When maintaining or repairing small engines, it is essential to be familiar with the key components that ensure smooth performance. These mechanisms, though intricate, play a critical role in the engine’s operation, influencing everything from fuel intake to the engine’s responsiveness.

By examining these essential elements, you gain insights into how the overall system functions efficiently. Recognizing the importance of these parts can help in troubleshooting and extending the life of your equipment. Whether you are fine-tuning or replacing elements, understanding their roles will lead to more effective maintenance.

In this guide, we will explore the inner workings of these essential mechanisms, providing a clear view of how each piece interacts with the rest of the engine. By the end, you will have a better grasp of how these components contribute to a smoothly running machine.

Engine Fuel System Overview

The engine’s fuel system plays a crucial role in delivering the right mixture of air and fuel to ensure optimal performance. It controls the flow and proportions of these elements, directly affecting engine efficiency and reliability. Understanding how this component functions is key to maintaining and troubleshooting small engines.

Key Features of the Fuel Mechanism

- Adjusts air-to-fuel ratio

- Ensures efficient combustion

- Supports smooth engine operation

Common Adjustments and Maintenance Tips

- Regularly inspect and clean the system

- Replace filters to avoid clogs

- Adjust settings for optimal fuel flow

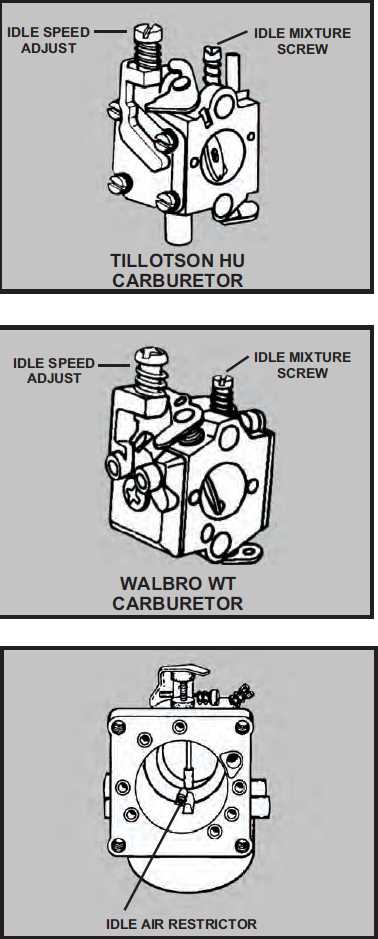

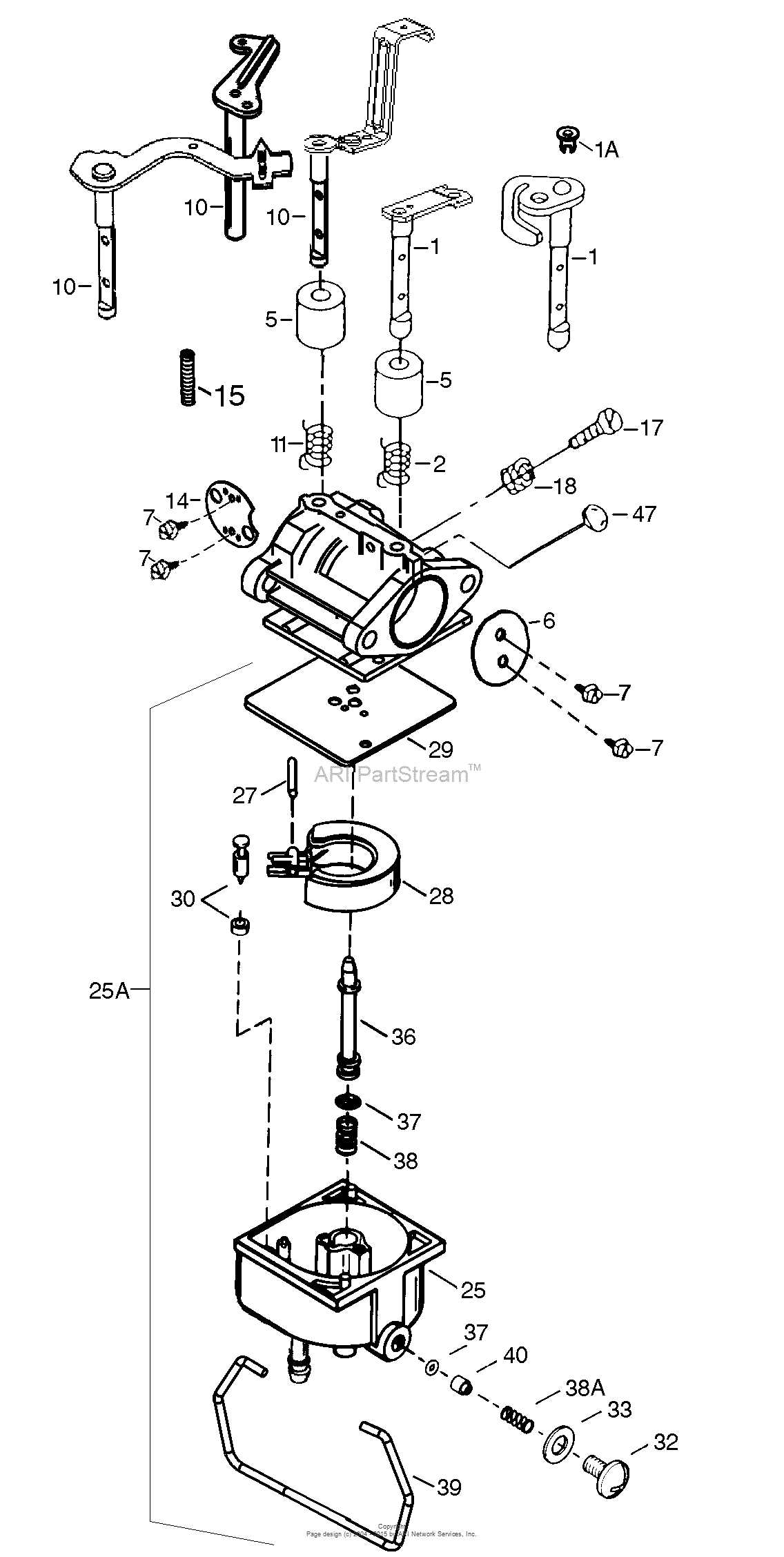

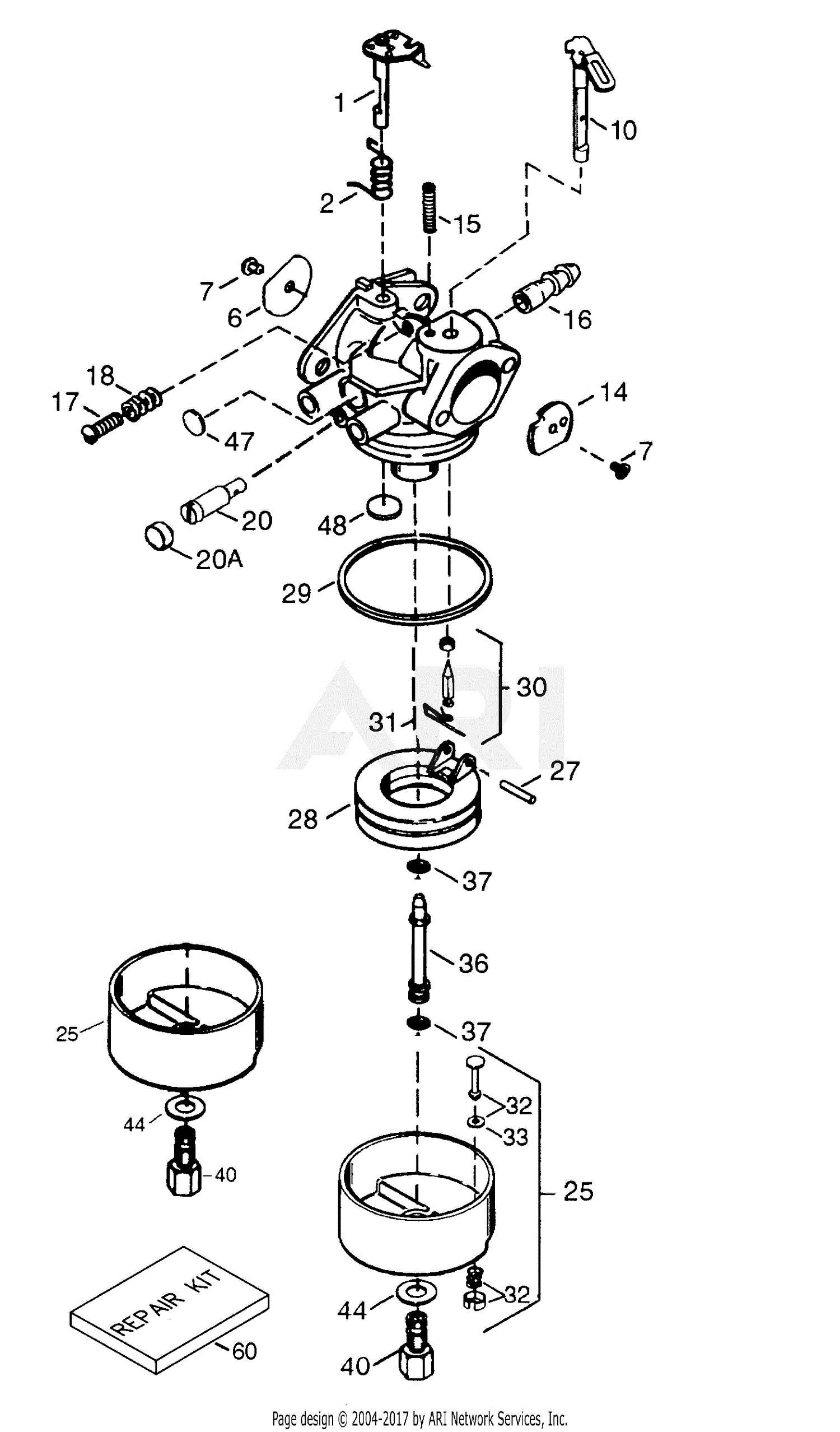

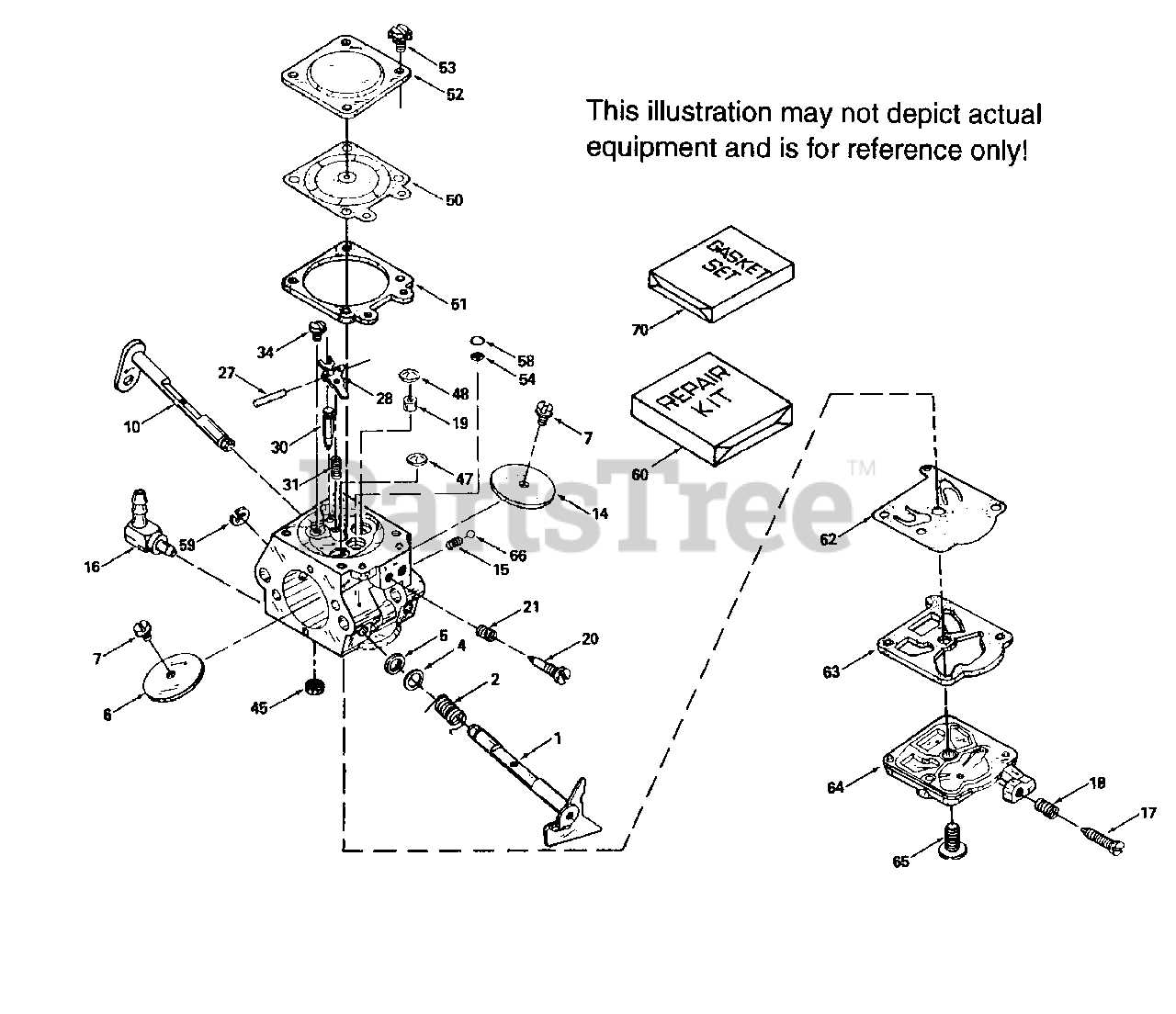

Key Components of Tecumseh Carburetors

The inner workings of small engine fuel systems rely on several essential elements to ensure proper fuel delivery and air intake balance. These mechanisms work together to maintain engine performance and efficiency, controlling the flow of fuel and air through precision-tuned passages and valves.

Float plays a critical role in regulating fuel levels. By adjusting its position, it ensures the right amount of liquid is consistently supplied to the engine.

The needle valve serves as a gatekeeper for fuel flow. It opens or closes depending on the demand for fuel, allowing precise control over the mixture.

Choke is another crucial feature,

How the Carburetor Functions in Small Engines

The operation of fuel and air mixing devices in small engines is crucial for efficient performance. These systems manage the flow of air and fuel, ensuring the correct ratio is delivered for combustion. This precise balance allows the engine to generate power smoothly, whether running at low speeds or full throttle.

At its core, the device is responsible for regulating airflow and blending it with fuel before entering the combustion chamber. The amount of fuel mixed depends on the engine’s needs at any given moment, with adjustments happening automatically as the throttle position changes.

For engines to work efficiently, these mechanisms must maintain optimal conditions. They prevent fuel waste and allow for smooth operation under various loads, ensuring consistent performance in different operating environments.

Common Signs of a Malfunctioning Carburetor

When an engine isn’t running as smoothly as it should, it can often be linked to issues in the system that manages air and fuel flow. Identifying the signs early can prevent more serious problems and ensure the engine continues to operate efficiently.

- Engine stalls: One of the most frequent indicators is when the motor unexpectedly cuts out while idling or at lower speeds.

- Difficulty starting: Trouble getting the engine to fire up can be a clear sign of an imbalance in fuel or air intake.

- Black smoke from the exhaust: This suggests an overly rich mixture, meaning too much fuel is being burned.

- Poor acceleration: If the engine hesitates

Understanding Carburetor Jets and Their Role

Jets play a crucial role in the fuel system, ensuring the precise mixture of fuel and air for optimal engine performance. They control the flow of fuel into the engine, influencing how efficiently the engine operates under different conditions.

The main and pilot jets are designed to regulate fuel delivery at various engine speeds. Main jets govern fuel flow during high speeds, while pilot jets handle low-speed and idle performance. The balance between these components is key to maintaining efficiency and preventing issues like stalling or rough idling.

Proper maintenance of these fuel channels is

Throttle and Choke Mechanism in Tecumseh Models

The throttle and choke system plays a crucial role in regulating the air-fuel mixture for optimal engine performance. This mechanism ensures that the correct amount of air and fuel enters the combustion chamber, affecting efficiency, power output, and emissions.

In many small engine applications, the throttle controls the engine speed by adjusting the airflow. A well-functioning throttle enables precise management of power, allowing users to achieve the desired performance based on varying operational conditions. Conversely, the choke serves to enrich the fuel mixture during the starting phase, facilitating easier ignition in cold conditions. It restricts airflow, ensuring that more fuel enters the combustion chamber when the engine is cold.

Understanding the relationship between these components is vital for maintenance and troubleshooting. Regular inspection of the throttle and choke assembly can prevent issues such as poor acceleration or stalling, enhancing the overall reliability of the engine.

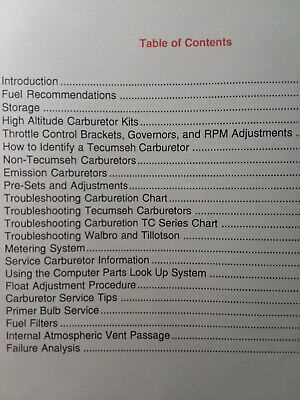

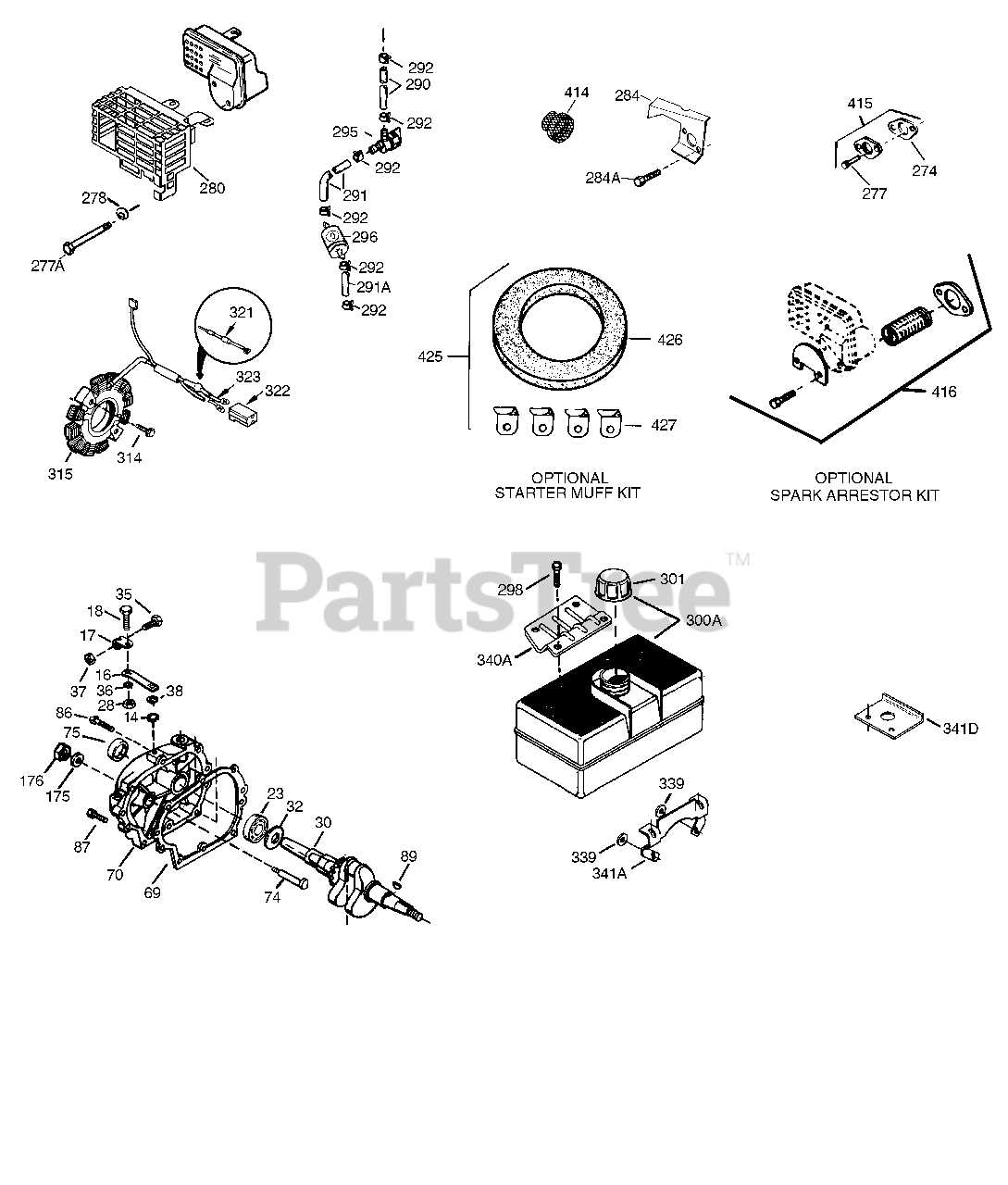

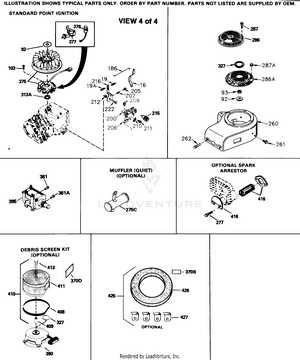

How to Identify Carburetor Part Numbers

Recognizing the correct identifiers for components in your engine system is crucial for maintenance and repairs. Accurate identification ensures you select the right replacements, enhancing the performance and longevity of your machinery.

Understanding the Identification Process

Start by examining the component itself. Most identifiers are stamped or printed on the body of the item. Look for a sequence of numbers or letters, which typically signify the model or version. These markings can often provide insights into compatibility with various models.

Utilizing Manufacturer Resources

Consult the manufacturer’s documentation or online resources. Many companies provide detailed catalogs or websites that allow you to search for specific identifiers based on your engine’s specifications. This can be an invaluable tool in ensuring you obtain the correct replacements.

Proper Maintenance for Carburetor Longevity

Ensuring the durability of fuel delivery mechanisms requires consistent upkeep and attention to detail. By adopting effective practices, users can significantly enhance the lifespan and functionality of these essential components. Regular maintenance not only prevents potential issues but also promotes optimal performance during operation.

Key Maintenance Practices

- Regular Cleaning: Remove any deposits or dirt that may accumulate, ensuring smooth operation.

- Inspect Seals and Gaskets: Check for wear and tear, replacing them as necessary to prevent leaks.

- Use Quality Fuel: Opt for high-grade fuel to minimize residue buildup and enhance efficiency.

- Adjust Air-Fuel Mixture: Proper tuning can improve performance and reduce emissions.

Signs of Neglect

- Inconsistent Performance: Difficulty in starting or irregular operation may indicate underlying issues.

- Fuel Leaks: Puddles or wet spots near the mechanism are signs of potential seal failures.

- Excessive Smoke: Unusual emissions can suggest an imbalance in the air-fuel mixture.

By incorporating these practices into a regular maintenance schedule, individuals can ensure their fuel delivery systems remain efficient and reliable over time.

Troubleshooting Tecumseh Carburetor Issues

Addressing common issues with fuel delivery systems can enhance the performance of your small engine. Understanding the typical problems and their symptoms is essential for effective maintenance. With the right approach, you can diagnose and resolve issues that may arise during operation.

1. Engine Won’t Start: If the engine fails to start, the fuel supply might be obstructed. Begin by checking the fuel lines for blockages. Inspect the fuel filter and ensure it is clean. Additionally, verify that the primer bulb is functioning correctly and that there is adequate fuel in the tank.

2. Irregular Idling: Uneven idling can indicate a problem with the air and fuel mixture. Inspect the adjustment screws on the mixture control to ensure they are set properly. A clogged air filter can also lead to irregular performance; replace it if necessary.

3. Excessive Fuel Consumption: High fuel usage may result from an incorrect mixture ratio. Check the settings of the adjustment screws and clean any debris that might affect the fuel flow. Ensuring that all components are in good condition will help optimize efficiency.

4. Stalling: If the engine stalls unexpectedly, inspect the fuel supply for any interruptions. A failing fuel pump or leaks in the fuel lines can lead to inadequate delivery. Ensure all connections are secure and replace damaged hoses.

By following these troubleshooting steps, you can identify and fix many issues related to fuel delivery systems, ensuring smoother operation and longevity for your engine.

Replacing Damaged Parts in Tecumseh Carburetors

Maintaining the efficiency of your engine often requires replacing worn or broken components within the fuel delivery system. Regular inspection and timely substitution of these elements can significantly enhance performance and longevity. Understanding the intricacies involved in this process is crucial for achieving optimal results.

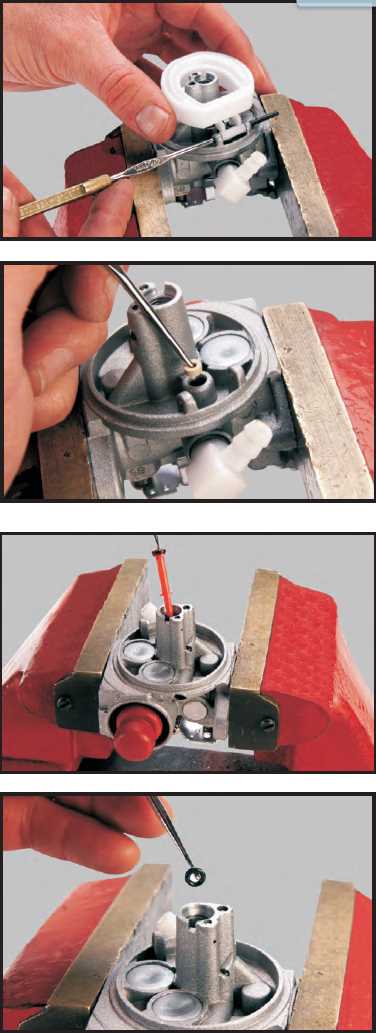

Identifying Worn Components

Before embarking on the replacement process, it is essential to accurately identify which elements are malfunctioning. Common indicators of damage may include irregular fuel flow, excessive leakage, or diminished engine power. Regular checks can help pinpoint issues, allowing for efficient maintenance.

Steps for Replacement

To initiate the replacement, first, ensure the engine is turned off and cooled down. Carefully detach the affected elements, taking care not to damage surrounding components. When installing new units, ensure a snug fit to prevent leaks and maintain proper functionality. Following the manufacturer’s guidelines during this process will ensure a smooth and successful replacement.

Proper maintenance and timely replacement of damaged elements are vital for the health of your engine. With a bit of diligence, you can ensure that your equipment remains in peak condition.

Adjust

Proper tuning of engine components is crucial for optimal performance and efficiency. Fine-tuning allows for the precise management of fuel and air mixture, ensuring smooth operation and reduced emissions. Adjustments may involve several elements, each playing a vital role in the overall function of the system.

Importance of Precision

Maintaining accuracy in adjustments is essential. Inaccurate settings can lead to poor fuel economy, increased wear on the engine, and potentially costly repairs. Regular checks and calibrations can help avoid these issues and enhance longevity.

Common Adjustment Techniques

Several methods can be employed to achieve the desired settings. For instance, tweaking the throttle response can significantly improve acceleration and responsiveness. Additionally, modifying idle speeds can enhance stability when the engine is not under load. Each adjustment should be approached with care, considering the unique requirements of the engine.

Summary: Regular and precise adjustments contribute to the efficiency and durability of engine components. By understanding the techniques and their significance, users can ensure reliable performance.