Maintaining a large lawn or commercial property requires machinery that is both powerful and reliable. To ensure the longevity of such equipment, understanding its internal workings and how the different elements interact is essential. Knowing how to identify and replace various components allows for smoother operation and extends the lifespan of the machine.

Detailed knowledge of the machinery’s layout provides clarity on how each section contributes to overall performance. With the right approach to maintenance, you can easily address wear and tear, helping to avoid unexpected breakdowns.

Whether you’re dealing with the engine, blades, or control systems, having a clear representation of the inner workings helps to keep the machine in top condition. Regular inspection and timely replacement of specific elements are key to ensuring optimal functionality.

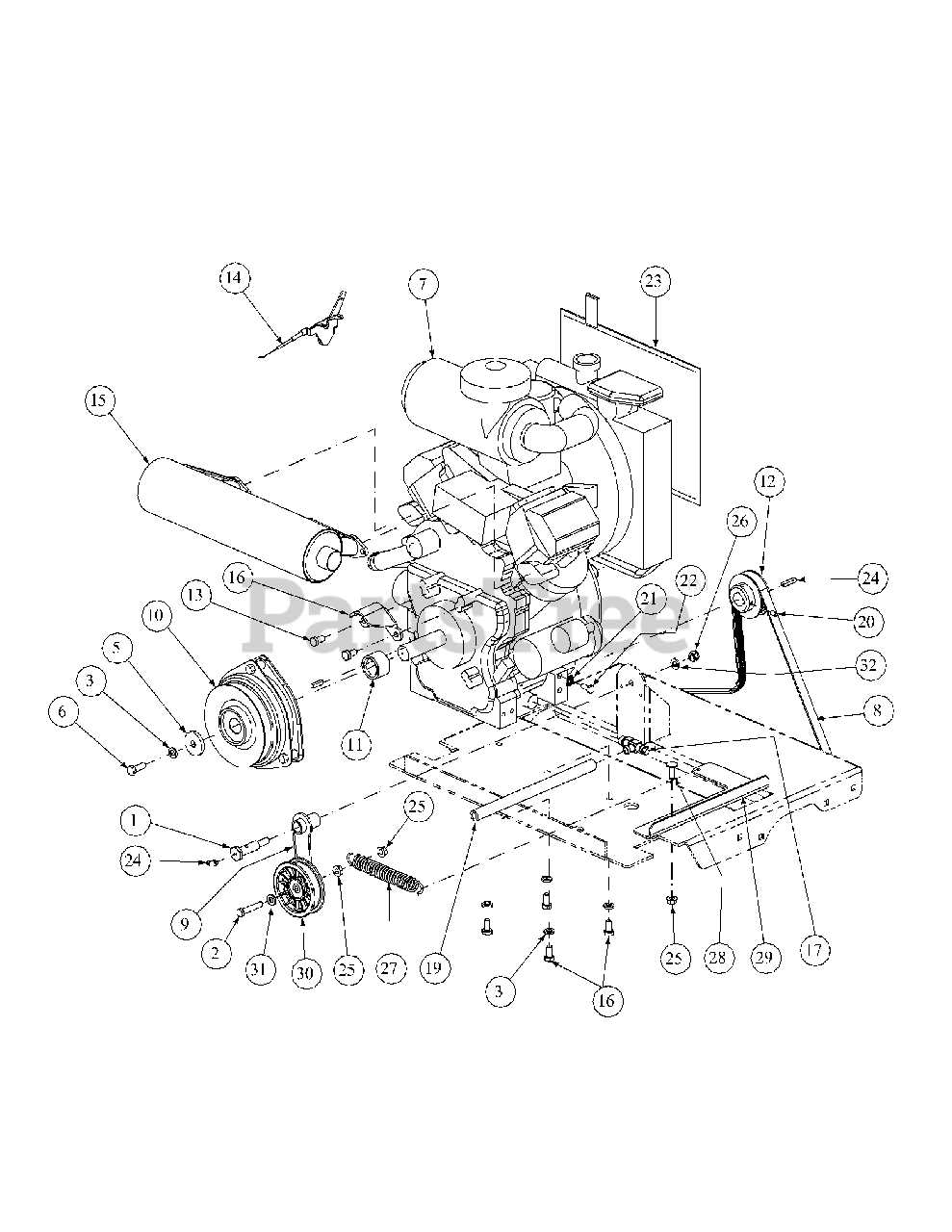

Component Breakdown of the M60 Model

This section provides a comprehensive overview of the key elements found in the M60 model. Understanding the layout and interconnections of these components is essential for maintaining optimal functionality and performance.

Engine and Power System

The core of the machine’s power is its engine, which drives all primary functions. This system includes various mechanical parts that ensure smooth operation, such as the fuel intake, cooling mechanisms, and exhaust.

- Fuel system ensuring continuous energy flow

- Cooling units to prevent overheating

- Exhaust system for emission control

Operational Controls

The control panel allows precise management of the machine’s functions. It includes various levers, switches, and dials to operate different systems, providing the user with full command over the equipment’s movements and capabilities.

- Steering controls for direction management

- Speed regulation mechanisms

- Blade control systems

Essential Mower Frame Components

The structure of a heavy-duty lawn mower is built on a sturdy framework that provides both support and stability during operation. Each component in this framework is crucial for ensuring smooth performance and handling across various terrains. Understanding the key elements that make up the frame can help in maintaining and enhancing the longevity of the machine.

Chassis: The foundation of the mower, the chassis, holds all the major parts together, ensuring that everything is aligned and secure. A durable chassis is essential for handling the stresses of frequent use.

Axles and Wheels: Positioned to carry the weight of the machine, axles and wheels enable smooth movement and steering. High-quality axles improve stability, while properly sized wheels contribute to better maneuverability.

Deck Support System: This assembly ensures that the cutting deck remains level and steady, providing an even cut across large areas. Proper alignment and support are vital for optimal cutting performance.

Mounting Brackets: These brackets secure various components to the main structure, allowing for adjustments and ensuring that all parts remain in place during operation. They are key to flexibility and ease of maintenance.

Reinforcement Bars: Added to strengthen critical points on the frame, reinforcement bars provide extra durability

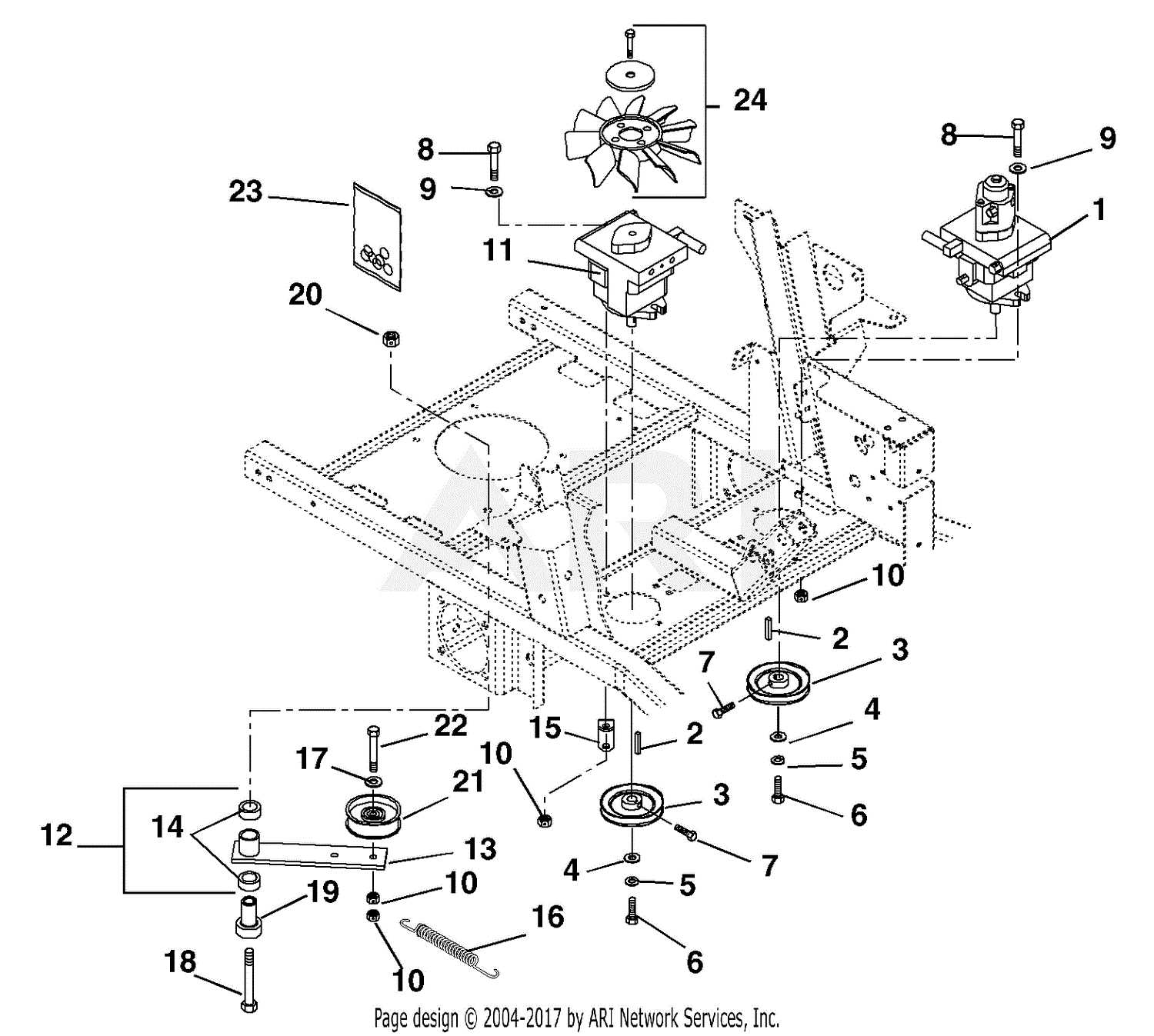

Drive System Parts Overview

The drive mechanism is a crucial component in ensuring smooth and efficient operation. It includes several interconnected elements that work together to transfer power from the engine to the wheels. Understanding the key elements of this system is important for maintaining optimal performance and preventing potential issues.

Key components in the drive mechanism include devices responsible for speed control, power distribution, and the transmission of motion. These elements function in unison to ensure a seamless driving experience, balancing power and stability during operation.

Regular maintenance of the drive mechanism helps prolong the lifespan of the equipment. Timely inspection and replacement of worn components are essential to avoid breakdowns and ensure continued reliability.

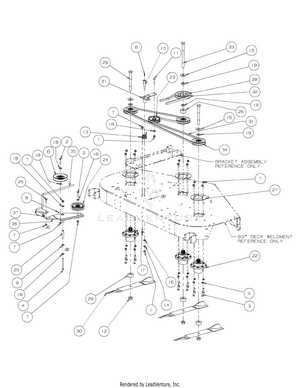

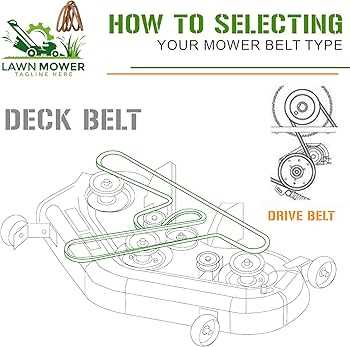

Deck Assembly Parts and Functions

The deck assembly plays a crucial role in ensuring the effective operation of the machine, contributing to its cutting precision and overall performance. Understanding the various elements involved helps in maintaining and optimizing the unit for long-term use.

Main Components of the Deck

- Blades: Responsible for trimming grass with accuracy, these rotating elements must be sharp and properly aligned.

- Spindles: These support the blades, allowing them to spin at the necessary speed and ensure an even cut.

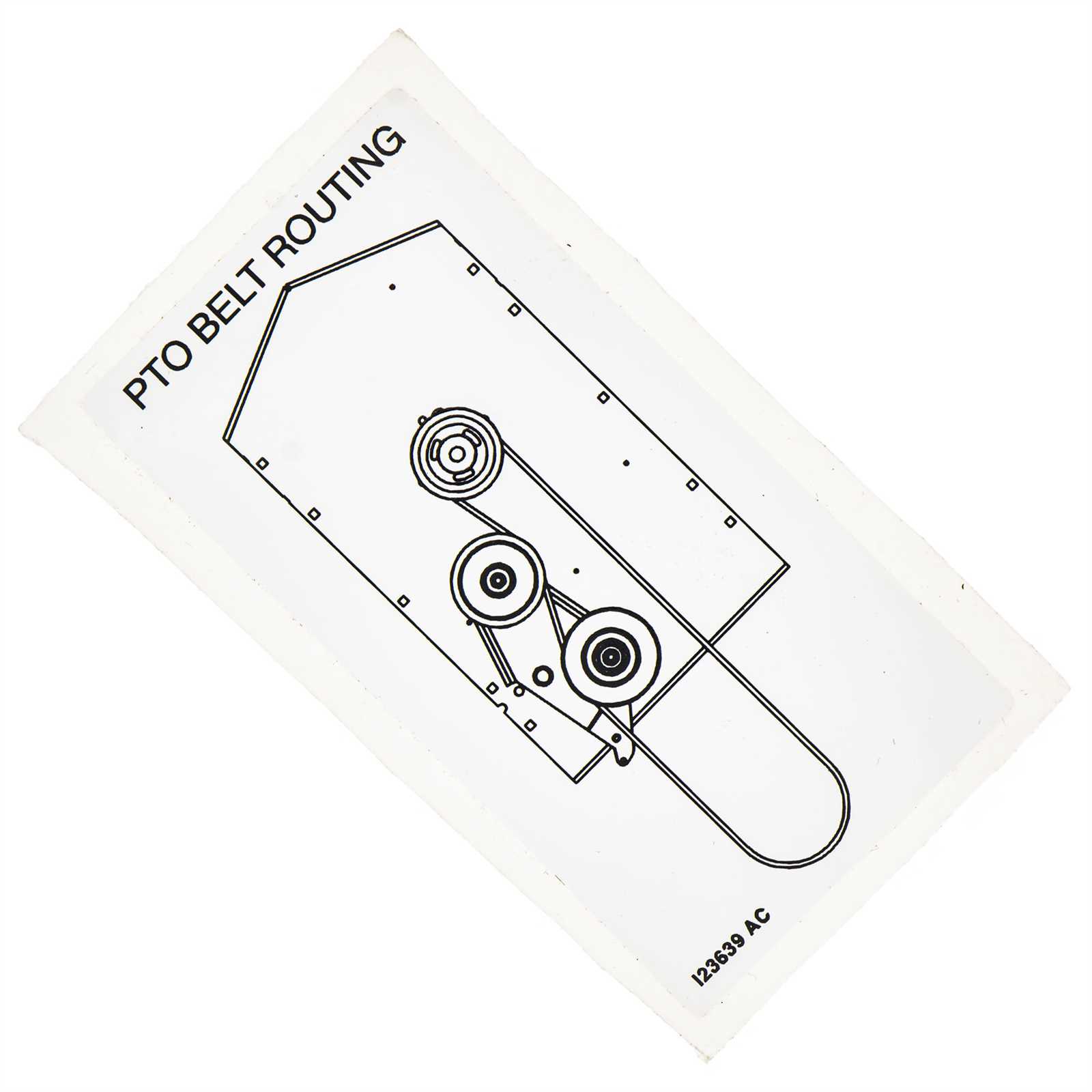

- Belts: Vital for transmitting power from the engine to the blades, belts need to be in good condition for smooth functioning.

Supporting Elements

- Pulleys: These assist in the movement of belts, ensuring consistent power flow to the cutting components.

- Deck Wheels: These small wheels help the deck glide smoothly over uneven terrain, preventing scalping of the grass.

- Height Adjustment Mechanism: Enables the operator to

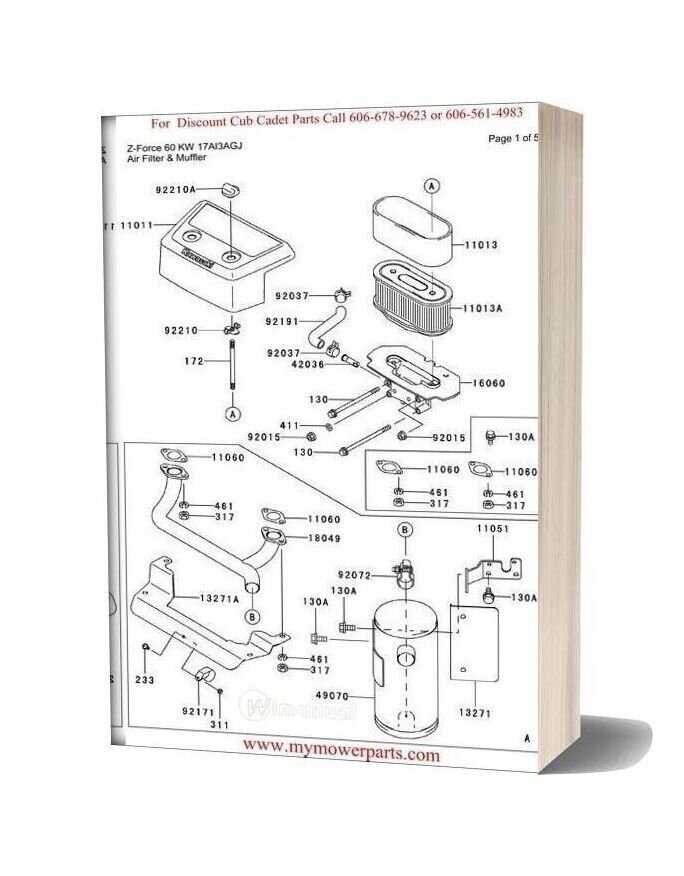

Engine Components and Maintenance

Proper upkeep of the engine ensures a long-lasting and efficient performance of your equipment. Regular inspections and timely servicing of the system are essential to avoid breakdowns and to maintain smooth operation. Understanding the core components and their roles is crucial for effective maintenance.

Component Description Maintenance Tips Air Filter Prevents dirt and debris from entering the engine. Check regularly for clogging and replace if necessary. Oil Filter Removes contaminants from engine oil. Change with each oil replacement to ensure proper filtration. Spark Plug Ignites the fuel-air mixture to start the engine. Inspect for wear and clean or replace as needed. Fuel System Blade System and Replacement Guide

The cutting mechanism is crucial for achieving an even and efficient mowing experience. Understanding its components and maintenance is essential for optimal performance. This section will delve into the elements of the cutting system, as well as provide guidance on when and how to replace worn parts to ensure your equipment operates effectively.

Key Components of the Cutting Mechanism

- Blades: The main element responsible for cutting grass. Regular sharpening is vital for maintaining efficiency.

- Spindles: These are the rotating shafts that hold the blades in place and enable their movement.

- Belts: They transfer power from the engine to the cutting system, facilitating smooth operation.

- Deck: The housing that protects the blades and other components while providing structural support.

Signs of Wear and When to Replace

- Blade Dullness: If the blades appear dull or have visible damage, it’s time for a replacement.

- Uneven Cutting: Noticeable unevenness in the grass cut can indicate blade wear or misalignment.

- Noisy Operation: Excessive noise during operation may signal issues with the cutting system, including worn-out components.

Replacement Process

To ensure the cutting system functions at its best, follow these steps for replacement:

- Power off the machine and disconnect the battery for safety.

- Remove the deck from the main unit for easier access to the blades.

- Carefully detach the old blades from the spindles using appropriate tools.

- Install the new blades, ensuring they are securely fastened and aligned correctly.

- Reassemble the deck and reconnect any disconnected parts before testing the machine.

Regular maintenance and timely replacement of components within the cutting mechanism can significantly enhance the performance and longevity of your equipment.

Steering and Control Mechanisms

The steering and control systems of a riding mower are essential for ensuring precise maneuverability and operational efficiency. These components work together to facilitate smooth navigation, allowing the operator to guide the machine effortlessly across various terrains.

Components Overview

Key elements of the steering and control mechanisms include the steering wheel, linkages, and the control levers. The steering wheel provides the primary interface for directing movement, while the linkages transmit the operator’s input to the wheels, enabling responsive handling. Control levers allow for adjustments in speed and direction, enhancing the user experience.

Maintenance Tips

Regular maintenance of these systems is vital for optimal performance. Ensure that all connections are secure and free from wear, as this can affect the responsiveness of the steering. Lubricating moving parts can also help reduce friction and prolong the lifespan of the components. Inspect the entire system periodically to identify any potential issues early on.

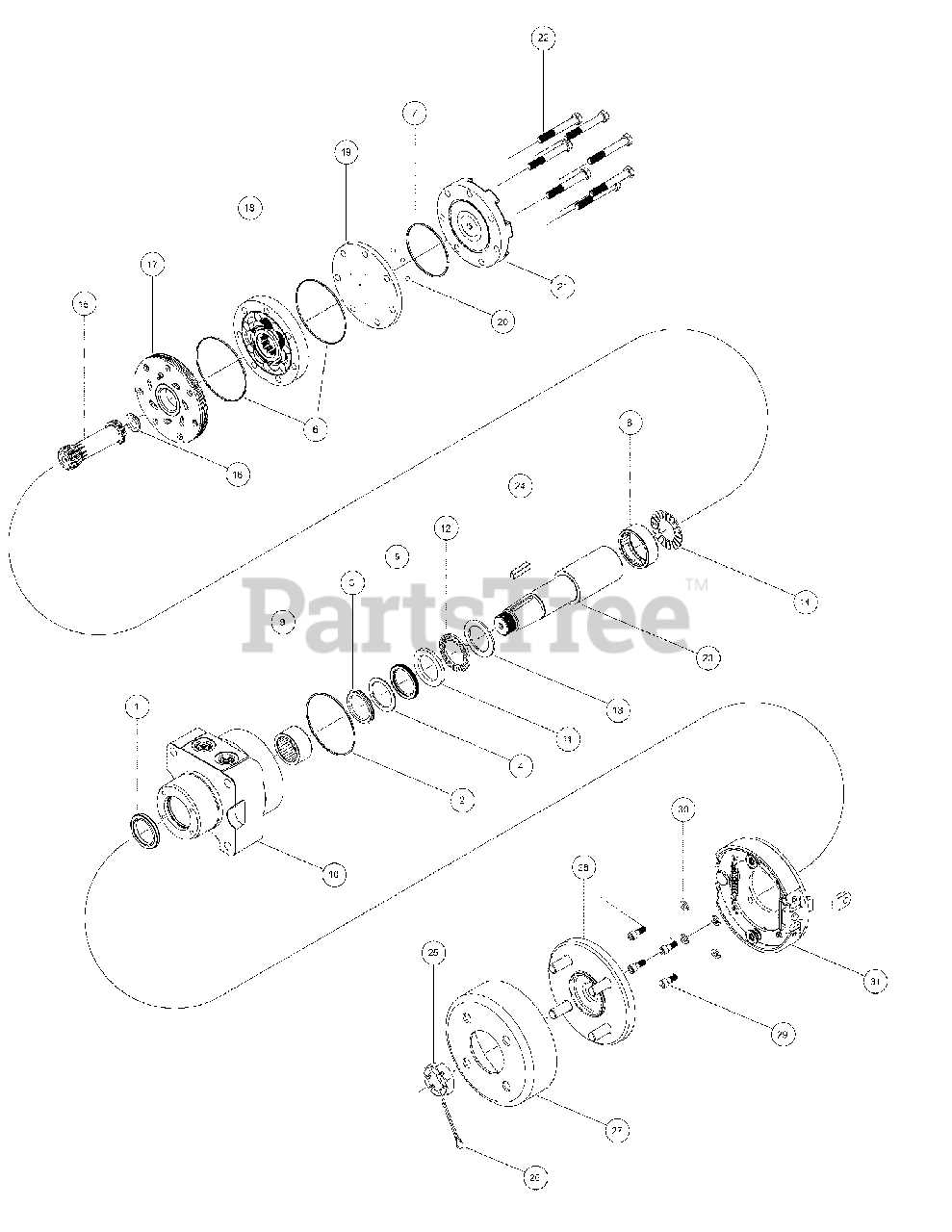

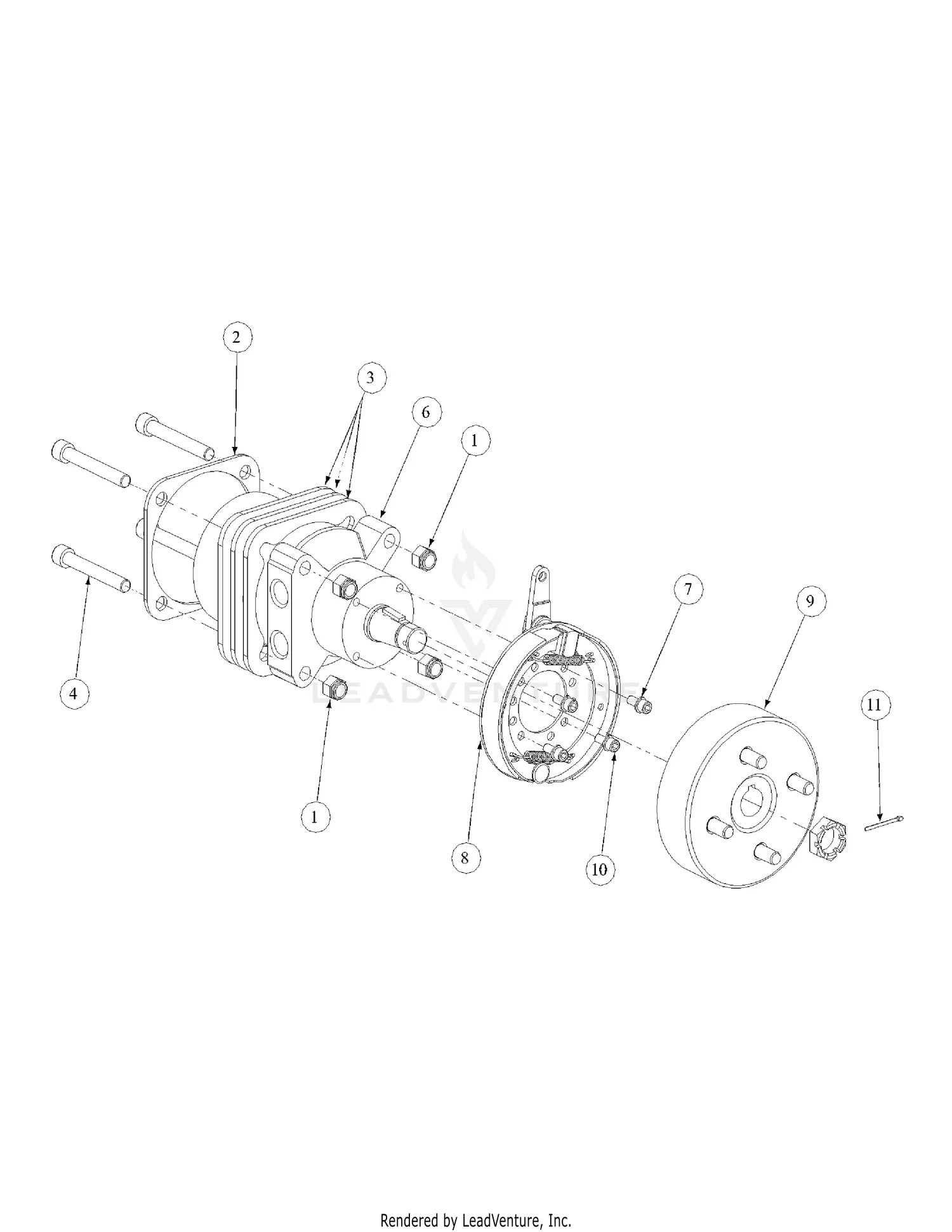

Hydraulic System Parts Explained

The hydraulic system plays a crucial role in the operation of various machinery, providing the necessary force for movement and control. Understanding the components of this system is essential for maintaining efficiency and ensuring reliability.

Hydraulic Pump: This device is responsible for converting mechanical energy into hydraulic energy, generating fluid flow to power different functions within the machinery.

Hydraulic Cylinder: These are vital for converting hydraulic energy back into mechanical force, allowing for the movement of different parts of the equipment.

Control Valves: These components regulate the flow of hydraulic fluid, directing it to specific areas as needed to facilitate precise control of the machinery’s movements.

Hydraulic Hoses: These flexible tubes transport the hydraulic fluid between components, designed to withstand high pressure while maintaining integrity.

Filters: Essential for ensuring the cleanliness of the hydraulic fluid, filters remove contaminants that could potentially harm the system’s efficiency and longevity.

By familiarizing oneself with these essential components, operators can better troubleshoot issues, perform maintenance, and enhance the overall functionality of the machinery.

Electrical Components and Wiring

This section delves into the essential electrical elements and their connections, which play a critical role in the overall functionality of the equipment. Understanding these components is vital for effective maintenance and troubleshooting.

Key Electrical Elements

- Batteries: Store electrical energy to power the system.

- Fuses: Protect circuits from overloads and short circuits.

- Relays: Control high-power circuits using low-power signals.

- Switches: Enable or disable electrical flow.

- Connectors: Ensure secure and reliable connections between wires.

Wiring Essentials

- Identify the wiring layout to ensure proper connections.

- Utilize high-quality wiring to prevent damage and ensure longevity.

- Regularly inspect for wear and tear, replacing components as necessary.

- Follow the manufacturer’s guidelines for safe and effective installation.

By familiarizing yourself with these electrical components and their wiring, you can enhance the reliability and performance of your machinery.

Seat and Comfort Features Breakdown

This section delves into the various seating and comfort elements that enhance the overall experience for users. A well-designed seat not only provides adequate support but also contributes to the operator’s efficiency and satisfaction during extended use.

Feature Description Ergonomic Design The seat is crafted to support the natural curves of the body, reducing fatigue during long hours of operation. Adjustability Features such as sliding mechanisms and height adjustments allow users to customize their seating position for optimal comfort. Cushioning High-density foam padding enhances comfort, providing a soft yet supportive seating surface. Armrests Integrated armrests reduce strain on the shoulders and neck, offering additional support during use. Backrest The contoured backrest promotes proper posture, helping to prevent discomfort over extended periods. Vibration Dampening Advanced materials and design techniques minimize the impact of vibrations, further enhancing user comfort. Common Replacement Parts and Availability

When maintaining outdoor power equipment, understanding the typical components that may need replacement is essential for optimal performance. This knowledge ensures that users can efficiently manage their machinery and minimize downtime by sourcing the necessary items without hassle.

Frequently Replaced Components

- Belts: Essential for transferring power, belts often wear out and require timely replacement.

- Blades: Dull or damaged blades can lead to poor cutting performance, necessitating regular changes.

- Filters: Air and fuel filters are crucial for maintaining engine efficiency and should be checked periodically.

- Batteries: Aging batteries may fail to hold a charge, making replacements necessary for reliable starts.

- Wheels: Wear and tear on wheels can affect maneuverability, making them a common item for replacement.

Sourcing and Availability

Finding replacement components is straightforward with various options available for users. Many local retailers and online platforms offer a wide range of options to ensure compatibility and ease of access.

- Local dealerships: Authorized sellers often stock original equipment and accessories.

- Online marketplaces: Websites provide extensive selections, often at competitive prices.

- Aftermarket suppliers: Alternative manufacturers may offer compatible components, providing more affordable choices.