The intricate design of modern fuel delivery systems plays a crucial role in ensuring optimal engine performance. This section delves into the various elements involved, highlighting their functions and interconnections. A comprehensive understanding of these components is essential for anyone looking to maintain or troubleshoot such systems effectively.

Each element within this complex assembly contributes significantly to the overall operation, influencing efficiency and reliability. By examining the layout and relationships between these components, one can gain valuable insights into the mechanics at play. Knowledge of these systems empowers users to make informed decisions during maintenance or repairs, ultimately enhancing the longevity of their vehicles.

Whether you are a seasoned technician or a passionate enthusiast, grasping the essentials of these critical components will provide a solid foundation for further exploration. Familiarity with their roles not only aids in effective diagnostics but also fosters a deeper appreciation for the engineering involved in fuel delivery systems.

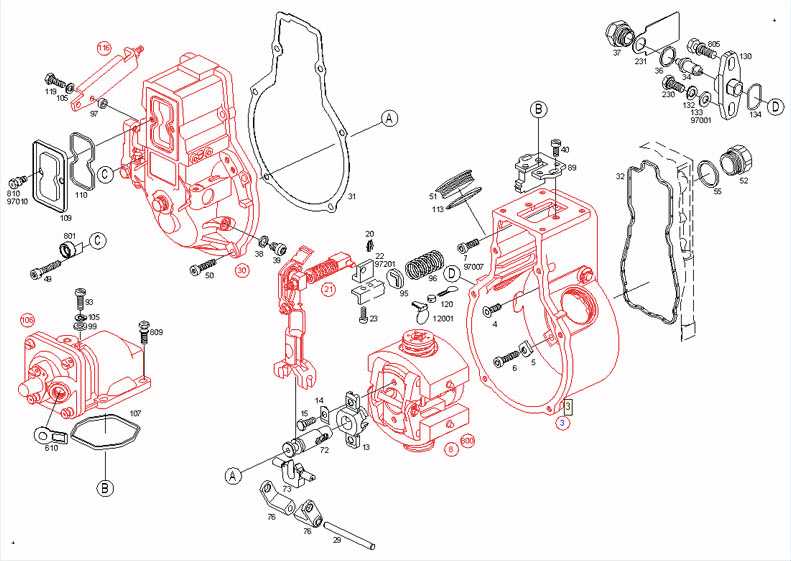

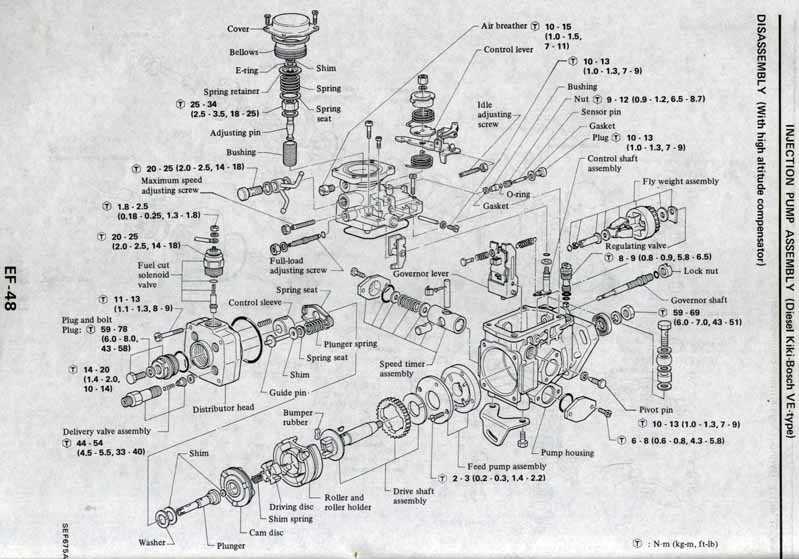

Bosch Injection Pump Overview

This section delves into the fundamental aspects of a specific fuel delivery mechanism utilized in various automotive applications. Understanding its structure and functionality is essential for effective maintenance and troubleshooting.

Key Components

The system comprises several critical elements that work in unison to ensure optimal performance. Each component plays a vital role in facilitating the efficient operation of the mechanism.

| Component | Function |

|---|---|

| Housing | Encases all internal parts, providing structural integrity. |

| Control Unit | Regulates the flow and timing of fuel delivery. |

| Valves | Manage the entry and exit of fuel, ensuring precision. |

| Pistons | Generate the necessary pressure for fuel distribution. |

Functionality Insights

The operation of this mechanism hinges on precise coordination among its components, contributing to improved efficiency and reduced emissions. Understanding this interaction is crucial for any automotive technician or enthusiast.

Understanding Pump Functionality

Comprehending the operation of a fuel delivery mechanism is crucial for maintaining efficiency and performance. This process involves several key components working in harmony to ensure optimal fuel flow and pressure.

Here are the primary functions associated with this mechanism:

- Fuel Intake: The mechanism draws in fuel from the reservoir, preparing it for processing.

- Pressurization: The system compresses the fuel to achieve the required pressure for efficient delivery.

- Distribution: Once pressurized, the fuel is routed to the appropriate engine components for combustion.

- Regulation: Maintaining consistent pressure levels is vital for performance, preventing leaks and ensuring proper flow.

Understanding these fundamental aspects aids in diagnosing issues and enhancing the overall functionality of the fuel system.

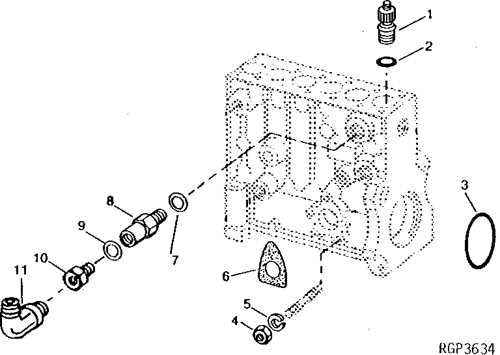

Key Components of Injection Pumps

Understanding the essential elements of fuel delivery systems is crucial for optimal engine performance. These mechanisms play a vital role in ensuring precise fuel distribution and efficiency.

- Fuel Delivery Mechanism: Responsible for transferring fuel from the tank to the combustion chamber.

- Control Unit: Regulates the timing and quantity of fuel injected based on engine demands.

- Timing Device: Ensures synchronization between fuel delivery and engine cycle.

- Throttle Valve: Manages airflow and fuel mix to maintain desired engine speed.

- Fuel Filter: Removes impurities from fuel to protect internal components.

Each of these components contributes significantly to the overall functionality, influencing performance and efficiency in various operating conditions.

Common Issues and Solutions

When dealing with mechanical systems, certain challenges can arise, impacting performance and efficiency. Understanding these common problems and their remedies can significantly enhance reliability and longevity.

Performance Drops

Symptoms: A noticeable decrease in efficiency or responsiveness may indicate underlying issues. This can result from wear and tear or misalignment in the components.

Solutions: Regular maintenance and timely replacement of worn-out elements can restore optimal function. Additionally, ensuring all parts are correctly aligned will prevent further complications.

Leakage Problems

Symptoms: Fluid leaks are a common occurrence that can lead to severe system failures. These often manifest as puddles or stains under the machinery.

Solutions: Identifying the source of the leak and promptly sealing or replacing the affected components is crucial. Regular inspections can help catch such issues early, minimizing downtime and repair costs.

Maintenance Tips for Longevity

Ensuring the extended life of mechanical components requires consistent care and attention. Regular maintenance not only enhances performance but also prevents premature wear and costly repairs. By following a few essential practices, you can significantly improve the durability of your equipment.

Routine Inspections: Periodically check the condition of your machinery. Look for any signs of wear, leaks, or irregularities that could indicate potential issues. Early detection is crucial for effective intervention.

Proper Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and helps prevent overheating, which can lead to serious damage over time. Use the appropriate lubricant recommended for your specific application.

Keep It Clean: Dirt and debris can accumulate and affect the functionality of your machinery. Regularly clean the exterior and any accessible internal components to maintain optimal performance.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule outlined in your user manual. This will provide you with specific intervals for servicing and part replacements, ensuring that you do not overlook critical upkeep.

Store Properly: If your equipment will not be in use for an extended period, store it in a clean, dry environment. Protect it from extreme temperatures and moisture to avoid corrosion and degradation of materials.

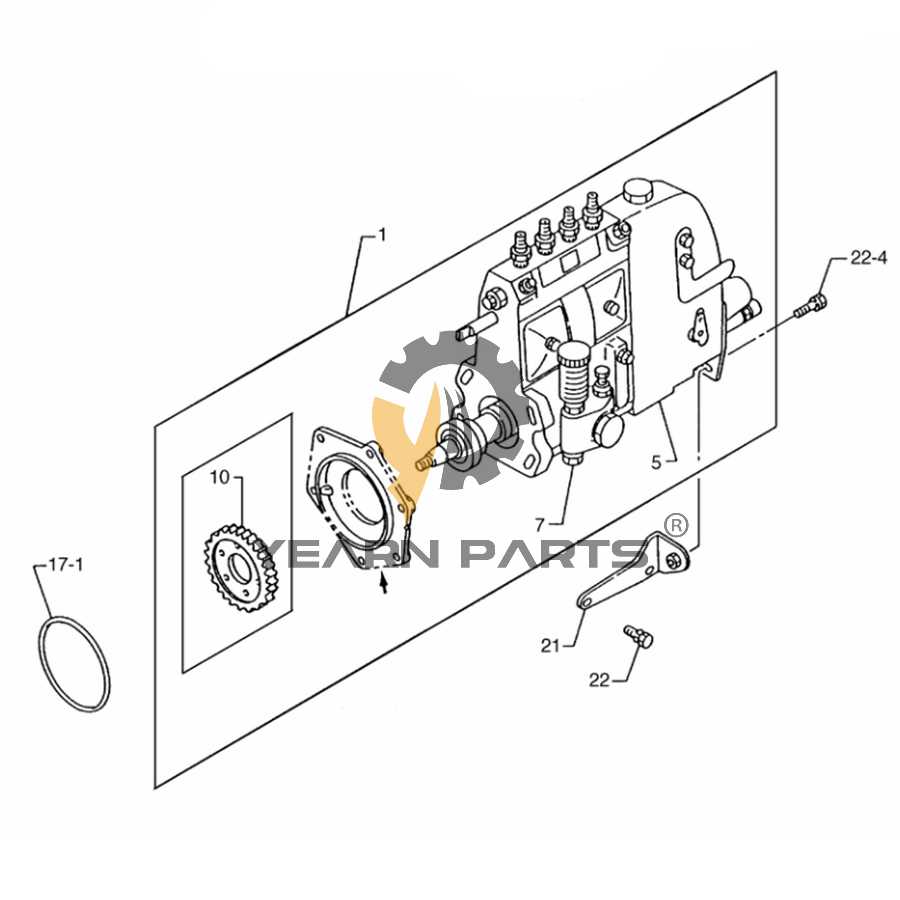

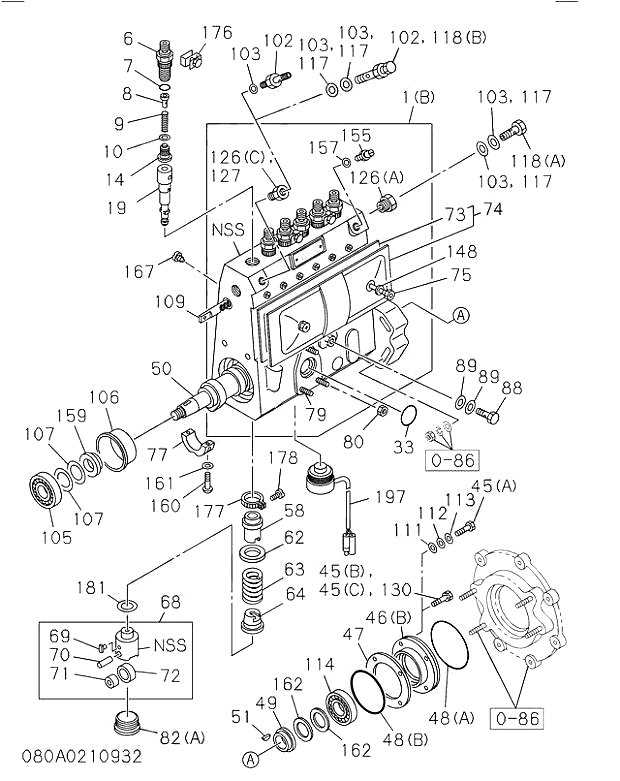

How to Identify Parts

Understanding the components of a mechanical system is essential for effective maintenance and repair. Familiarizing yourself with various elements can significantly enhance your ability to troubleshoot and optimize performance. Identifying these elements accurately will allow for more informed decisions regarding repairs or replacements.

First, consult the user manual or technical documentation associated with the equipment. These resources typically provide detailed illustrations and descriptions of each component, aiding in recognition. Second, use online resources and forums where enthusiasts share their insights and experiences. Visual aids, such as images and videos, can be particularly helpful in making distinctions between similar components.

Lastly, engage with professionals or experienced individuals who can offer guidance. Their expertise can provide valuable context and clarification, especially for more complex assemblies. By utilizing these strategies, you can enhance your understanding and ensure the longevity of your mechanical system.

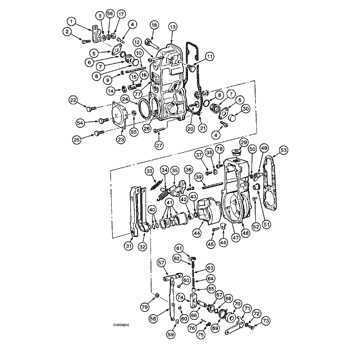

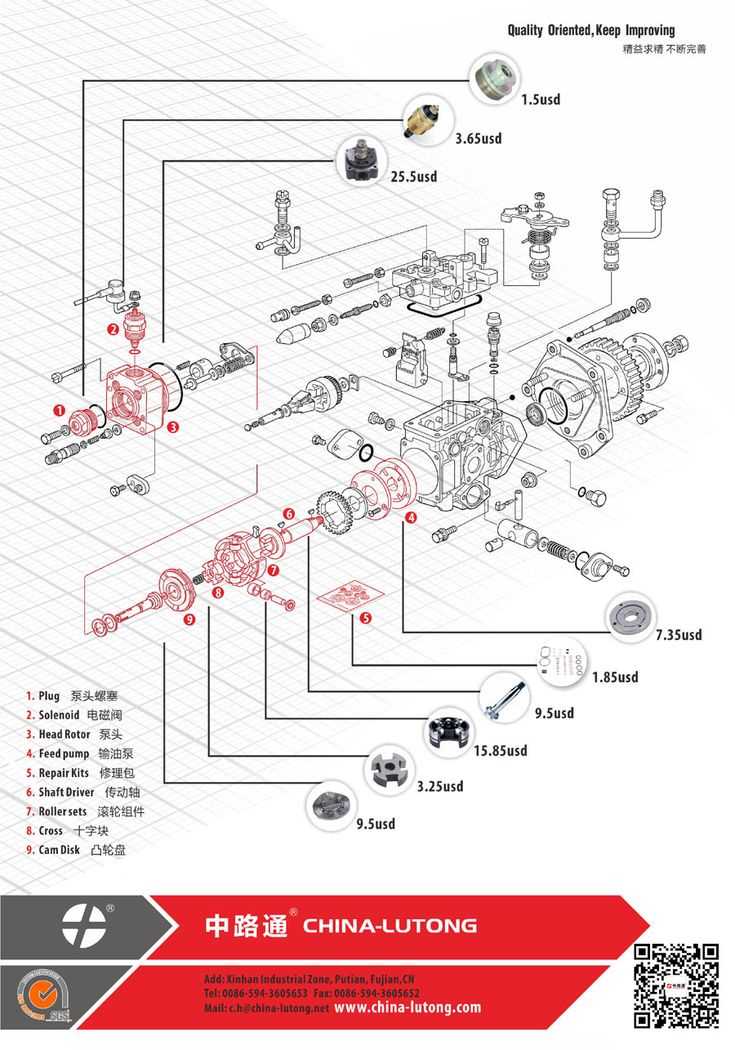

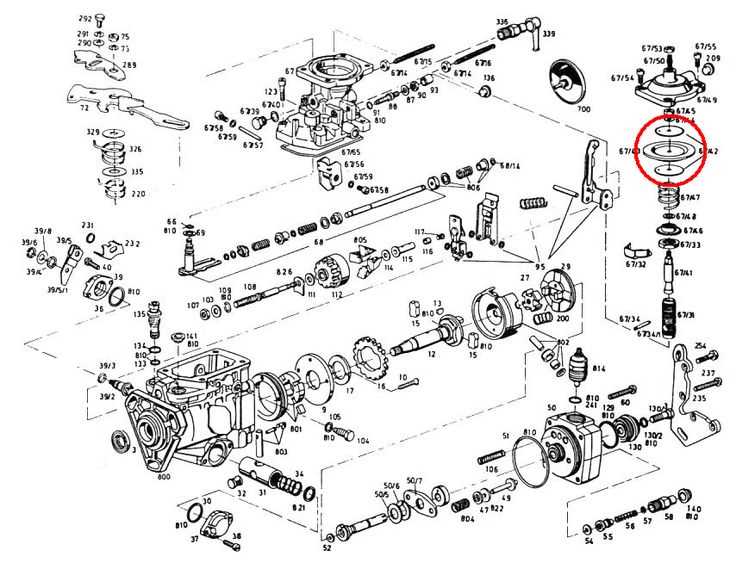

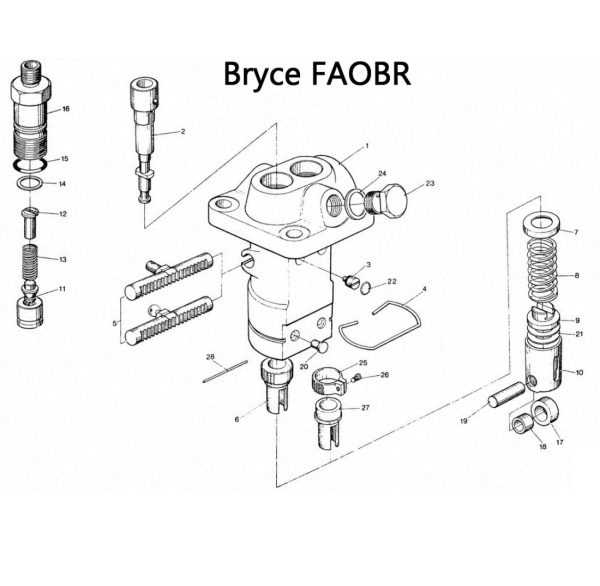

Diagram Analysis: Visual Guide

This section provides a detailed overview of the visual representation of essential components, facilitating a better understanding of their interrelationships and functions.

By examining the illustration, one can gain insights into various elements and their roles. The following points highlight key aspects to consider:

- Identifying individual components and their placements.

- Understanding the flow of operation within the system.

- Recognizing how each part contributes to overall functionality.

Analyzing this visual aid enables users to troubleshoot issues more effectively and make informed decisions regarding maintenance and repairs.

Replacement Parts Selection Guide

Choosing the right components for your machinery is crucial for maintaining optimal performance and longevity. This guide aims to assist users in navigating the options available when sourcing essential elements for their systems. Understanding the various factors involved in selecting replacements can significantly impact functionality and efficiency.

| Criteria | Description |

|---|---|

| Compatibility | Ensure that the component matches the specifications of the existing system to avoid functionality issues. |

| Quality | Select high-quality alternatives that meet or exceed the original standards to ensure durability and performance. |

| Cost | Consider the budget while balancing cost with quality to make a wise investment for the long term. |

| Manufacturer Reputation | Research the reliability of the manufacturer to guarantee that the replacements are trustworthy and effective. |

| Warranty | Look for options that offer warranties or guarantees, providing peace of mind regarding the purchase. |

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is essential for achieving efficient and effective results. This section outlines the necessary tools that will facilitate the repair process, ensuring a smoother experience for both novice and experienced individuals.

| Tool | Description |

|---|---|

| Wrenches | Used for loosening or tightening fasteners, providing the necessary leverage. |

| Screwdrivers | Essential for fastening or removing screws, available in various types and sizes. |

| Socket Set | Allows for the application of torque to fasteners in tight spaces. |

| Pliers | Useful for gripping, bending, or cutting wires and small components. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specified torque. |

Installation Procedures Explained

This section outlines the essential steps for properly setting up the mechanical assembly. Understanding the process ensures optimal functionality and longevity of the system.

Preparation is Key: Before starting, gather all necessary tools and components. Familiarize yourself with the layout to streamline the installation.

Step-by-Step Assembly: Begin by securing the primary unit in place. Ensure all connections are snug but not over-tightened, as this could lead to damage. Follow the specified sequence for attaching each component to maintain structural integrity.

Final Checks: Once assembled, inspect all connections for leaks and secure any loose fittings. A thorough examination helps prevent future issues and guarantees reliable performance.

FAQs About Bosch Pumps

This section addresses common inquiries related to fuel delivery mechanisms, focusing on their components and functionalities. Understanding these elements can help users make informed decisions about maintenance and troubleshooting.

What are the common issues encountered?

Users often experience challenges such as irregular flow rates or inconsistent performance. These problems can stem from various factors, including wear and tear of individual components or contamination within the system.

How can one ensure optimal performance?

Regular maintenance is crucial for preserving efficiency. Routine checks of filters and seals, along with timely replacements of worn components, can significantly enhance functionality. Additionally, following manufacturer guidelines for servicing can prolong the lifespan of the entire assembly.

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding of complex systems. Various sources offer in-depth knowledge that can assist both beginners and seasoned professionals in mastering the intricacies of mechanical components.

Books and Manuals

Comprehensive literature provides a wealth of information, ranging from basic principles to advanced techniques. Look for technical guides that focus on system functionality and maintenance.

Online Courses and Tutorials

Numerous platforms offer structured learning paths, allowing individuals to gain practical skills and theoretical knowledge. Engaging with video content and interactive exercises can solidify your grasp of essential concepts.