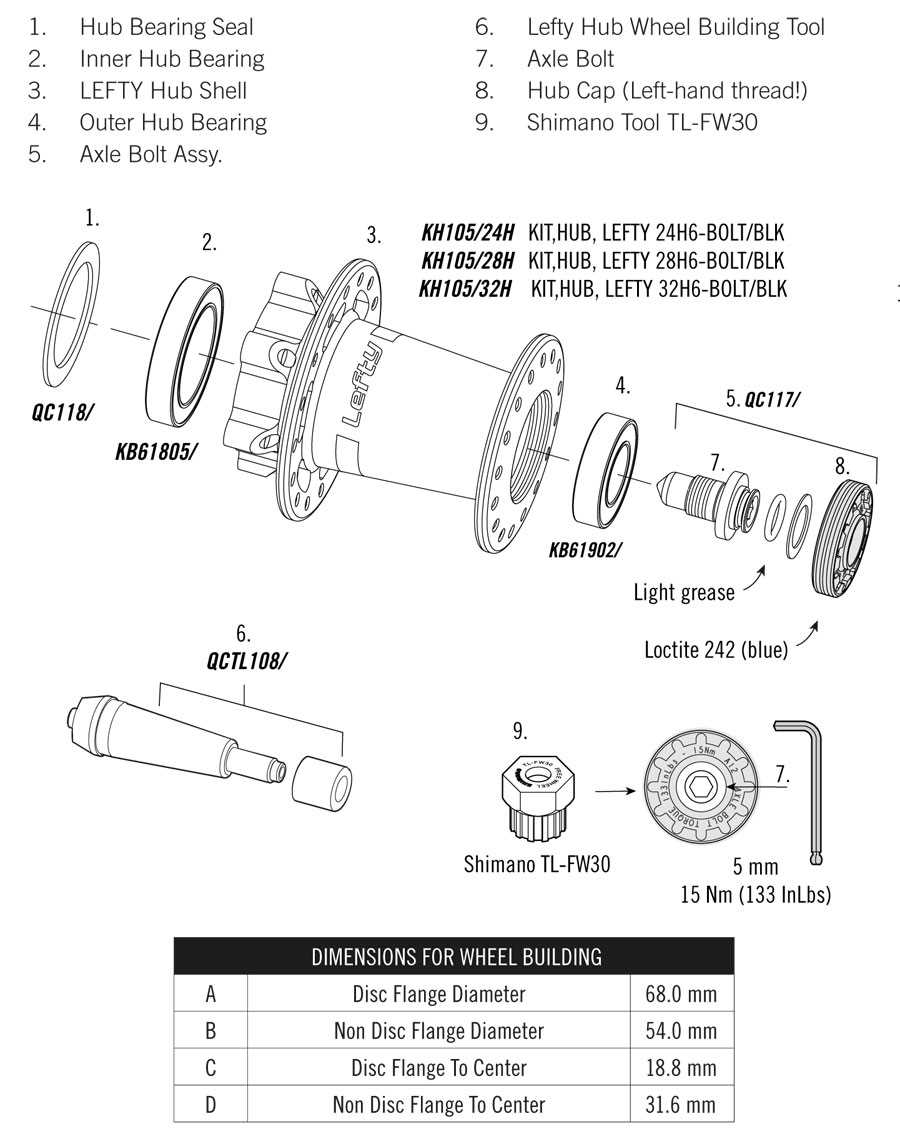

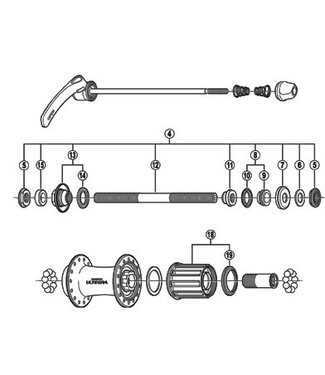

How to Read Hub Diagrams

Understanding the layout of a wheel assembly can significantly enhance your maintenance and repair skills. Familiarizing yourself with the visual representations of components allows for more efficient troubleshooting and assembly. Each section of the illustration conveys crucial information about the individual elements and their relationships within the system.

Begin by identifying the main elements shown in the representation. Look for labels that denote each component, such as bearings, spacers, and shells. These identifiers provide clarity on what each piece does and how it interacts with others. Pay attention to arrows and lines that indicate movement or connection, as they can reveal how the system functions as a whole.

Next, observe the numerical references often included in these visuals. They typically correspond to a key or legend that explains the components in greater detail. This can guide you in locating replacement parts or understanding assembly procedures. Take note of any measurements provided, as they are essential for ensuring compatibility during repairs or upgrades.

Finally, practice reading various illustrations to become more comfortable with different styles and formats. Each representation may vary, but with time, you will develop an intuition for interpreting the information effectively, making you a more proficient technician.

Importance of Proper Hub Maintenance

Ensuring the longevity and optimal performance of a cycling component requires regular upkeep and attention. Neglecting this essential aspect can lead to various issues, ultimately affecting the overall experience and safety of the ride.

Benefits of Regular Maintenance

- Enhances Performance: Regular checks improve efficiency and responsiveness.

- Increases Longevity: Timely interventions can prevent premature wear and tear.

- Ensures Safety: Proper care reduces the risk of failures during use.

Key Maintenance Practices

- Regular Inspection: Frequently examine for signs of damage or wear.

- Lubrication: Keep moving parts well-lubricated to ensure smooth operation.

- Tightening: Regularly check and tighten all fasteners to prevent loosening.

Common Issues with Bike Hubs

Understanding typical problems associated with wheel assemblies can enhance overall performance and longevity. Below are some frequently encountered challenges and their implications.

- Noisy Operation: Unusual sounds can indicate wear or improper lubrication.

- Difficulty in Spinning: Resistance during rotation often points to internal friction or debris accumulation.

- Play in the Axle: Excessive movement can lead to misalignment and affect handling.

- Sealing Issues: Water or dirt ingress can compromise internal components, leading to failure.

Regular maintenance can help mitigate these issues and ensure smooth functionality.

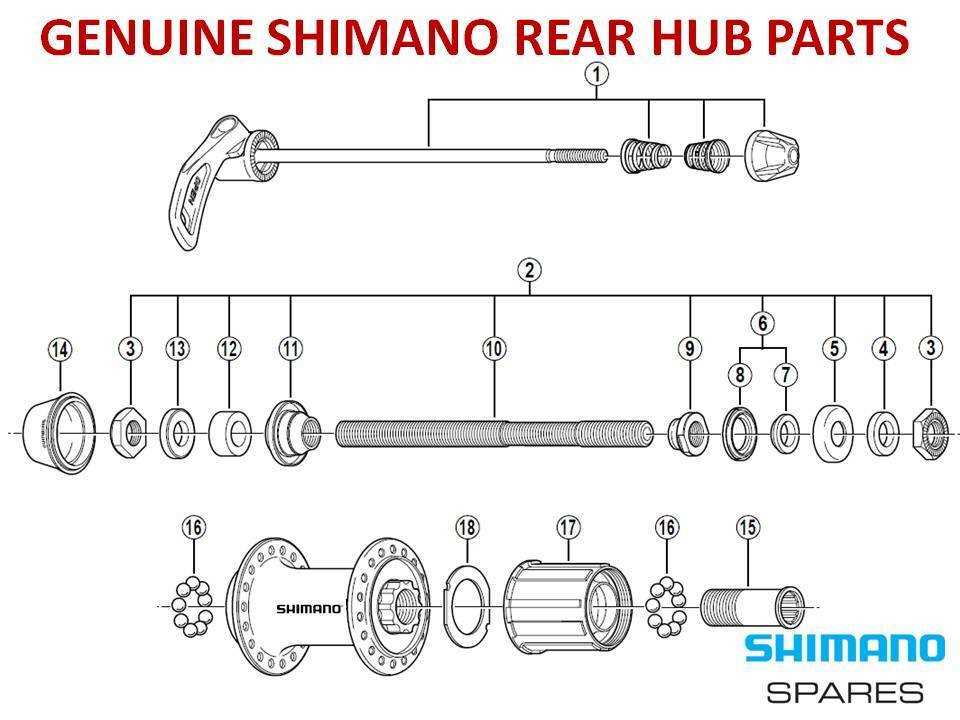

Replacing Hub Parts: A Guide

Maintaining the essential components of your wheel assembly is crucial for optimal performance. This guide offers insight into the process of replacing worn or damaged elements to ensure a smooth and efficient ride.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Bearings | Rough rotation, noise | Clean thoroughly before installing new ones |

| Axle | Bending, scoring | Ensure proper alignment when replacing |

| Seal | Leakage, wear | Check for compatibility with existing assembly |

By understanding the key indicators of deterioration and following the appropriate steps for replacement, you can significantly enhance the longevity and performance of your ride.

Choosing the Right Hub for You

Selecting the ideal centerpiece for your wheel assembly is crucial for performance and riding experience. With various options available, understanding your specific needs will guide you to the best choice.

Consider Your Riding Style

- Casual commuting

- Mountain trails

- Road racing

- Freestyle tricks

Key Features to Evaluate

- Weight: Lighter options enhance speed.

- Durability: Choose materials that withstand wear.

- Engagement: Look for responsive engagement for better control.

- Compatibility: Ensure it fits your frame and wheel specifications.

By assessing these factors, you can delve deeper into the features that matter most, leading to an ultimate selection tailored to your riding aspirations.

Hub Design Variations in Bikes

Different designs serve distinct purposes and enhance performance, offering riders a variety of options to suit their needs. These variations can significantly influence handling, durability, and maintenance, making it essential to understand their unique features.

Conventional designs typically feature a simple structure, promoting ease of use and maintenance. However, advanced configurations integrate technologies for better aerodynamics and weight distribution, appealing to competitive cyclists.

Disc systems are gaining popularity due to their superior stopping power, especially in wet conditions, while traditional rim systems remain favored for their lightweight characteristics and simplicity. Each style has its pros and cons, tailored to different riding experiences.

Additionally, customized models allow for personal adjustments, enhancing comfort and performance. Understanding these variations can ultimately help riders make informed decisions based on their individual preferences and riding conditions.

Tools Needed for Hub Repairs

When it comes to maintaining and fixing the central mechanism of your two-wheeled companion, having the right instruments at your disposal is crucial. Proper tools not only streamline the process but also ensure that repairs are executed efficiently and effectively. Below is a list of essential implements you will need for successful maintenance.

- Wrenches: A set of adjustable and fixed wrenches will help in loosening and tightening various components.

- Socket Set: Different sizes of sockets are vital for accessing hard-to-reach fasteners.

- Torque Wrench: This tool ensures that you apply the correct amount of force when tightening screws, preventing damage.

- Screwdrivers: Both flathead and Phillips varieties are necessary for handling screws of different types.

- Plier Set: Needle-nose and standard pliers will assist in gripping and bending small components.

- Cleaning Supplies: Rags, brushes, and degreasers will help keep the area clean and free from debris.

- Lubricants: A good quality grease or oil is essential for ensuring smooth operation of moving parts.

- Spoke Wrench: This tool is crucial for adjusting and aligning the spokes correctly.

- Measuring Tools: Calipers and rulers will aid in ensuring precise measurements during repairs.

Having these tools on hand will empower you to tackle maintenance tasks with confidence, ensuring your ride remains in optimal condition.

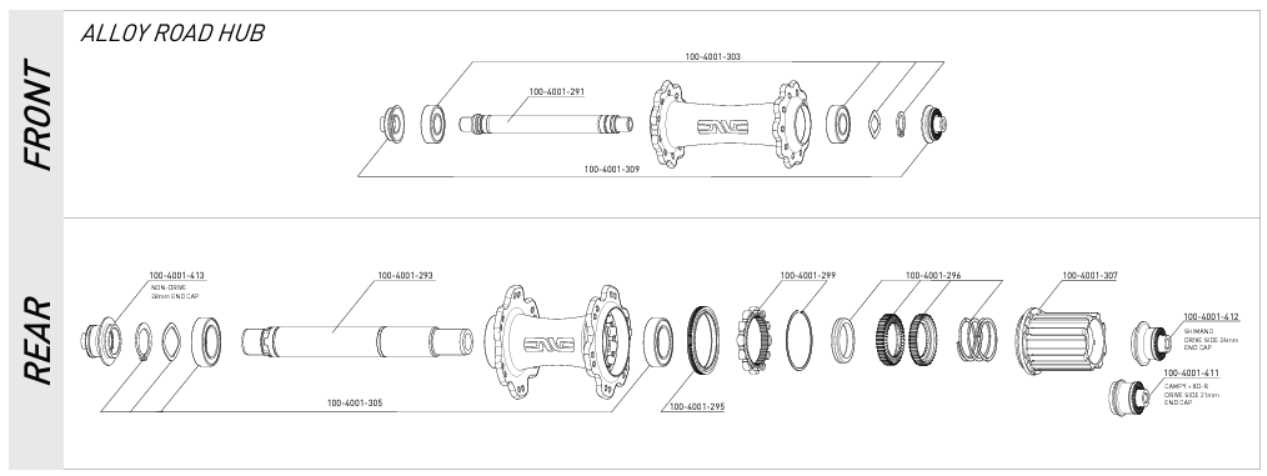

Differences Between Front and Rear Hubs

The variations between the two types of wheel assemblies play a crucial role in the overall performance and handling of a cycle. Understanding these distinctions can greatly enhance the riding experience and maintenance knowledge for enthusiasts.

| Aspect | Front Assembly | Rear Assembly |

|---|---|---|

| Functionality | Steering and stability | Power transfer and braking |

| Weight Distribution | Lighter and less complex | Heavier due to additional components |

| Components | Fewer parts, simpler design | More intricate with gears and mechanisms |

| Maintenance | Easier to service | Requires more attention due to complexity |

Impact of Hub Quality on Performance

The quality of rotational components plays a crucial role in overall cycling efficiency and experience. Subpar manufacturing can lead to increased friction, decreased responsiveness, and a less enjoyable ride. In contrast, high-quality construction enhances smoothness, durability, and reliability, significantly influencing performance during various conditions.

Material choice is a key factor affecting the integrity and functionality of these components. Lightweight and robust materials contribute to a lower weight while ensuring longevity. Conversely, inferior materials can compromise strength and lead to premature wear, negatively impacting speed and control.

Precision engineering also greatly influences how these mechanisms perform. Tightly controlled tolerances and meticulous assembly ensure optimal engagement and reduce slippage or play. Well-designed rotational elements provide a direct connection between the rider’s input and the ground, enhancing responsiveness and handling.

In conclusion, investing in high-quality rotational mechanisms is essential for any serious enthusiast. It not only improves immediate performance but also enhances the overall cycling experience, leading to greater enjoyment and satisfaction on every ride.

Upgrading Your Bike Hub System

Enhancing the rotational components of your two-wheeled vehicle can significantly improve performance and efficiency. This process involves evaluating existing mechanisms and considering advancements that cater to your riding style, whether it be casual, competitive, or adventurous.

Benefits of Upgrading

- Improved responsiveness and speed

- Increased durability for long-lasting use

- Better compatibility with modern accessories

Key Considerations

- Assess your current setup for potential weaknesses.

- Research materials and designs that enhance performance.

- Consult experts or experienced riders for recommendations.

By focusing on these aspects, you can delve into the ultimate enhancements that suit your needs and elevate your riding experience.