In the realm of small machinery, a comprehensive understanding of the various components that drive performance is crucial. Each element plays a vital role in ensuring the overall efficiency and functionality of the device. By delving into the intricacies of these assemblies, one can enhance maintenance practices and troubleshoot issues more effectively.

One of the key aspects to explore is the arrangement of the internal mechanisms that influence fuel delivery and combustion. Familiarizing oneself with these components not only aids in recognizing potential problems but also facilitates informed decision-making when it comes to repairs and replacements. An organized view of these elements can significantly simplify complex processes.

Moreover, grasping the interconnections between different sections allows for a deeper appreciation of how each part contributes to the operational success of the equipment. This knowledge empowers users to optimize performance and extend the lifespan of their machines, ensuring they remain reliable tools in any gardening or landscaping endeavor.

Mantis Tiller Carburetor Overview

This section provides a comprehensive understanding of a crucial component responsible for optimal engine performance. The focus is on its essential functions, including the mixture of air and fuel, which significantly impacts efficiency and power output.

Understanding the Mechanism is vital for maintenance and troubleshooting. A well-functioning unit ensures smooth operation and can prevent various issues that may arise during usage.

Key components within the assembly work together to regulate flow and ensure that the engine runs smoothly. Familiarity with these elements allows for effective repairs and enhancements, ultimately leading to improved performance.

Importance of Carburetor Functionality

The performance of any engine relies heavily on the precision of its fuel-air mixing system. This critical component ensures that the right amount of fuel combines with air, enabling the engine to operate efficiently and smoothly. Without optimal functionality, an engine may struggle, resulting in decreased performance and increased emissions.

Enhanced Engine Performance

A well-functioning mixing device leads to improved power output and responsiveness. When the right fuel-air ratio is achieved, the engine can generate maximum power while maintaining fuel efficiency. Conversely, any malfunction can lead to poor acceleration and reduced power, which can be frustrating for the user.

Fuel Efficiency and Emissions

Proper operation of this system also significantly impacts fuel consumption and environmental emissions. An efficient mix ensures that fuel is burned completely, which not only conserves resources but also minimizes harmful pollutants. Regular maintenance and timely adjustments can help maintain this balance, promoting a cleaner environment and reducing operational costs.

In summary, the functionality of this essential engine component is vital for achieving optimal performance, enhancing fuel efficiency, and minimizing environmental impact.

Common Carburetor Issues in Tillers

Understanding frequent complications in fuel delivery systems is essential for maintaining optimal performance in gardening machinery. These problems can lead to inefficiencies, reduced power output, and even failure to start. Recognizing the symptoms early can save time and effort during repairs.

Fuel Flow Problems

Inadequate fuel supply often results from clogs or blockages in the fuel pathways. This can be caused by dirt, debris, or even old fuel residue. Regular cleaning and inspection of the system can prevent these issues from escalating.

Air Mixture Imbalances

Improper air-fuel mixtures can cause engine sputtering or stalling. This is usually a result of malfunctions in the adjustment screws or gaskets. Ensuring correct settings and replacing worn components is crucial for smooth operation.

Identifying Mantis Tiller Parts

Understanding the components of your gardening equipment is essential for optimal performance and maintenance. Familiarity with the various elements will enable you to troubleshoot issues and enhance efficiency.

Key components to recognize include:

- Engine: The powerhouse that drives the entire mechanism.

- Fuel System: Critical for delivering the necessary energy to the engine.

- Transmission: Responsible for transferring power effectively.

- Cutting Mechanism: The element that interacts with the soil.

- Control Handles: Ensure user maneuverability and comfort.

By mastering the identification of these elements, you can delve into repairs and maintenance with confidence.

Carburetor Maintenance Best Practices

Proper upkeep of fuel delivery components is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Here are some best practices to ensure smooth operation.

- Regular Cleaning: Accumulation of debris can hinder functionality. Clean components regularly using appropriate solvents.

- Inspect Seals and Gaskets: Check for wear and tear. Replace any damaged seals to prevent leaks.

- Check Fuel Quality: Ensure that the fuel used is fresh and free from impurities. Old or contaminated fuel can cause operational issues.

- Adjust Settings: Periodically verify that all adjustments are set according to the manufacturer’s specifications for optimal performance.

- Storage Practices: If the equipment will not be used for an extended period, empty the fuel tank and run the engine until it stalls to prevent varnish build-up.

By following these guidelines, you can maintain efficiency and prolong the life of your fuel system components.

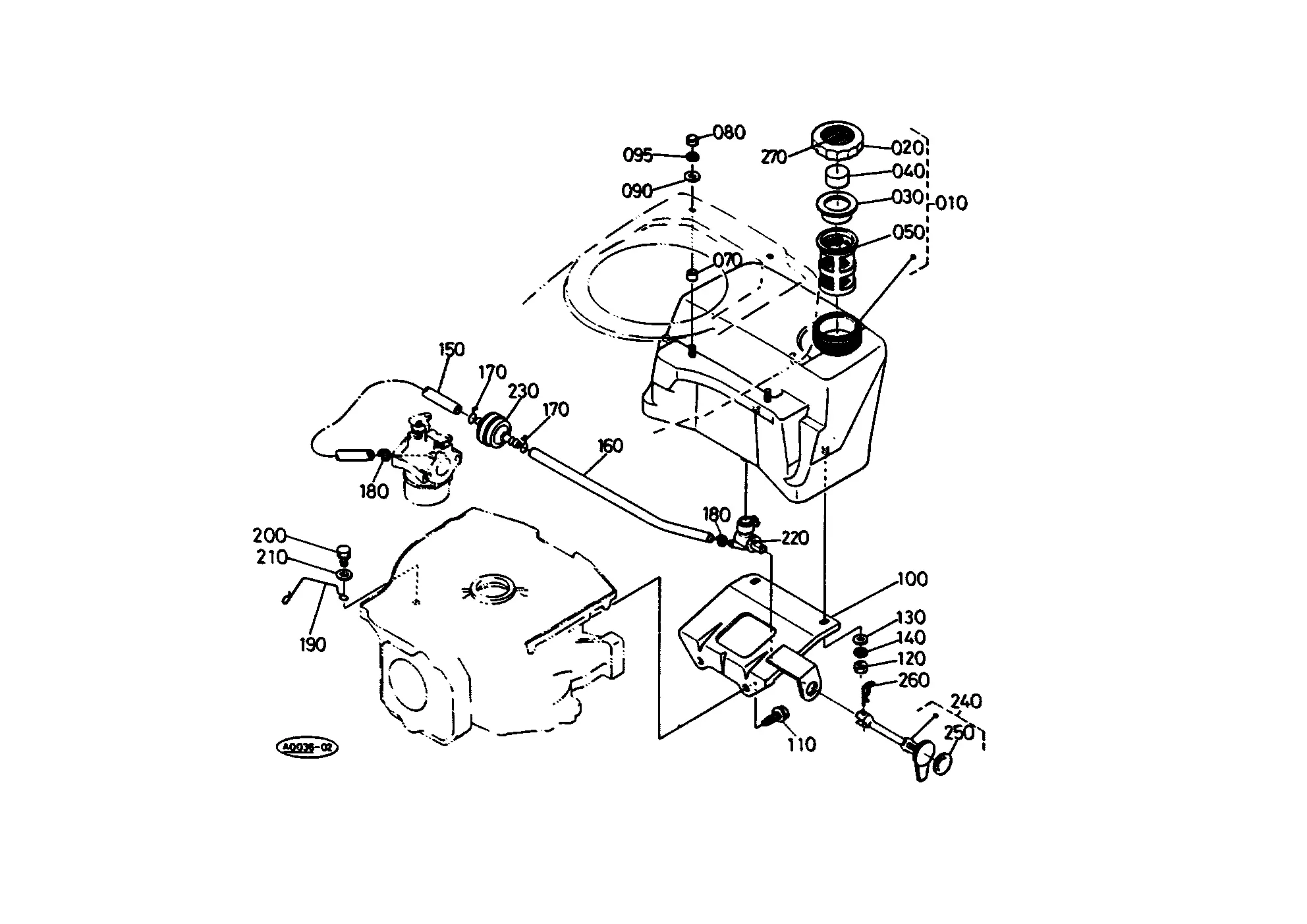

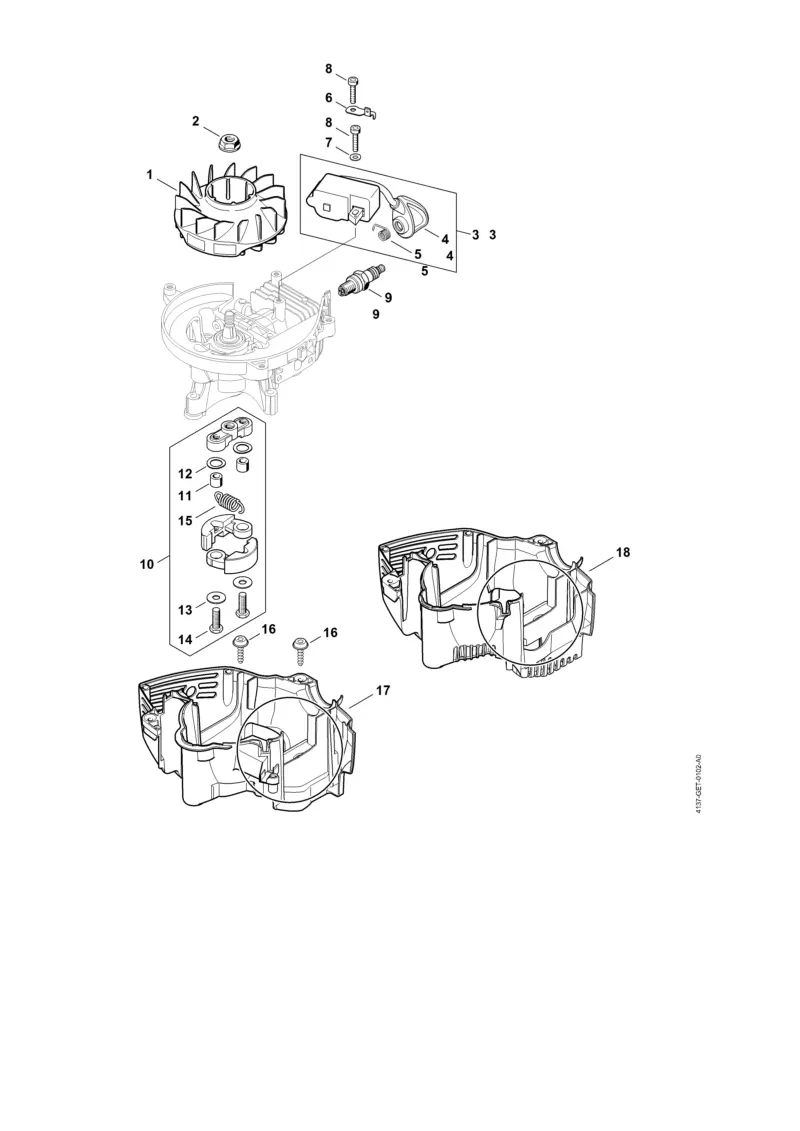

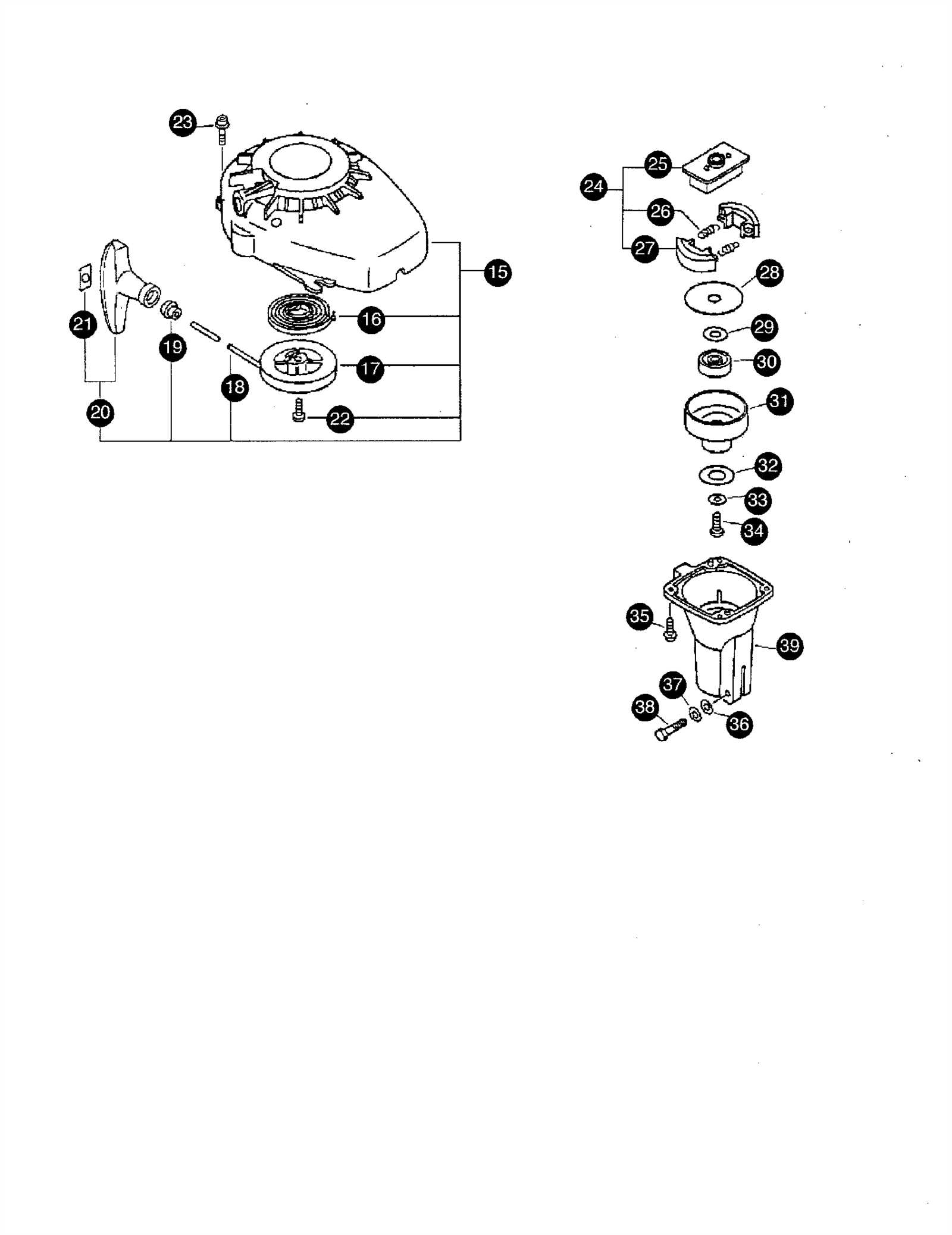

Understanding Carburetor Diagrams

Grasping the intricacies of engine fuel delivery systems can significantly enhance your repair and maintenance skills. These visual representations serve as a vital tool for identifying various components and their interrelations within the assembly. By dissecting these illustrations, you can gain insights into functionality and troubleshooting techniques.

Components typically include elements such as valves, jets, and chambers, each playing a crucial role in the overall mechanism. Understanding how these parts interact will enable you to diagnose issues more effectively.

Additionally, familiarizing yourself with symbols and labels used in these visuals will help streamline the repair process, making it easier to reference specific areas when addressing concerns. Mastering this knowledge is essential for anyone looking to enhance their expertise in engine maintenance.

Tools Needed for Repairs

When undertaking maintenance or repair tasks, having the right equipment is essential for achieving effective results. The appropriate tools not only facilitate the process but also ensure safety and accuracy. Below is a list of commonly required implements that can aid in restoring functionality to various mechanical components.

1. Screwdrivers: A set of both flat-head and Phillips screwdrivers is crucial for removing and securing screws. Ensure that the sizes match the fasteners used in your equipment.

2. Wrenches: A collection of adjustable and fixed wrenches will help tackle nuts and bolts of different sizes, allowing for easy disassembly and reassembly.

3. Pliers: Needle-nose and standard pliers are beneficial for gripping, twisting, and cutting wires or small components during the repair process.

4. Cleaning Supplies: Brushes, rags, and cleaning solvents are vital for maintaining hygiene and removing debris from surfaces, ensuring optimal performance after repairs.

5. Safety Gear: Always wear gloves and safety goggles to protect yourself from debris and potential hazards while working.

Equipped with these essential tools, you can confidently approach repair tasks, ensuring that each step is carried out efficiently and safely.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to reassembling essential components of a garden machine. Following a systematic process ensures optimal performance and longevity.

Preparation

- Gather all necessary tools and components.

- Clean the workspace to avoid contamination.

- Review the manufacturer’s instructions for any specific guidelines.

Assembly Steps

- Begin with the main unit; ensure all seals are intact.

- Carefully position the essential elements, aligning them according to the schematic.

- Secure each part with the appropriate fasteners, checking for tightness.

- Reconnect any necessary hoses or wiring, ensuring proper fit.

- Conduct a final inspection for any loose connections or misplaced parts.

How to Clean Your Carburetor

Regular maintenance of your engine’s fuel delivery system is essential for optimal performance. Over time, deposits and residue can build up, affecting efficiency and functionality. This guide will help you restore smooth operation with straightforward cleaning techniques.

Gather Your Supplies

Before starting, assemble the necessary tools: a screwdriver, cleaning solution, soft brushes, and a clean cloth. Ensure you also have safety gear, such as gloves and goggles, to protect yourself during the process.

Step-by-Step Cleaning Process

Begin by disassembling the components gently. Use the cleaning solution to soak parts that have significant buildup. Employ a soft brush to scrub away grime, paying special attention to small crevices. Rinse thoroughly and dry each piece before reassembly. Finally, reattach everything securely to restore functionality. Remember to perform this task regularly to maintain performance.

Symptoms of a Faulty Carburetor

Recognizing the signs of a malfunctioning fuel management system is crucial for maintaining optimal performance. When the flow of air and fuel becomes imbalanced, various issues can arise, affecting both efficiency and functionality.

One common indication is difficulty starting the engine, often accompanied by backfiring or stalling shortly after ignition. Another symptom is an irregular idle, where the engine may run erratically or fluctuate in speed. Additionally, if there’s an unusual increase in fuel consumption, it may point to an improper mixture. Lastly, excessive smoke from the exhaust can signal that the system is not effectively regulating fuel delivery.

Ordering Replacement Parts Online

When it comes to maintaining outdoor equipment, finding the right components can often be a challenging task. However, the convenience of online shopping has transformed the way enthusiasts acquire essential elements for their machinery. With just a few clicks, users can access a wide variety of options tailored to their specific needs, making the process straightforward and efficient.

To ensure a seamless experience, it is crucial to verify the specifications and compatibility of the items you intend to purchase. Most retailers provide detailed descriptions and even user reviews, which can guide you in selecting the correct replacement. Additionally, many online platforms offer convenient search features that allow you to filter results based on brand, model, or type of equipment.

Furthermore, consider the shipping policies and return options when placing your order. Reliable vendors often provide tracking information, enabling you to monitor your shipment. Should any issues arise, having a clear return policy is essential for resolving discrepancies. By prioritizing these factors, you can confidently order the necessary elements online and ensure your machinery remains in optimal condition.

When to Seek Professional Help

Understanding the intricacies of engine components can be challenging, and certain situations may warrant the expertise of a skilled technician. When faced with persistent issues or complications that exceed basic maintenance knowledge, it is crucial to recognize when professional assistance is necessary. A qualified mechanic can provide insights and solutions that are not easily achievable through self-service methods.

Identifying Complex Problems

If you notice symptoms such as erratic performance, difficulty in starting, or unusual noises, these may indicate underlying issues that require a deeper examination. Attempting to resolve complex malfunctions without adequate experience can lead to further complications. Engaging a professional ensures that any repairs or adjustments are conducted safely and effectively.

Service and Maintenance Needs

Regular upkeep is essential for optimal functionality, but some tasks may demand specialized tools or knowledge. If you lack the resources or confidence to perform certain maintenance activities, it’s advisable to consult an expert. They can assist in ensuring that all components are functioning harmoniously, prolonging the life of the equipment and enhancing overall performance.