When it comes to maintaining and repairing your equipment, having a clear visual representation of its components can be invaluable. This guide aims to provide insights into the intricate layout of essential parts, ensuring you have the knowledge necessary for effective troubleshooting and enhancement.

Understanding the layout of machinery components not only simplifies the repair process but also enhances your overall operational efficiency. By exploring various elements, you can gain a deeper appreciation for how each part contributes to the machine’s functionality.

In this exploration, we will delve into the specific arrangements and connections that define your equipment, empowering you with the ultimate understanding needed to keep your machinery in optimal condition. Whether you’re a seasoned technician or a novice enthusiast, this information will serve as a valuable resource.

Overview of the Riding Mower

This section provides a comprehensive look at a specific model of riding mower, focusing on its features, capabilities, and overall performance. Designed for efficiency and ease of use, this machine serves both residential and commercial needs effectively.

Key Features

- Powerful engine for optimal cutting performance

- Ergonomic seating for enhanced comfort during extended use

- Robust build quality ensuring durability

- Advanced mowing technology for precise grass management

Benefits

- Time-saving operation due to wide cutting deck

- Improved maneuverability in tight spaces

- Reduced fatigue with user-friendly controls

- Versatile attachments for multi-season use

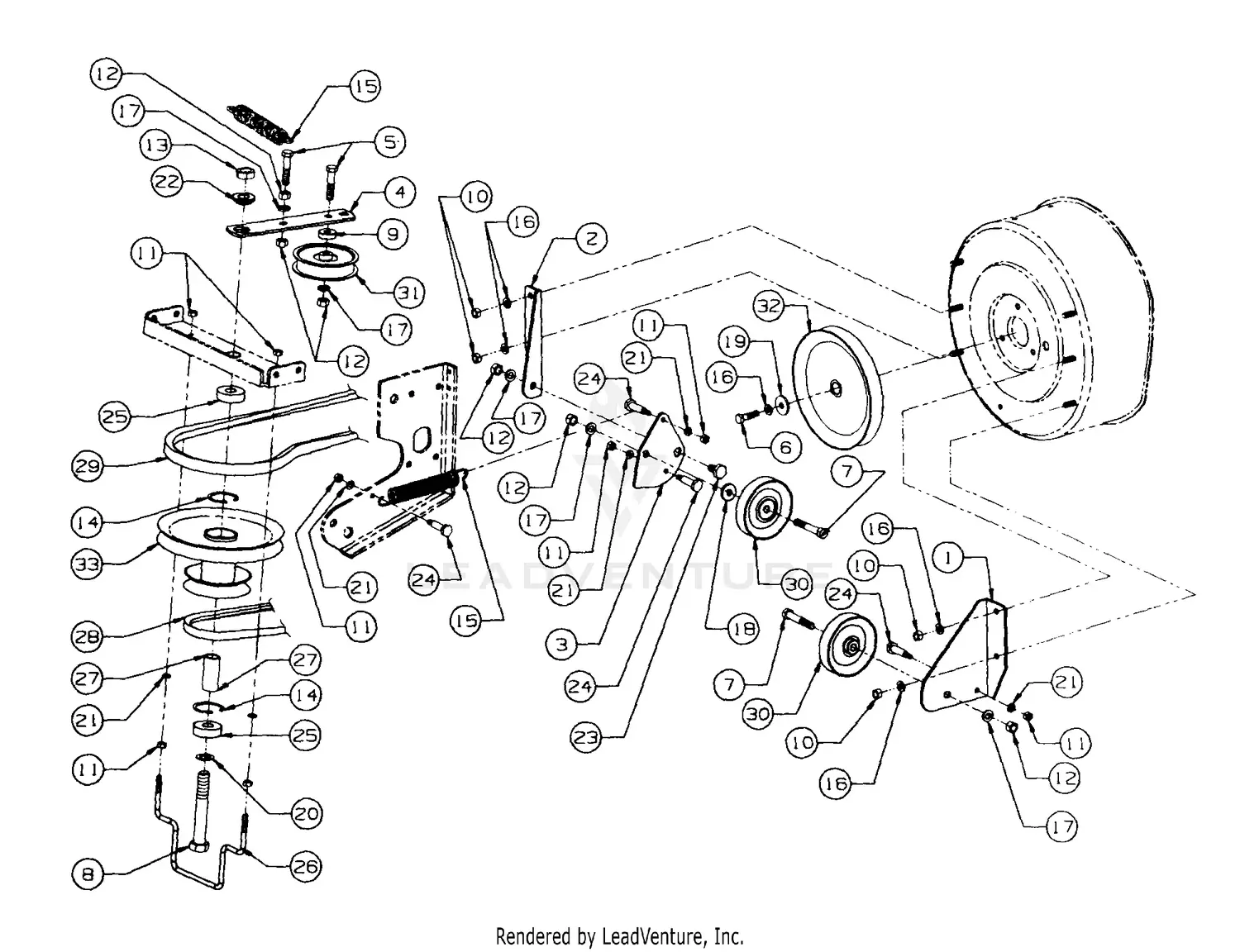

Importance of Parts Diagrams

Understanding the intricate workings of machinery requires a clear visual representation of its components. These illustrations serve as essential guides for both assembly and maintenance, helping users identify individual elements and their relationships within the overall structure. By providing detailed views, they simplify troubleshooting and repair processes, ensuring efficiency and accuracy.

Moreover, having access to these visual aids enhances the user’s ability to order replacements and upgrades. This clarity can save time and reduce frustration, as it allows for a quicker assessment of what is needed. In addition, such resources are invaluable for training purposes, enabling new users to familiarize themselves with the equipment more effectively.

Ultimately, these resources contribute to the longevity and optimal performance of machinery. By promoting informed decision-making regarding repairs and enhancements, they play a crucial role in maintaining operational efficiency and reliability.

Identifying Key Components

Understanding the essential elements of your equipment is crucial for effective maintenance and repair. Recognizing how these components interact will enhance your ability to troubleshoot and optimize performance. This section will guide you through the major parts and their functions, helping you to become more familiar with the machinery.

Main Functional Elements

Every machine consists of several critical components that work together seamlessly. Familiarity with these elements not only aids in repair tasks but also extends the lifespan of your equipment. Below is a breakdown of some of the primary functional parts.

| Component | Description |

|---|---|

| Engine | The power source that drives all operations, converting fuel into mechanical energy. |

| Transmission | Responsible for transferring power from the engine to the wheels, enabling movement and control. |

| Steering System | Allows for directional control, providing maneuverability and precision during operation. |

| Deck | The part where cutting or mowing occurs, often housing the blades and ensuring an even cut. |

Auxiliary Features

In addition to the main components, various auxiliary features enhance functionality and user experience. Understanding these can provide further insight into improving efficiency and ease of use.

| Feature | Purpose |

|---|---|

| Fuel System | Stores and supplies fuel to the engine, crucial for operation. |

| Electrical System | Controls the ignition and powers various electronic components, ensuring optimal functionality. |

| Cooling System | Prevents overheating by dissipating heat generated during operation. |

| Safety Features | Includes mechanisms such as shut-off switches and guards to protect the operator and the machine. |

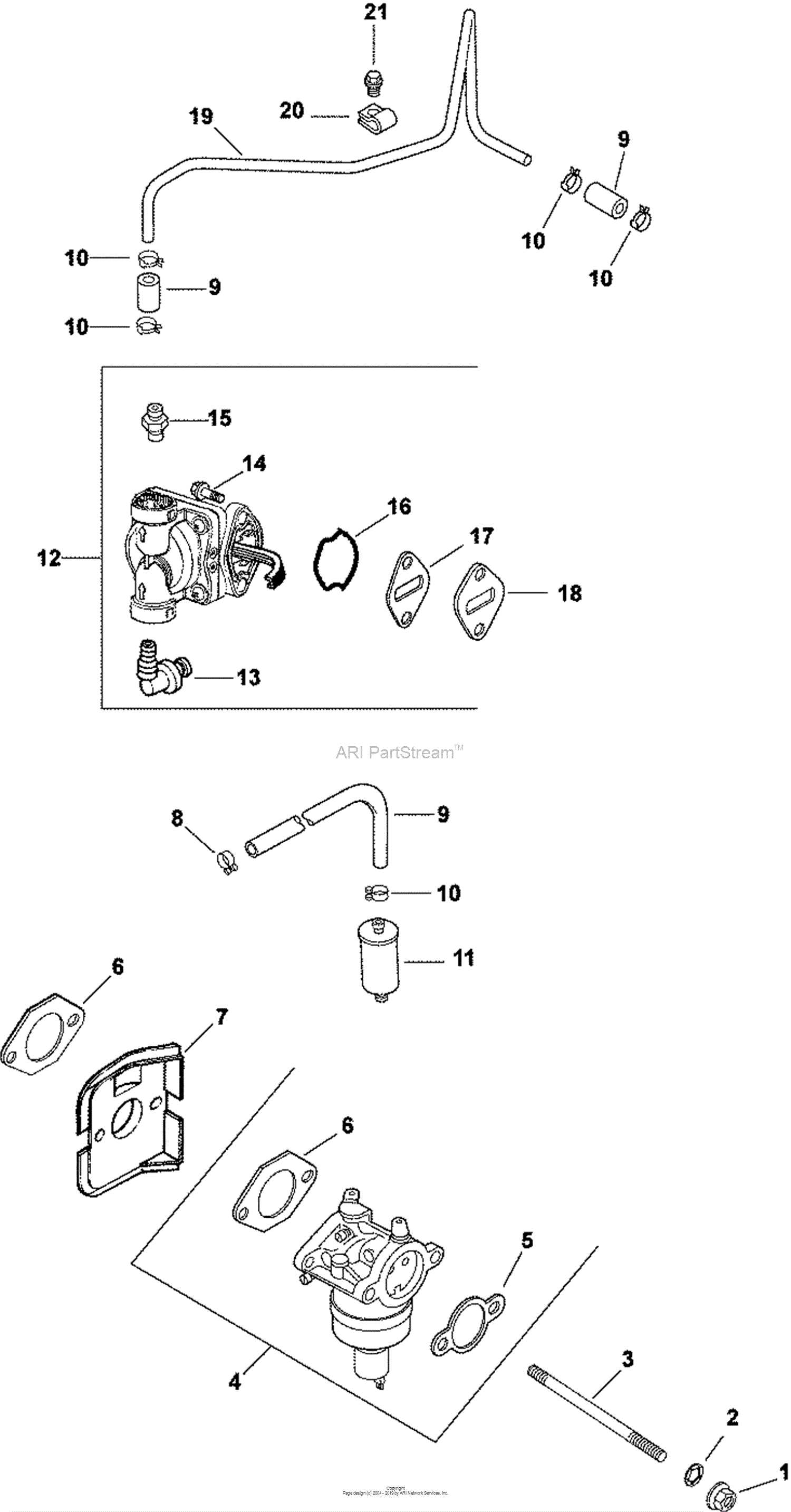

Engine Specifications and Parts

This section delves into the intricate details of the power unit and its essential components. Understanding these specifications is crucial for optimal performance and maintenance, ensuring that the machinery operates efficiently and reliably.

The engine is typically equipped with a robust four-stroke design, known for its durability and fuel efficiency. Key metrics include displacement, horsepower output, and torque characteristics, all of which contribute to the machine’s overall capability. Regular maintenance of these specifications can significantly enhance longevity and performance.

Critical components such as the air filter, fuel system, ignition system, and cooling mechanism play vital roles in the engine’s functionality. Each part must be examined periodically to prevent wear and ensure smooth operation. Familiarity with these elements enables users to diagnose issues swiftly and conduct necessary repairs or replacements.

Ultimately, a comprehensive understanding of the engine and its components not only facilitates better maintenance practices but also enhances the overall user experience by maximizing the machine’s efficiency and reliability.

Transmission System Details

The transmission system is a crucial component that ensures the efficient transfer of power from the engine to the wheels. Understanding its structure and function can significantly enhance the maintenance and performance of the machinery. This section delves into the various elements that constitute the transmission mechanism, highlighting their roles and interactions.

- Drive Belt: This flexible loop transfers power from the engine to the transmission, allowing for smooth acceleration and deceleration.

- Transmission Housing: The casing that contains the internal components, protecting them from external elements and facilitating efficient operation.

- Gears: These critical components adjust the torque and speed of the vehicle, enabling it to operate effectively under various conditions.

- Shifter Mechanism: This allows the operator to select different speeds and directions, ensuring versatility in operation.

- Fluid System: This system lubricates and cools the transmission, maintaining optimal performance and preventing overheating.

Regular inspection and maintenance of these components are essential for prolonging the lifespan of the transmission and ensuring the overall functionality of the equipment. Understanding how each part interacts can aid in troubleshooting and enhancing operational efficiency.

Electrical System Overview

The electrical framework of a machinery unit plays a pivotal role in its operation and performance. This system encompasses various components that work in unison to ensure functionality, reliability, and efficiency. Understanding these elements can enhance troubleshooting and maintenance efforts.

Main Components

Key elements of the electrical network include the battery, starter motor, alternator, and ignition system. Each part contributes to the overall operation, allowing for seamless power distribution and effective engine management.

Wiring and Connectivity

The connections between components are critical for maintaining a stable electrical supply. Proper wiring practices ensure safety and performance, preventing potential failures or malfunctions.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting the engine. |

| Starter Motor | Engages the engine to initiate combustion. |

| Alternator | Charges the battery and powers electrical systems while running. |

| Ignition System | Ignites the fuel-air mixture for engine operation. |

Understanding the Chassis Design

The framework of a vehicle serves as its backbone, providing stability and support for various components. An in-depth exploration of this structure reveals how its engineering influences overall performance and durability. The design is not merely a physical outline; it integrates functionality, safety, and ease of maintenance into one cohesive unit.

Key aspects of the chassis design include:

- Material Selection: The choice of materials significantly affects weight and strength.

- Structural Integrity: A well-designed framework ensures resilience against stress and impact.

- Ergonomics: Consideration of user comfort and accessibility is crucial in the layout.

Additionally, the configuration plays a vital role in how the vehicle handles various terrains and conditions. A well-thought-out arrangement enhances maneuverability and stability, allowing for a more enjoyable user experience.

Maintenance considerations also stem from the chassis design:

- Accessibility: Components should be easily reachable for repairs and inspections.

- Modularity: A modular design facilitates upgrades and replacements, extending the vehicle’s lifespan.

- Weight Distribution: Proper distribution helps improve handling and reduces wear on parts.

Ultimately, the design of the framework not only influences performance but also defines the longevity and efficiency of the entire machine.

Common Replacement Parts

Maintaining outdoor machinery often requires timely replacement of specific components to ensure optimal performance. Understanding which elements typically need attention can significantly enhance the longevity and efficiency of your equipment.

Essential Components

Among the most frequently replaced items are blades, which endure wear over time and directly affect cutting efficiency. Additionally, filters play a critical role in keeping the engine clean, making regular replacement essential for smooth operation.

Wear Items

Another category to consider includes belts and batteries. Belts can fray and lose effectiveness, while batteries may diminish in power after prolonged use. Ensuring these items are in good condition is vital for reliable performance.

Being proactive about these common replacements not only saves time but also prevents potential breakdowns during crucial tasks.

Maintenance and Care Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a systematic approach will help prevent potential issues and enhance efficiency.

- Check oil levels regularly and change as recommended.

- Inspect filters and replace them to ensure proper airflow and function.

- Keep the exterior clean to prevent rust and debris buildup.

Additionally, attention to specific components can lead to the ultimate improvement in performance.

- Sharpen blades periodically for a clean cut.

- Lubricate moving parts to minimize wear and tear.

- Inspect tires for wear and maintain proper pressure.

By incorporating these practices into your routine, you can effectively prolong the lifespan and enhance the functionality of your machine.

Where to Find Parts Diagrams

Locating technical illustrations for machinery components can significantly enhance your maintenance and repair efforts. These visual guides are invaluable for understanding the structure and organization of various elements, allowing for precise assembly and troubleshooting.

Online resources, such as manufacturer websites and dedicated forums, often provide downloadable manuals and visual references. Additionally, third-party websites specializing in equipment maintenance may offer comprehensive archives for easy access. Local dealers and repair shops can also be great sources, as they typically have access to official documentation and can provide assistance in obtaining the necessary resources.

Utilizing social media platforms and community groups can facilitate connections with fellow enthusiasts who might share their own experiences and resources. Engaging with these communities often leads to discovering rare materials and insights that can further aid in your endeavors.

Aftermarket vs. OEM Parts

The choice between replacement components from original manufacturers and those from third-party suppliers is a common dilemma for many equipment owners. Each option presents distinct advantages and considerations that can impact performance, longevity, and overall satisfaction. Understanding these differences is essential for making an informed decision tailored to individual needs and budget.

Benefits of OEM Components

Original equipment manufacturer components are designed specifically for particular models, ensuring a precise fit and optimal functionality. Quality assurance is a significant advantage, as these items typically undergo rigorous testing to meet industry standards. Furthermore, using OEM components often helps maintain the warranty on the equipment, providing peace of mind for the owner.

Advantages of Aftermarket Options

On the other hand, aftermarket offerings often come at a more affordable price point, appealing to budget-conscious consumers. Many third-party suppliers produce high-quality alternatives that can outperform their OEM counterparts. Additionally, the variety available can enhance customization possibilities, allowing users to select components that better suit their specific preferences or operational needs. However, it is essential to research and choose reputable brands to ensure reliability and compatibility.

Assembly and Disassembly Guide

This section provides a comprehensive overview for effectively assembling and disassembling your machinery. Understanding the proper techniques and procedures is crucial for maintaining performance and ensuring longevity. This guide will assist you in navigating the various components, facilitating a smoother process whether you are reassembling or taking apart parts for repair or replacement.

Preparation Steps

Before commencing the assembly or disassembly process, it is vital to gather all necessary tools and components. Ensure that your workspace is organized and free from distractions. Additionally, consulting the user manual can provide valuable insights into specific requirements and safety measures pertinent to your model. Familiarizing yourself with the main components will streamline the entire procedure.

Disassembly Process

Start by carefully removing any protective covers or casings. Take note of the order in which parts are removed; documenting this can significantly aid in reassembly. Utilize appropriate tools to avoid damaging any components. As you proceed, group similar pieces together to simplify the assembly stage. Always follow safety protocols, including wearing protective gear and disconnecting power sources when necessary.

Common Issues and Solutions

When working with outdoor machinery, it’s not uncommon to encounter a range of challenges that can affect performance and reliability. Understanding these issues and their potential solutions is crucial for maintaining efficiency and extending the lifespan of your equipment.

Engine Performance Problems

One of the frequent challenges users face is engine-related issues. Symptoms may include difficulty starting, stalling, or reduced power output. Regular maintenance can often resolve these problems. Check the fuel system for blockages, ensure the air filter is clean, and inspect the spark plug for wear. Replacing damaged components can restore optimal functionality.

Mechanical Failures

Mechanical failures, such as broken belts or malfunctioning gears, can significantly impact operation. It’s essential to perform routine inspections to identify signs of wear and tear early. Using the correct tools and replacement parts can simplify repairs. If a component is beyond repair, consulting a professional may be necessary to avoid further complications.