The efficient operation of a winter clearing accessory is crucial for maintaining accessibility during harsh weather conditions. This section delves into the various elements that constitute a specific model of a winter maintenance tool, providing insights into its assembly and functionality. A comprehensive understanding of these components enables users to optimize performance and ensure longevity.

In exploring the intricate design, we will identify the essential elements involved in the mechanism, illustrating how each piece contributes to the overall efficiency of the equipment. A well-structured overview of the individual components aids in troubleshooting and replacement, allowing users to effectively manage their winter clearing tasks.

Moreover, recognizing the interconnected nature of these components enhances the user’s capability to perform routine maintenance and repairs. This knowledge not only fosters a deeper appreciation for the machinery but also empowers operators to maintain peak performance throughout the winter season.

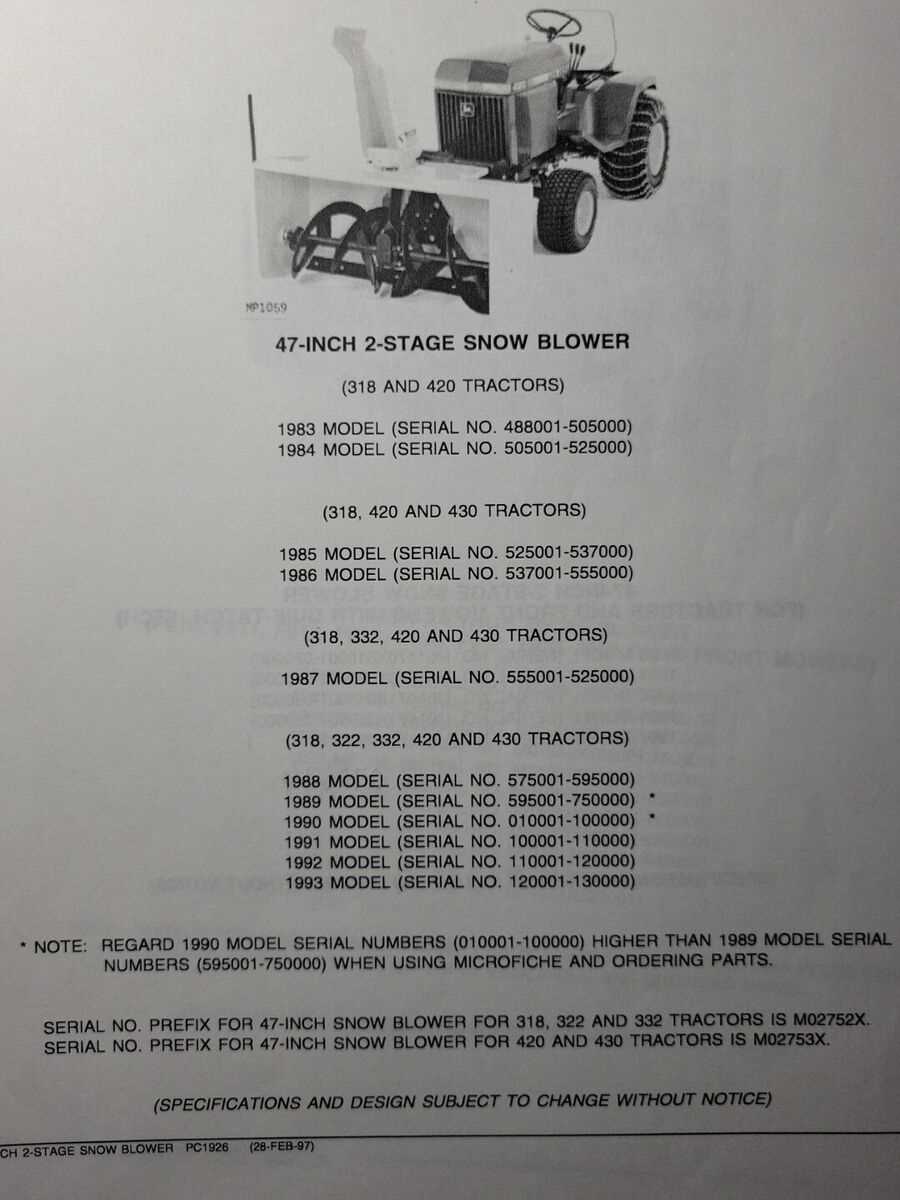

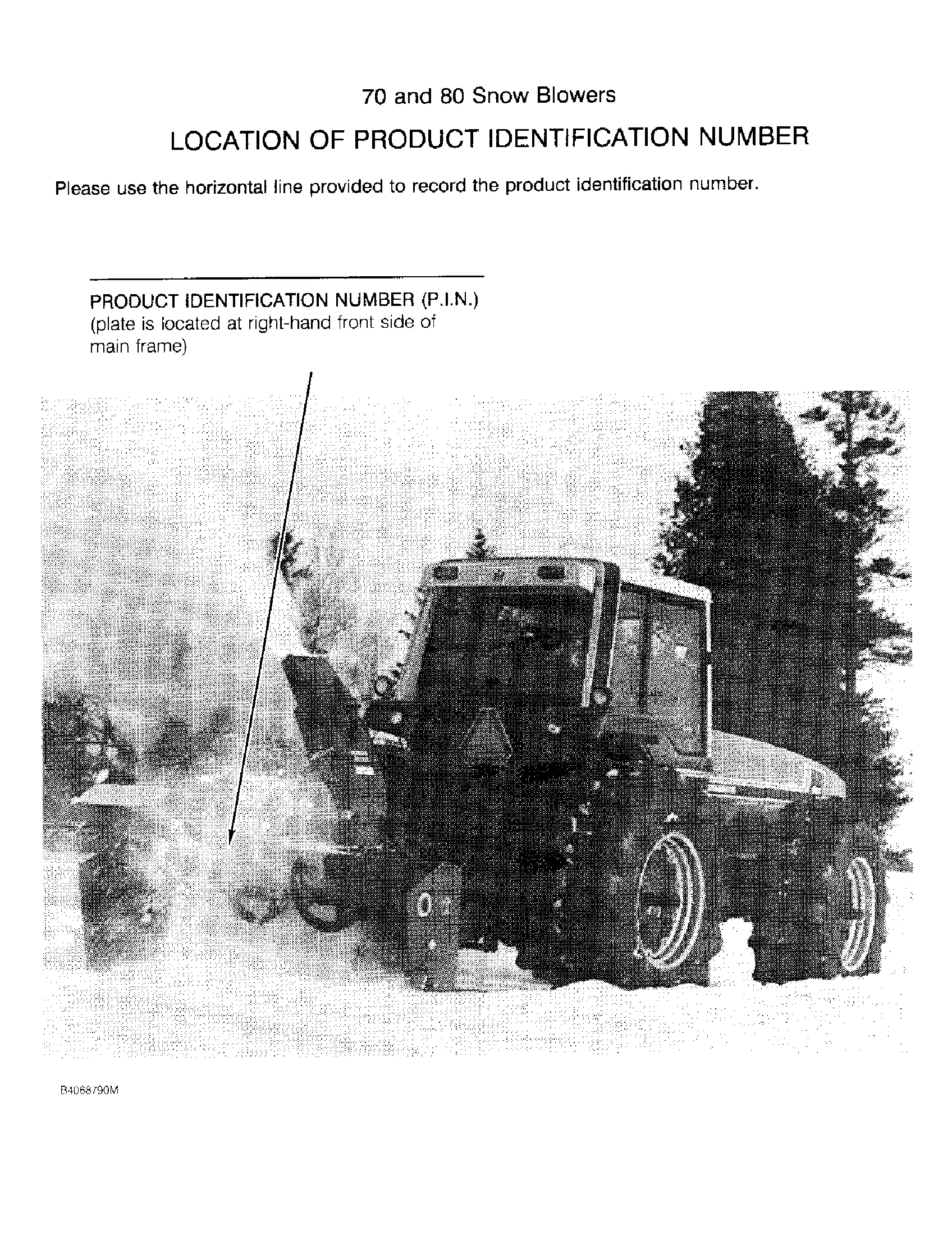

Overview of John Deere Snow Blowers

This section provides a comprehensive look at the equipment designed for efficient winter clearing, emphasizing their functionality, design, and essential features. Such machinery plays a crucial role in maintaining accessibility and safety during harsh weather conditions, showcasing a blend of power and innovation.

Key Features and Benefits

The equipment is engineered to tackle various snow conditions, offering enhanced maneuverability and performance. Features like adjustable height settings and robust construction ensure durability and adaptability to different terrains. Users benefit from reduced physical strain, making snow removal tasks more manageable and efficient.

Maintenance and Care

Regular upkeep is vital for optimal performance and longevity. Routine inspections and timely replacements of essential components are recommended to prevent operational issues. Keeping the machinery in top condition enhances efficiency, allowing for consistent performance throughout the winter season.

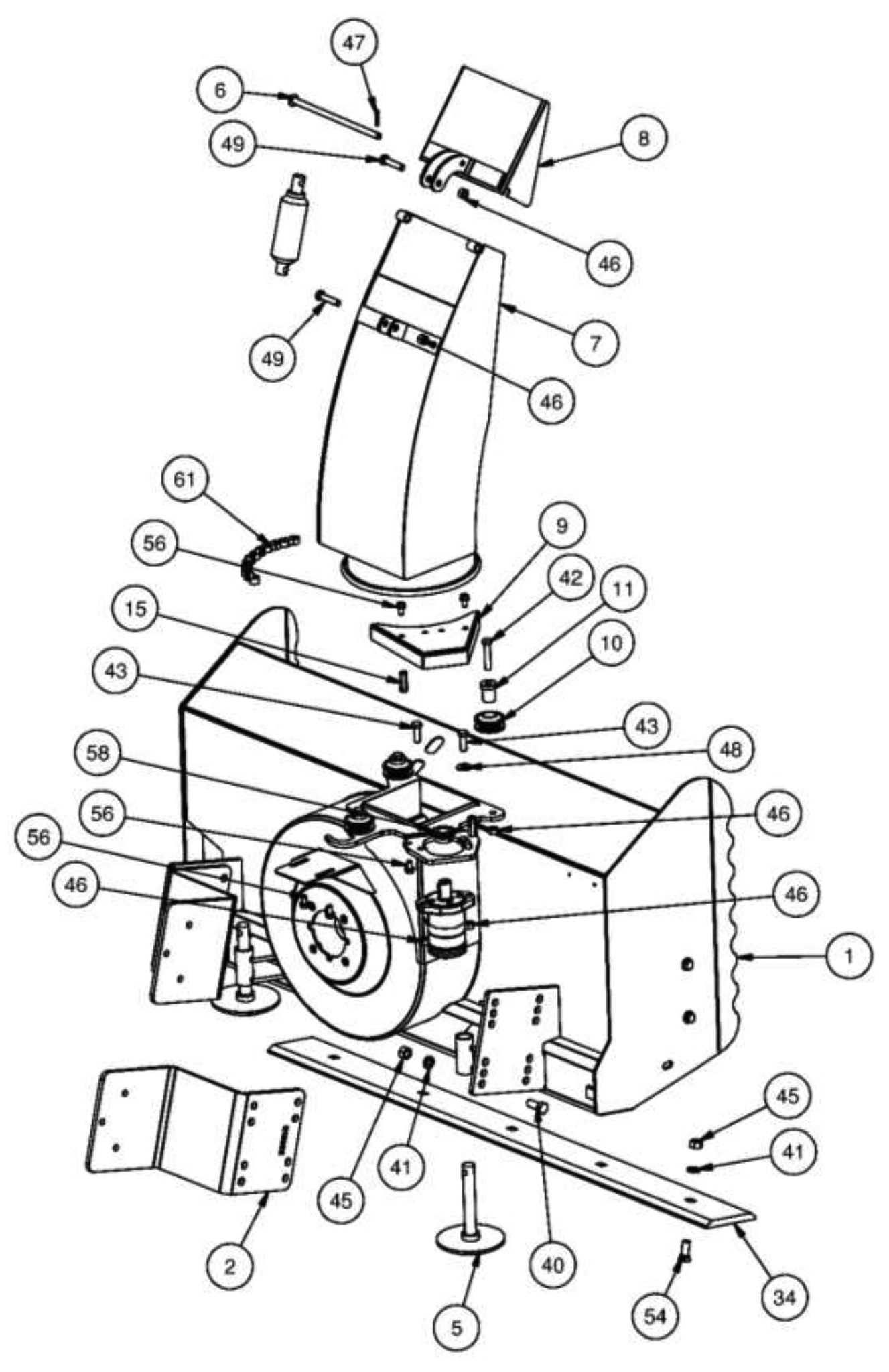

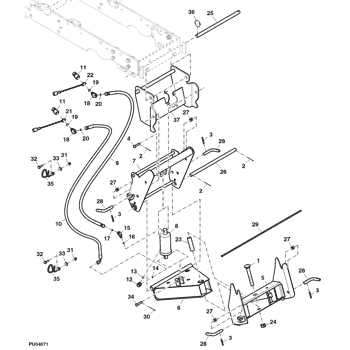

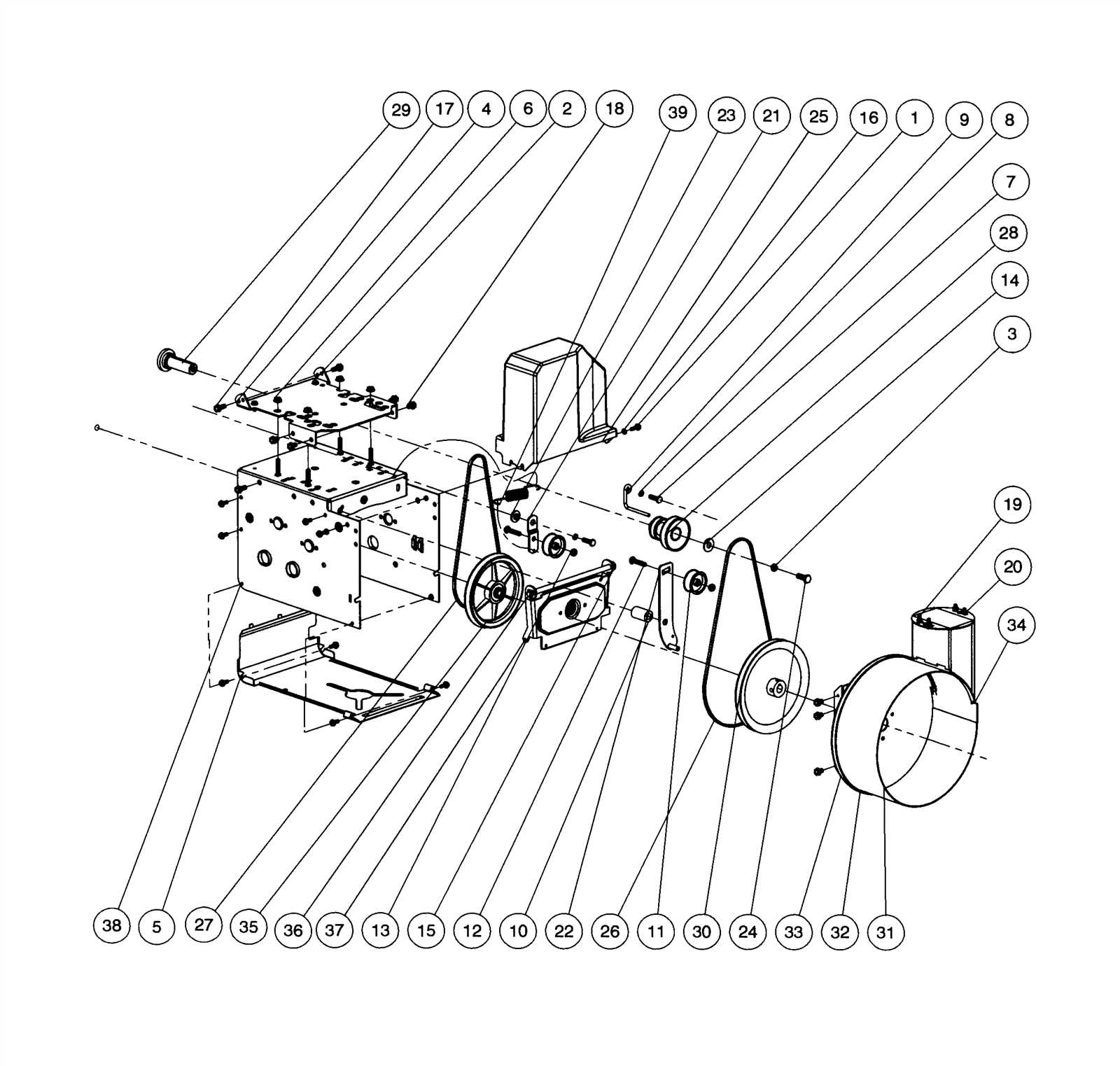

Key Components of 54-Inch Model

This section explores the essential elements of a specific model designed for winter clearing. Understanding these vital components enhances operational efficiency and maintenance practices.

Main Functional Elements

The primary parts include a robust housing that protects internal mechanisms and a powerful mechanism responsible for the effective displacement of accumulated material. These features work in harmony to ensure smooth performance in various conditions.

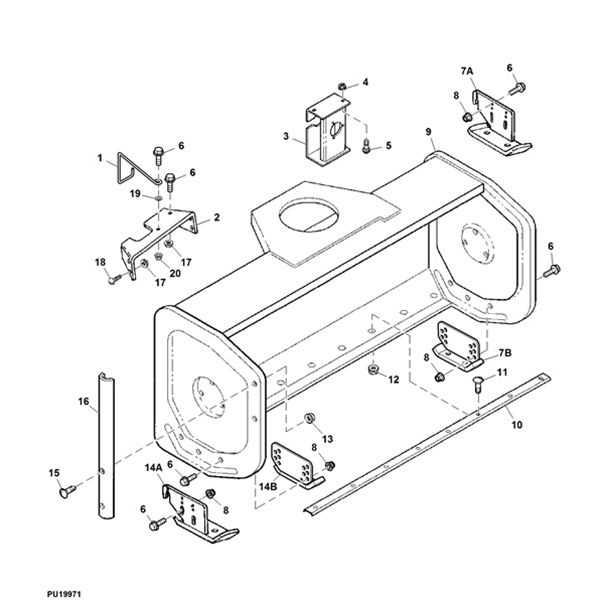

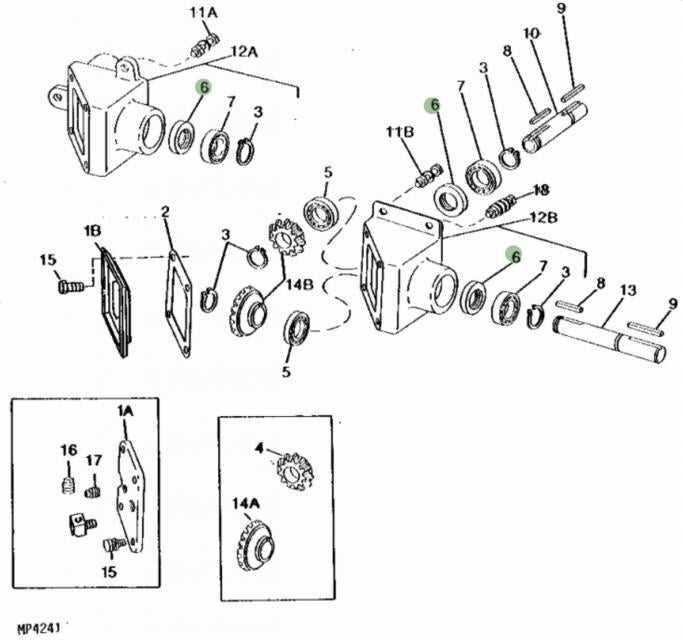

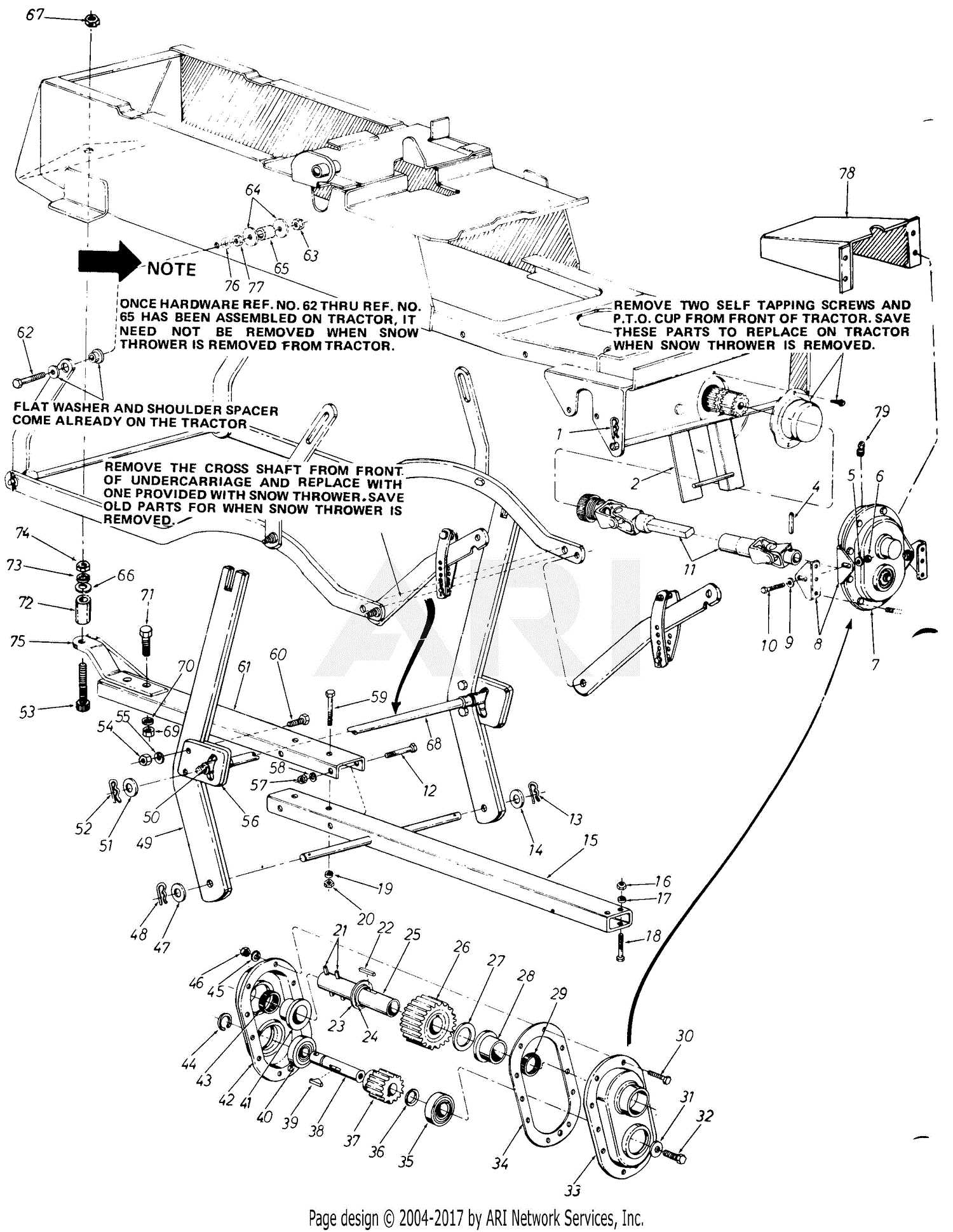

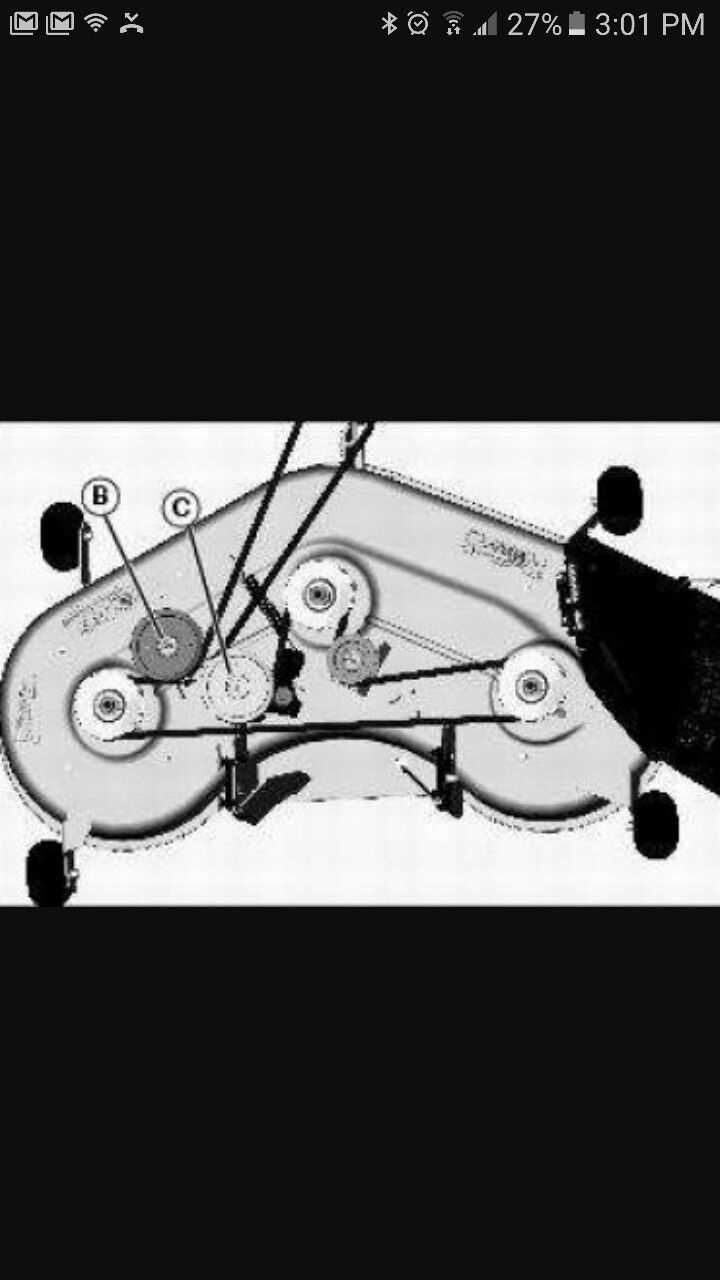

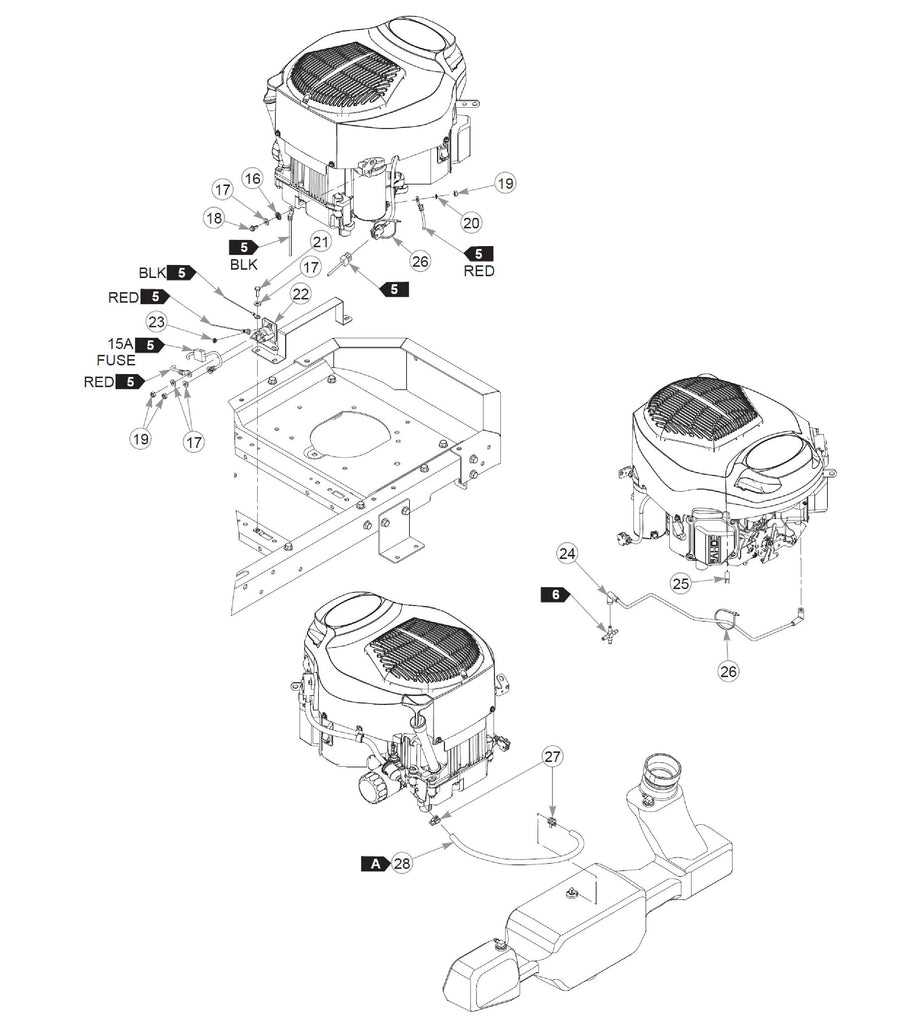

Understanding the Parts Diagram

The visual representation of components is essential for effective maintenance and repair of machinery. It serves as a guide to identify each element and understand its function within the assembly. Familiarizing oneself with this visual aid can greatly enhance troubleshooting efforts and facilitate the ordering of necessary replacements.

Key Elements to Identify

- Labels: Each component typically has a label indicating its name or identification number.

- Connections: Understanding how components connect and interact is crucial for assembly and disassembly.

- Exploded Views: These views provide a clear picture of how parts fit together and can highlight any missing elements.

Benefits of Utilizing the Visual Representation

- Improved accuracy in identifying required replacements.

- Enhanced ability to perform repairs independently.

- Greater understanding of the overall functionality of the machinery.

Common Issues and Troubleshooting Tips

When operating equipment designed for clearing winter precipitation, encountering problems is not uncommon. Understanding these challenges and having a set of troubleshooting strategies can enhance performance and ensure reliability. Below are some frequently faced issues along with practical solutions to assist in maintaining optimal functionality.

Frequent Challenges

- Difficulty in starting the machine

- Inadequate clearing performance

- Unusual noises during operation

- Blockages or jamming in the mechanism

Troubleshooting Suggestions

-

Starting Issues:

- Check the fuel level and ensure it is fresh.

- Inspect the battery connections for corrosion or looseness.

- Examine the ignition system components for faults.

-

Poor Performance:

- Adjust the speed settings according to the surface conditions.

- Ensure that the auger and impeller are free from debris.

- Regularly sharpen the blades to maintain efficiency.

-

Noisy Operation:

- Check for loose screws and bolts that may cause vibrations.

- Inspect moving parts for wear and replace if necessary.

- Lubricate any parts that require it to reduce friction.

-

Blockages:

- Clear any accumulated material in the chute regularly.

- Make sure to operate at the recommended speed to prevent clogging.

- Use a tool designed for clearing blockages safely.

Maintenance Practices for Longevity

Ensuring the durability and efficiency of equipment requires a systematic approach to upkeep. Regular maintenance not only extends the life of your machine but also enhances its performance, reducing the risk of unexpected breakdowns. By following essential practices, users can maintain their machinery in optimal condition, resulting in smoother operations and less frequent repairs.

Here are key practices to consider:

- Regular Inspections: Conduct thorough checks on all components to identify wear and tear early.

- Lubrication: Keep moving parts well-lubricated to minimize friction and prevent rust.

- Cleaning: Remove debris and dirt accumulation, which can affect performance and lead to damage.

- Component Replacement: Replace worn or damaged parts promptly to ensure safe and efficient operation.

- Storage: Store equipment in a dry, sheltered location to protect it from harsh weather conditions.

Implementing these practices not only promotes longevity but also ensures that your machinery remains reliable throughout its service life.

Replacement Parts and Accessories

Maintaining optimal performance of outdoor equipment is crucial for effective operation during challenging weather conditions. A range of components and supplementary items are available to ensure your machine runs smoothly and efficiently. This section outlines various options for enhancing functionality and prolonging the lifespan of your equipment.

- High-quality replacement components: These include essential mechanisms that may wear down over time, ensuring your machinery operates at peak efficiency.

- Additional attachments: Consider investing in various accessories that can expand the capabilities of your machine, providing greater versatility for different tasks.

- Maintenance kits: These kits often contain all necessary items for routine servicing, helping you keep your equipment in prime condition.

- Wear-resistant accessories: Look for enhancements designed to withstand harsh conditions, extending the durability and performance of your unit.

When selecting components and accessories, prioritize compatibility with your specific model. Regular maintenance, combined with the right enhancements, can lead to significant improvements in performance and longevity.

Identifying Specific Part Numbers

When it comes to maintaining and repairing your equipment, recognizing the exact identifiers for each component is crucial. Understanding these designations helps ensure that you select the right items for your needs, enhancing functionality and longevity. This process not only streamlines repairs but also minimizes the chances of ordering incorrect replacements.

Importance of Accurate Identification

Accurate identification of components plays a significant role in efficient equipment management. By using the correct identifiers, users can avoid delays caused by miscommunication or misordering. Furthermore, proper selection supports optimal performance, preventing potential issues down the line.

Where to Find Part Identifiers

To locate the identifiers, consult the manufacturer’s resources, including manuals and official websites. Additionally, many online forums and communities dedicated to machinery provide valuable insights from experienced users. Utilizing these sources can lead to a deeper understanding of component specifications and compatibility.

Assembly Instructions for Snow Blower

This section provides a comprehensive guide for putting together the equipment designed for clearing winter precipitation effectively. Proper assembly ensures optimal performance and longevity of the machine. Following these instructions step-by-step will help you achieve a successful setup.

Begin by gathering all necessary components and tools. Ensure you have a clean workspace to organize the pieces systematically. Familiarize yourself with the various elements included in the kit, as this will aid in identifying where each component fits during assembly.

Start with the base structure, attaching the main frame securely. Use the specified fasteners and ensure they are tightened adequately to prevent any loosening during operation. Next, assemble the mechanism that facilitates the movement of the clearing equipment. Pay close attention to the orientation of each part as indicated in the accompanying visual reference.

Once the primary components are in place, proceed to connect the additional features such as the control system and safety mechanisms. Verify that all connections are secure and functioning as intended. After completing the assembly, conduct a thorough inspection to ensure everything is correctly installed.

Finally, familiarize yourself with the operation procedures before use. Review the instructions provided for maintenance to keep the equipment in peak condition throughout its service life. Proper assembly and regular upkeep will contribute to efficient performance during the winter season.

Safety Considerations During Operation

When operating heavy machinery designed for clearing surfaces during winter conditions, safety should always be a top priority. Proper precautions and awareness can prevent accidents and ensure a smooth and efficient operation. This section outlines essential safety measures that should be observed to protect the operator and others in the vicinity.

Pre-Operation Checks

Before engaging in any task, it is crucial to conduct thorough inspections of the equipment. Ensure that all components are functioning correctly and that there are no visible damages or leaks. Check fluid levels and ensure that safety features are operational. Taking these steps helps to mitigate risks associated with equipment failure.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective gear is vital. Operators should don sturdy footwear with good traction to prevent slips. Additionally, wearing gloves can protect hands from cold and potential injuries, while high-visibility clothing enhances visibility in low-light conditions. Furthermore, using ear protection may be necessary if the machinery produces significant noise levels.

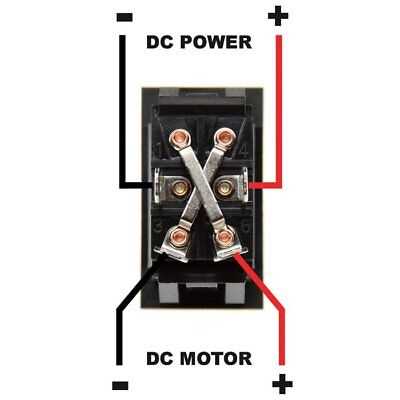

Upgrading Features and Performance

Enhancing the capabilities and efficiency of outdoor machinery can significantly improve its effectiveness in challenging conditions. By integrating advanced components and innovative technologies, users can optimize their equipment for better functionality and user experience. This section explores various options for boosting both features and performance, ensuring reliable operation during demanding tasks.

Enhanced Efficiency through Modern Components

Investing in state-of-the-art accessories can lead to notable improvements in operational efficiency. For instance, incorporating high-performance motors or improved drive systems can enhance productivity while reducing energy consumption. Additionally, upgrading the cutting mechanism can facilitate better handling of diverse terrains, making it easier to navigate through tougher materials.

Technological Advancements for Improved User Experience

Modern innovations offer features that enhance user interaction and overall satisfaction. Implementing intuitive controls and user-friendly interfaces allows operators to manage functions effortlessly. Furthermore, adding smart technology, such as automated monitoring systems, can provide real-time feedback, ensuring optimal performance and timely maintenance reminders. These enhancements not only make the machinery more efficient but also contribute to a smoother operation experience.

Where to Purchase Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Numerous options are available to ensure you acquire high-quality substitutes that fit your needs. Understanding your purchasing avenues can save time and provide peace of mind.

Authorized Dealers: One of the best places to source replacement items is through authorized dealerships. These retailers offer genuine components that guarantee compatibility and reliability. They often have knowledgeable staff who can assist in identifying the exact pieces required for your machine.

Online Retailers: The internet is an excellent resource for finding a wide range of alternatives. Various online marketplaces and specialized websites provide detailed descriptions and customer reviews. This enables you to compare prices and read feedback from other users, ensuring a well-informed decision.

Local Hardware Stores: Don’t overlook nearby hardware shops, as they often stock commonly needed components. These stores can provide immediate access without the wait for shipping, making them a convenient option for urgent repairs.

Manufacturer’s Website: Many manufacturers offer direct sales through their websites. Visiting the official site allows you to browse their catalog and order the required items directly, often with the benefit of warranties and return policies.

Online Forums and Community Groups: Engaging with online communities can be beneficial. Enthusiasts and experts frequently share sources and recommendations for where to find specific components. These forums can also provide insights into aftermarket options that might be more affordable.

Customer Reviews and User Experiences

This section highlights the feedback and impressions from users regarding their experiences with the equipment in question. By examining various perspectives, potential buyers can gain valuable insights into its performance, reliability, and overall satisfaction.

General Impressions

- Many users appreciate the robust construction, which contributes to longevity and durability.

- Several reviews mention effective operation even in challenging weather conditions, enhancing user confidence.

- The ease of assembly and setup is frequently praised, making it accessible for those new to such machinery.

Performance Feedback

- Users report that the equipment efficiently clears large areas, saving time and effort.

- Many find the adjustable features highly beneficial, allowing customization based on specific needs.

- Some feedback highlights occasional maintenance challenges, suggesting a need for regular checks to ensure optimal functionality.