When it comes to maintenance and repair of electrical equipment, having a comprehensive visual representation of the internal and external components is essential. Such illustrations serve as a valuable resource for both professionals and DIY enthusiasts, facilitating easier identification and troubleshooting of issues. Whether you are looking to replace a malfunctioning piece or simply wish to understand the assembly better, a clear and detailed layout can make all the difference.

These visual guides not only enhance comprehension but also streamline the repair process by providing an organized overview of each element’s placement and function. Knowing the configuration of various parts can help users avoid common pitfalls during disassembly and reassembly, ensuring that tools are restored to optimal working condition. Furthermore, these resources are instrumental in ordering the correct replacements, thereby minimizing downtime.

In this article, we will delve into the specifics of these useful illustrations, exploring their significance in the context of equipment maintenance. By examining the intricacies of component arrangements, we aim to empower users with the knowledge needed to effectively navigate repairs and enhancements, ultimately extending the lifespan of their devices.

Understanding Bosch CSG15 Components

Gaining insight into the various elements of a specific power tool enhances both its maintenance and operational efficiency. Each component plays a vital role in ensuring that the device functions seamlessly. By exploring these essential parts, users can better appreciate their significance and learn how to troubleshoot potential issues.

Key Elements of the Tool

Among the most critical components are the motor and the housing, which work together to provide the necessary power and protection. The motor is the heart of the device, converting electrical energy into mechanical force. Meanwhile, the housing serves as a protective shell, shielding internal parts from damage while offering a comfortable grip for users.

Additional Components and Their Functions

Moreover, various attachments and accessories are designed to enhance functionality. Blades are essential for making precise cuts, while guards ensure safety during operation. Understanding how these additional elements interact with the main structure allows for more effective usage and maintenance practices.

Key Features of Bosch CSG15

This model stands out due to its innovative design and powerful performance. The equipment is crafted to enhance user experience and efficiency, making it a preferred choice for professionals and DIY enthusiasts alike. Various functionalities contribute to its versatility, ensuring it can handle a wide range of tasks effectively.

Powerful Performance

Equipped with a robust motor, this tool delivers exceptional power, enabling it to tackle challenging jobs with ease. The high-speed operation allows for quick cutting through various materials, making it ideal for both detailed and extensive projects.

User-Friendly Design

The ergonomic structure of this device ensures comfortable handling, reducing fatigue during extended use. Features such as adjustable settings and easy blade changes facilitate seamless operation, catering to the needs of users at different skill levels.

Common Applications of CSG15 Model

This versatile tool is widely utilized across various industries, offering solutions for both professional and DIY tasks. Its design caters to a range of cutting needs, making it an indispensable asset in workshops and construction sites.

Here are some of the primary uses of this model:

- Woodworking: Ideal for precision cutting of various wood types, it excels in creating intricate designs and ensuring clean edges.

- Metal Fabrication: Suitable for cutting through thin metal sheets, this tool is often employed in automotive repair and metalworking projects.

- Construction: Frequently used for framing and structural tasks, it helps in achieving accurate cuts for various building materials.

- Renovation Projects: Perfect for homeowners and contractors alike, it assists in modifying existing structures or creating new layouts.

Furthermore, its portability makes it a favored choice for tasks that require mobility, such as on-site repairs and installations. The tool’s efficiency and versatility continue to enhance its popularity among users looking for reliable cutting solutions.

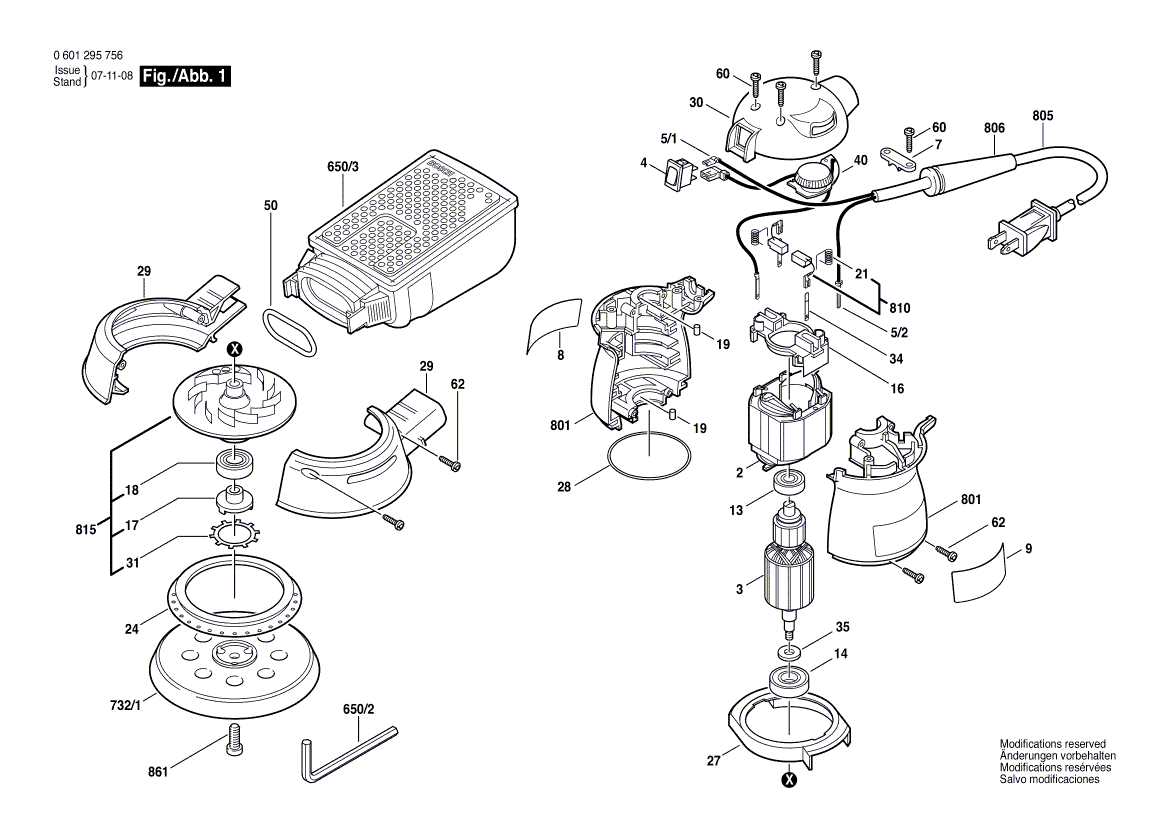

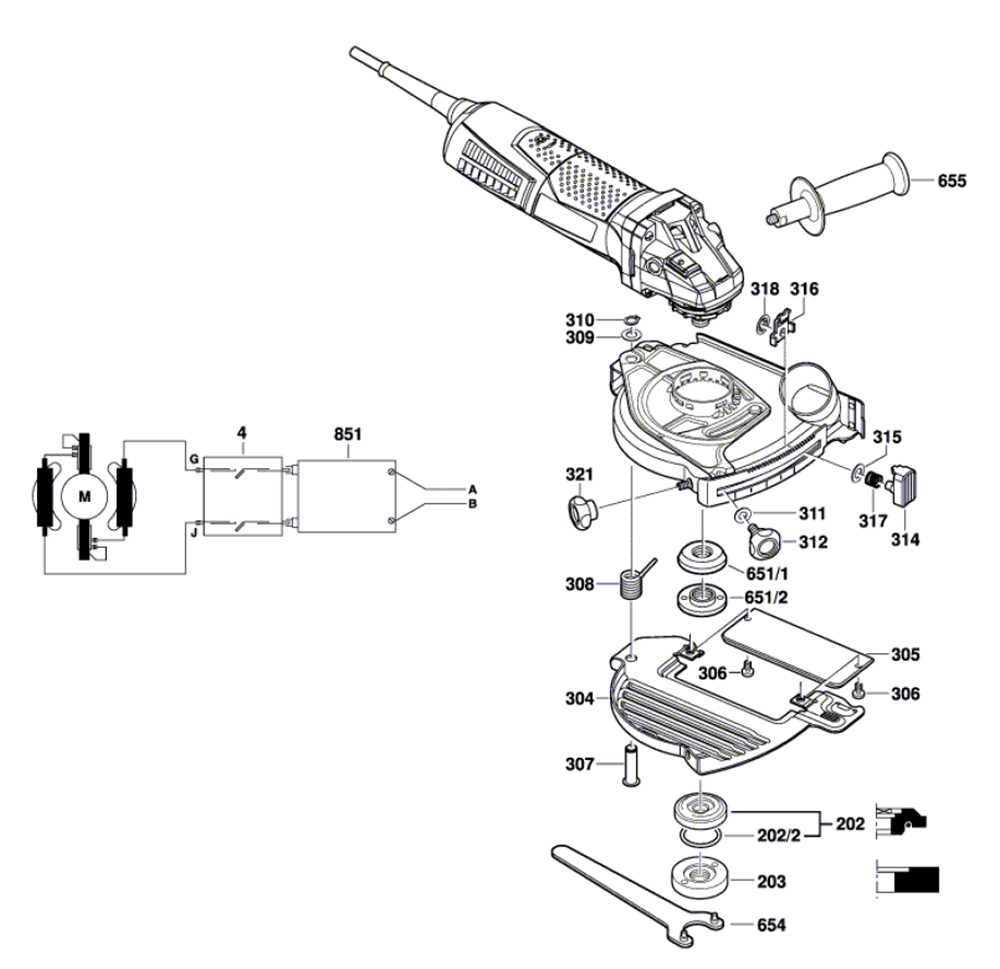

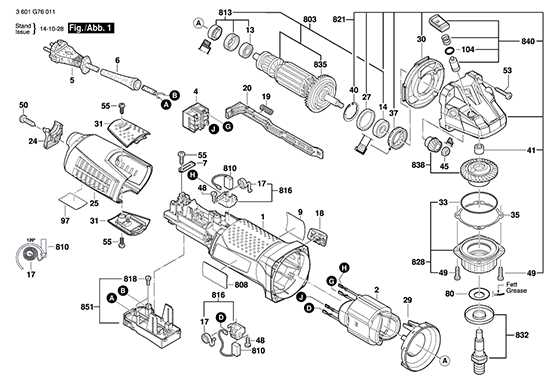

Importance of Parts Diagram

Understanding the intricacies of mechanical assemblies is crucial for effective maintenance and repair. A visual representation of components within a machine serves as a valuable tool for both technicians and hobbyists. It enables users to identify individual elements and comprehend their interrelationships, ultimately facilitating smoother repairs and upgrades.

Enhanced Efficiency

Having a clear visual reference significantly boosts efficiency during troubleshooting. Technicians can quickly pinpoint faulty elements and determine necessary replacements without wasting time searching through manuals or disassembling entire units. This expedites the repair process, reducing downtime and improving overall productivity.

Facilitating Learning

For those new to machinery, a comprehensive visual guide fosters a deeper understanding of how systems function. It allows learners to visualize the arrangement and roles of each component, aiding in the acquisition of practical knowledge. This educational aspect empowers individuals to perform maintenance tasks more confidently and accurately.

Identifying CSG15 Replacement Parts

Understanding the components of a power tool is essential for ensuring optimal performance and longevity. Whether you are replacing worn elements or upgrading features, recognizing the correct substitutes can significantly impact your project’s success. This section focuses on the process of pinpointing the appropriate replacements to maintain your equipment effectively.

Common Components and Their Functions

Every tool comprises various essential elements that contribute to its overall functionality. Familiarity with these components enables users to identify what may require attention or replacement. Key parts include the motor, cutting mechanisms, and housing, each playing a vital role in the tool’s operation. Recognizing signs of wear or damage in these areas can help you determine what needs to be replaced to keep the equipment running smoothly.

Finding Compatible Substitutes

When searching for suitable replacements, it’s important to ensure compatibility with your specific model. Many manufacturers provide detailed listings and specifications for each element, allowing users to verify that new components will fit and function correctly. Additionally, consulting reputable suppliers and utilizing online resources can streamline the process of finding the right substitutes, ultimately leading to better tool maintenance and performance.

Tools Needed for CSG15 Maintenance

Proper upkeep of equipment requires a set of essential instruments that ensure efficient performance and longevity. Understanding which tools are necessary can greatly simplify the maintenance process, allowing users to address common issues swiftly and effectively. A well-equipped toolkit not only aids in routine checks but also facilitates repairs and adjustments, enhancing overall functionality.

Essential Instruments

To begin with, having a reliable screwdriver set is crucial for handling various screws and fasteners. Additionally, a comprehensive wrench set will enable users to tighten or loosen bolts and nuts as needed. A pair of pliers can be helpful for gripping, twisting, and cutting wires or other materials during maintenance tasks. Lastly, a sturdy utility knife is essential for any cutting or trimming requirements that may arise.

Measurement and Diagnostic Tools

Accurate measurements are vital for effective maintenance. A digital multimeter can assist in checking electrical connections and diagnosing any potential issues. Furthermore, a caliper can provide precise measurements of parts to ensure correct alignment and fit. Keeping a set of maintenance manuals or guides on hand can also prove beneficial for troubleshooting and reference during upkeep procedures.

Step-by-Step Assembly Process

Assembling complex machinery requires precision and attention to detail. This section outlines a systematic approach to successfully piecing together essential components, ensuring optimal functionality and durability. By following a structured process, users can enhance their understanding and efficiency in assembling intricate devices.

1. Gather Necessary Components

Begin by collecting all required elements. Organizing parts by type can simplify the assembly process. Make sure to check for any missing items before proceeding.

2. Prepare Your Workspace

A clean and well-lit environment is crucial for effective assembly. Ensure that you have ample space to work and that all tools are readily accessible. This will facilitate smoother progress as you move through the steps.

3. Refer to the Assembly Instructions

Consult the provided guidelines thoroughly before starting. Understanding the sequence of assembly will help prevent errors and reduce the likelihood of rework.

4. Begin with the Base Components

Start by attaching the foundational elements. This often involves securing the primary structure, which will support subsequent parts. Ensure that all fasteners are tightened properly for stability.

5. Add Intermediate Parts

Once the base is secure, proceed with attaching intermediate components. Follow the order specified in the instructions, making certain that each piece aligns correctly with its counterpart.

6. Install Final Elements

Conclude the assembly by placing the final pieces. Double-check connections to guarantee that everything is integrated seamlessly. Pay close attention to any additional requirements for securing or adjusting these components.

7. Conduct a Final Inspection

Before putting the assembled unit to use, perform a thorough inspection. Verify that all components are correctly positioned and secured. Testing the assembly at this stage can help identify any issues that may need addressing.

8. Maintain Documentation

Document the assembly process and any observations. Keeping records can be beneficial for future reference or if disassembly is needed later on. This will also aid in troubleshooting any potential problems down the line.

Common Issues and Solutions

This section aims to address frequent challenges encountered with power tools, along with practical solutions to enhance their performance and longevity. By understanding these common problems, users can take proactive measures to maintain their equipment and ensure efficient operation.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat generation during operation can lead to reduced efficiency and potential damage. | Ensure proper ventilation and allow the tool to cool down between uses. Regularly clean air vents to prevent blockage. |

| Poor Performance | Notably reduced cutting speed or power can hinder project progress. | Check and replace worn-out components. Ensure proper alignment and that the tool is suitable for the intended task. |

| Excessive Vibration | Unusual vibrations during use can indicate mechanical issues or imbalances. | Inspect for loose parts and tighten as necessary. Consider using anti-vibration accessories to enhance stability. |

| Electrical Failures | Intermittent power loss or failure to start may arise from electrical issues. | Examine the power cord for damage and replace if necessary. Consult a professional for internal electrical repairs. |

| Dust Accumulation | Build-up of debris can obstruct moving parts and impair functionality. | Regularly clean the tool after each use, focusing on crevices and filters to ensure unobstructed operation. |

Safety Tips for CSG15 Users

When operating power tools, it is essential to prioritize safety to prevent accidents and injuries. Understanding and following proper precautions can enhance the user experience and ensure a secure working environment. This section outlines critical guidelines to follow while using such equipment.

Personal Protective Equipment (PPE)

Always wear appropriate personal protective gear when working with machinery. This includes safety goggles to shield your eyes from debris, ear protection to prevent hearing damage, and gloves that provide a secure grip without compromising dexterity. Additionally, ensure that your footwear is sturdy and slip-resistant to maintain balance and stability.

Tool Maintenance and Operation

Regular maintenance is vital for optimal performance and safety. Before each use, inspect the tool for any signs of wear or damage. Ensure that all components are securely fastened and functioning correctly. Familiarize yourself with the operating instructions and adhere to them strictly. If unsure about any aspect of the tool’s operation, consult the manual or seek guidance from a knowledgeable source.

Remember, a safe work environment not only protects the user but also contributes to the overall success of any project.

Where to Purchase Bosch Parts

Finding high-quality components for your equipment can be a daunting task. Numerous options are available, but selecting reliable sources is crucial to ensure you receive authentic and compatible items. Whether you need replacement items or accessories, understanding where to shop can simplify the process.

Authorized Retailers

One of the best ways to ensure quality is to purchase from authorized distributors. These establishments are recognized by the manufacturer and offer genuine merchandise. They often have knowledgeable staff who can assist you in finding the right items for your needs.

Online Marketplaces

Another convenient option is exploring various online platforms. Major e-commerce sites provide a wide selection and the ability to compare prices easily. Be sure to check seller ratings and customer reviews to avoid counterfeit products. Additionally, manufacturer websites may offer direct sales or links to trusted retailers.

Always prioritize quality over cost when shopping for equipment components. Choosing the right source can save time and ensure the longevity of your tools.

How to Read Parts Diagrams

Understanding the intricacies of assembly schematics is crucial for anyone involved in maintenance or repair work. These illustrations serve as visual guides, providing insight into the components that make up a specific device or machine. By deciphering these visuals, users can easily identify individual pieces, their arrangement, and the relationships between them.

To effectively interpret these schematics, begin by familiarizing yourself with the symbols and notations commonly used in the illustrations. Each icon represents a different element, such as screws, bolts, or electronic components. Pay close attention to the labels, as they often provide essential information regarding specifications and compatibility.

Next, examine the overall layout of the schematic. Typically, components are organized in a logical sequence that reflects their assembly order. This structure can help in understanding how to disassemble or reassemble a unit efficiently. Additionally, many schematics include a legend or key that explains the various symbols and their meanings, which can be invaluable for clarifying any uncertainties.

Lastly, it’s important to cross-reference the visual with an accompanying list of components, often found in the documentation. This list usually provides part numbers and descriptions, ensuring that users can accurately identify and source replacements. By combining the visual information with textual details, you can enhance your understanding and execution of maintenance tasks.

Warranty Information for CSG15

The warranty coverage ensures that your equipment remains in optimal working condition. It’s designed to provide peace of mind by offering repairs or replacements for defects in materials or craftsmanship within the specified warranty period. Below are key aspects you should be aware of regarding the warranty policy.

- Standard coverage typically lasts for a set period from the purchase date, covering manufacturing defects and faults under normal use.

- Extended warranty options may be available for additional coverage beyond the initial period.

- To make a warranty claim, you will need to provide proof of purchase, such as a receipt or an invoice.

- Warranty claims might not cover issues caused by improper usage, accidental damage, or modifications made to the product.

- Repairs or replacements under warranty are usually carried out through authorized service centers.

For more detailed information, including any specific exclusions or limitations, it’s essential to review the full terms and conditions that accompany your equipment.

Customer Reviews and Feedback

Understanding user experiences provides valuable insights into the overall performance and satisfaction associated with the product. By analyzing feedback from real users, potential buyers can make informed decisions based on both positive experiences and areas of improvement mentioned by others. This section highlights the key trends, preferences, and critiques shared by individuals who have interacted with the tool, offering a balanced perspective.

Common Praise Points

Many users appreciate the tool’s reliability and efficiency in delivering consistent results. Reviews frequently mention its ease of use, which makes it accessible for both professionals and hobbyists. Durability and ergonomic design are also praised, contributing to overall satisfaction. The high performance under various conditions is another recurring theme in positive feedback.

Areas for Improvement

While the tool receives high marks for its functionality, a few users have pointed out areas where enhancements could be made. Some mention the need for minor adjustments to certain features, while others highlight specific issues related to comfort during extended use. Addressing these concerns could lead to an even better user experience.

| Aspect | Positive Feedback | Improvement Suggestions |

|---|---|---|

| Performance | Consistently effective | None mentioned |

| Design | Ergonomic, user-friendly | Minor comfort issues for long usage |

| Durability | Long-lasting, robust | Rare reports of wear |