When delving into the intricacies of fuel delivery systems, it’s essential to grasp the arrangement and functionality of various elements involved. This section aims to clarify how each component works in harmony, ensuring optimal performance of the entire system. A clear visual representation can significantly enhance comprehension, providing insights into the relationship between individual parts.

Exploring the configuration of these elements is crucial for both enthusiasts and professionals alike. By understanding how each piece interacts, one can troubleshoot effectively and optimize the setup for better efficiency. This knowledge not only aids in repairs but also empowers users to make informed decisions during upgrades or modifications.

Ultimately, having a solid grasp of the arrangement and roles of these components leads to a more profound appreciation of the technology at hand. Whether you are a seasoned expert or a curious newcomer, mastering these details can enhance your expertise in the field and contribute to successful maintenance and performance improvements.

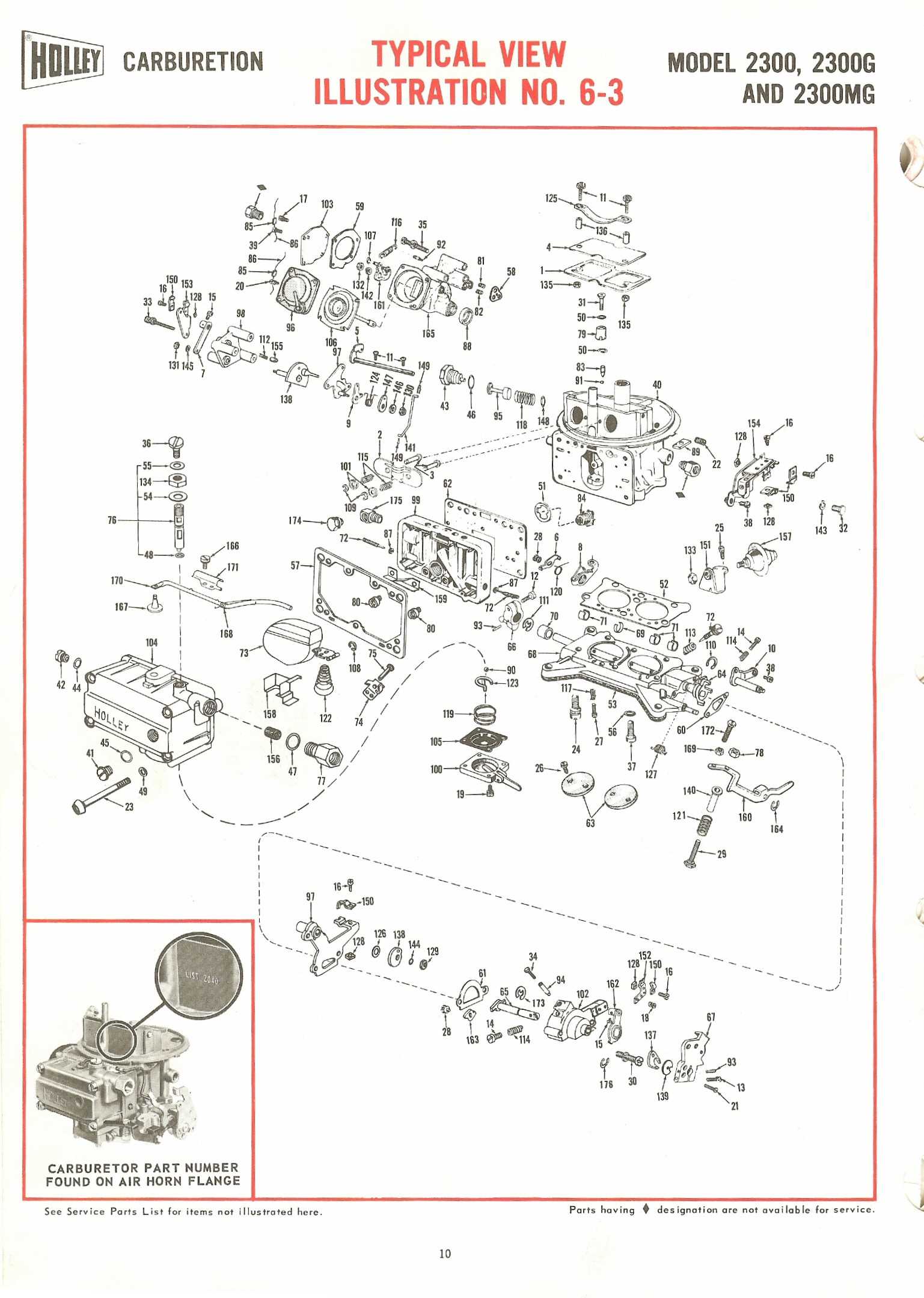

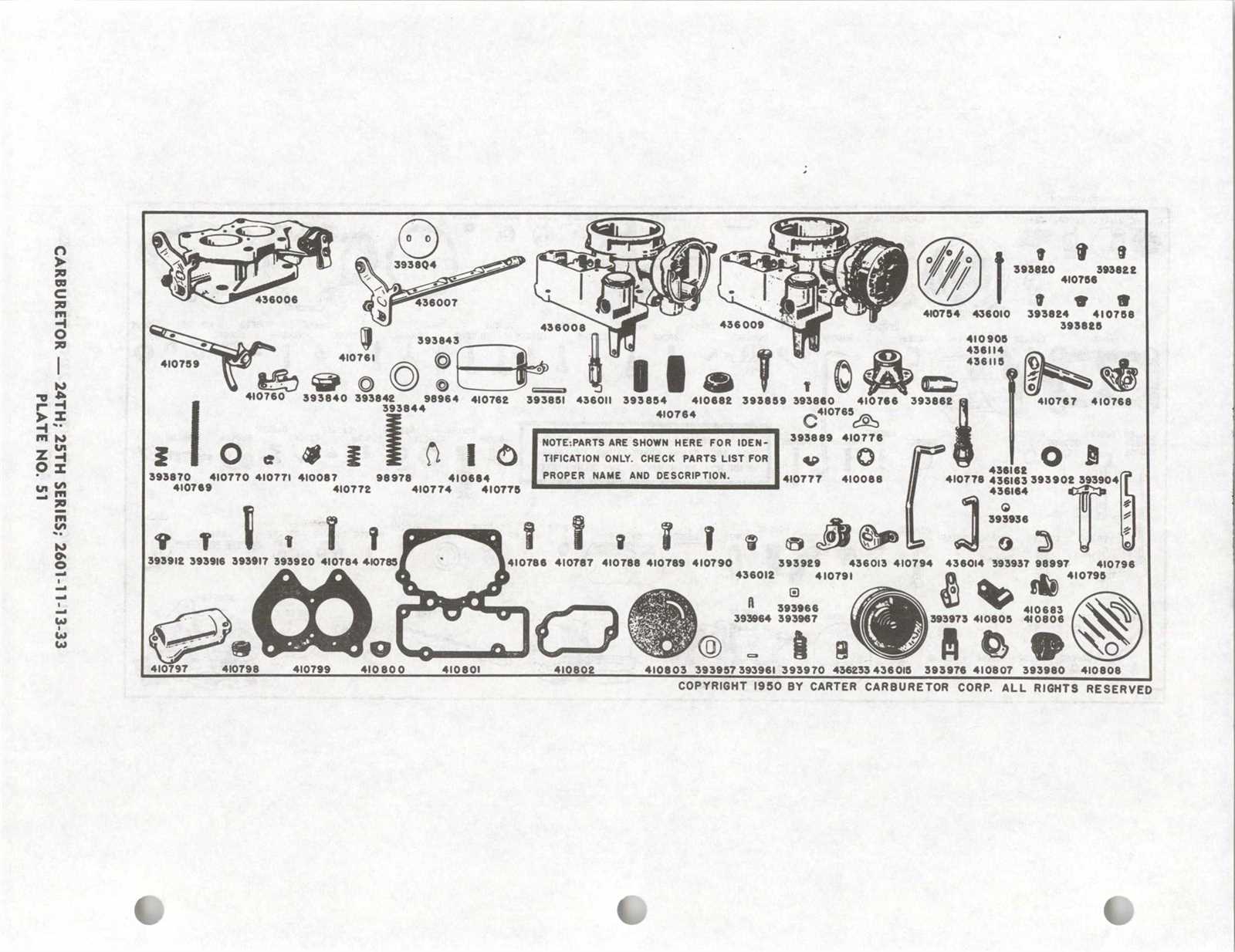

Carter AFB Components Overview

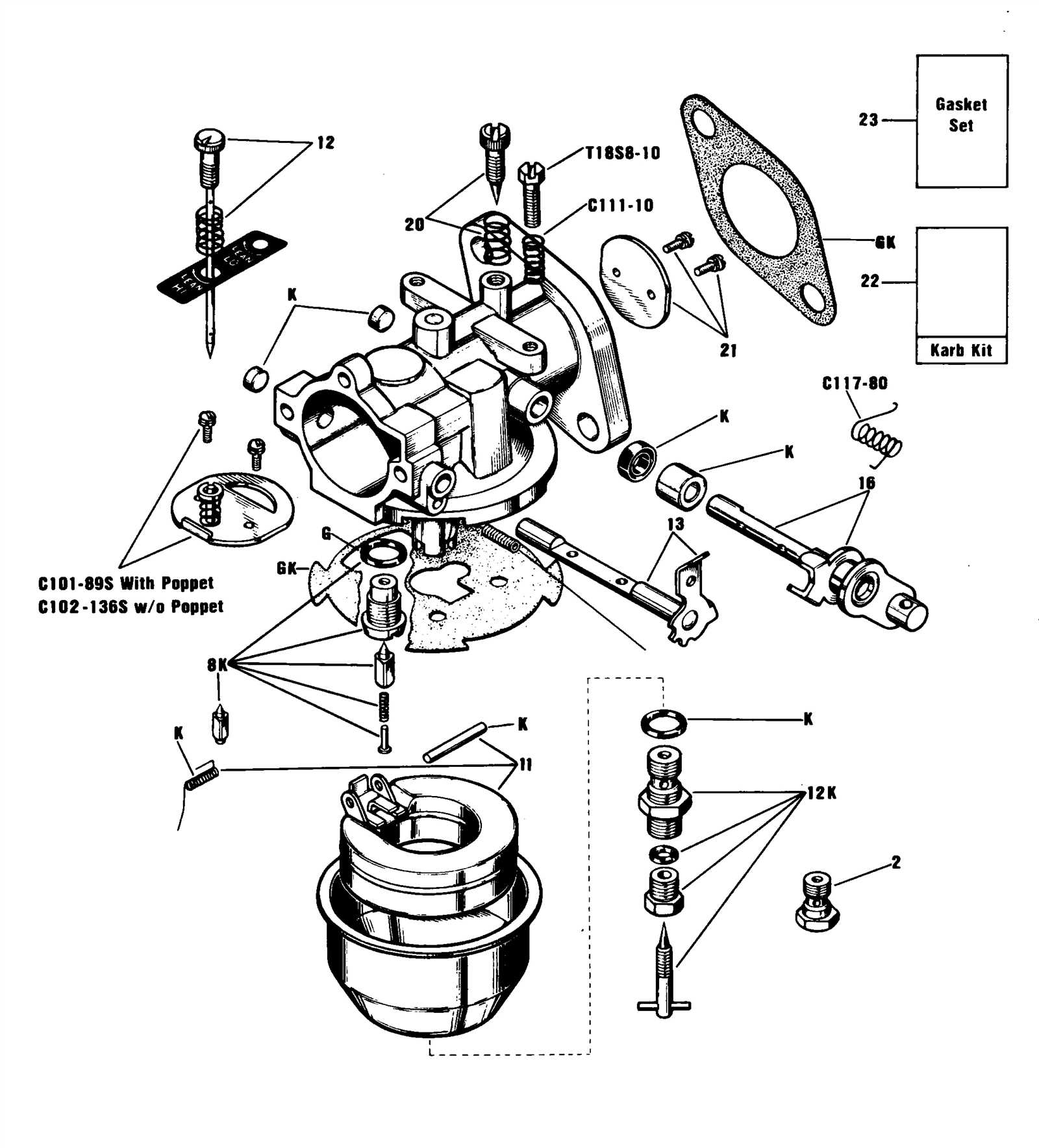

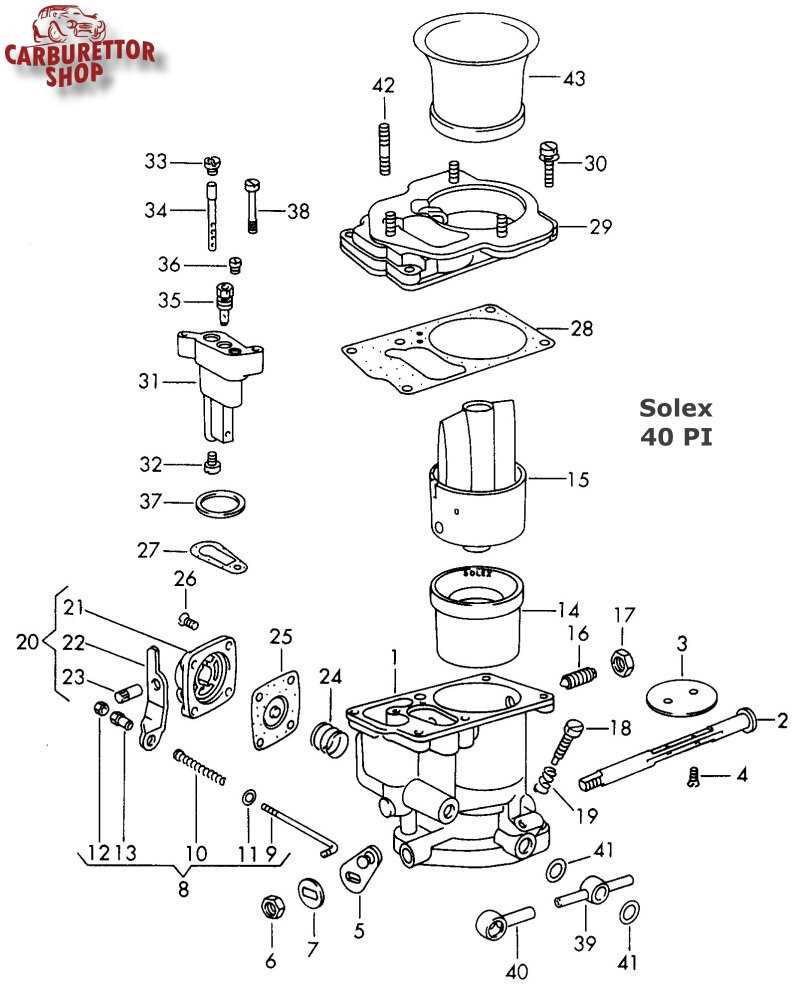

This section provides a comprehensive look at the various elements that comprise a specific type of carburetor, which plays a crucial role in engine performance. Understanding the function and interrelation of these components is essential for effective maintenance and optimization.

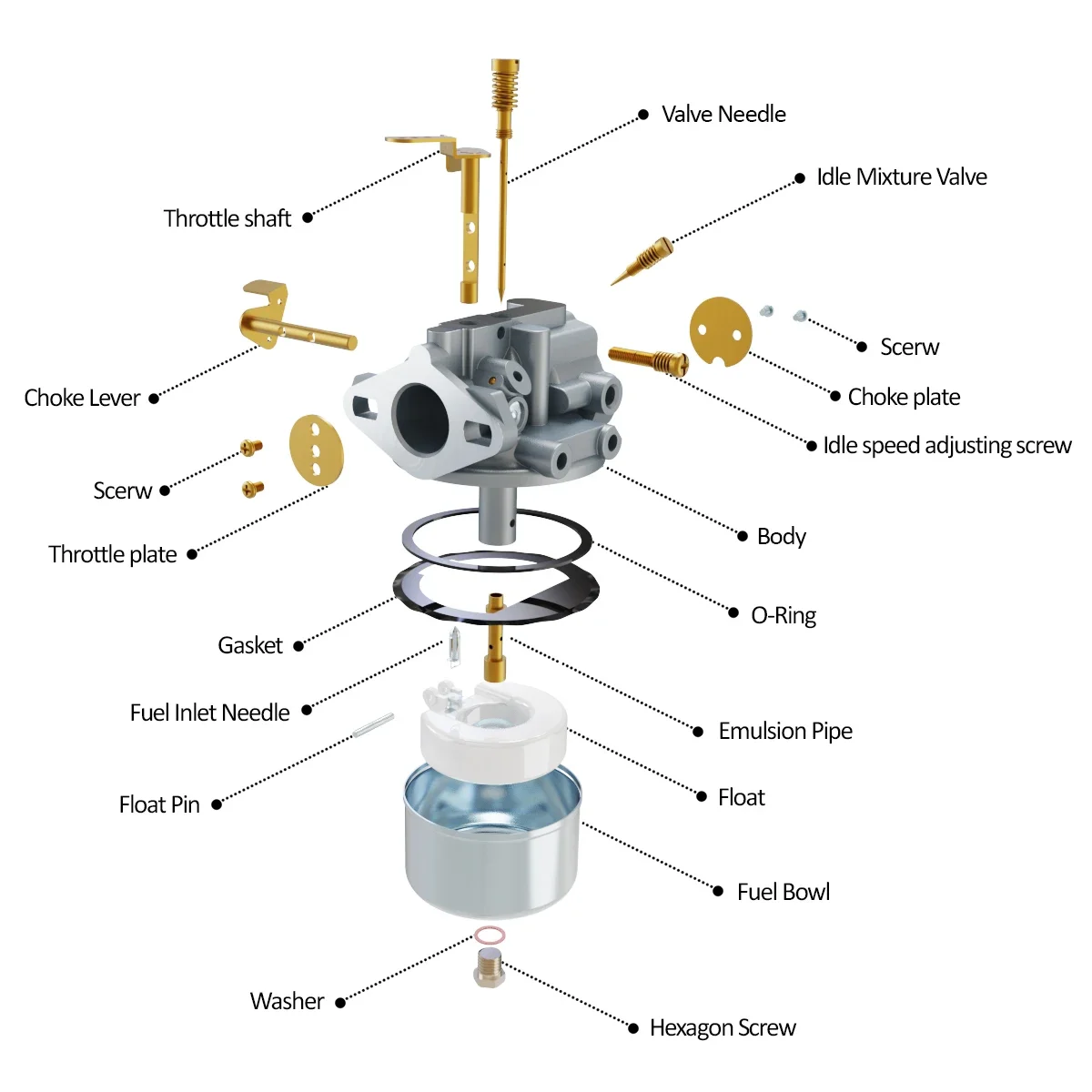

Fuel Delivery System: This system is responsible for supplying the appropriate amount of fuel to the engine. It includes elements such as jets, floats, and needles, all of which ensure the correct fuel-air mixture for efficient combustion.

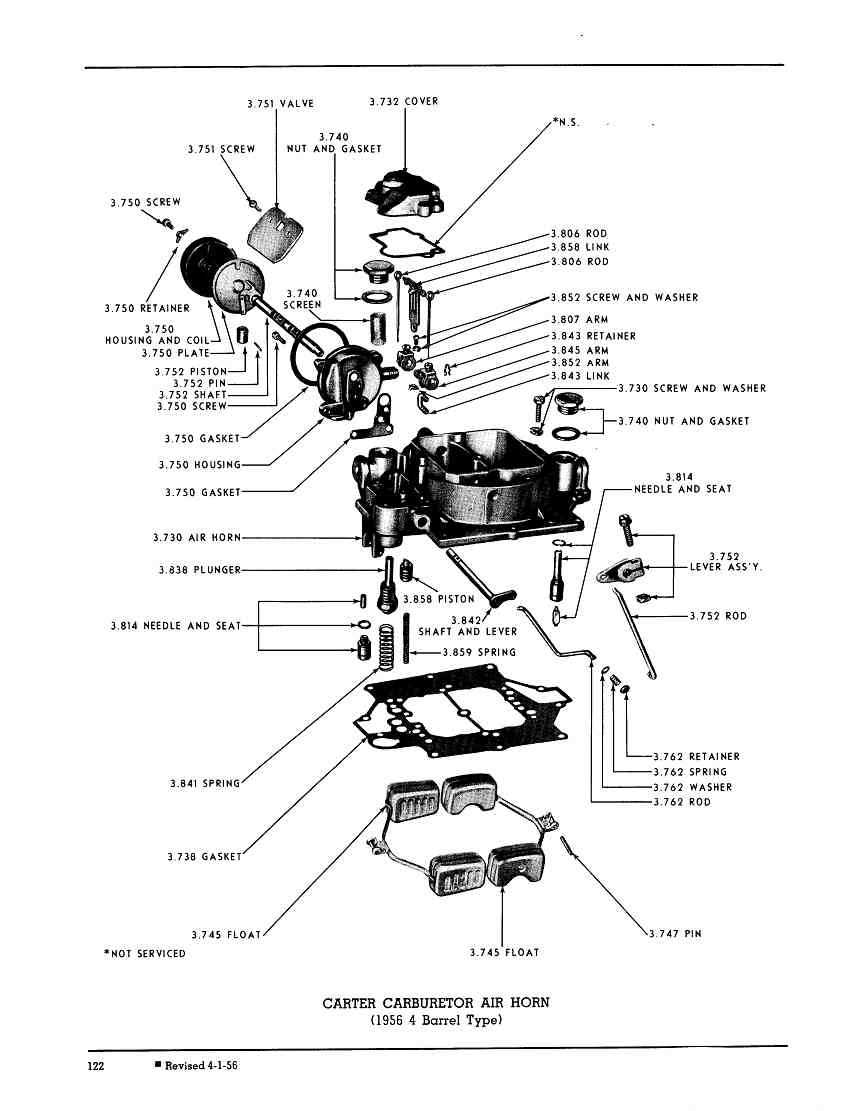

Air Intake Mechanism: The air intake setup facilitates the flow of air into the combustion chamber. It typically consists of an air horn and various passages that direct airflow, playing a vital role in maintaining optimal engine efficiency.

Throttle Body Assembly: This component controls the engine’s power output by regulating airflow. The throttle linkage connects the accelerator pedal to the throttle body, allowing the driver to adjust the engine’s response according to driving conditions.

Choke System: A choke is utilized to enrich the fuel mixture during cold starts, improving engine ignition. This system can be automatic or manual, depending on the design, and its proper functioning is key to reliable operation.

Adjustment Mechanisms: Various screws and adjustments allow for fine-tuning the performance of the carburetor. These include idle speed screws and mixture screws, which enable the user to achieve optimal performance based on specific conditions.

Understanding Carburetor Functionality

Carburetors play a crucial role in the performance of internal combustion engines by mixing air and fuel in the optimal ratio for combustion. This process is essential for efficient engine operation, ensuring that the mixture is neither too rich nor too lean, which can affect performance and emissions.

Basic Principles of Operation

The core function of a carburetor involves creating a vacuum that draws in air, which then mixes with fuel from a reservoir. This mixture is then atomized and delivered to the engine’s intake manifold. The design allows for precise adjustments, enabling the engine to respond to varying demands during acceleration and deceleration.

Key Components and Their Roles

Several components within the device significantly influence its efficiency. The float chamber maintains a consistent fuel level, while jets regulate the fuel flow into the airstream. Additionally, the choke and throttle mechanisms control air intake, allowing for better performance under different operating conditions.

Key Parts of Carter AFB

This section explores essential components of a specific type of carburetor commonly found in classic vehicles. Understanding these elements can enhance performance and ensure proper operation, making it vital for enthusiasts and restorers alike.

Essential Components

Float Chamber: This crucial element regulates the fuel level, ensuring a consistent supply to the engine. Proper adjustment is key to maintaining optimal performance.

Throttle Plate

Throttle Plate: The device controls air and fuel flow into the engine, directly impacting acceleration and power. A well-functioning throttle plate is vital for responsiveness.

Fuel Delivery Mechanism Explained

The efficiency of an engine largely depends on how well it receives the necessary fuel for combustion. This system is designed to ensure that the right amount of fuel flows to the engine, optimizing performance and minimizing waste. Understanding the components involved in this process is crucial for anyone looking to enhance or troubleshoot their vehicle’s performance.

Key Components of the System

Several elements work together to facilitate effective fuel delivery. These components include the fuel pump, filter, injectors, and various lines connecting them. Each plays a vital role in ensuring that fuel is not only supplied but also properly managed for efficient combustion.

Operational Overview

The process begins with the fuel pump drawing gasoline from the tank and pushing it through the fuel lines. A filter ensures that impurities are removed before the fuel reaches the injectors, which then atomize the fuel for optimal mixing with air in the combustion chamber. This precise coordination is essential for achieving the desired power output while maintaining fuel economy.

| Component | Function |

|---|---|

| Fuel Pump | Draws fuel from the tank and delivers it to the engine. |

| Fuel Filter | Removes impurities from the fuel before it reaches the injectors. |

| Injectors | Atomize the fuel for mixing with air in the combustion chamber. |

| Fuel Lines | Connect the various components, allowing for efficient fuel flow. |

Air-Fuel Mixture Regulation

The balance between air and fuel in an internal combustion engine is crucial for optimal performance and efficiency. Proper management of this mixture ensures that the engine operates smoothly, minimizing emissions and maximizing power output. Achieving the right ratio allows for effective combustion, which is vital for the engine’s overall functionality.

Additionally, monitoring and fine-tuning the air-fuel ratio can prevent issues such as backfiring, stalling, and excessive fuel consumption. By utilizing advanced mechanisms, drivers can achieve the ideal mixture, which translates to better fuel economy and reduced environmental impact. Thus, effective regulation not only contributes to the engine’s health but also supports broader ecological goals.

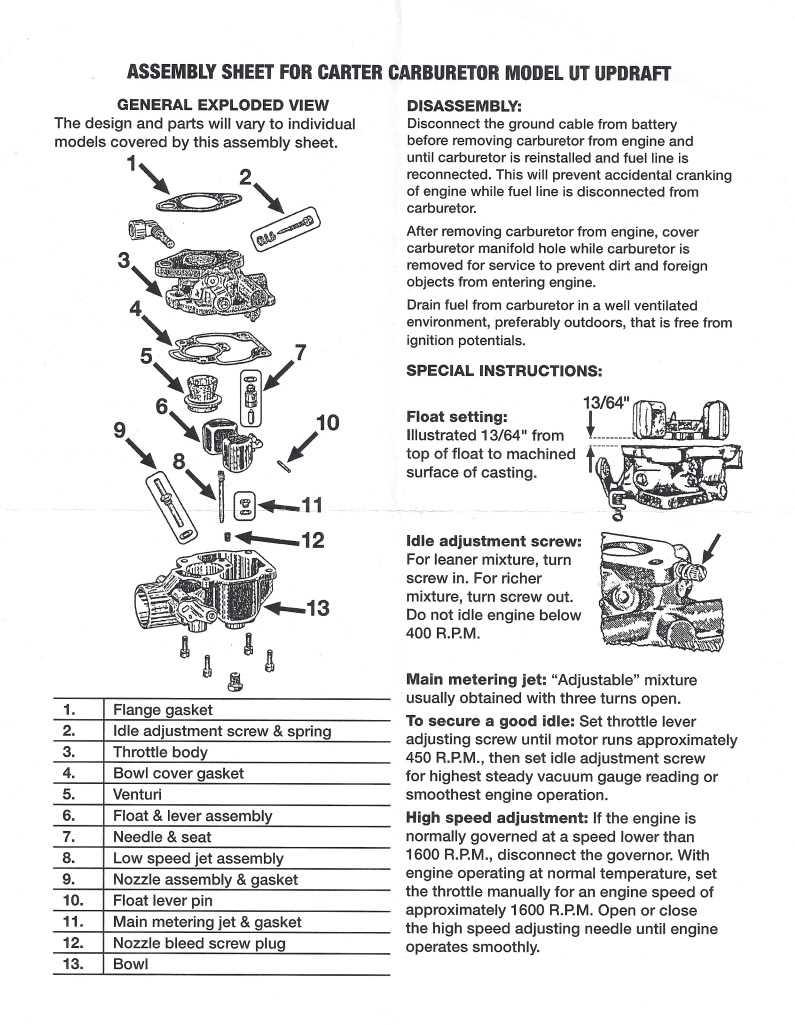

Adjusting the Idle Settings

Fine-tuning the idle parameters of your engine is crucial for optimal performance and efficiency. Proper adjustments can enhance engine responsiveness and improve fuel economy, ensuring a smoother operation during low-speed conditions.

Understanding the Idle Speed

The idle speed refers to the engine’s revolutions per minute (RPM) when the vehicle is at a standstill and the throttle is closed. Adjusting this setting can prevent stalling and promote a consistent engine operation. A speed that is too low may cause the engine to struggle, while a speed that is too high can lead to excessive wear.

Steps to Adjust the Idle Settings

Begin by warming up the engine to its normal operating temperature. Locate the adjustment screw, typically found on the throttle body. Turn the screw clockwise to increase the idle speed, or counterclockwise to decrease it. After adjustments, monitor the RPM to ensure they fall within the manufacturer’s recommended range. Test drive the vehicle to confirm smooth acceleration and stability.

Common Issues and Solutions

When working with engine components, it’s essential to be aware of frequent problems that can arise and how to address them effectively. Understanding these challenges can enhance performance and extend the life of your equipment.

Frequent Problems

- Fuel leakage due to worn seals

- Inconsistent performance stemming from clogged jets

- Difficulty in starting the engine caused by improper adjustments

- Unusual noises indicating mechanical issues

Effective Solutions

- Inspect and replace seals regularly to prevent leaks.

- Clean or replace jets to ensure proper fuel flow.

- Adjust settings carefully based on manufacturer specifications to facilitate easy starting.

- Conduct a thorough inspection to identify and resolve mechanical issues promptly.

By being proactive and addressing these common challenges, users can maintain optimal functionality and reliability of their equipment.

Maintenance Tips for Longevity

To ensure the prolonged functionality of your equipment, regular upkeep is essential. Consistent attention to key components can prevent wear and enhance performance over time.

1. Regular Cleaning: Dust and debris can accumulate and hinder operation. Frequent cleaning helps maintain optimal airflow and prevents overheating.

2. Lubrication: Proper lubrication of moving parts reduces friction and wear. Utilize recommended oils and greases to keep mechanisms running smoothly.

3. Inspection: Conduct routine inspections to identify signs of wear or damage early. Addressing issues promptly can avert larger problems down the line.

4. Adjustment: Periodic adjustments to settings and alignments can enhance performance and efficiency. Ensure that components are calibrated according to specifications.

5. Environmental Considerations: Keep the unit in a suitable environment to minimize exposure to extreme temperatures and humidity, which can lead to premature failure.

By adhering to these practices, you can significantly extend the lifespan of your equipment and ensure reliable operation for years to come.

Rebuilding the Carburetor

Revitalizing a fuel delivery mechanism can significantly enhance engine performance. This process involves disassembling the device, cleaning its components, and replacing worn parts to ensure optimal functionality. Careful attention to detail during the rebuild can lead to improved fuel efficiency and a smoother operation.

Essential Steps for the Rebuild

Begin by gathering all necessary tools and replacement components. Disassemble the unit systematically, keeping track of each part’s placement. Clean all surfaces thoroughly to remove deposits that could hinder performance. Inspect each element for wear or damage and replace as needed.

Components Overview

| Component | Function | Replacement Tips |

|---|---|---|

| Float | Regulates fuel level | Ensure it moves freely and is not cracked |

| Jet | Controls fuel flow | Clean with a fine wire or replace if damaged |

| Gaskets | Seals connections | Use high-quality materials to prevent leaks |

| Needle Valve | Manages fuel intake | Check for proper seating and replace if worn |

After reassembly, perform a thorough check for leaks and adjust settings as necessary. A well-rebuilt mechanism can greatly enhance engine responsiveness and reliability, ensuring a satisfying driving experience.

Performance Upgrades Available

Enhancing the efficiency and output of your engine can be achieved through various modifications. These upgrades can significantly improve overall performance, responsiveness, and fuel economy. Below are some popular options for elevating engine capabilities.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Air Intake System | Replaces the factory air intake to increase airflow. | Improved throttle response and horsepower. |

| High-Performance Carburetor | Upgraded carburetor designed for better fuel delivery. | Enhanced acceleration and fuel atomization. |

| Exhaust System Upgrade | Modified exhaust for reduced backpressure and improved flow. | Increased horsepower and a more aggressive sound. |

| Ignition System | Advanced ignition components for more efficient spark. | Better combustion and fuel efficiency. |

| Re-gearing | Changing gear ratios for optimized power delivery. | Improved acceleration and towing capacity. |

Comparative Analysis with Other Models

This section delves into the differences and similarities between a specific carburetor model and its counterparts within the industry. Understanding these distinctions can provide valuable insights into performance, efficiency, and application suitability.

Key Features Comparison

When evaluating various carburetors, several features stand out. These include airflow capacity, fuel delivery mechanisms, and overall design efficiency. Below is a comparative table highlighting these aspects across selected models.

| Model | Airflow Capacity (CFM) | Fuel Delivery Type | Design Efficiency |

|---|---|---|---|

| Model A | 600 | Mechanical | High |

| Model B | 500 | Electronic | Medium |

| Model C | 700 | Mechanical | Very High |

Performance Insights

In terms of performance, each model showcases unique strengths. For instance, while one may excel in airflow efficiency, another might offer better fuel atomization. Such factors are crucial for enthusiasts and professionals when selecting the appropriate component for their specific needs.

Resources for Further Research

Exploring comprehensive resources can greatly enhance your understanding of automotive components and their functionalities. These materials provide insights into design, troubleshooting, and maintenance practices that are essential for enthusiasts and professionals alike.

Books: Consider consulting manuals and textbooks focused on vehicle mechanics and systems. These publications often include detailed illustrations and explanations that can aid in grasping complex topics.

Online Forums: Participating in automotive discussion boards and communities allows you to connect with fellow enthusiasts. Sharing experiences and seeking advice can lead to valuable insights and practical tips.

Videos and Tutorials: Platforms like YouTube host a plethora of instructional videos. These visual guides can be particularly helpful for understanding assembly and disassembly processes.

Manufacturer Websites: Official sites often provide technical specifications and updates that are crucial for accurate understanding and application. Visiting these resources can help keep your knowledge current.

Local Workshops: Engaging in hands-on workshops can provide practical experience. These events often feature expert instruction, allowing you to apply your knowledge in real-world scenarios.