When it comes to maintaining outdoor machinery, a clear grasp of its various elements is essential. Each piece plays a pivotal role in ensuring optimal performance and longevity. Familiarizing oneself with these components can simplify repairs and enhance overall efficiency.

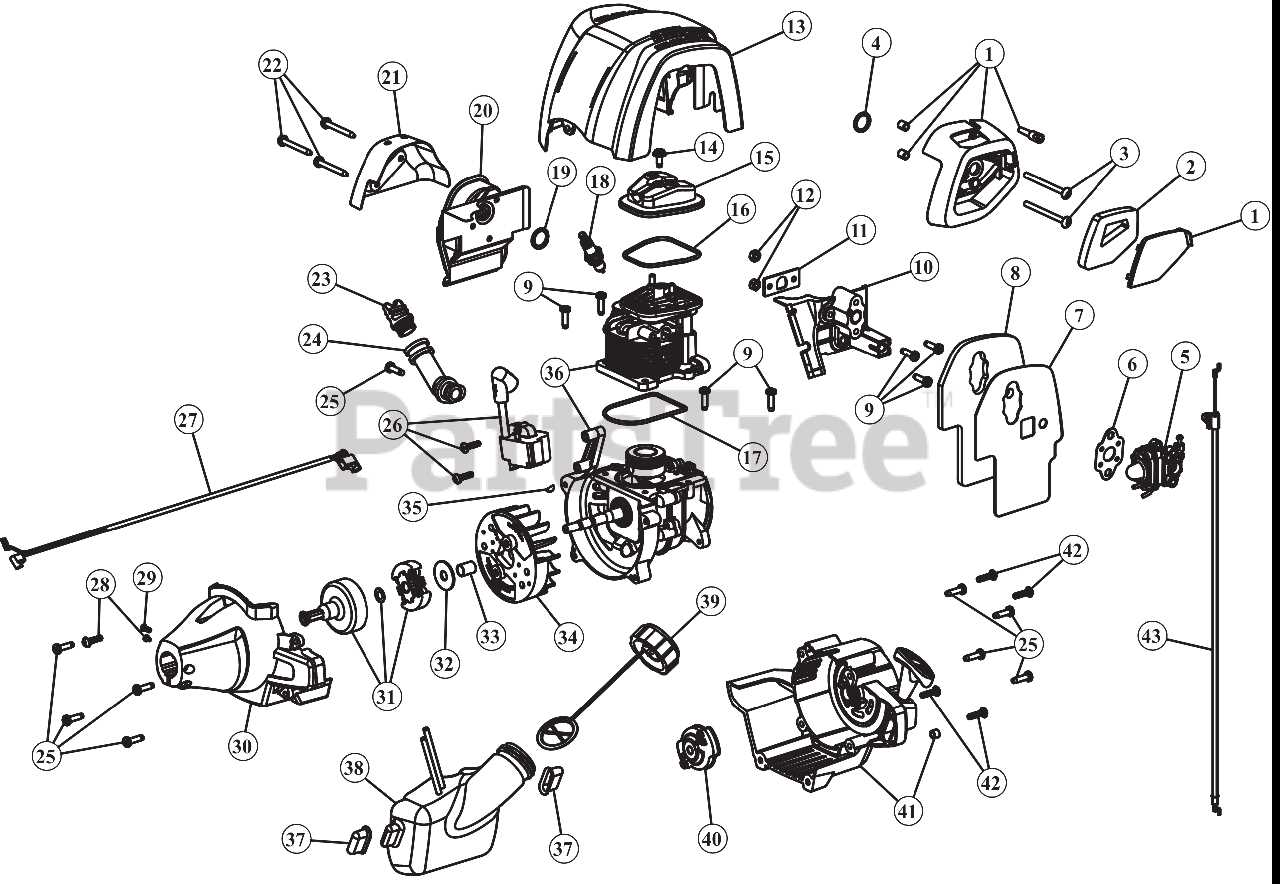

Detailed schematics serve as invaluable resources for owners and technicians alike. They provide a visual representation of how each part interacts within the system. This understanding can lead to more effective troubleshooting and a smoother repair process.

Exploring the intricacies of your machinery not only empowers you to handle repairs with confidence but also deepens your appreciation for the engineering behind it. Knowing where each component fits and how it functions can transform the way you approach maintenance tasks.

Overview

This section provides a comprehensive look at a popular outdoor power equipment model designed for various gardening and landscaping tasks. Renowned for its durability and performance, this machine is equipped with features that enhance efficiency and ease of use. Ideal for both homeowners and professionals, it offers a blend of power and versatility.

With a robust engine and a well-designed framework, this equipment ensures reliable operation in various conditions. Its user-friendly controls make it accessible for operators of all skill levels. The model is also praised for its maintenance-friendly design, facilitating straightforward upkeep and repairs.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for effective operation |

| Durability | Built with sturdy materials to withstand rigorous use |

| User Interface | Intuitive controls for ease of handling |

| Maintenance | Designed for simple servicing and repairs |

In summary, this equipment exemplifies reliability and efficiency, making it a preferred choice for various outdoor tasks. Its thoughtful design and powerful features contribute to a seamless experience, whether for routine yard maintenance or more demanding projects.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate relationships between various elements of machinery. These illustrations facilitate the identification and comprehension of individual sections, ensuring that maintenance and repairs can be performed efficiently.

Clarity is enhanced when users can reference these visuals, as they highlight the arrangement and connectivity of parts. This ultimately leads to reduced errors during assembly or disassembly, promoting a smoother operational experience.

Additionally, having access to such detailed visuals allows individuals to delve into specific areas of concern, making troubleshooting simpler. The availability of these resources ensures that even novice users can approach repairs with confidence.

Key Components of SS470

This section explores the essential elements that contribute to the overall functionality and performance of the model in question. Understanding these components is vital for maintenance and effective operation, ensuring longevity and reliability.

Engine System

- Power Output: The engine is designed to deliver a specific horsepower, impacting performance and efficiency.

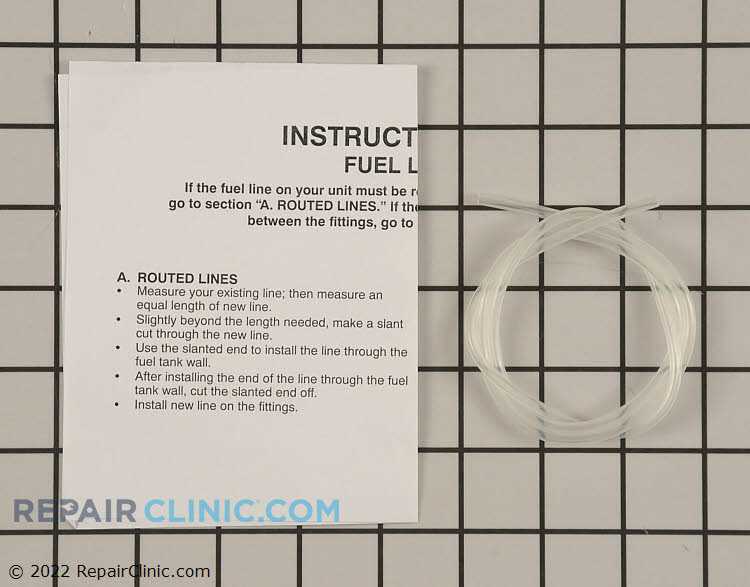

- Fuel System: Includes the tank, lines, and filters, all crucial for optimal fuel delivery.

- Cooling Mechanism: Ensures the engine remains within operational temperature limits.

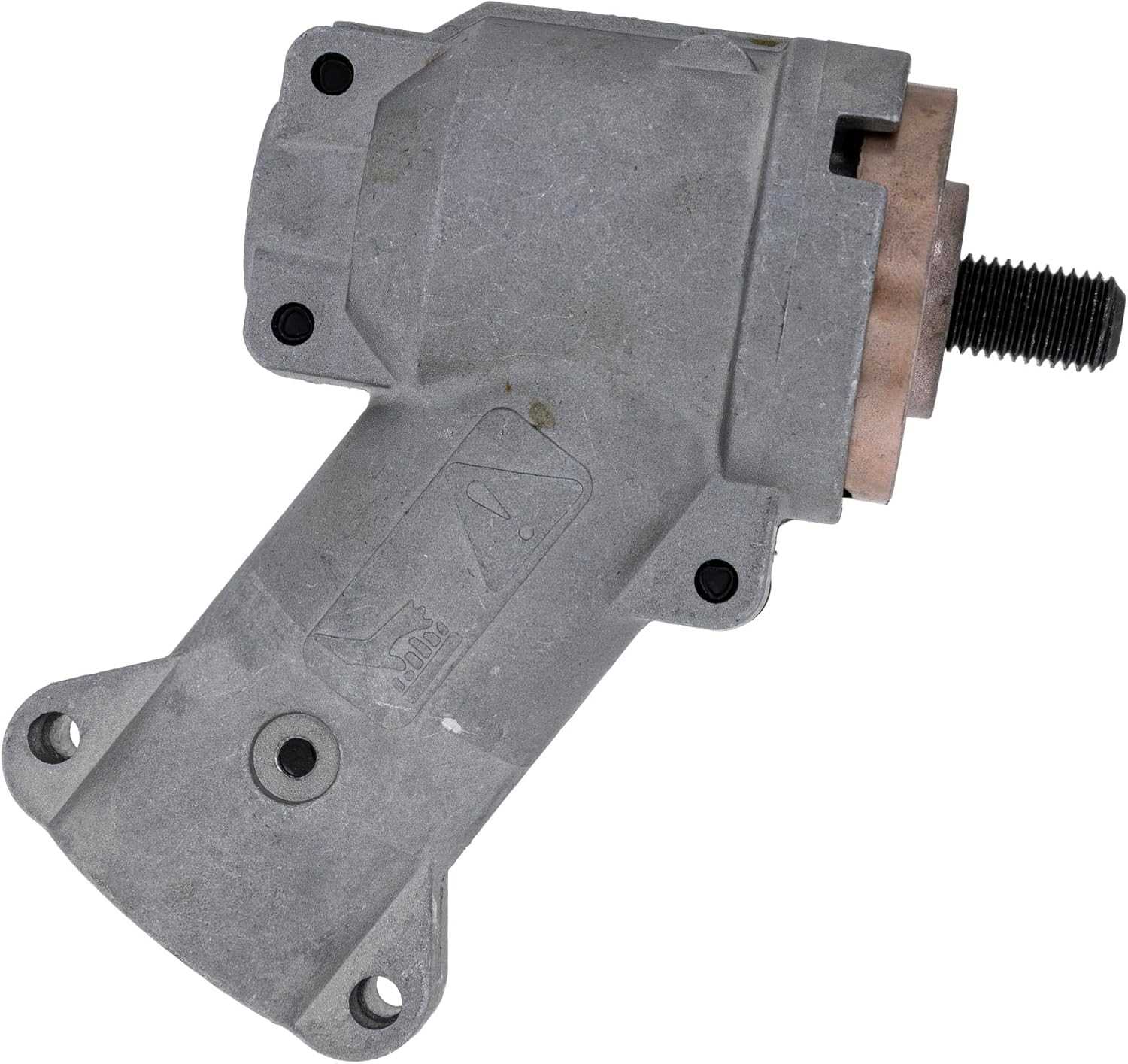

Drive and Transmission

- Transmission Type: Varies between manual and automatic, affecting user control and ease of operation.

- Drive Components: Includes belts and gears, essential for transferring power from the engine to the wheels.

- Wheel Assembly: Features tires and rims that influence traction and stability.

Each of these key elements plays a significant role in enhancing the overall performance and user experience of the machinery.

Understanding Maintenance Needs

Proper upkeep is essential for ensuring the longevity and efficiency of any machinery. Regular maintenance not only enhances performance but also helps to prevent unexpected breakdowns. By recognizing the critical components that require attention, users can keep their equipment operating smoothly and reliably.

Routine checks play a vital role in identifying potential issues before they escalate. This includes examining fluid levels, filters, and belts, as well as ensuring that all moving parts are adequately lubricated. Regular cleaning of external surfaces also helps to prevent the buildup of debris that can impede functionality.

Understanding the specific maintenance intervals recommended by the manufacturer is crucial. Following these guidelines ensures that each part receives the appropriate care at the right time, which can significantly reduce wear and tear. Additionally, documenting maintenance activities provides a useful reference for tracking performance and addressing recurring issues promptly.

Ultimately, staying proactive about maintenance not only protects your investment but also enhances the overall safety and efficiency of your equipment. A well-maintained machine not only performs better but also contributes to a more enjoyable user experience.

Finding Replacement Parts Easily

Locating suitable components for your equipment can significantly enhance its longevity and performance. Understanding how to navigate available resources will save you time and ensure you find the right items for your needs.

Utilizing Online Resources

There are various online platforms that offer detailed catalogs of components. Here are some tips to make the most of these resources:

- Search for trusted websites specializing in machinery components.

- Use model numbers for precise results.

- Check reviews and ratings for reliability.

Local Retail Options

Visiting local suppliers can also be advantageous. Consider the following:

- Build relationships with local dealers who understand your equipment.

- Inquire about special orders if items are not in stock.

- Attend local trade shows for direct access to vendors.

Common Issues with SS470

Every machine has its quirks, and this particular model is no exception. Users often encounter various challenges that can affect performance and reliability. Understanding these common problems can help in effective troubleshooting and maintenance.

- Engine Starting Problems:

- Weak battery leading to insufficient power.

- Clogged fuel filter restricting flow.

- Dirty spark plug causing ignition issues.

- Overheating:

- Insufficient coolant levels.

- Blocked air intake or exhaust.

- Faulty thermostat failing to regulate temperature.

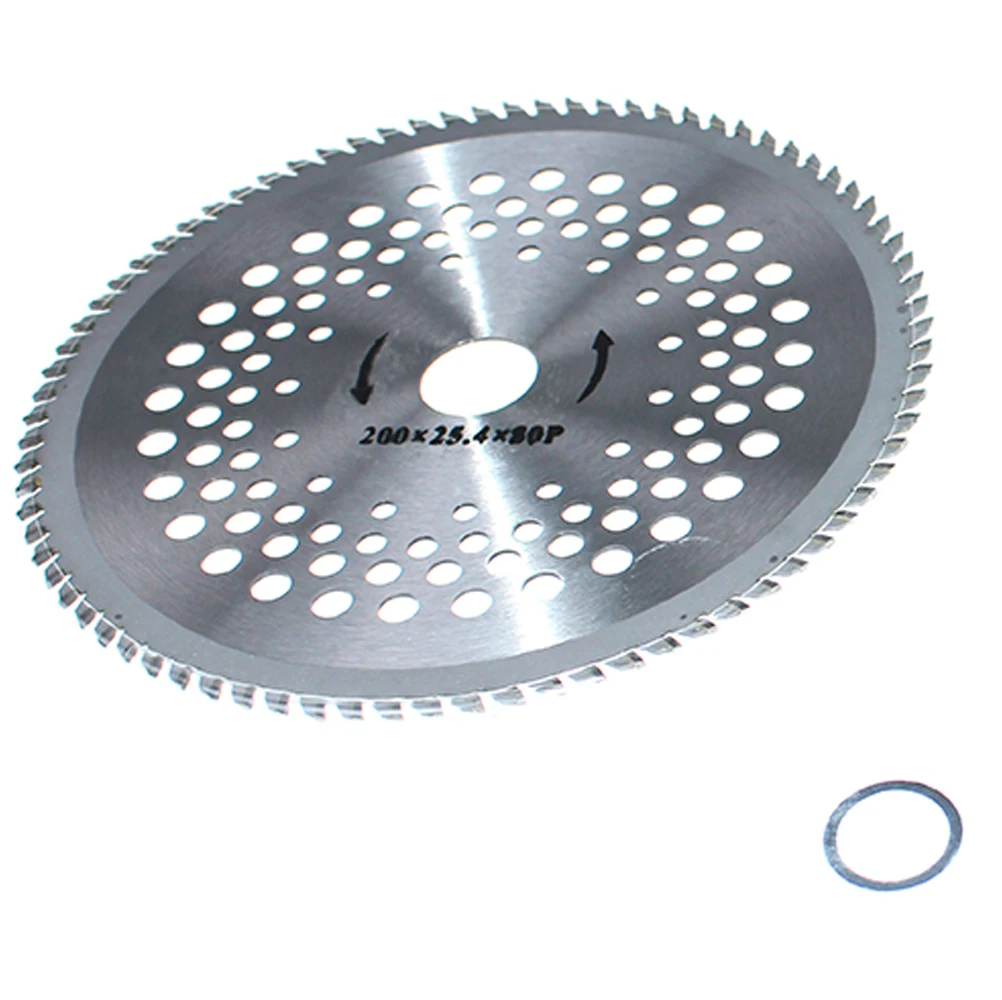

- Poor Cutting Performance:

- Dull blades resulting in uneven cuts.

- Incorrect height settings affecting grass length.

- Debris accumulation under the deck hindering movement.

- Transmission Issues:

- Slipping gears due to worn components.

- Fluid leaks leading to inadequate lubrication.

- Incorrect belt tension affecting power transfer.

Addressing these common issues promptly can enhance the longevity and efficiency of your equipment, ensuring it operates smoothly when needed most.

Assembly Instructions for SS470

Proper assembly of your equipment is essential for optimal performance and longevity. This section provides a clear, step-by-step guide to ensure that all components are correctly fitted together, minimizing the risk of errors and enhancing functionality.

Begin by gathering all necessary tools and components. Refer to the user manual to identify each part, ensuring you have everything required before starting. Organize your workspace to allow easy access to all elements.

Start the assembly by securing the base frame. Ensure all bolts are tightened according to specifications, preventing any instability during operation. Next, attach the main operating unit, aligning it properly with the designated points on the frame. Double-check that all connections are secure before proceeding.

Once the main components are in place, proceed with the installation of additional features. Follow the sequence outlined in the manual to avoid complications. Each section should fit snugly; if resistance is felt, reassess alignment and adjust accordingly.

Finally, conduct a thorough inspection of the assembled unit. Ensure that all moving parts operate smoothly and that there are no loose connections. Completing these steps carefully will enhance the efficiency and safety of your equipment, leading to successful operation.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for ensuring optimal performance and longevity. Using original items guarantees compatibility and reliability, preventing potential issues that may arise from aftermarket alternatives. Here are some reliable sources to consider when searching for these essential components.

Authorized Dealers: One of the best places to start your search is with authorized retailers. These locations often have a comprehensive selection of original components and can provide expert advice on installation and maintenance.

Official Websites: Many manufacturers maintain online shops where you can browse and order genuine items directly. This option often ensures that you receive the latest models and updates for your machinery.

Local Repair Shops: Trusted local repair shops may also stock authentic components or can order them on your behalf. Establishing a relationship with these professionals can lead to valuable insights about your equipment’s needs.

Online Marketplaces: Reputable online platforms may offer original items, but it’s crucial to verify the seller’s credentials. Look for reviews and ratings to ensure you’re purchasing from a reliable source.

Prioritizing authenticity when sourcing components is vital for maintaining the efficiency and safety of your equipment. By choosing the right sources, you can ensure you are getting the best quality for your investment.

DIY Repair Tips for Owners

Maintaining your outdoor equipment can save you both time and money. Understanding the basics of repairs allows you to tackle common issues yourself. This guide offers practical tips to help you confidently manage repairs and keep your machine running smoothly.

Basic Tools You Will Need

- Wrenches and sockets

- Screwdrivers (flathead and Phillips)

- Pliers

- Replacement parts

- Oil and cleaning supplies

Common Repair Tasks

- Changing the Oil: Regular oil changes are essential. Ensure the engine is cool, remove the drain plug, and replace the old oil with fresh lubricant.

- Cleaning Air Filters: Clogged filters reduce efficiency. Remove the filter, clean it with compressed air or replace it as needed.

- Tightening Bolts: Periodically check and tighten loose bolts to prevent parts from becoming dislodged during operation.

- Inspecting Belts: Look for wear and tear on belts. Replace them if you notice fraying or cracking.

With the right tools and knowledge, you can handle minor repairs, ensuring longevity and optimal performance for your equipment.

Benefits of Using Original Components

Utilizing genuine parts ensures optimal performance and longevity for your machinery. Original components are designed specifically for your equipment, providing a perfect fit and seamless integration.

One major advantage is reliability. These authentic elements are tested rigorously, reducing the risk of breakdowns and enhancing operational efficiency. Users can trust that they are receiving a product that meets high-quality standards.

Additionally, employing original pieces often leads to better resale value. Buyers typically prefer equipment that has been maintained with authentic parts, recognizing the benefits of durability and reliability.

Lastly, using these components can simplify the repair process. Technicians familiar with the equipment can more easily identify issues when original elements are utilized, ultimately saving time and money.

Resources for Troubleshooting Problems

When faced with mechanical issues, having access to reliable resources is essential for effective problem-solving. Various guides, manuals, and online platforms can provide valuable insights and instructions, helping users identify and rectify issues swiftly. Utilizing these resources can save time and enhance the overall maintenance experience.

Online Forums and Communities

Engaging with online forums dedicated to equipment troubleshooting can be incredibly beneficial. These platforms often feature experienced users who share their knowledge and solutions to common issues. Participating in discussions can lead to discovering innovative fixes and tips tailored to specific challenges.

Manufacturer’s Guides and Videos

Official manuals and instructional videos from manufacturers offer a wealth of information. These resources typically include step-by-step troubleshooting procedures, ensuring users have access to accurate and comprehensive guidance. Additionally, visual aids can enhance understanding and make complex tasks more manageable.