When it comes to maintaining a reliable garden tractor, having a clear understanding of its various components is essential. Each part plays a critical role in ensuring the machine operates efficiently, allowing users to tackle a range of tasks, from mowing to hauling. This section will delve into the intricate layout of these essential elements, providing valuable insights for both novice and experienced operators.

Identifying the different elements and their respective functions is vital for effective maintenance and repair. By familiarizing oneself with the configuration of these components, users can more easily troubleshoot issues and perform necessary replacements. This knowledge empowers individuals to extend the lifespan of their equipment while optimizing performance.

In this guide, we will explore the arrangement of crucial sections within a garden tractor, highlighting how each contributes to the overall functionality. Understanding these connections not only enhances user confidence but also promotes a more proactive approach to care and upkeep.

Components Overview

This section provides a comprehensive look at the various elements that make up the specific model of lawn equipment, highlighting their functions and interconnections. Understanding these components is essential for maintenance and repair, ensuring optimal performance and longevity.

- Engine: The heart of the machine, responsible for providing the necessary power for operation.

- Transmission: This assembly facilitates the transfer of power from the engine to the wheels, allowing for smooth movement.

- Deck: The protective housing that encompasses the cutting mechanism, crucial for maintaining the lawn’s aesthetics.

- Wheels: These elements enable mobility, supporting the entire structure while providing stability on various terrains.

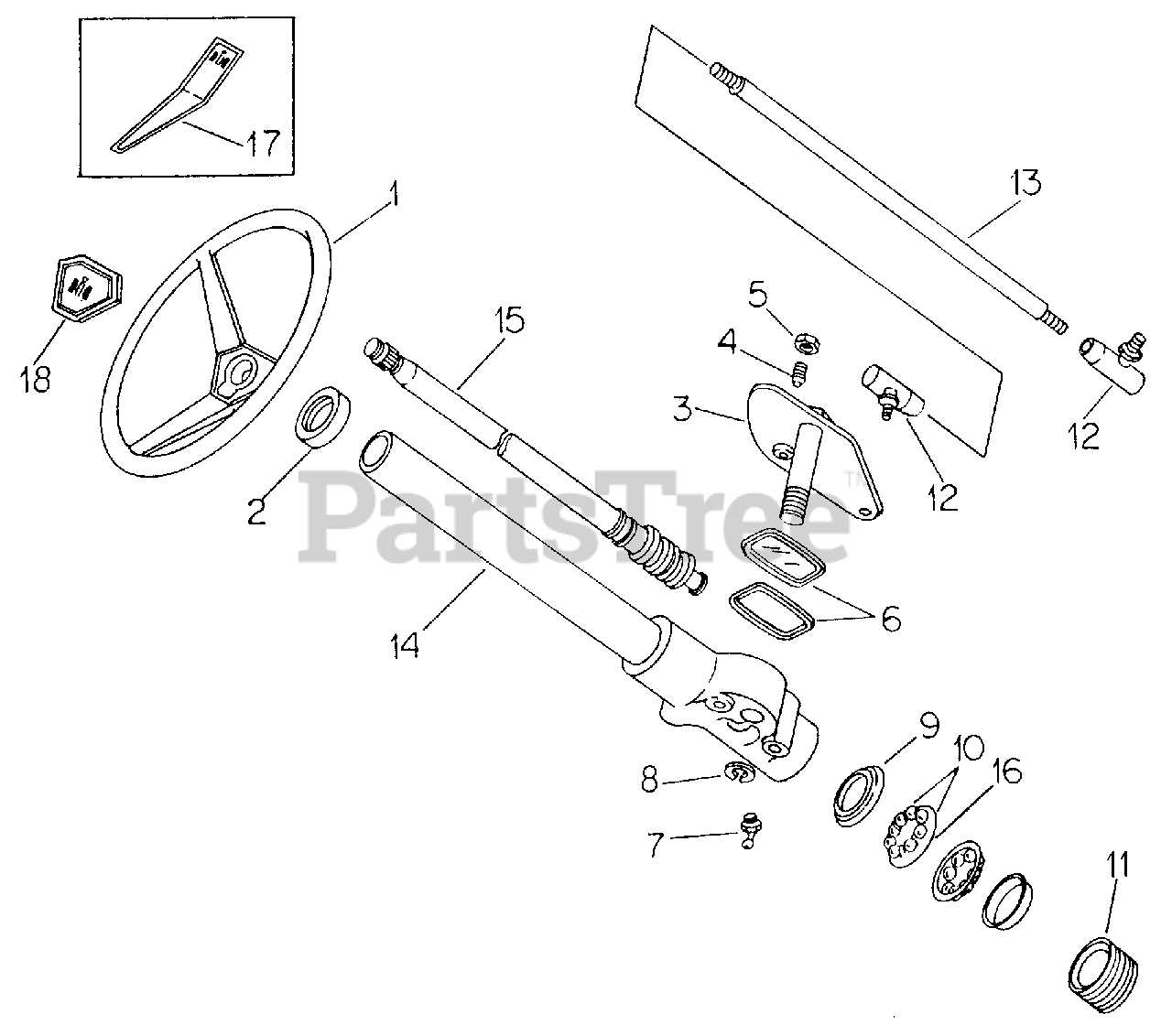

- Steering Mechanism: Essential for maneuvering the equipment, allowing for precise navigation around obstacles.

Each of these components plays a vital role in the overall functionality and efficiency of the machine. Familiarity with their locations and functions can aid users in troubleshooting and performing necessary repairs.

Key Functional Components

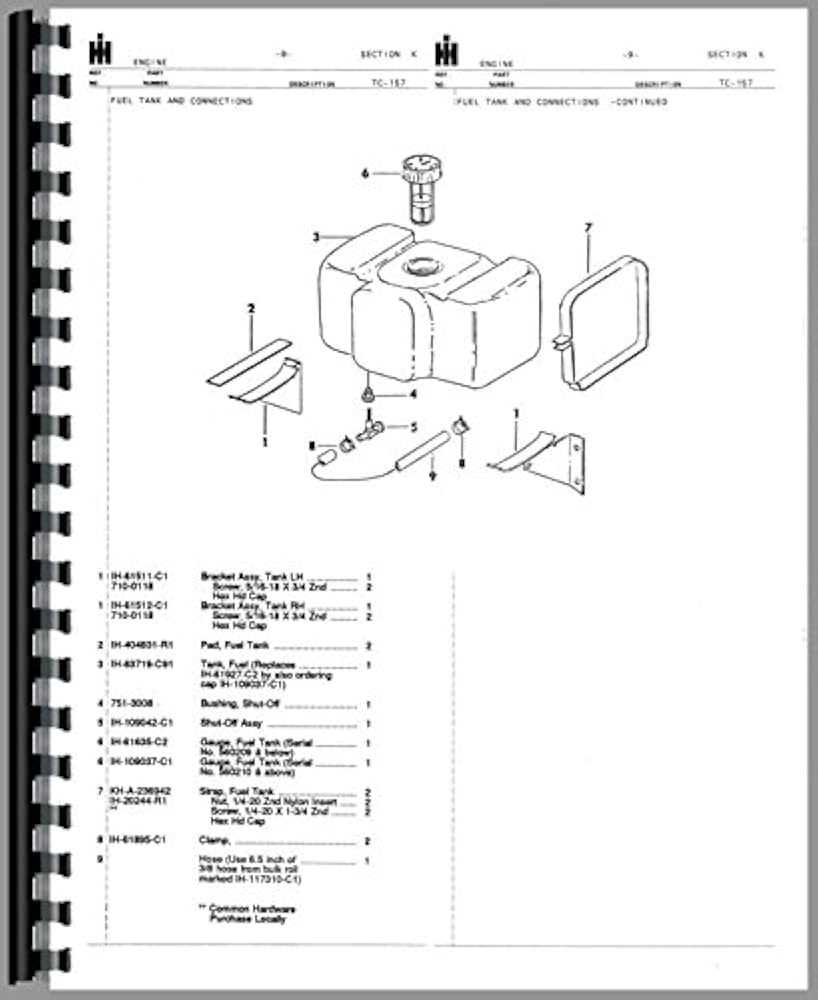

- Fuel System: Supplies energy to the engine, crucial for operation.

- Electrical System: Powers the starter and other electrical components, ensuring reliable performance.

- Cutting Mechanism: Engages the blades for effective grass trimming, vital for achieving desired lawn height.

- Control Panel: Provides user interface for operating various functions, enhancing usability.

Understanding these essential components allows for more informed maintenance decisions, ultimately leading to a better user experience.

Key Components of Cub Cadet 1450

The effective functioning of a garden tractor relies on several essential elements that work in unison to ensure optimal performance. Each component plays a crucial role in enhancing the overall efficiency and usability of the machine, making it an indispensable tool for landscaping and maintenance tasks.

Engine: The powerhouse of the machine, this unit provides the necessary torque and power for various tasks. A robust engine ensures reliability and longevity, allowing users to tackle challenging jobs without fear of breakdowns.

Transmission: This component facilitates the transfer of power from the engine to the wheels, enabling smooth movement across different terrains. A well-designed transmission allows for seamless gear shifts, improving maneuverability and control.

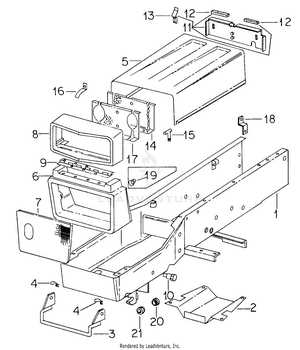

Chassis: Serving as the foundational framework, the chassis supports all other components and provides stability during operation. A durable chassis enhances the overall durability and resilience of the equipment.

Deck: The cutting deck is vital for maintaining a neat and tidy lawn. Equipped with sharp blades, this component ensures a clean cut, contributing to the aesthetics of the yard.

Steering System: An efficient steering mechanism is essential for navigating around obstacles and tight corners. Precision in steering enhances the user’s experience, allowing for effortless control.

Wheels: These elements provide traction and stability, crucial for moving across various surfaces. The design and material of the wheels impact the overall handling and performance of the machine.

Understanding these vital components is essential for proper maintenance and troubleshooting. Ensuring that each element functions correctly will enhance the longevity and effectiveness of the garden tractor.

Understanding the Engine Assembly

The engine assembly is a crucial component of any outdoor power equipment, playing a pivotal role in its overall functionality. This complex system consists of various interrelated parts that work together to convert fuel into mechanical energy, powering the machinery and enabling it to perform its intended tasks. A thorough understanding of this assembly helps in effective maintenance and troubleshooting, ensuring optimal performance over time.

At the heart of the engine lies the cylinder block, which houses the pistons and other vital elements. The cylinder head sits atop the block, sealing the combustion chamber and facilitating airflow through the intake and exhaust valves. Each of these components is designed to withstand the immense pressure and heat generated during operation, showcasing the engineering ingenuity behind their construction.

In addition to the cylinder block and head, the assembly includes the crankshaft, which converts the linear motion of the pistons into rotational motion, driving the output. The camshaft synchronizes the timing of the valves, ensuring efficient airflow and combustion. Each element must function harmoniously, as any misalignment can lead to significant performance issues.

Regular inspections and maintenance of the engine assembly are vital. Checking for wear and tear, ensuring proper lubrication, and replacing any damaged components are essential practices to keep the equipment running smoothly. Understanding the intricacies of this assembly not only aids in better care but also enhances the user’s capability to address potential issues before they escalate.

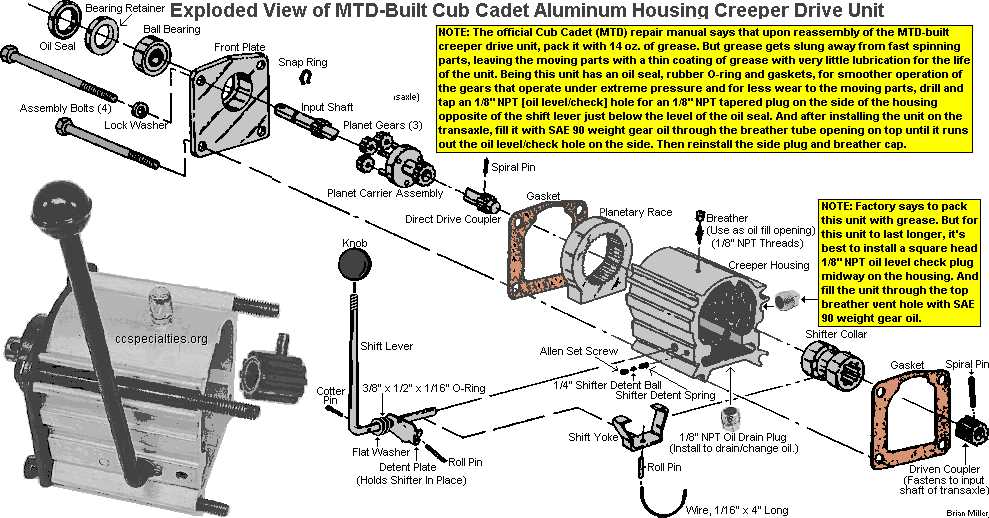

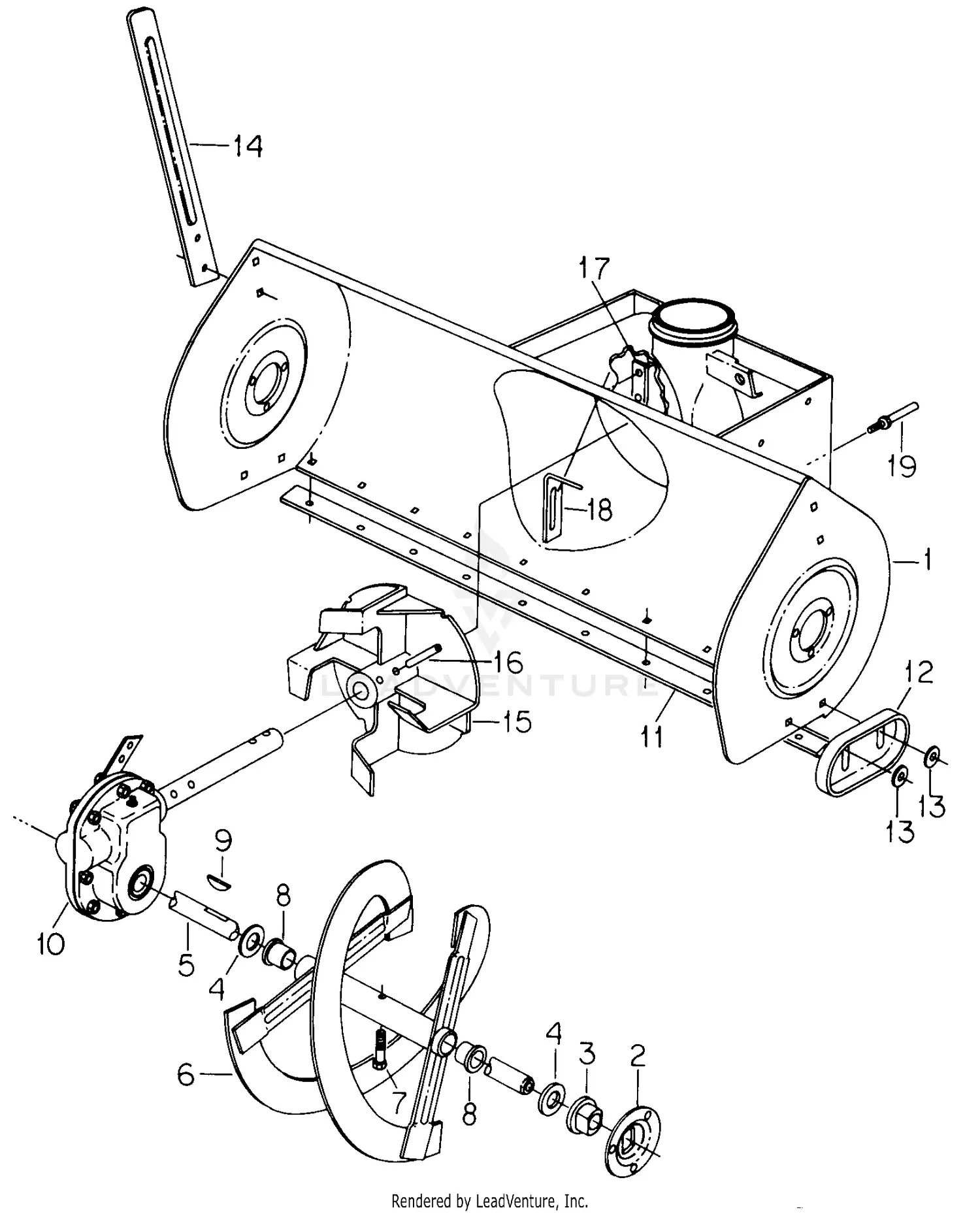

Transmission System Details

The transmission mechanism plays a crucial role in the operation of a gardening vehicle, ensuring efficient power transfer from the engine to the wheels. This system is designed to facilitate smooth gear shifts, allowing for optimal performance in various terrains. Understanding the components and functionality of this system is essential for maintenance and troubleshooting.

Components of the Transmission System

The key elements of the transmission assembly include gears, belts, and pulleys. Each component works in harmony to provide the necessary torque and speed adjustments. Gears serve as the primary means of changing speed ratios, while belts ensure that power is transmitted efficiently. Pulleys contribute to the overall effectiveness by assisting in the engagement and disengagement of the drive mechanism.

Maintenance Considerations

Regular upkeep of the transmission system is vital for longevity and performance. Key maintenance tasks include checking fluid levels, inspecting for wear and tear, and ensuring proper alignment of components. Addressing issues promptly can prevent costly repairs and enhance the overall functionality of the vehicle.

Electrical Wiring Layout Explained

The layout of electrical connections plays a crucial role in the functionality of machinery. Understanding how components interconnect can lead to better maintenance, troubleshooting, and modifications. This section provides an overview of the wiring configuration, emphasizing the importance of each component and its relationship within the system.

Key Components of the Wiring System

A well-organized electrical framework includes various elements that work together to ensure proper operation. Below is a summary of the essential parts involved:

| Component | Function |

|---|---|

| Battery | Supplies power to start the engine and operate electrical systems. |

| Ignition Switch | Controls the flow of electricity to the engine and electrical accessories. |

| Starter Motor | Engages the engine to initiate combustion and power the machine. |

| Alternator | Charges the battery and powers electrical systems while the engine is running. |

| Wiring Harness | Organizes and protects electrical wires, connecting various components. |

Understanding the Wiring Connections

Each connection within the layout is vital for maintaining a seamless flow of electricity. Faulty or loose connections can lead to operational issues or complete failure of the system. Regular inspections of the wiring can prevent unexpected breakdowns and ensure optimal performance.

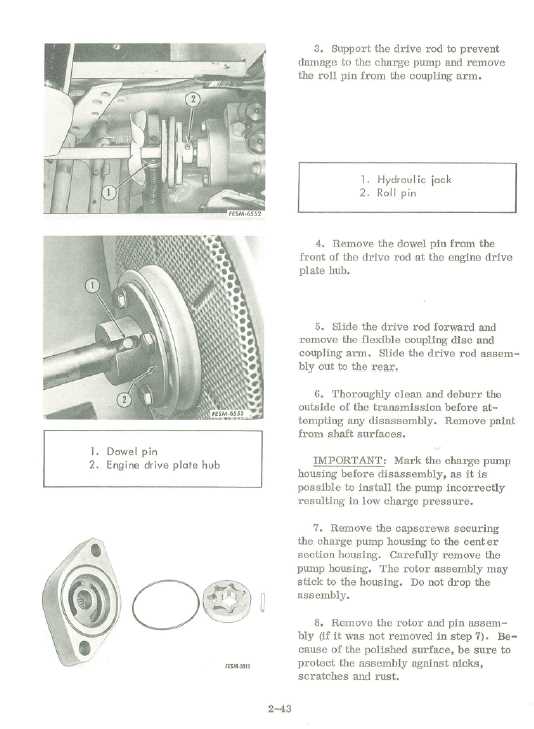

Hydraulic System Functionality

The hydraulic system plays a crucial role in the operation of various machinery, providing the necessary force to perform multiple tasks efficiently. This system utilizes fluid dynamics to transmit power, allowing components to move and operate smoothly. Understanding the functionality of hydraulic systems is essential for maintaining optimal performance and ensuring longevity.

Principles of Operation

At its core, a hydraulic system operates on the principle of fluid mechanics. By utilizing incompressible fluid, it transmits force through pipes and hoses to different parts of the machinery. When pressure is applied to the fluid in a confined space, it exerts force equally in all directions, enabling the movement of pistons or other components. This mechanism is what allows for lifting, steering, and other critical functions in various applications.

Components Involved

The efficiency of the hydraulic system relies on several key elements, including pumps, cylinders, and valves. Pumps are responsible for creating pressure within the fluid, while cylinders convert that pressure into mechanical movement. Valves regulate the flow of fluid, ensuring that the system responds appropriately to operator commands. Each of these components must work in harmony to achieve the desired functionality, making proper maintenance and understanding vital for effective operation.

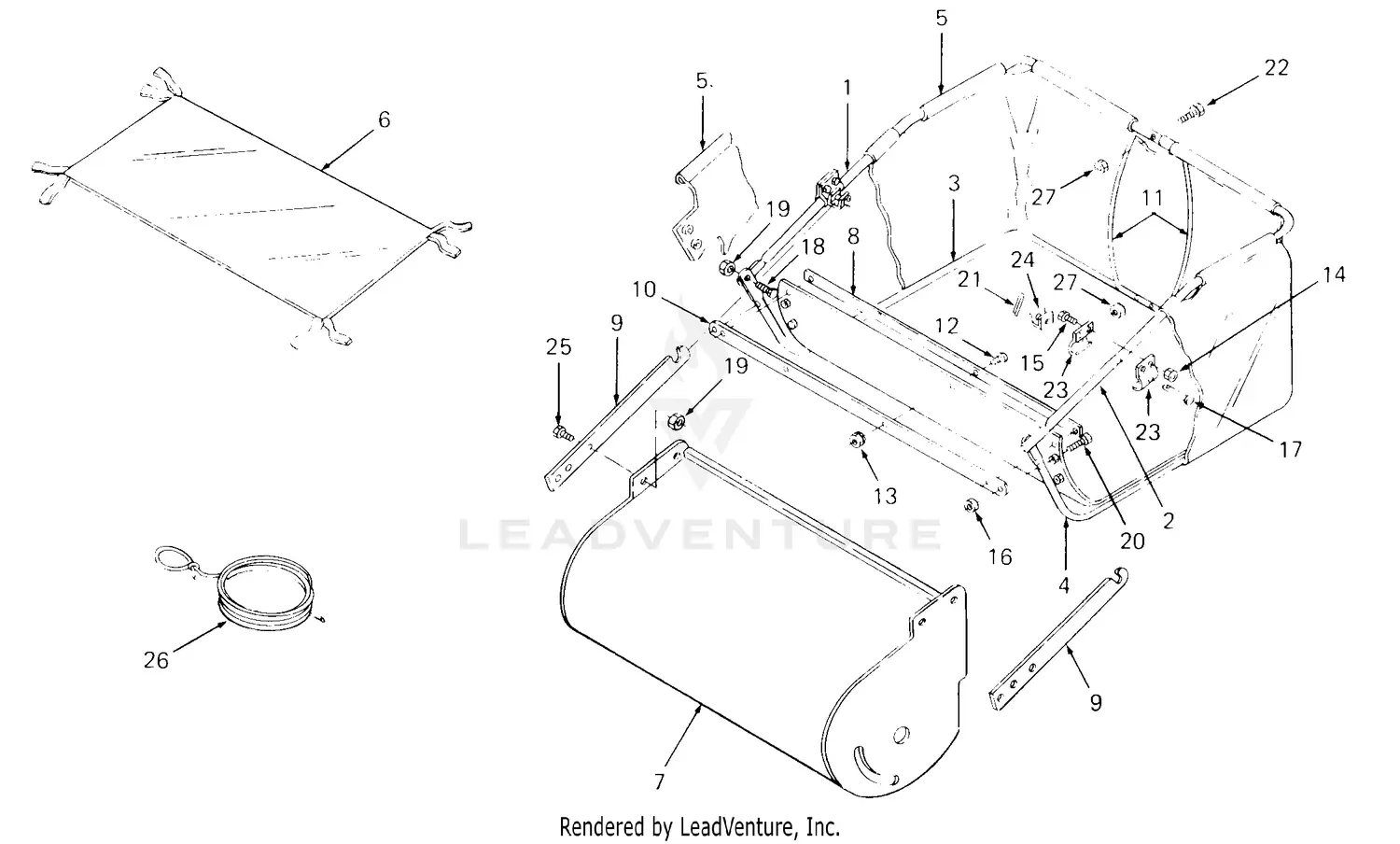

Deck and Cutting Mechanism Parts

The efficiency of a lawn mower greatly depends on its deck and cutting components. These elements work together to provide a clean and precise cut, ensuring an even appearance for the grass. Understanding the various elements involved in this system can help in maintaining optimal performance and prolonging the life of the equipment.

Key Components of the Cutting System

The cutting system consists of several crucial components that contribute to its functionality. Each part plays a specific role, from the blades that slice through the grass to the housing that protects them. Familiarity with these components allows for effective troubleshooting and maintenance.

| Component | Description |

|---|---|

| Blades | Sharp metal pieces responsible for cutting the grass at various heights. |

| Deck Housing | The protective casing that encloses the cutting blades and supports the mower’s structure. |

| Spindle Assembly | Holds the blades in place and allows them to rotate, driving the cutting action. |

| Belt | Transmits power from the engine to the spindle assembly, facilitating blade movement. |

| Anti-Scalping Wheels | Help prevent the deck from digging into the ground, ensuring an even cut across varying terrains. |

Maintenance Tips for Optimal Performance

Regular inspection and maintenance of the deck and cutting components are essential for ensuring their longevity and performance. Keeping the blades sharp, checking for wear in the spindle assembly, and ensuring proper belt tension can significantly enhance the efficiency of the mowing process. Additionally, cleaning the deck after each use helps prevent grass buildup and rust, further extending the lifespan of the equipment.

Maintenance and Serviceable Components

Regular upkeep is crucial for ensuring optimal performance and longevity of your equipment. Understanding the various components that require routine attention will help maintain functionality and prevent potential issues. This section focuses on key elements that can be serviced or replaced to enhance operational efficiency.

Engine Care: The heart of any machinery, the engine, needs periodic checks and maintenance. Regular oil changes, filter replacements, and ensuring that cooling systems are clean will keep the engine running smoothly and efficiently.

Transmission Inspection: A well-functioning transmission is vital for power transfer and movement. Routine inspections for fluid levels and potential leaks, along with timely servicing, are essential for seamless operation.

Blade Maintenance: Keeping the cutting blades sharp is essential for effective performance. Regular cleaning and sharpening will not only improve cutting efficiency but also reduce wear and tear on other components.

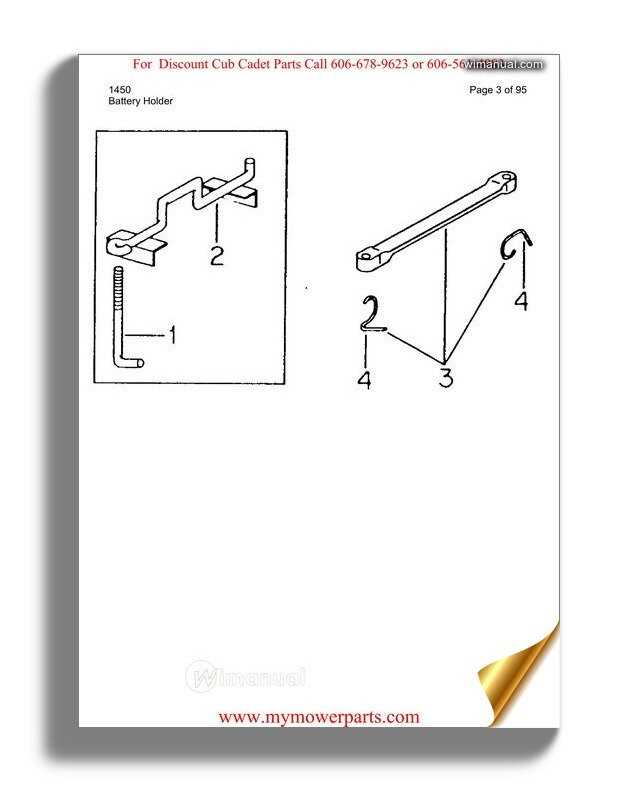

Battery Management: The battery serves as the power source for starting the engine and powering various electrical systems. Regular checks on the battery’s charge and terminals will ensure reliable starts and efficient operation.

Tire Condition: Proper tire pressure and tread depth are important for stability and traction. Regularly inspecting and maintaining tires can prevent safety issues and enhance performance on various terrains.

By focusing on these critical aspects, you can ensure that your equipment remains in top condition, maximizing its lifespan and efficiency.

Parts Identification Guide

This section aims to assist users in recognizing and understanding the various components of a specific outdoor equipment model. Identifying these elements is crucial for effective maintenance and repair. By becoming familiar with each component, owners can ensure their machinery operates efficiently and effectively.

Component Overview

Understanding the different segments of your machinery will enable you to diagnose issues quickly and order the correct replacements when needed. Below is a simplified list of key elements commonly found in outdoor equipment, along with their respective descriptions.

| Component Name | Description |

|---|---|

| Engine Assembly | The main power source that drives the entire machine. |

| Transmission Unit | Responsible for transferring power from the engine to the wheels. |

| Chassis | The frame that supports all components and provides stability. |

| Deck | The platform that houses the cutting blades or other working attachments. |

| Control Panel | Interface used by the operator to manage the machine’s functions. |

Identifying Components

When examining the machine, it is helpful to refer to a labeled guide or schematic. This can aid in visualizing where each component is situated and how they interact with one another. Having this knowledge will empower users to perform routine checks and resolve minor issues independently.

Common Replacement Parts Needed

When maintaining a lawn care machine, certain components tend to wear out and require frequent substitution. Understanding which elements are most susceptible to damage can help ensure optimal performance and longevity of the equipment. This section highlights some of the commonly needed replacements that every operator should keep on hand.

| Component | Description | Frequency of Replacement |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean airflow. | Every 50 hours of operation |

| Oil Filter | Filters contaminants from the engine oil, maintaining lubrication efficiency. | Every 100 hours of operation |

| Blades | Sharpens cutting performance and ensures a clean cut on grass. | Every 25 hours of operation or as needed |

| Belt | Transfers power from the engine to the cutting deck or wheels. | Every 200 hours of operation |

| Battery | Provides electrical power for starting and operating electrical components. | Every 2-3 years, depending on usage |

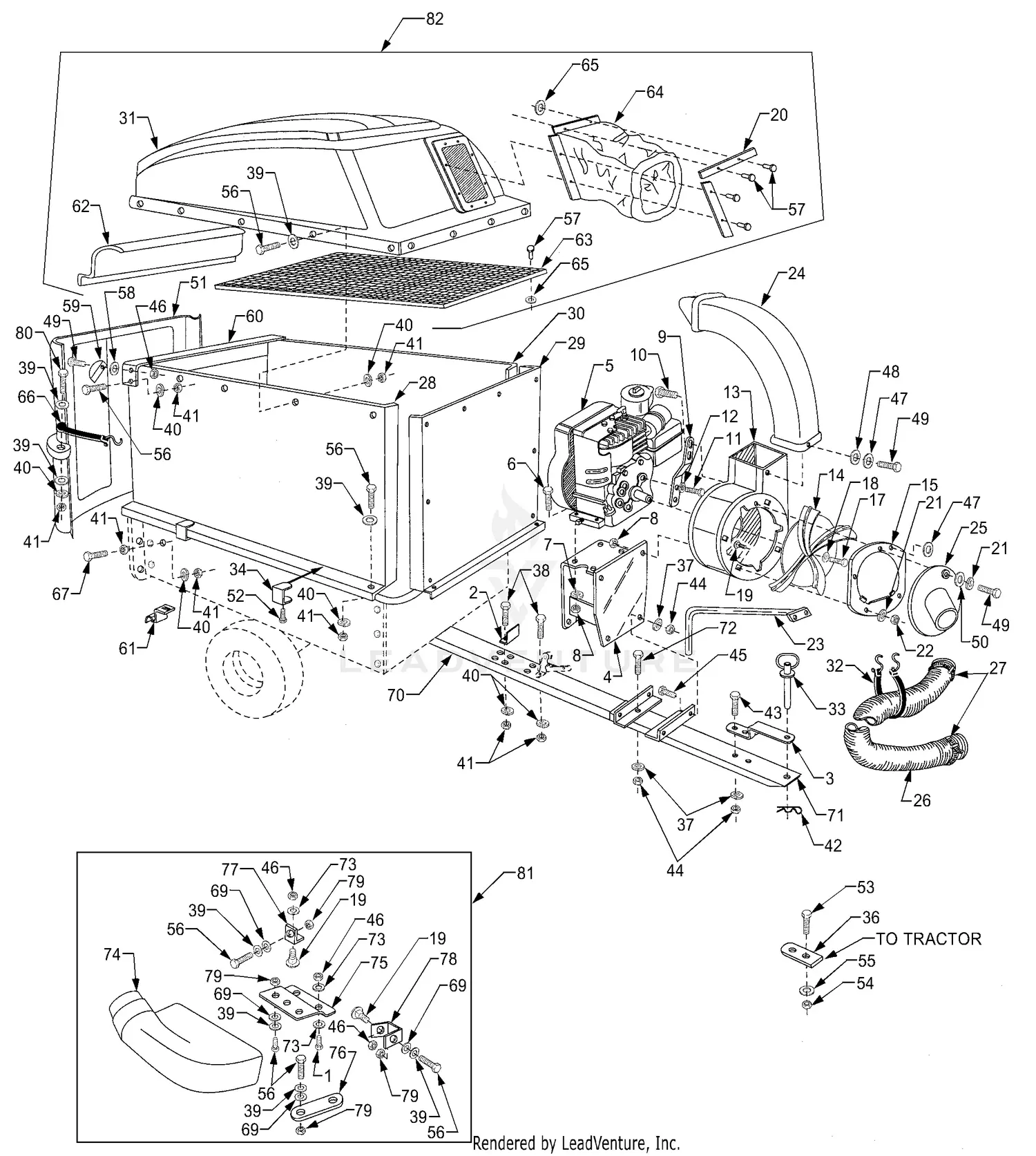

Accessories for Enhanced Performance

To optimize the functionality and efficiency of your machine, various enhancements and supplementary tools can significantly elevate its performance. These add-ons are designed to improve operational capabilities, provide versatility, and ensure a smoother experience, whether for routine maintenance or specialized tasks.

Essential Attachments

Incorporating key attachments can drastically increase productivity. Options such as snow blades, tillers, and grass sweepers enable users to tackle a broader range of tasks, making the equipment more versatile throughout the year. These enhancements not only aid in specific functions but also contribute to time-saving and efficiency in operations.

Performance Upgrades

Investing in performance upgrades can lead to noticeable improvements in speed and power. Upgrades like high-capacity batteries or advanced air filters can enhance the overall effectiveness of your machine, ensuring it operates at peak performance. These modifications can be especially beneficial in demanding conditions, allowing for better results and extended use.

Tools for Assembly and Repair

Effective assembly and maintenance of machinery require a variety of specialized instruments to ensure efficiency and precision. The right tools not only facilitate the process but also contribute to the longevity and performance of the equipment. Understanding the essential implements needed for these tasks can significantly enhance your repair experience.

Hand Tools: A comprehensive toolkit often includes a selection of hand tools such as wrenches, screwdrivers, and pliers. These basic implements are fundamental for loosening, tightening, and adjusting components. Selecting high-quality options can make a notable difference in achieving accurate and secure fittings.

Power Tools: For more demanding tasks, power tools like drills and impact wrenches offer added convenience and speed. These tools enable you to tackle larger projects more efficiently, especially when dealing with stubborn or heavy components. Ensuring that power tools are well-maintained will enhance their performance and extend their lifespan.

Measuring Instruments: Precision is vital in assembly and repair work. Tools such as calipers and measuring tapes help ensure that all parts fit together seamlessly. Utilizing these measuring devices can prevent errors and reduce the likelihood of future issues arising from improper assembly.

Safety Equipment: In any maintenance or repair operation, safety should be a priority. Protective gear, including gloves, goggles, and ear protection, should always be worn to safeguard against potential hazards. Investing in high-quality safety equipment is essential for creating a secure working environment.

By equipping yourself with the appropriate tools and safety gear, you can significantly improve the efficiency and effectiveness of your assembly and maintenance efforts. A well-prepared toolkit not only simplifies the process but also enhances the overall experience of working with machinery.

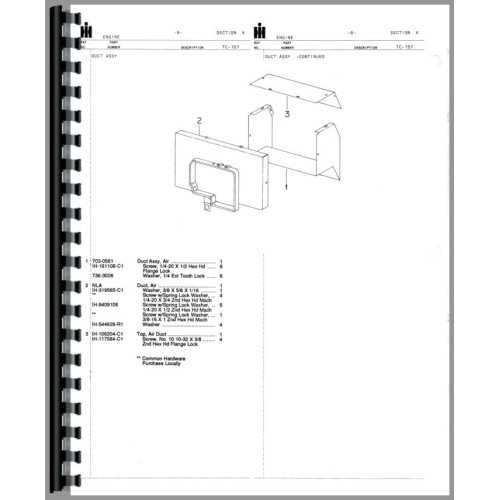

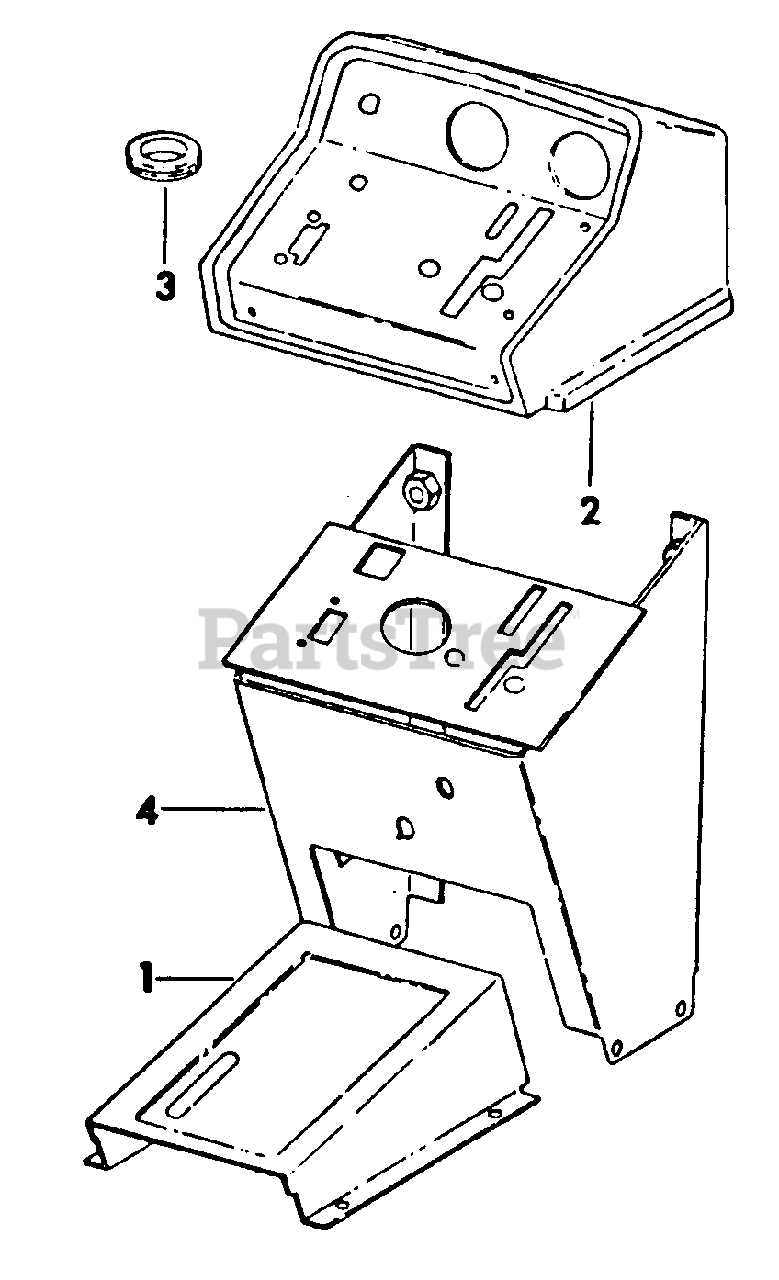

Illustrated Parts Breakdown

This section provides a comprehensive visual representation of various components used in the specific model of riding equipment. Understanding the layout and function of each element is crucial for effective maintenance and repair. Illustrated guides serve as valuable resources for identifying parts and ensuring proper assembly.

Key Components Overview

- Engine Assembly

- Transmission System

- Chassis Structure

- Deck and Blade Assembly

- Electrical System

Benefits of Visual Guides

- Enhances understanding of equipment functionality.

- Facilitates easier identification of necessary replacements.

- Simplifies the repair process for users of all skill levels.

- Promotes confidence in performing maintenance tasks.