In the world of lawn maintenance, having a reliable machine is essential for achieving a well-groomed yard. The efficiency and performance of these machines heavily depend on their individual elements, which work harmoniously to provide optimal results. Each component plays a vital role, from the engine to the cutting blades, ensuring that the device operates smoothly and effectively.

Understanding how these elements fit together can greatly enhance one’s ability to maintain and repair the equipment. Familiarity with the layout of the various pieces not only aids in troubleshooting but also simplifies the process of replacements and upgrades. This knowledge empowers users to take control of their machinery, ensuring longevity and reliability.

Whether you’re a seasoned professional or a weekend warrior, grasping the intricacies of your lawn care device can transform your maintenance experience. By exploring the layout of these key elements, you can navigate repairs and improvements with confidence, ultimately elevating your lawn care game to the next level.

Overview of the 60-Inch Mower

This section provides a comprehensive look at the 60-inch mower, designed for efficiency and ease of use in various landscaping tasks. Engineered with cutting-edge technology, it delivers superior performance and reliability, making it an excellent choice for both residential and commercial applications. Its innovative features enhance the overall mowing experience, ensuring that users achieve optimal results with minimal effort.

Key Features

The 60-inch mower boasts a robust engine that offers ample power for tackling diverse terrains. Its advanced cutting system ensures a clean and precise cut, contributing to a well-manicured lawn. Additionally, the ergonomic design promotes user comfort during operation, allowing for extended periods of use without fatigue.

Maintenance and Care

Essential Components of Z-Force 60

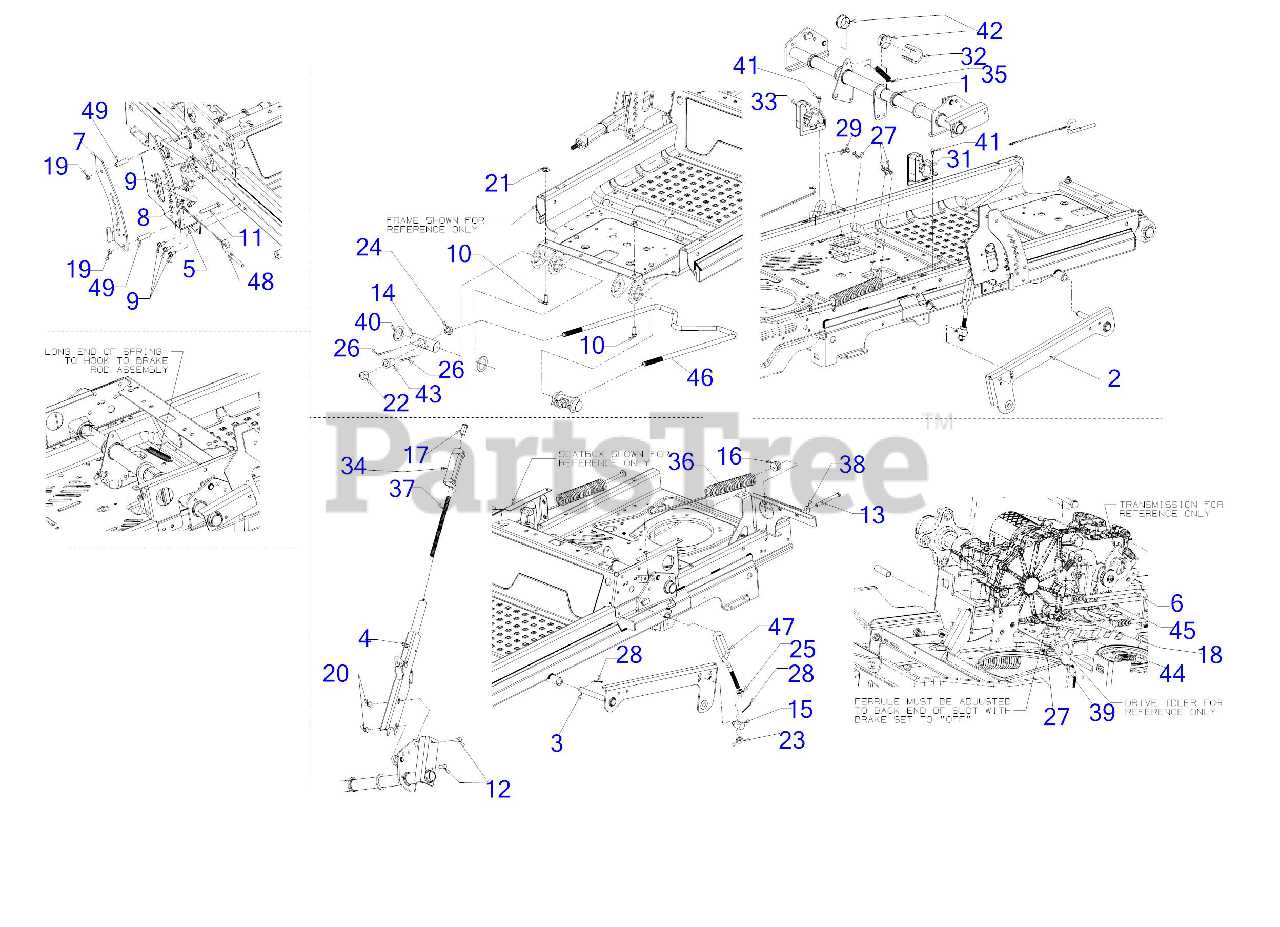

The effective operation of any lawn maintenance machine relies on its core elements. Understanding these crucial components can enhance performance and ensure longevity, ultimately contributing to a more efficient mowing experience. The various sections of the machine work together harmoniously, each playing a significant role in its overall functionality.

Key Elements and Their Functions

Among the essential features are the cutting deck, engine, and transmission system. The cutting deck is responsible for achieving a clean cut and can vary in size, allowing for flexibility depending on the area being maintained. The engine serves as the powerhouse, providing the necessary energy to operate all components effectively. Meanwhile, the transmission system ensures smooth movement and control, enabling operators to maneuver easily across different terrains.

Maintenance and Care

Proper upkeep of these elements is vital for optimal performance. Regular inspections and timely replacements of worn-out parts can prevent larger issues from arising. By focusing on the care of these fundamental components, users can enjoy a reliable and efficient lawn care experience for years to come.

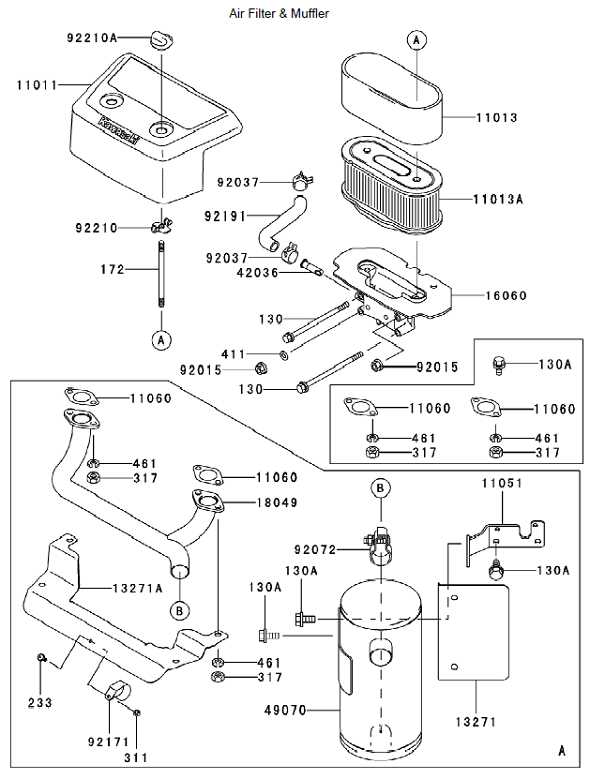

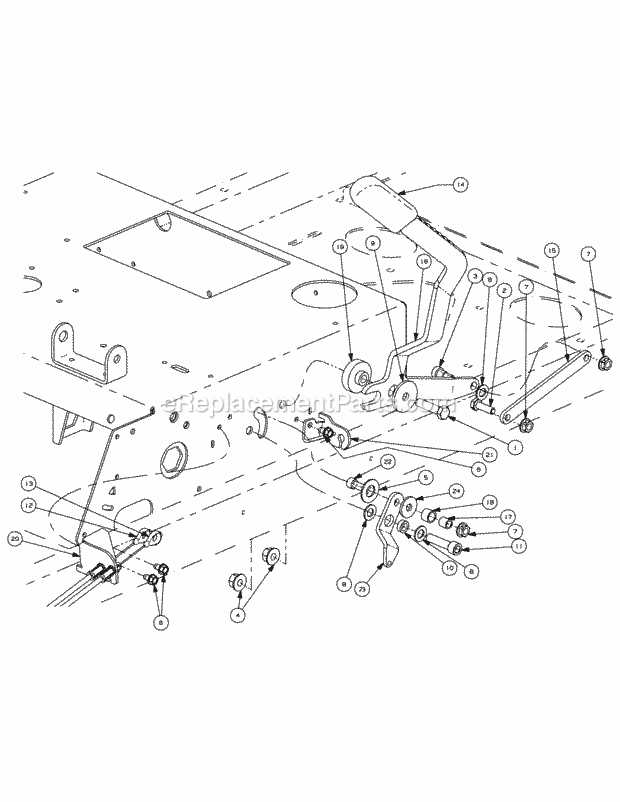

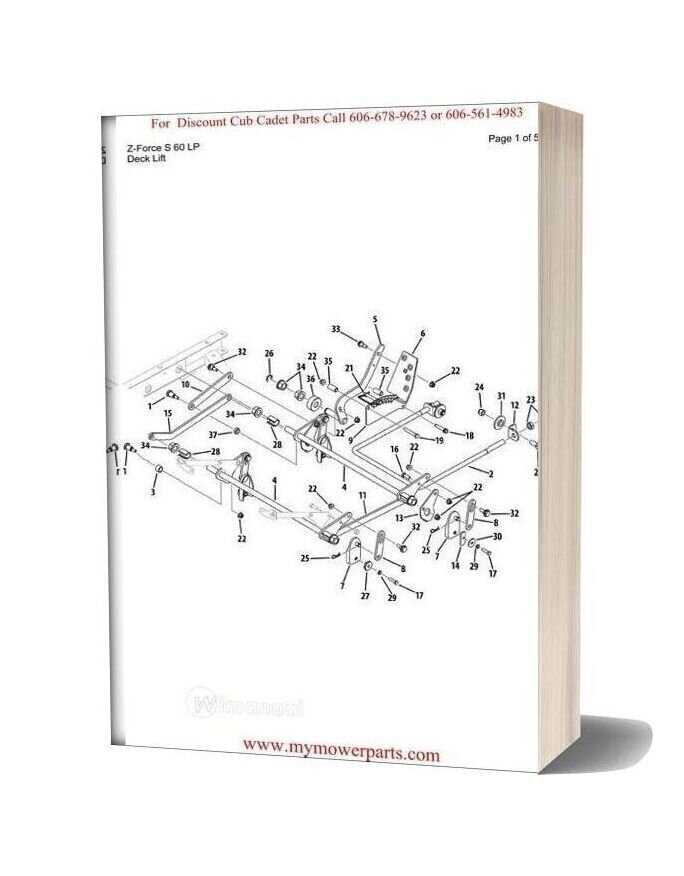

Understanding the Parts Diagram

Gaining insight into the layout of components within a machine is essential for effective maintenance and repairs. This visual representation serves as a guide, helping users identify various elements and their relationships. By familiarizing oneself with this illustration, individuals can enhance their comprehension of the equipment’s structure and functionality.

Key Benefits of Familiarity

Recognizing each element’s location and role enables more efficient troubleshooting and replacement procedures. Additionally, understanding this layout can lead to better performance, as it encourages proactive care and attention to critical areas.

Common Components Illustrated

Several key elements are typically featured in such representations, highlighting their importance in the overall functioning of the machine. Below is a brief overview of these elements:

| Component | Description | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Drives the entire system, providing necessary power. | ||||||||||||||||||||||||||||||

| Transmission | Transfers power from the engine to the wheels, enabling movement. | ||||||||||||||||||||||||||||||

| Blades | Essential for cutting grass or other materials efficiently. | ||||||||||||||||||||||||||||||

| Wheels | Facilitate mobility, allowing the unit to navigate various terrains.

Maintenance Tips for Z-Force 60Regular upkeep is essential for ensuring the longevity and efficiency of your lawn care equipment. Implementing a few key practices can help maintain optimal performance and prevent unexpected breakdowns. These tips aim to guide you through essential maintenance tasks that enhance the durability of your machine. 1. Routine Inspection: Conduct frequent checks on your equipment to identify any signs of wear or damage. Look for frayed belts, loose bolts, and worn tires. Addressing minor issues promptly can prevent more significant problems in the future. 2. Clean the Deck: Keep the mowing deck free from grass clippings and debris. A clean deck ensures even cutting and prevents rusting. Regularly wash the underside with water and a brush to remove buildup. 3. Change Oil Regularly: Replacing the oil according to the manufacturer’s recommendations is vital for engine health. Fresh oil reduces friction and helps keep internal components clean. 4. Sharpen Blades: Dull blades can tear grass rather than cut it, leading to a ragged lawn appearance. Sharpening blades regularly ensures a clean cut, promoting healthier grass growth. 5. Store Properly: During off-seasons, store your equipment in a dry, sheltered area. This protects it from the elements and extends its lifespan. Consider using a cover to shield it from dust and moisture. Following these maintenance tips will help you keep your lawn care equipment in excellent condition, ensuring it operates efficiently for years to come. Common Issues with Z-Force 60 Parts

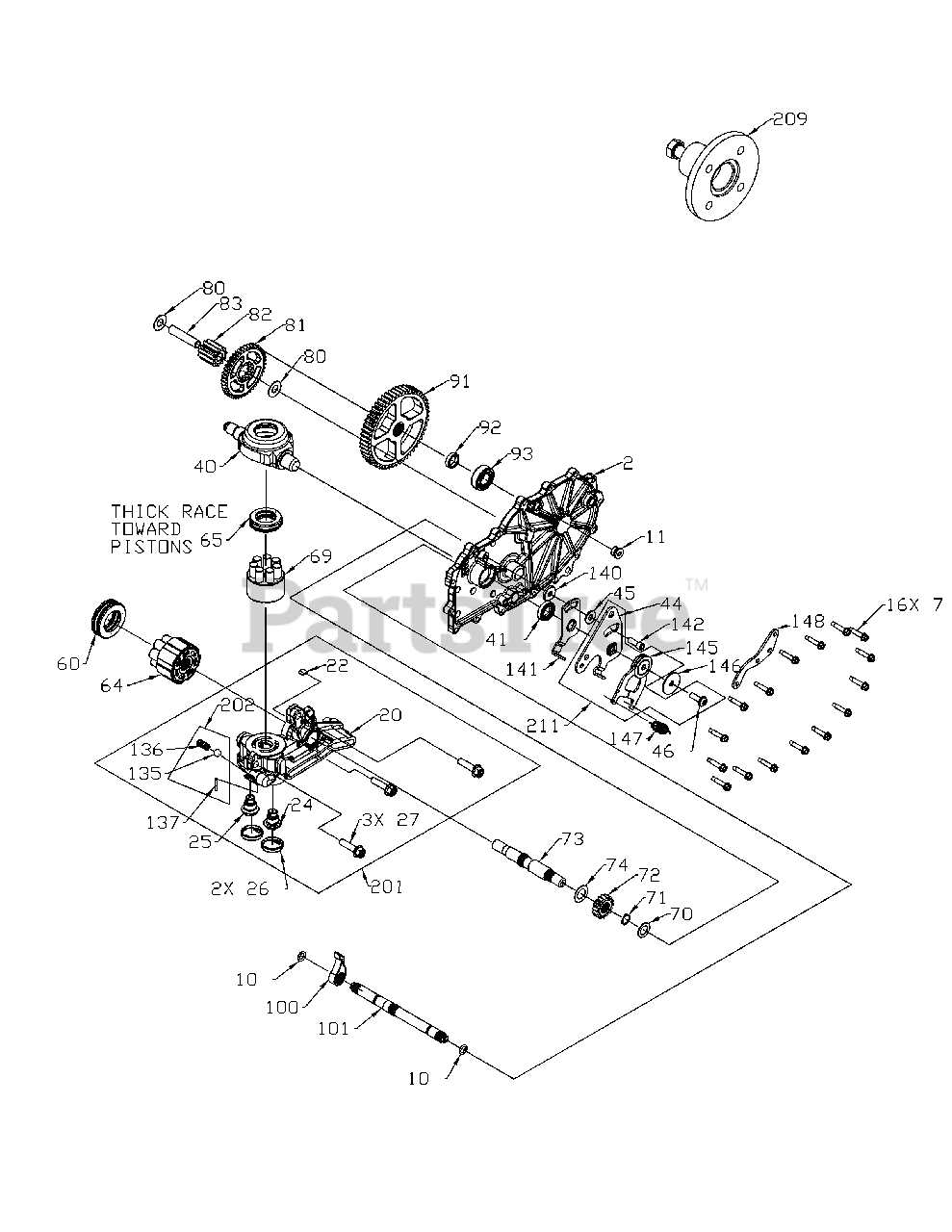

The performance of any machinery is heavily reliant on the condition of its components. This section addresses frequent challenges faced by users regarding the assembly of the Z-Force 60 model. Understanding these issues can assist in maintaining optimal functionality and prolonging the lifespan of the equipment. Wear and Tear

Regular usage can lead to significant wear on various elements. Common signs include decreased efficiency and unusual noises during operation. It is essential to monitor these indicators and replace worn-out items promptly to prevent further complications. Alignment IssuesImproper alignment of moving components can result in unbalanced performance and additional strain on the engine. Regular checks and adjustments are necessary to ensure that all parts are correctly aligned, promoting smoother operation and enhancing the overall experience. Replacement Parts for Z-Force 60

Maintaining a high-performing lawn care machine is essential for ensuring its longevity and efficiency. When components wear out or malfunction, it is crucial to have access to quality alternatives that can restore functionality and performance. This section will explore the various options available for sourcing and replacing necessary elements in your equipment. Quality and Compatibility are paramount when selecting alternatives. Opting for reputable suppliers can help you find components that not only fit perfectly but also meet or exceed the original specifications. This ensures that your equipment operates smoothly, providing the best results in your landscaping tasks. Common Alternatives often include drive belts, blades, and filters, which are essential for optimal performance. Regular inspection of these elements can prevent larger issues and enhance the overall efficiency of your machine. Always consider the manufacturer’s guidelines when making replacements to ensure compatibility and effectiveness. Ultimately, investing in reliable alternatives can significantly enhance the functionality and lifespan of your equipment, allowing you to tackle various landscaping challenges with ease. Tools Needed for Z-Force 60 RepairWhen it comes to maintaining and fixing your machine, having the right tools is essential for a smooth and efficient process. Proper equipment ensures that repairs can be performed safely and effectively, minimizing the risk of damage and prolonging the lifespan of the unit. Below, you’ll find a list of necessary instruments and their applications to facilitate the repair tasks. Essential ToolsThe following tools are commonly required for performing various repairs:

Additional AccessoriesIn addition to the basic tools, certain accessories may enhance your repair experience:

Safety Guidelines for Z-Force 60 MaintenanceEnsuring the safety of both the operator and the machine is crucial during maintenance procedures. Adhering to specific precautions can prevent accidents and promote efficient upkeep. Understanding and implementing these guidelines will contribute to a safer work environment.

Following a systematic approach to maintenance is vital. Consider the following steps to enhance safety:

By adhering to these guidelines, you can maintain a safe environment while performing necessary maintenance on your equipment. How to Order Replacement PartsWhen it comes to maintaining your outdoor equipment, obtaining the necessary components can seem daunting. However, following a systematic approach can simplify the process significantly. This section outlines the essential steps to efficiently acquire the required items for your machine. First, identify the specific components needed for your equipment. This can be done by consulting the user manual or referencing a visual reference that illustrates the various elements. Having the exact names and numbers will facilitate smoother transactions. Next, consider your options for purchasing. You can explore authorized dealers, local retailers, or online platforms. Each choice may offer different pricing and availability, so it’s beneficial to compare these factors before making a decision. Once you’ve selected a supplier, prepare to place your order. Be ready to provide details such as the component name, identification number, and quantity required. This information ensures accuracy and helps prevent delays in processing your request. Lastly, after placing your order, monitor the status of your shipment. It’s advisable to keep track of delivery timelines and any tracking information provided by the supplier. This diligence will help you plan for the installation of the new components effectively. Wiring Diagram for Z-Force 60This section provides a comprehensive overview of the electrical connections essential for the efficient functioning of the 60-inch riding mower. Understanding the wiring layout is crucial for maintenance and troubleshooting, ensuring that all components operate harmoniously. By familiarizing oneself with the electrical setup, operators can effectively diagnose issues and enhance the mower’s performance. Key Components and Their FunctionsIn any riding mower, several key elements contribute to its overall operation. Each part has a specific role, ensuring that the machine runs smoothly and efficiently. Below is a summary of the primary components involved in the electrical system:

Understanding the Electrical LayoutA clear grasp of the electrical layout is vital for ensuring safety and efficiency. The connections between components must be correctly established to prevent malfunctions. Refer to the provided schematic to identify the various links and understand their arrangement. Service Manual InsightsThis section provides valuable information derived from the service manual, focusing on maintenance and operational guidance for the machinery. Understanding these insights is essential for ensuring optimal performance and longevity of the equipment. Key aspects highlighted in the manual include:

Additionally, the manual often emphasizes:

By adhering to these insights, users can ensure their machinery operates smoothly and effectively over time. Owner Reviews and Feedback

This section highlights the experiences and opinions of users who have invested in a specific lawn maintenance machine. Their insights provide valuable information for potential buyers and help in understanding the overall performance, reliability, and satisfaction derived from the equipment. Positive Experiences

Areas for Improvement

|