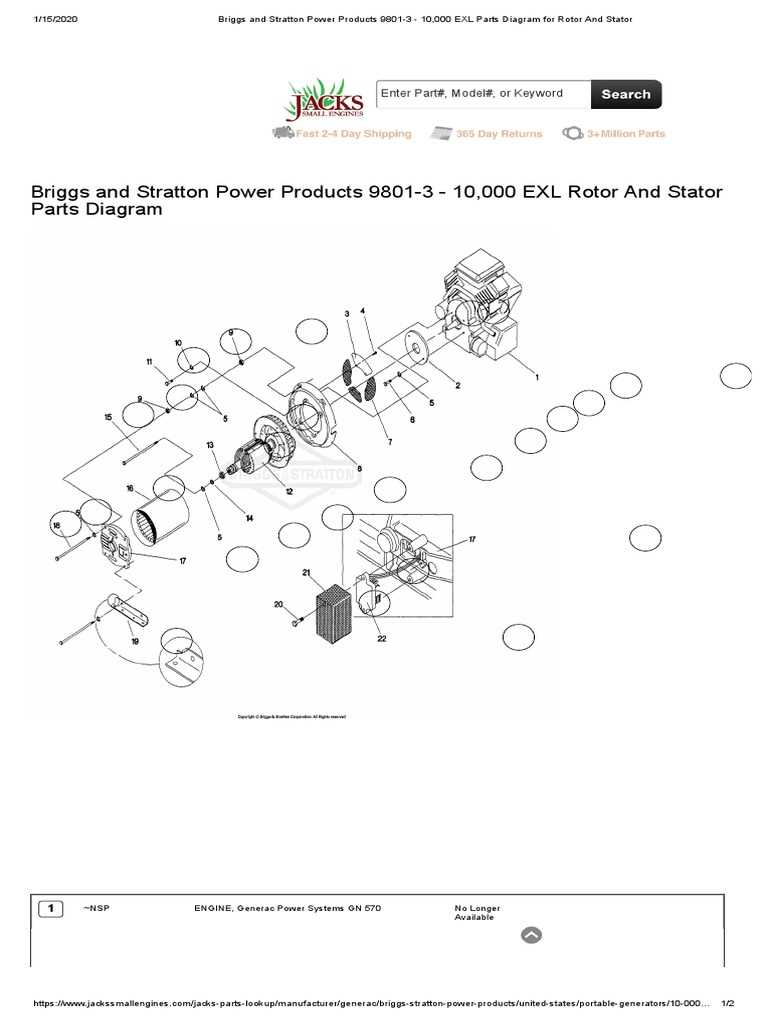

In the realm of small engine maintenance, comprehending the structure and organization of various elements is crucial for effective troubleshooting and repair. A well-illustrated representation can significantly enhance one’s understanding of how each component interacts within the system. This insight not only aids in identifying specific pieces but also supports efficient assembly and disassembly processes.

Exploring a visual representation of mechanical elements allows enthusiasts and professionals alike to grasp the intricate relationships between different units. By examining these illustrations, users can develop a clearer perspective on how each part contributes to the overall functionality of the engine. This knowledge empowers individuals to make informed decisions regarding repairs, replacements, and maintenance strategies.

Ultimately, having access to a comprehensive visual guide serves as a valuable resource. It simplifies the task of locating and identifying critical components, fostering confidence in one’s ability to manage repairs effectively. With a solid understanding of the layout, users can tackle maintenance tasks with precision and ease.

Understanding Briggs Parts Diagrams

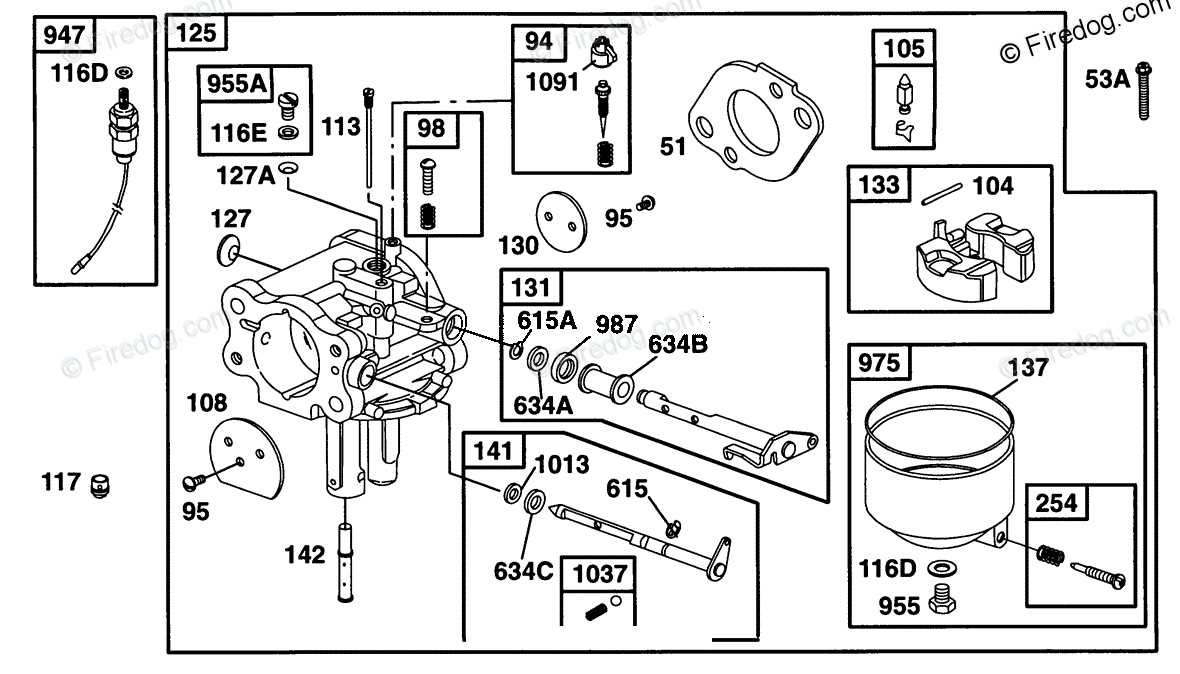

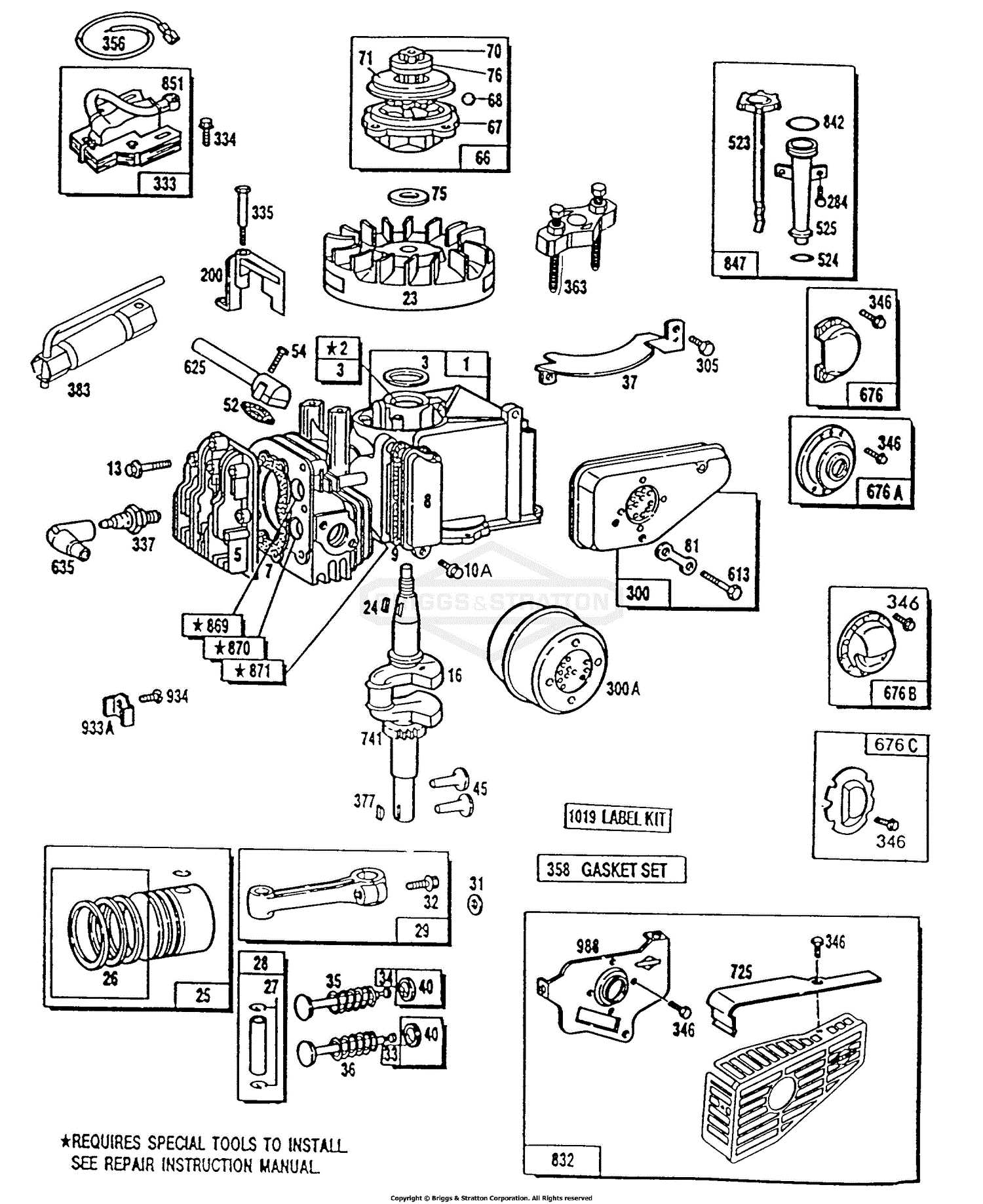

Interpreting the illustrations that showcase the components of small engines is essential for maintenance and repair. These visual representations provide a comprehensive overview of the various elements, their arrangements, and how they interact within the system. Gaining insight into these visuals can significantly enhance one’s ability to troubleshoot and perform necessary servicing tasks effectively.

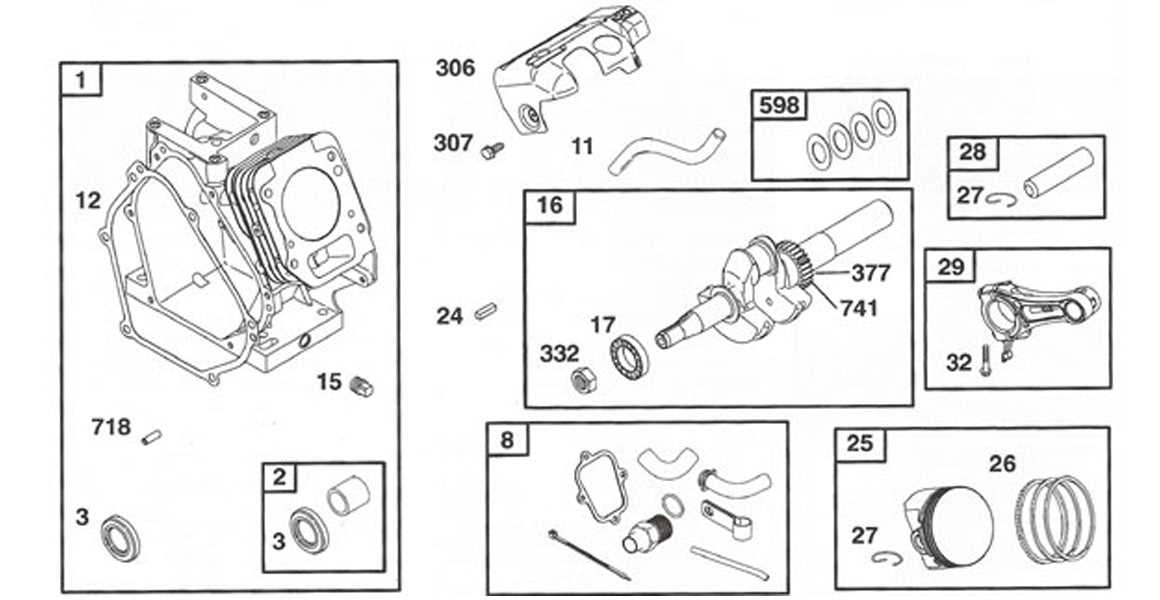

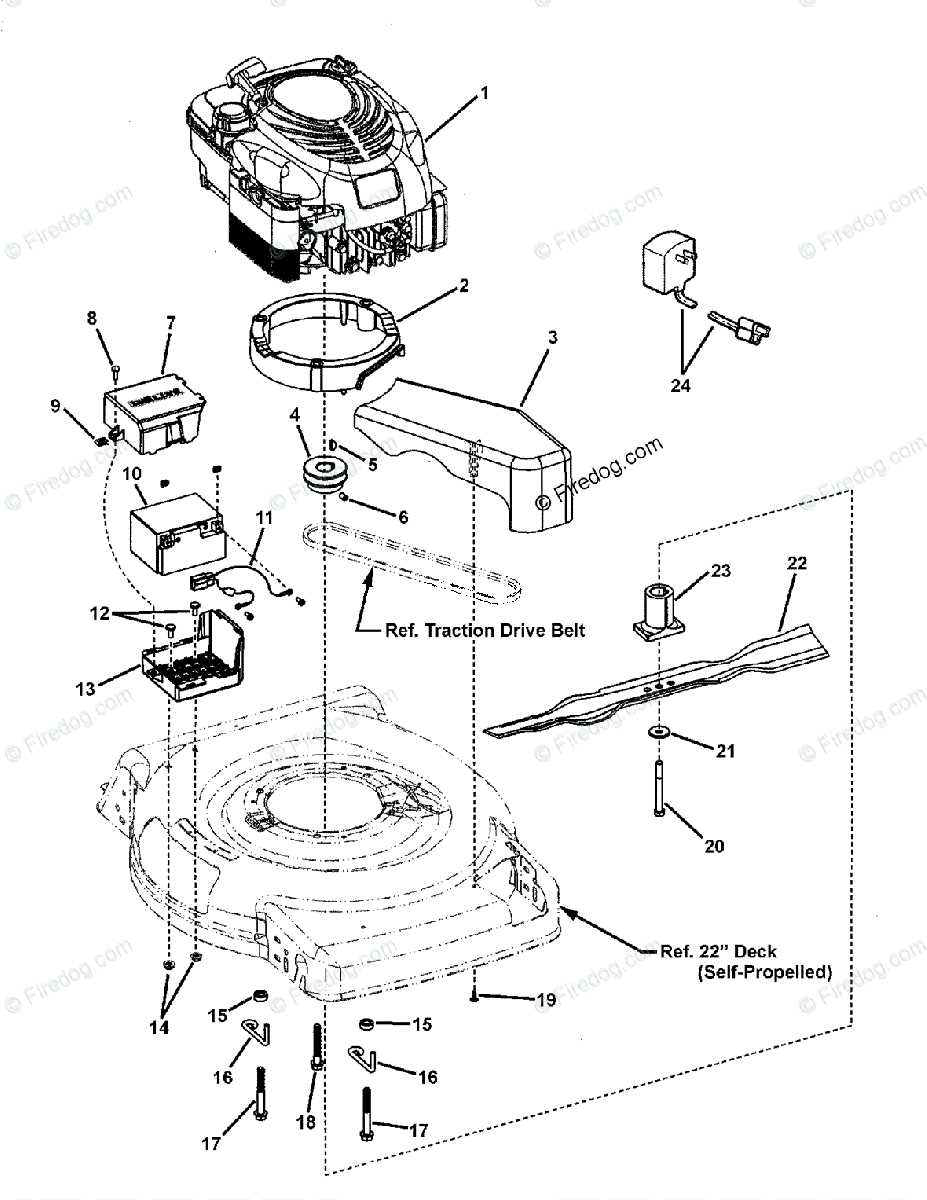

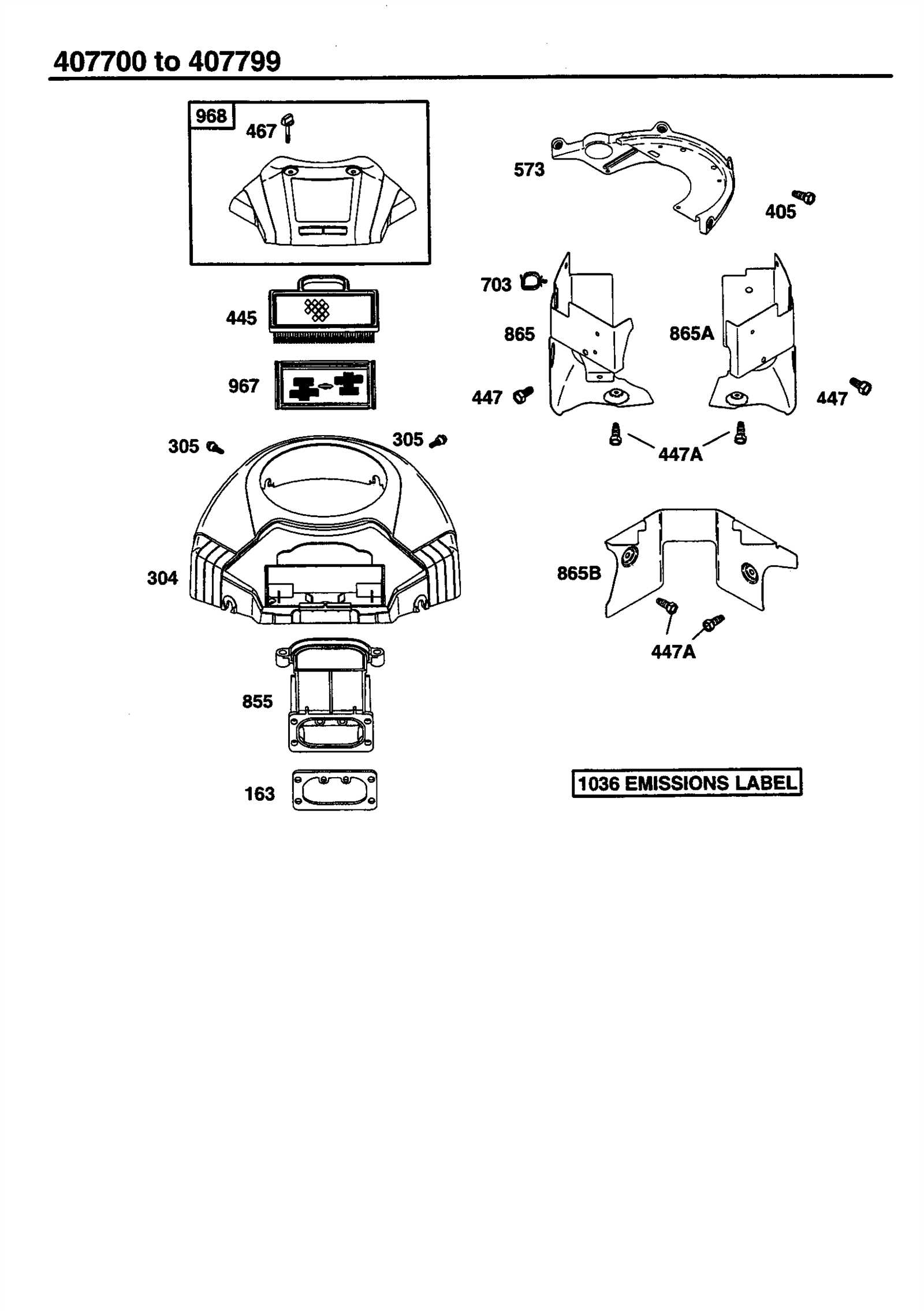

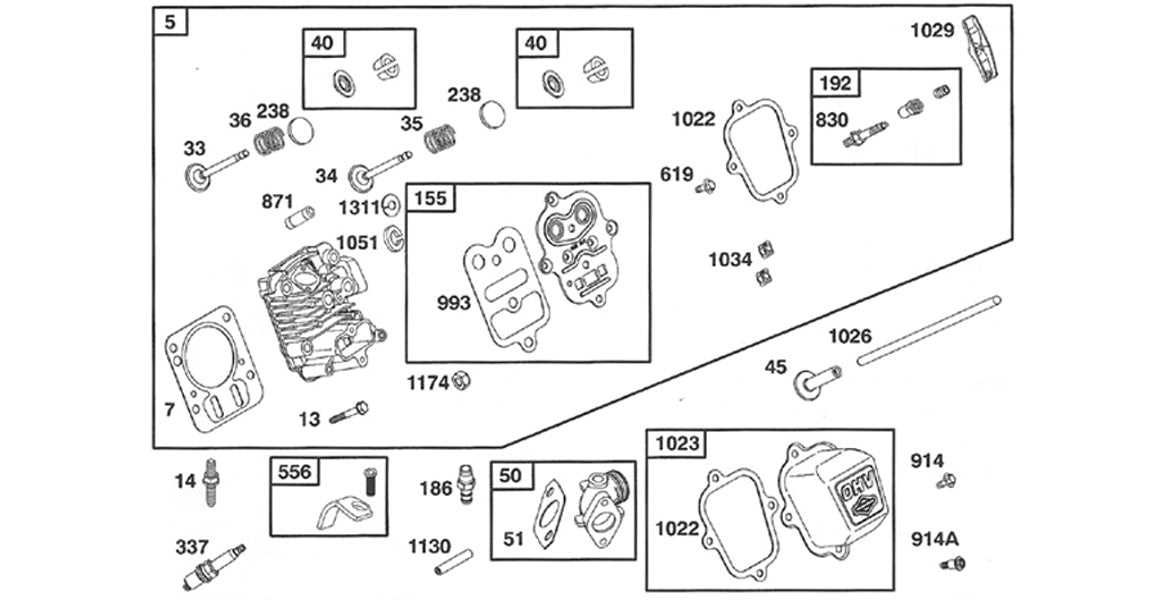

Key Elements of the Illustrations

These visuals typically include several critical components, each labeled to facilitate easy identification. Understanding the function of each part aids in comprehending the overall mechanics of the engine. Familiarity with these representations can streamline the process of locating replacement elements and determining compatibility with existing equipment.

Importance of Accurate Interpretation

Accurate understanding of these visuals is crucial for anyone involved in engine maintenance. Misinterpretation can lead to incorrect repairs or parts selection, resulting in inefficiency or damage. By familiarizing oneself with the symbols and layout used in these illustrations, one can ensure effective maintenance and prolong the life of the engine.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion |

| Piston | Converts combustion energy into mechanical power |

| Crankshaft | Transforms the linear motion of the piston into rotational motion |

| Carburetor | Mixes air and fuel for optimal combustion |

| Ignition System | Ignites the air-fuel mixture at the right time |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in ensuring the efficiency and effectiveness of various machinery and equipment. These visual representations provide clear guidance for assembly, maintenance, and repair processes, allowing users to identify components easily and understand their interrelationships.

Without reliable visuals, users may struggle to assemble or repair their devices correctly, potentially leading to malfunctions or safety hazards. Comprehensive and accurate illustrations enable users to follow procedures step by step, significantly reducing the risk of errors.

Furthermore, well-designed visuals enhance the learning experience for technicians and users alike. By utilizing clear and detailed representations, individuals can gain a better understanding of how different elements function together, fostering a deeper knowledge of the equipment as a whole.

In conclusion, the significance of precise visual representations cannot be overstated. They are essential tools that contribute to the longevity and reliability of machinery, ensuring that users can operate and maintain their equipment with confidence.

Common Components of Briggs Engines

Understanding the fundamental elements of small engines is essential for maintenance and repair. These essential parts work together to ensure efficient operation and reliable performance. Each component plays a unique role in the overall functionality of the engine, contributing to its power generation and operational efficiency.

Among the critical elements are the fuel system, which is responsible for delivering the necessary energy source; the ignition system, which ignites the fuel-air mixture for combustion; and the cooling system, designed to maintain optimal operating temperatures. Additionally, the crankshaft and camshaft facilitate the movement of internal components, while the air filter ensures a clean air supply for combustion.

Regular inspection and understanding of these vital components can significantly enhance the longevity and reliability of the engine. Proper maintenance practices, such as timely replacement of worn parts and ensuring cleanliness, contribute to the smooth operation of the machinery.

Reading and Interpreting Diagrams

Understanding visual representations is crucial for effective troubleshooting and maintenance. These illustrations provide essential insights into the components and their arrangements, making it easier to identify issues and perform necessary tasks. Mastering the interpretation of these visuals can greatly enhance efficiency and accuracy in various mechanical processes.

When engaging with these visuals, consider the following aspects:

- Symbols and Legends: Familiarize yourself with the various symbols used in the illustrations. Each symbol typically represents a specific component or action.

- Orientation: Pay attention to the orientation of the visual. Some diagrams may be presented from unique angles, which can affect how you interpret the layout.

- Connections: Look closely at the connections between components. Understanding how different parts interact is essential for diagnosing problems.

- Scale and Detail: Note the scale of the illustration. Detailed views may offer more insights, while simplified representations may focus on overall structure.

By honing your skills in reading these visuals, you will improve your ability to troubleshoot effectively and perform maintenance tasks with confidence.

Finding Replacement Parts Easily

Locating suitable components for your equipment can significantly enhance its performance and longevity. Understanding how to efficiently find these necessary items simplifies maintenance and repairs, ensuring your machine operates at its best.

Utilizing Online Resources

The internet offers a wealth of resources to aid in your search for replacements. Here are some effective strategies:

- Visit manufacturer websites for official listings and specifications.

- Explore online marketplaces that specialize in machinery components.

- Join forums or community groups focused on similar equipment for recommendations and insights.

Consulting Local Suppliers

Local suppliers can be invaluable in your quest for necessary items. Consider the following:

- Build relationships with local retailers who can provide personalized assistance.

- Check inventory availability to avoid delays in your repair projects.

- Ask for advice on compatible components to ensure optimal functionality.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components ensures superior quality and reliability for your machinery. These components are designed specifically for particular models, providing a perfect fit and optimal performance. By opting for these parts, users can experience enhanced longevity and efficiency in their equipment, ultimately leading to reduced maintenance costs and improved functionality.

Quality Assurance

Original components undergo rigorous testing and quality checks, guaranteeing that they meet the manufacturer’s standards. This ensures that users receive products that are built to last and perform at their best, significantly lowering the risk of premature failure or malfunction.

Compatibility and Performance

Using original components guarantees compatibility with existing systems, allowing for seamless integration and operation. This compatibility leads to better performance overall, as the components work harmoniously with other machinery elements, enhancing efficiency and productivity.

Maintenance Tips for Briggs Engines

Proper upkeep of small engines ensures optimal performance and longevity. Regular maintenance practices help in identifying potential issues before they escalate, leading to efficient operation and reduced repair costs. Following some essential guidelines can significantly enhance the lifespan and reliability of your engine.

Regular Inspections

Conducting frequent checks is crucial. Inspecting the engine for signs of wear or damage can prevent unexpected breakdowns. Pay close attention to the fuel system, air filter, and electrical connections. A clean air filter improves airflow, while clean fuel lines prevent blockages.

Fluid Changes

Changing the oil and other fluids at recommended intervals is vital for maintaining engine health. Fresh oil lubricates moving parts effectively, reducing friction and wear. Additionally, replacing the fuel filter and spark plugs periodically contributes to smoother operation. Always consult the manufacturer’s guidelines for specific maintenance schedules to ensure compliance.

How to Troubleshoot Engine Issues

Tackling problems with a motor requires a systematic approach to identify the root cause. Understanding common symptoms can help narrow down potential failures and facilitate effective repairs. By observing the engine’s behavior and applying troubleshooting techniques, one can effectively resolve issues and restore optimal performance.

Identifying Common Symptoms

Engines can exhibit various warning signs when issues arise. Noticing unusual sounds, performance drops, or starting difficulties can lead to quicker diagnostics. Below are some frequent symptoms and possible underlying problems:

| Symptom | Possible Cause |

|---|---|

| Rough idling | Clogged fuel filter |

| Difficulty starting | Weak battery or faulty ignition system |

| Excessive smoke | Oil leaks or fuel mixture issues |

| Unusual noises | Worn components or loose parts |

Step-by-Step Troubleshooting Process

To effectively address engine problems, follow these steps:

- Start by conducting a visual inspection for any obvious issues, such as leaks or damaged components.

- Check fluid levels, including oil, fuel, and coolant, ensuring they are within the recommended ranges.

- Utilize diagnostic tools to read error codes, if available, for more precise troubleshooting.

- Perform tests based on the identified symptoms, focusing on specific areas like the ignition system or fuel delivery.

- Document findings and carry out necessary repairs or replacements to restore proper functionality.

Tools Needed for Repairs

To effectively carry out maintenance and fixes on mechanical equipment, having the right tools is essential. A well-equipped toolkit not only facilitates the repair process but also ensures that tasks are completed efficiently and safely. Various instruments serve different purposes, making it crucial to understand which ones are necessary for specific jobs.

Essential Instruments

Among the primary tools required, wrenches and screwdrivers are indispensable for assembling and disassembling components. A set of pliers can aid in gripping and bending materials, while a torque wrench helps to apply the correct force during assembly. Additionally, a multimeter is invaluable for troubleshooting electrical issues.

Safety Gear

In addition to standard tools, personal protective equipment is vital to safeguard against injuries. Items such as gloves, goggles, and masks should be included in your toolkit. Prioritizing safety not only protects the individual but also contributes to a more effective repair process.

Identifying Specific Part Numbers

Understanding the details related to various components can significantly enhance the efficiency of maintenance and repairs. Recognizing the precise identifiers associated with each element is essential for ensuring compatibility and proper functionality in machinery. This section delves into the methodologies for determining these unique codes that are critical for sourcing the right components.

Understanding Component Identifiers

Each element in a machine typically has its own unique identifier, which serves as a reference for ordering and replacement. These codes often include numbers and letters that can indicate size, model, or version. Familiarizing oneself with the different formats and arrangements of these identifiers can aid in quickly locating the required item.

Utilizing Resources for Identification

To accurately pinpoint the correct identifiers, various resources can be employed. Manufacturer websites often provide detailed catalogs and search tools. Additionally, forums and community platforms can offer insights from experienced users who have navigated similar challenges. Utilizing these resources can streamline the identification process, ensuring that the right components are obtained swiftly.

Upgrading Your Briggs Engine

Enhancing the performance of your engine can significantly improve its efficiency and longevity. By implementing various modifications and improvements, you can achieve better power output, fuel efficiency, and overall functionality. This section explores essential upgrades that can take your engine to the next level.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Air Filter | Replacing the standard air filter with a high-flow version. | Increases airflow, enhancing combustion and power. |

| Exhaust System | Installing a performance exhaust system to reduce back pressure. | Improves exhaust flow, resulting in better engine response. |

| Fuel System | Upgrading the carburetor or fuel injectors for optimal fuel delivery. | Enhances fuel atomization, leading to more efficient combustion. |

| Ignition System | Switching to a high-performance ignition coil and spark plugs. | Ensures a more powerful spark, improving ignition timing and performance. |

Consider these upgrades to maximize the potential of your engine. Each modification can contribute to a smoother operation and greater overall satisfaction with your equipment.

Where to Buy Authentic Parts

Finding reliable sources for genuine components is essential for maintaining the optimal performance of your equipment. Authentic replacements not only ensure longevity but also enhance the overall efficiency of your machinery. When seeking these original elements, it’s crucial to consider various avenues that guarantee quality and authenticity.

Authorized Dealers

One of the most dependable options is to purchase from authorized distributors. These vendors are officially recognized and often offer a wide range of genuine components. They provide assurances regarding the authenticity of the items, along with expert guidance on suitable replacements for your machinery.

Online Retailers

Another convenient choice is reputable online marketplaces. These platforms typically feature a vast selection of original components, complete with customer reviews and ratings. It’s essential to verify the credibility of the seller and check for return policies to ensure you are receiving genuine items.