When it comes to maintaining and upgrading your lawn equipment, having a clear understanding of how the various elements come together is crucial. Proper knowledge of the arrangement and functionality of each component ensures smooth operation and easier troubleshooting when issues arise. This guide will provide an in-depth look into the structure of key elements, offering insight into how they work together for optimal performance.

The following breakdown covers various essential elements, including the mechanical and electrical components that make up the heart of your machine. By reviewing this layout, users can better familiarize themselves with how to handle repairs, maintenance, or upgrades effectively. Whether you’re a novice or an experienced technician, this resource will help you navigate the intricacies of your equipment with confidence.

Understanding Cub Cadet XT1 42 Components

The design of this outdoor machinery integrates a variety of key elements that work in harmony to ensure smooth operation. Each component serves a vital role, contributing to its overall functionality, durability, and performance. Knowing the essential aspects of these elements can enhance your ability to maintain and repair the equipment efficiently.

Key Functional Elements

- Power Source: The engine delivers the necessary power, driving the entire system and ensuring optimal operation during long working hours.

- Transmission: This part allows for the seamless transfer of energy from the engine to the wheels, providing mobility and control.

- Steering Mechanism: Responsible for directional control, the steering system ensures precise maneuverability even in challenging terrains.

Structural Components

- Frame: A robust structure that supports the weight and stability of the machine, crucial for balance and durability.

- Cutting Deck: Equipped with multiple blades, this section efficiently trims vegetation while maintaining an even cut height.

- Wheels and Tires: These provide traction and stability

Engine System Overview

The engine system is a vital component in any machinery, providing the necessary power to ensure smooth operation and performance. This section provides a broad look at the key elements involved in the engine’s functionality and how each part contributes to efficient performance.

- Power Source: The heart of the system, responsible for generating energy that drives the machine.

- Cooling Mechanism: A crucial feature to prevent overheating and maintain consistent performance, especially during extended use.

- Fuel Delivery: A system designed to supply the engine with the proper fuel mixture to ensure optimal power output.

- Exhaust Management: A system that efficiently handles waste gases produced during operation, ensuring safe and clean performance.

- Ignition Setup: The process that initiates the engine’s power generation, ensuring quick and reliable starting.

Each of these components plays a role in ensuring that the engine functions reliably and at peak efficiency, with a focus on durability

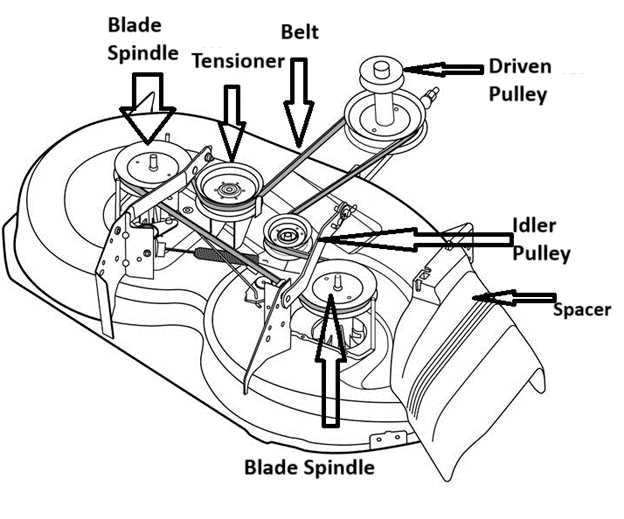

Deck Assembly Breakdown

The deck assembly is a critical component that plays a vital role in ensuring smooth and efficient performance during operation. Understanding its structure and the relationship between various parts helps in maintaining optimal functionality. A detailed examination of the individual elements will allow for better troubleshooting and regular upkeep, extending the longevity of the equipment.

Key elements in the assembly include the main cutting area, supporting components, and connections that work in harmony to deliver consistent performance. Each segment is designed with precision to provide balanced operation and allow for easy adjustments when necessary. A thorough understanding of these elements will assist in identifying wear and tear, ensuring seamless performance over time.

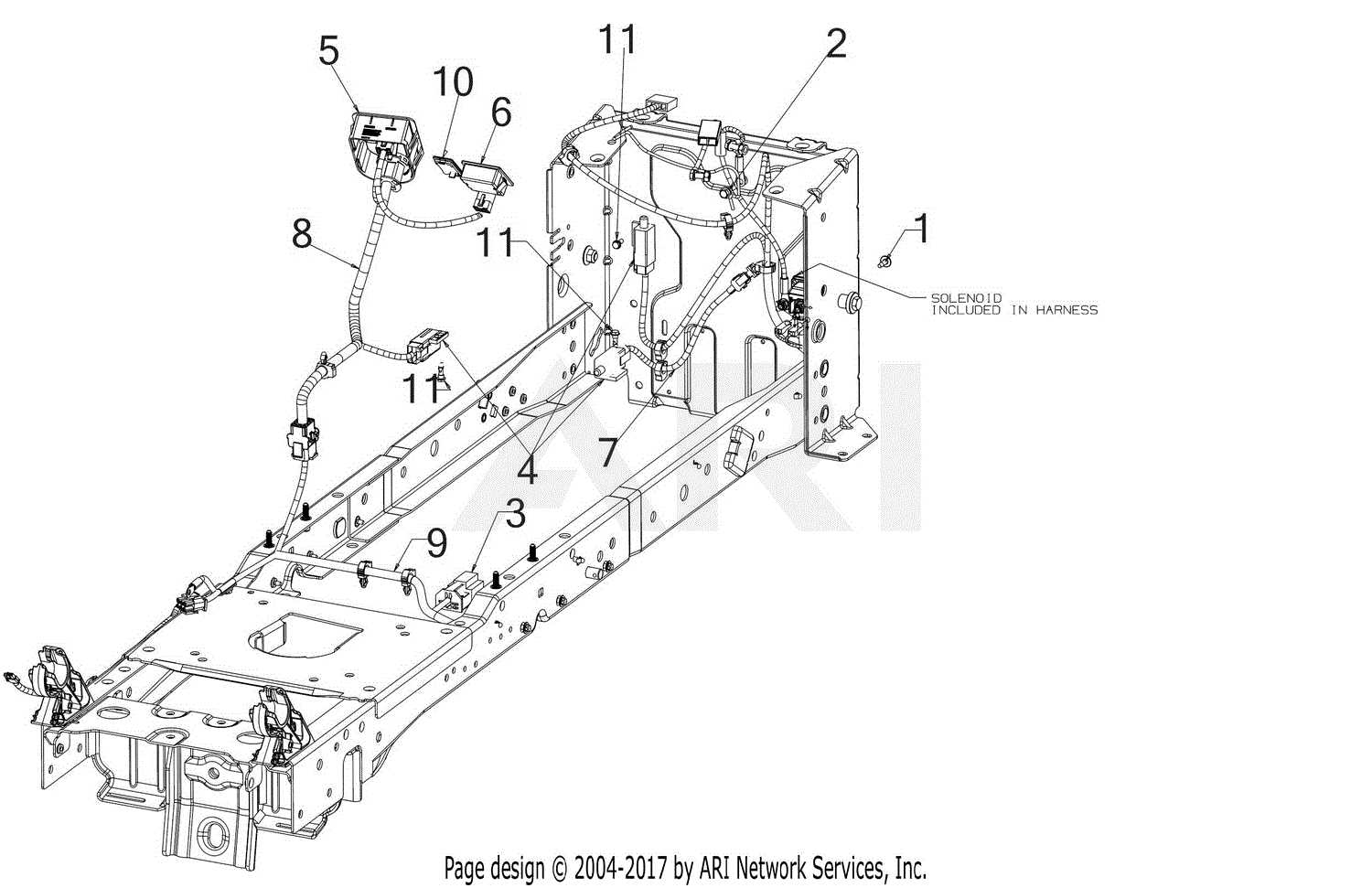

Chassis and Frame Structure

The core framework of a riding vehicle plays a crucial role in providing structural integrity, ensuring durability, and supporting all other components. The balance between strength and weight directly impacts the performance, while the layout of the framework determines the overall stability and ease of operation.

Below is a breakdown of the key elements involved in the construction of the structure:

Component Description Main Frame This serves as the primary support structure, designed to hold the weight of the engine, transmission, and operator while ensuring stability during operation. Cross Members These are horizontal supports that reinforce the overall structure, enhancing rigidity and distributing loads evenly across the framework. Mounting Points Strategically placed locations where different components, such as the engine or steering system, are securely attached to the structure. Steering Mechanism Details

The steering system plays a crucial role in ensuring the machine’s maneuverability and precise control. Understanding how the different components interact allows for better maintenance and potential adjustments when needed. This section provides a closer look at how the steering assembly functions, focusing on the relationship between its key elements and their influence on overall performance.

Key Components and Their Role

The primary parts involved in the steering mechanism include the control arm, pivot point, and linkages. These elements work together to translate the driver’s input into the motion of the front wheels. The control arm directs the movement, while the linkages ensure that the wheels respond accurately. Proper alignment and adjustment of these components are essential for smooth operation.

Common Adjustments and Maintenance

Regular inspections of the steering system are vital to ensure it remains responsive and efficient. Checking for wear in the joints, tightening loose connections, and lubricating pivot points are some of the essential maintenance tasks. These preventive measures can extend the lifespan of the system and improve handling.

Cutting Blade Configuration

The arrangement and design of the cutting implement play a crucial role in achieving an efficient and precise mowing experience. Understanding the various aspects of blade alignment and adjustment ensures optimal performance and longevity of the machinery.

Blade Length and Shape: The dimensions and contour of the cutting tool significantly impact the quality of the cut. Longer blades may cover more ground but require proper balance and power to function effectively.

Angle and Height Adjustment: Adjusting the angle and height at which the blades operate can dramatically affect the cut quality. Proper elevation ensures that the blades can maneuver through different types of terrain, providing a clean finish.

Material Composition: The choice of materials used in blade construction influences durability and performance. High-quality steel can withstand wear and tear while maintaining a sharp edge for extended periods.

Maintenance and Care: Regular inspections and maintenance of the cutting apparatus are essential for ensuring optimal functionality. Keeping blades sharp and free of debris enhances their cutting efficiency and prolongs their lifespan.

Fuel System Parts Layout

The fuel system is crucial for the optimal performance of any outdoor power equipment. Understanding its layout can significantly enhance maintenance and troubleshooting efforts. This section will explore the various components involved in the fuel delivery process, detailing their roles and interconnections within the assembly.

Key Components

At the heart of the fuel mechanism lies the tank, which stores the gasoline before it is transported to the engine. Attached to the tank is a fuel line that directs the liquid towards the carburetor. The carburetor is responsible for mixing the fuel with air in the right proportions, ensuring efficient combustion. Additionally, a fuel filter is incorporated to remove any impurities, safeguarding the engine’s performance.

Maintenance Considerations

Regular inspection of the fuel delivery system is essential for longevity and reliability. Checking for leaks in the fuel lines, ensuring the filter is clean, and verifying the carburetor’s functionality can prevent potential issues. Utilizing high-quality fuel and adhering to manufacturer recommendations for maintenance intervals will contribute to the overall efficiency of the equipment.

Transmission and Drive Mechanism

The drive system of a lawn tractor plays a crucial role in its overall performance, ensuring smooth operation and efficient power transfer from the engine to the wheels. Understanding the various components involved in this mechanism helps in maintaining and troubleshooting the machine effectively.

Key Components

- Engine: Provides the necessary power for operation.

- Transmission: Transfers power from the engine to the wheels, allowing for speed variations.

- Drive Belt: Connects the engine to the transmission, facilitating movement.

- Wheels and Axles: Responsible for movement across different terrains.

Functionality Overview

The interaction between these components ensures that the machine can maneuver with ease. The engine generates power, which is transmitted through the drive belt to the transmission. The transmission regulates the speed and torque delivered to the wheels, allowing for optimal performance whether traversing flat surfaces or navigating inclines. Regular inspection and maintenance of these elements are essential for the longevity and efficiency of the vehicle.

Seat and Comfort Features

The design of the seating area plays a crucial role in enhancing the overall user experience. Comfortable seating can significantly impact operator satisfaction and efficiency, making it essential to prioritize ergonomic features. Various attributes contribute to this aspect, ensuring that individuals can operate machinery for extended periods without discomfort.

Ergonomic Design

An ergonomic seating structure provides essential support for the lower back, promoting proper posture while in use. Adjustable seating mechanisms allow for customization based on individual preferences, accommodating different body types. This flexibility enhances comfort and reduces fatigue during operation.

Additional Comfort Features

Incorporating additional comfort features further elevates the overall experience. Features such as cushioning and weather-resistant materials ensure a pleasant ride regardless of external conditions. Moreover, the integration of armrests and user-friendly controls enhances usability, making the operation more enjoyable.

Feature Description Adjustable Seat Allows customization for optimal comfort and support. Cushioned Design Soft padding to reduce pressure points and enhance comfort. Weather-Resistant Materials Durable materials designed to withstand various weather conditions. Armrests Provides additional support for the arms and improves overall comfort. User-Friendly Controls Intuitive placement of controls for easy access and operation. Electrical Components Arrangement

The organization of electrical elements within machinery is crucial for ensuring optimal performance and reliability. A well-structured layout facilitates easy access for maintenance and enhances the overall efficiency of the system. Each component plays a vital role, and their strategic placement can significantly impact functionality and safety.

Key Components Overview

Understanding the primary electrical components and their interconnections is essential. This section highlights the fundamental elements that contribute to the machine’s operation.

Component Function Battery Stores electrical energy for starting the engine and powering electrical systems. Ignition Coil Converts battery voltage to a higher voltage to create a spark for ignition. Starter Motor Initiates engine operation by cranking the engine when the ignition is engaged. Fuse Protects the electrical circuit by breaking the connection in case of overload. Component Arrangement Strategies

Effective arrangement of these components involves careful consideration of accessibility, heat dissipation, and electromagnetic interference. Ensuring proper spacing and orientation can prevent damage and enhance the lifespan of each element.

Front and Rear Wheel Design

The design of the front and rear wheels plays a crucial role in the overall functionality and stability of outdoor equipment. These components not only support the weight of the machinery but also influence its maneuverability and performance on various terrains. Understanding the intricacies of wheel construction can provide valuable insights into enhancing the operational efficiency of the equipment.

Front wheels are typically designed for agility and responsiveness. Their configuration often allows for easier steering and navigation, especially in tight spaces. The diameter and tread pattern are essential in determining how well the wheels can grip the ground, affecting traction and control.

Rear wheels, on the other hand, are generally built for stability and support. Their design is crucial in distributing the weight of the equipment, which is particularly important when operating on uneven surfaces. A robust rear wheel setup can enhance the overall balance and prevent tipping, ensuring safer operation during various tasks.

In conclusion, both front and rear wheel designs are integral to the performance of outdoor machinery. Their thoughtful engineering contributes to a seamless experience, allowing users to achieve optimal results while maintaining control and safety.

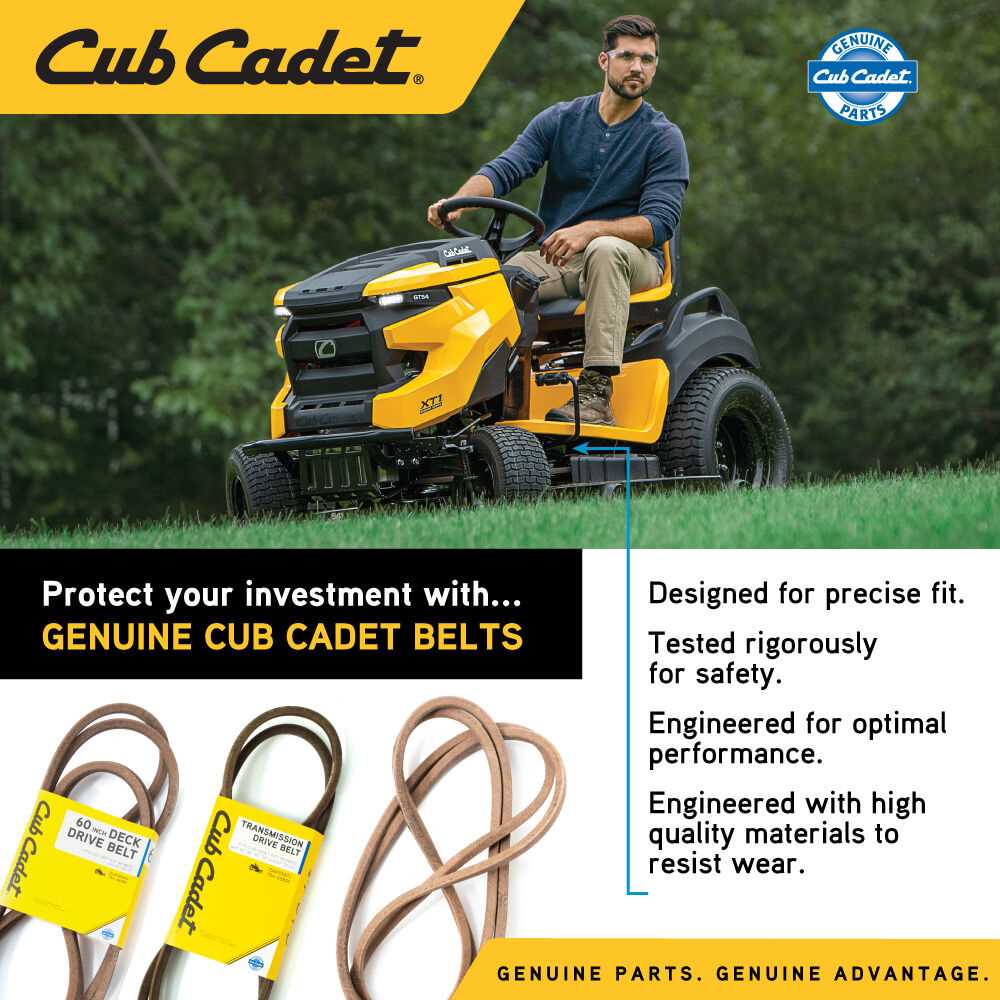

Maintenance Parts and Accessories

Proper upkeep of outdoor equipment is essential for optimal performance and longevity. Ensuring you have the right components and enhancements can significantly impact the efficiency and reliability of your machinery. This section outlines various items and tools that contribute to effective maintenance practices.

- Oil Filters: Regularly replacing oil filters helps maintain engine health by ensuring clean oil circulation.

- Air Filters: Keeping air filters clean prevents debris from entering the engine, promoting better airflow and performance.

- Belts: Inspecting and replacing worn belts is crucial for the proper functioning of various systems, ensuring smooth operation.

- Blades: Sharp blades provide cleaner cuts, enhancing the appearance of your lawn and reducing stress on the engine.

- Battery: A reliable battery is essential for easy starts and overall electrical system functionality.

In addition to these essential items, consider investing in accessories that enhance the versatility of your equipment:

- Mulching Kits: These kits help recycle grass clippings, providing nutrients back to the soil.

- Tow-Behind Attachments: These accessories allow for additional functionalities, such as hauling or spreading materials.

- Covers: Protecting your machinery with covers can prevent weather damage and prolong its life.

Incorporating quality maintenance items and thoughtful accessories into your routine will ensure your equipment remains in top condition, ready to tackle any task with ease.

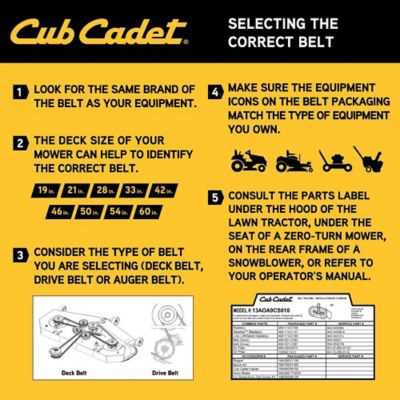

Understanding the Mower Belt System

The belt mechanism is a crucial component in any lawn care equipment, responsible for transferring power from the engine to various parts of the machine. This system plays an essential role in the functionality and efficiency of the mower, ensuring smooth operation and optimal performance. A well-maintained belt setup not only enhances the cutting performance but also prolongs the lifespan of the equipment.

Components of the Belt Mechanism

This system typically consists of several key elements, including the drive belts, pulleys, and idlers. The drive belts are responsible for conveying power from the engine to the blades or wheels, while pulleys serve as guides that direct the movement of the belts. Idlers, on the other hand, help to maintain tension in the system, ensuring that the belts function correctly.

Importance of Regular Maintenance

Regular inspection and maintenance of the belt mechanism are vital for preventing potential issues such as slippage or breakage. Signs of wear or damage, such as fraying or cracking, should be addressed promptly to avoid costly repairs. By ensuring that the belt system is in good condition, users can achieve a more efficient mowing experience.