When working with mechanical and outdoor equipment, understanding the structure and arrangement of various elements is crucial. Each component has a specific role, and ensuring their correct positioning and maintenance can greatly extend the lifespan of the machine. Knowing how to navigate through the detailed layout of these elements allows for more efficient repairs and servicing.

This section delves into the technical details, offering a clear overview of the essential elements and how they are connected. With the right knowledge, troubleshooting common issues becomes much easier. This guide will provide a step-by-step breakdown, ensuring that every aspect is covered thoroughly.

By exploring the arrangement and function of various mechanical elements, you can ensure your equipment runs smoothly. Whether you’re replacing a single unit or performing a full maintenance check, having access to an organized overview is vital for optimal performance.

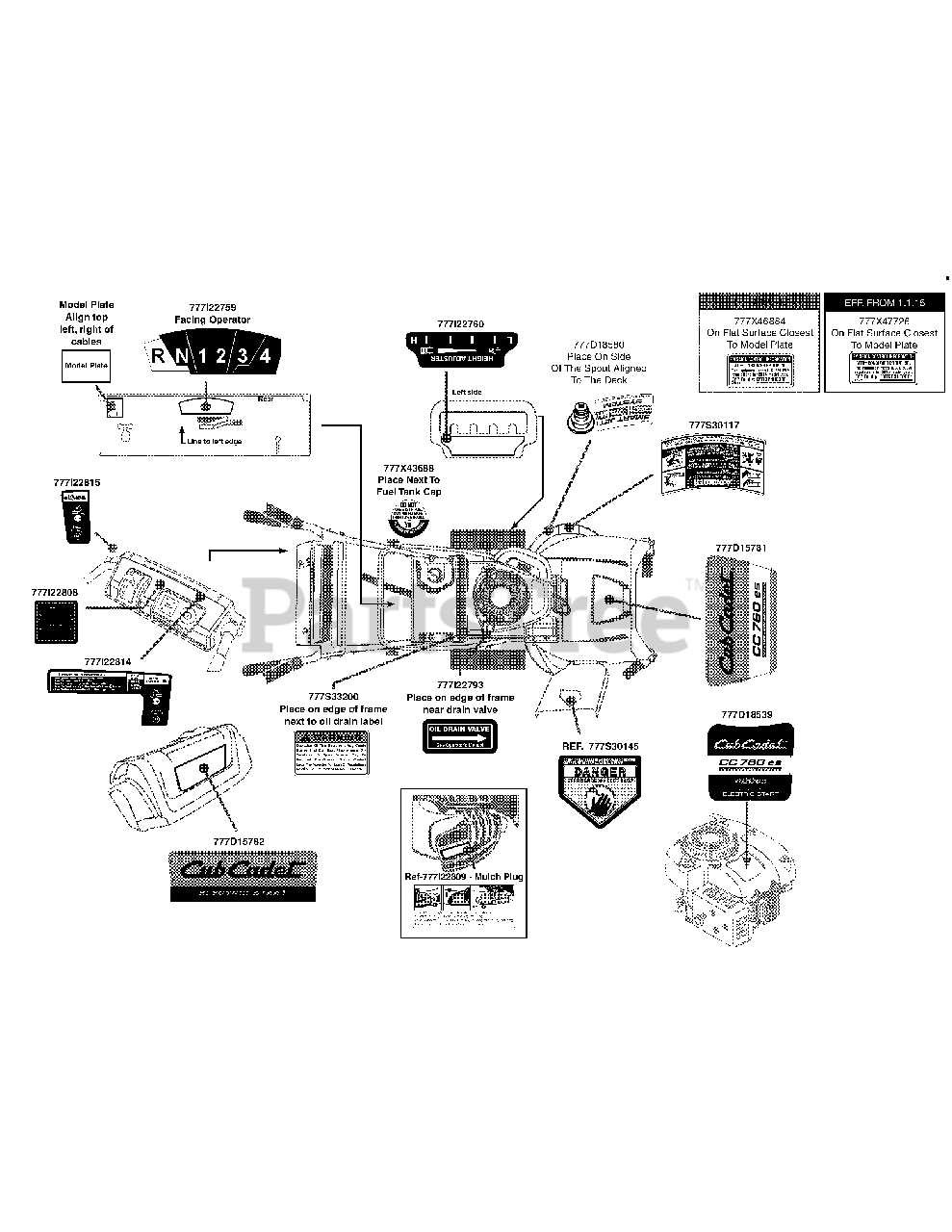

Understanding the Cub Cadet CC760ES Structure

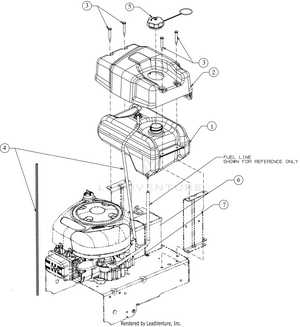

The design of this equipment is built with efficiency and durability in mind, providing users with a seamless experience. Its configuration allows for smooth operation, combining essential elements that contribute to both functionality and ease of use. By understanding the internal layout, one can easily identify how the various components work together to optimize performance.

Key sections of the machine’s structure are organized in a way that simplifies maintenance and improves longevity. Below is a table that outlines the main structural elements:

| Component | Description | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chassis | The foundation that supports the entire framework, ensuring stability during operation. | ||||||||||||||||||

| Engine Assembly | The power source responsible for driving the machine, allowing it to perform

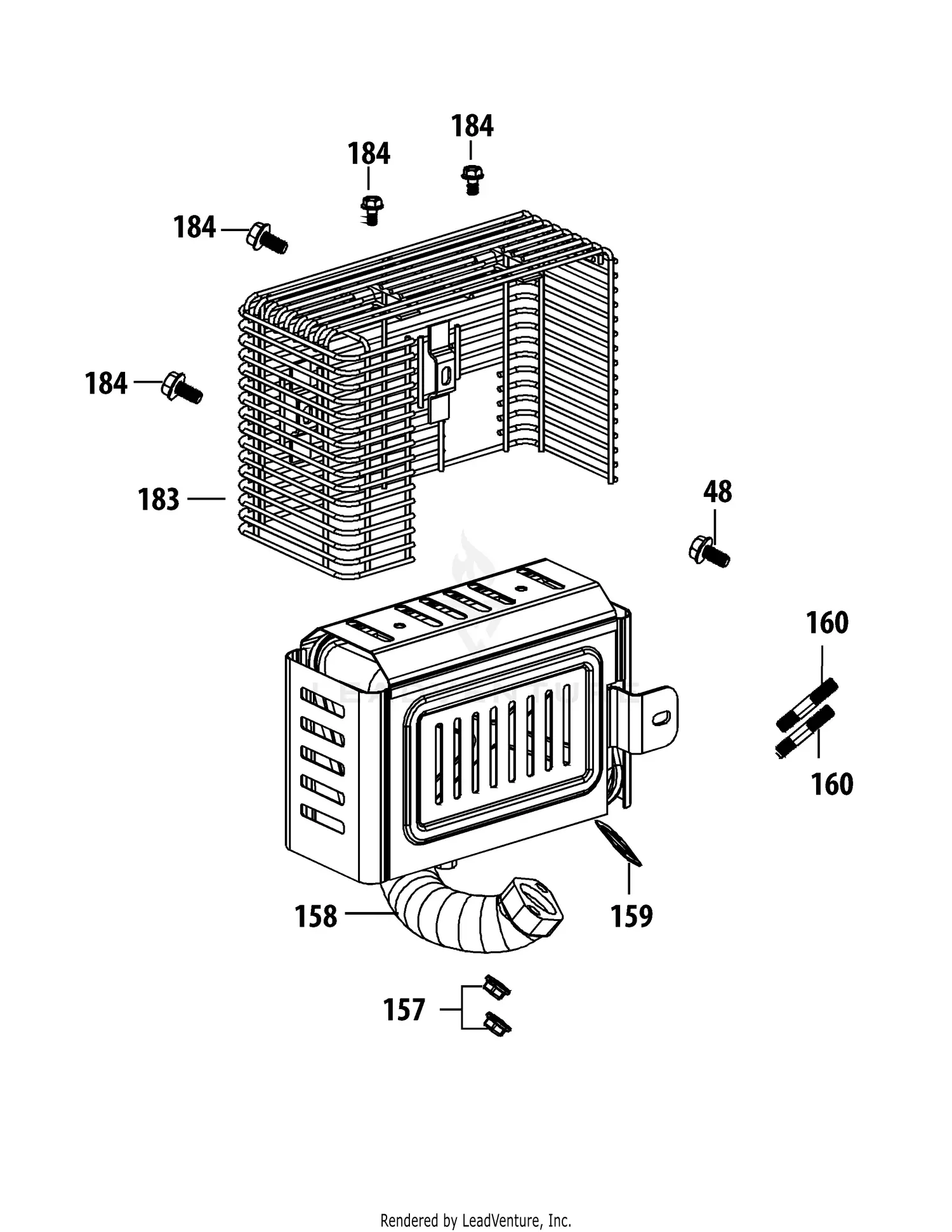

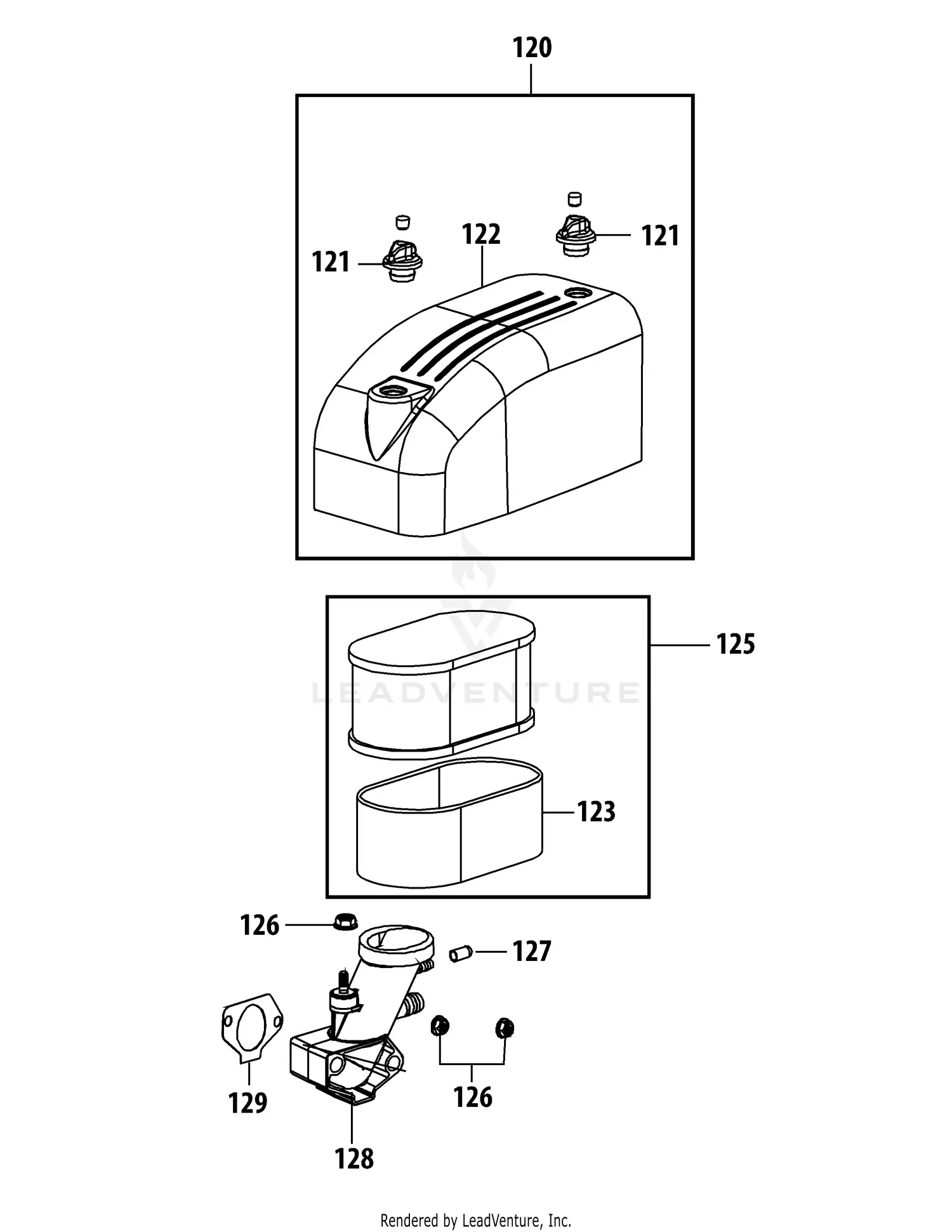

Key Components of the MowerThe primary elements of this machine are designed to ensure smooth operation and efficient cutting performance. Each section plays a vital role in maintaining functionality and delivering high-quality results. Understanding these essential parts helps in both troubleshooting and regular maintenance, ensuring the equipment continues to work at its peak. Engine: The engine powers the entire system, driving the blades and providing the necessary force to move forward. It’s the heart of the machine, and keeping it in good condition is critical for optimal performance. Blade System: At the core of the cutting function, the blades are responsible for slicing through grass with precision. Regular sharpening and proper alignment are key to a clean and even cut. Drive System: This component ensures that the equipment moves smoothly across the terrain, allowing for control and maneuverability. Whether operating on flat ground or uneven surfaces, a well Engine Parts Overview and Function

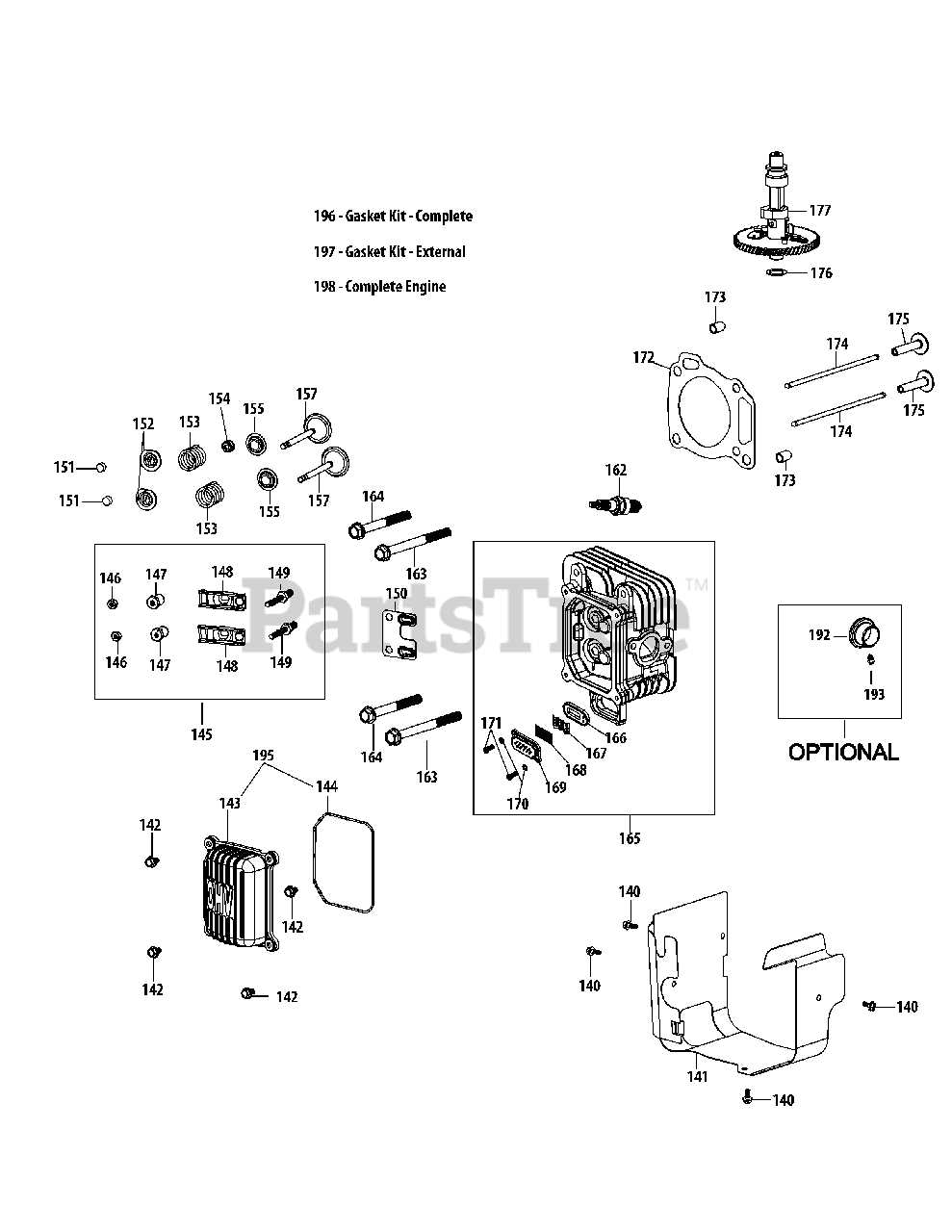

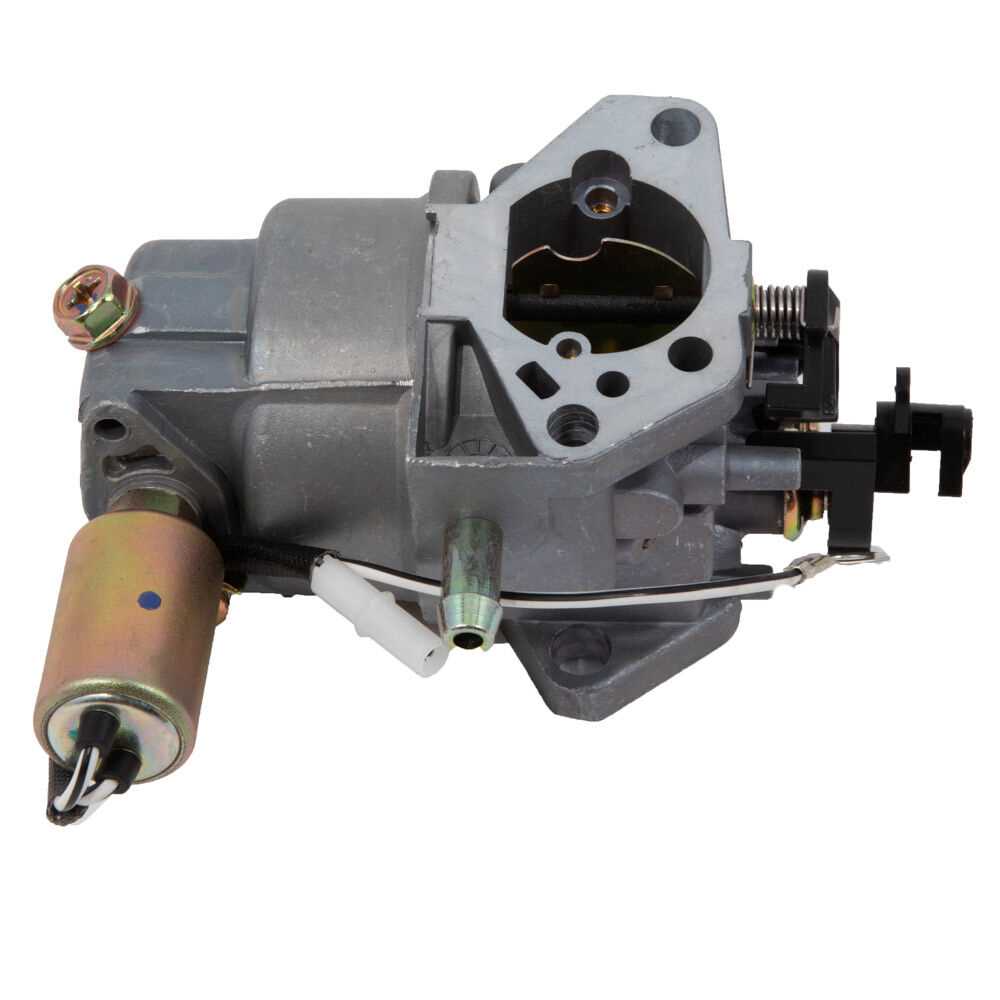

Engines are complex machines composed of numerous components that work together to transform fuel into mechanical power. Each element plays a vital role in ensuring smooth operation and optimal performance. By understanding the function of these elements, it becomes easier to identify issues and maintain the system efficiently. Main Components and Their RolesThe core structure of the engine includes the cylinder, piston, and crankshaft. The cylinder houses the piston, which moves up and down, converting combustion energy into mechanical motion. The crankshaft, in turn, transfers this energy to other parts of the system, generating rotational power. Supporting Mechanisms

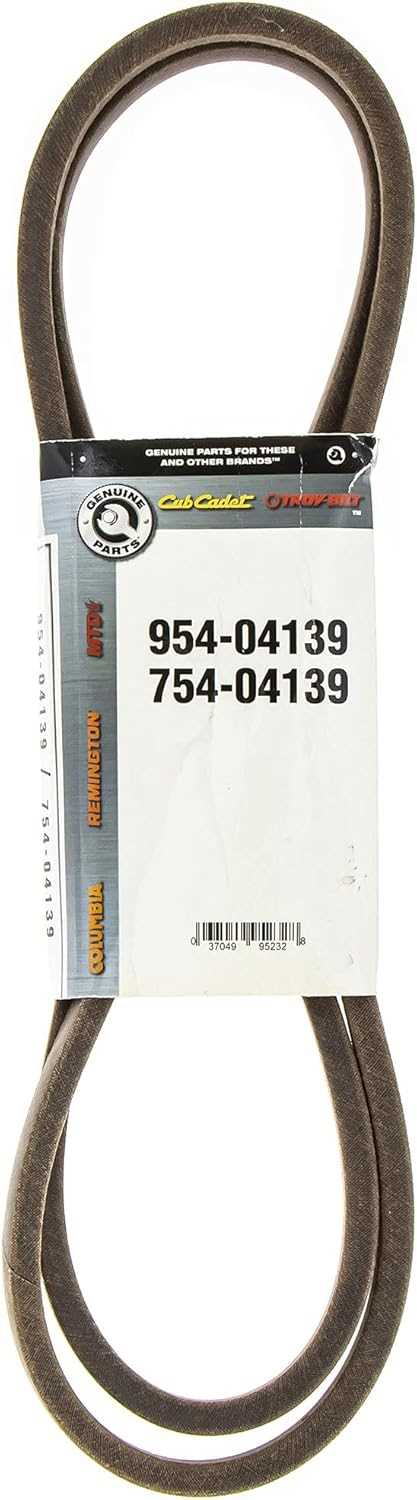

Supporting mechanisms such as the camshaft and valves regulate the flow of air and fuel, while Blade System and Cutting MechanismThe efficiency of any cutting equipment largely depends on its blade configuration and the mechanics behind its operation. A well-designed system ensures smooth and precise cutting, contributing to an overall seamless performance. The interaction between the blades and the cutting platform is crucial for achieving clean, even results across different terrains and conditions. At the heart of this setup is a rotating blade system, engineered to handle diverse workloads. Its sharp edges allow for swift and uniform grass cutting, while the mechanism beneath ensures proper alignment and balance during operation. This coordination reduces vibrations, enhancing both durability and the precision of the cut. To maintain optimal performance, the cutting mechanism requires periodic adjustments and sharpening. A well-maintained blade system guarantees consistent cutting height and minimizes wear and tear, thus extending the lifespan of the equipment. The seamless combination of design and maintenance practices forms the foundation for efficient operation. Drive Control System Breakdown

The drive control system is a crucial component responsible for managing the movement and speed regulation of the machine. This section delves into the individual elements that interact to ensure smooth propulsion and efficient operation. Understanding the key mechanisms and their functions helps in identifying issues or enhancing performance during maintenance or troubleshooting.

|