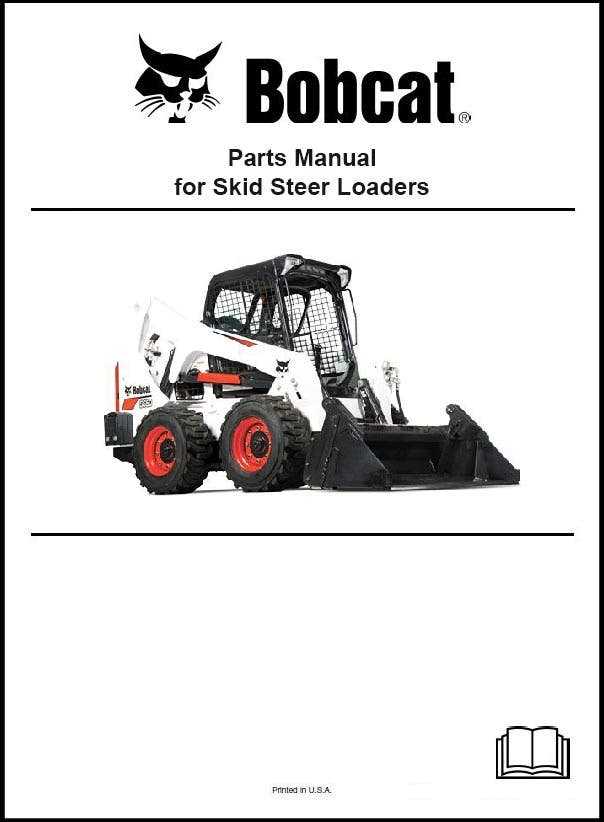

When operating a compact loader, having a clear grasp of its various components is essential for effective maintenance and efficient performance. This understanding allows operators to troubleshoot issues promptly and ensure the machine operates at peak efficiency. Familiarity with the intricate relationships between different elements contributes significantly to the longevity of the equipment.

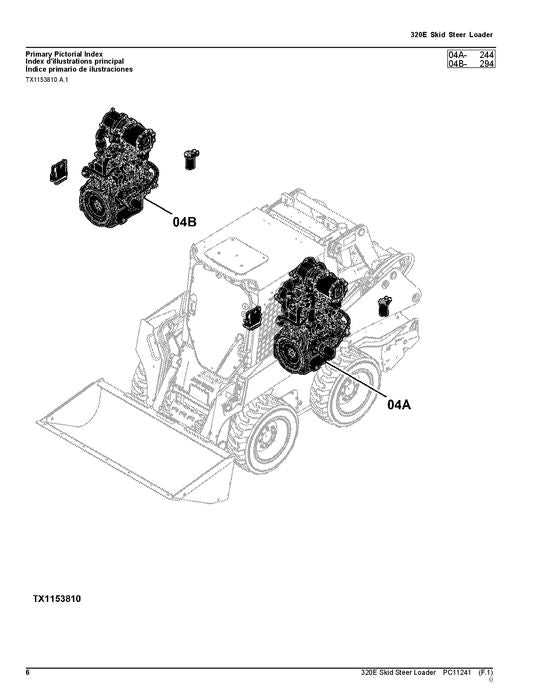

Visual aids can play a crucial role in this learning process. They provide a comprehensive overview of the equipment’s configuration, showcasing how individual elements fit together and function in harmony. This insight is particularly valuable when it comes to identifying specific sections that may require attention or replacement.

By utilizing these visual representations, operators can enhance their practical skills, leading to more informed decisions during repairs and servicing. This knowledge not only saves time but also minimizes the risk of costly mistakes, ensuring that the machinery remains reliable and effective in various working conditions.

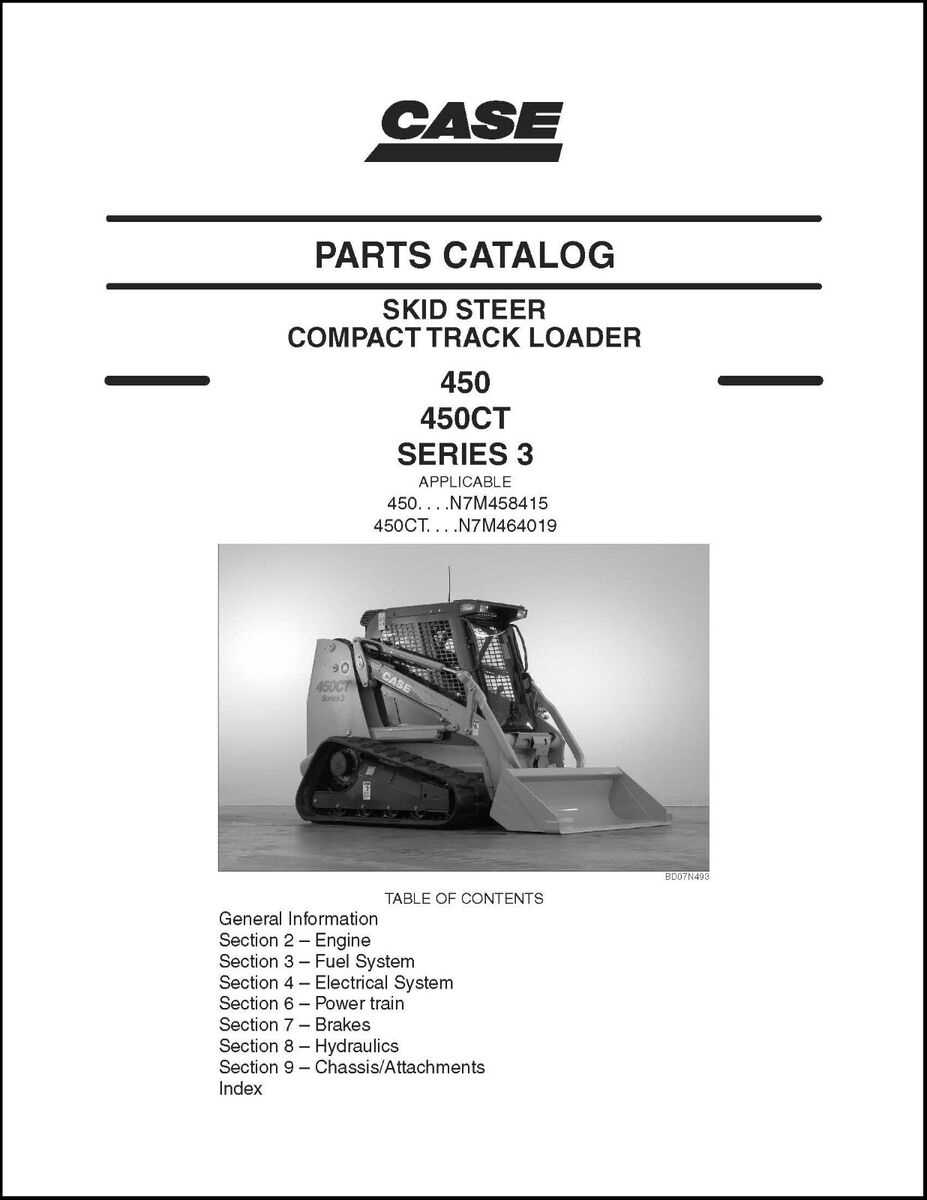

Understanding Case 450 Skid Steer

This section explores the essential components and functionalities of a popular compact construction machine. It highlights how these units facilitate various tasks in diverse environments, making them indispensable in the construction and landscaping industries.

Key Features and Benefits

Compact machinery offers numerous advantages, including versatility and ease of maneuverability. Operators can efficiently handle a range of attachments, allowing for the completion of multiple tasks with a single machine. Additionally, their robust design ensures durability and reliability, even in challenging conditions.

Common Applications

These machines are widely used in various sectors. Common applications include site preparation, material handling, and landscaping. Their ability to navigate tight spaces and perform heavy lifting makes them ideal for both commercial and residential projects.

| Feature | Description |

|---|---|

| Versatility | Can accommodate various attachments for different tasks. |

| Compact Size | Ideal for working in confined areas. |

| Durability | Designed to withstand tough conditions and heavy use. |

| Ease of Use | User-friendly controls for operators of all skill levels. |

Key Components of the Skid Steer

This section explores the essential elements that make up a compact loader, highlighting their roles and significance in overall functionality. Understanding these components is crucial for optimal operation and maintenance.

- Engine: Powers the machine, providing the necessary force for various tasks.

- Hydraulic System: Enables movement and operation of attachments through fluid pressure.

- Transmission: Transmits power from the engine to the wheels or tracks, allowing for mobility.

- Frame: The sturdy structure that supports all components and provides stability.

- Loader Arms: Essential for lifting and lowering loads, these arms connect the attachments to the main body.

- Cab: The operator’s area, designed for comfort and visibility, often equipped with controls and displays.

Each of these components plays a vital role in ensuring that the machinery operates efficiently and effectively, facilitating a range of construction and landscaping tasks.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and efficiency of heavy machinery. Implementing a consistent maintenance schedule can prevent unexpected breakdowns and extend the life of your equipment.

Routine Inspections

- Check fluid levels, including oil and coolant.

- Inspect belts and hoses for wear and tear.

- Examine tires for proper inflation and damage.

- Look for leaks around hydraulic components.

Preventive Measures

- Change oil and filters as per the manufacturer’s recommendations.

- Grease all moving parts to reduce friction.

- Clean air filters to maintain optimal airflow.

- Ensure electrical connections are secure and free of corrosion.

Identifying Replacement Parts

When it comes to maintaining heavy machinery, understanding how to locate and recognize the necessary components is crucial. Proper identification ensures that equipment operates efficiently and extends its lifespan.

Understanding Component Functionality

Each element within the machinery serves a specific role, contributing to overall performance. Familiarizing yourself with these functions can help you pinpoint which pieces require replacement when issues arise.

Utilizing Reference Materials

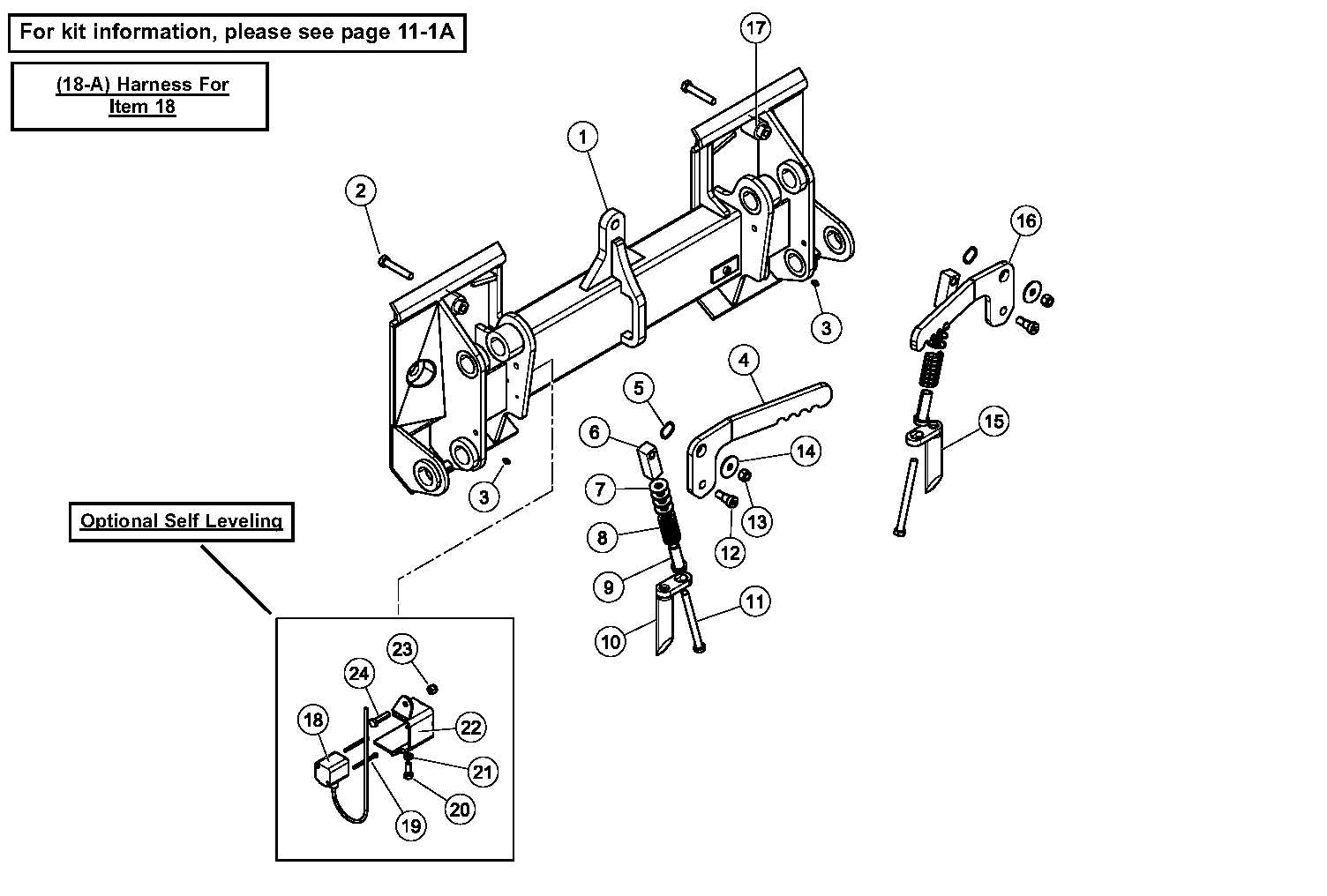

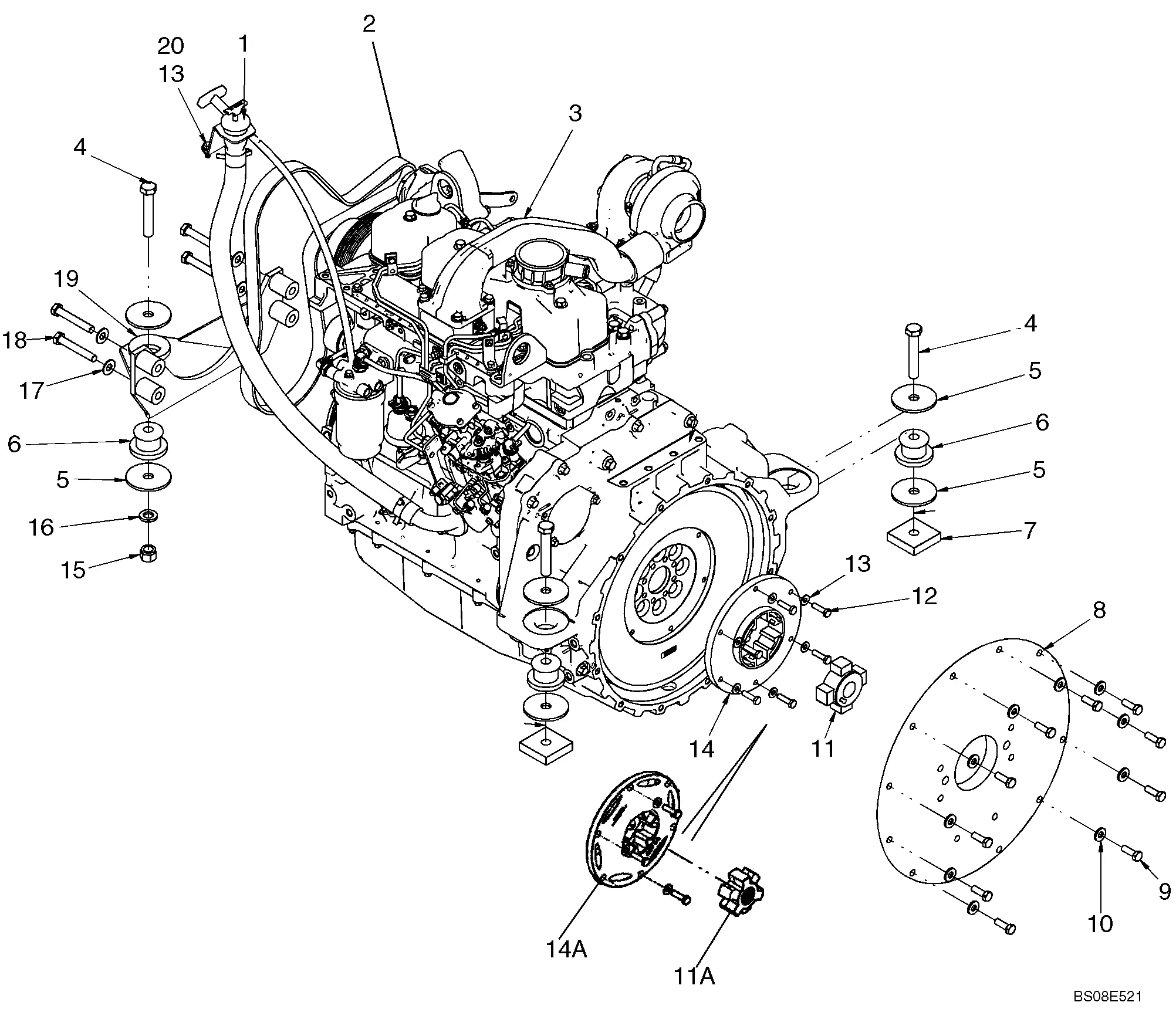

Consulting manuals or online resources can provide valuable insights into the specific components you need. Diagrams and charts are particularly helpful for visualizing the layout and determining the exact replacements required.

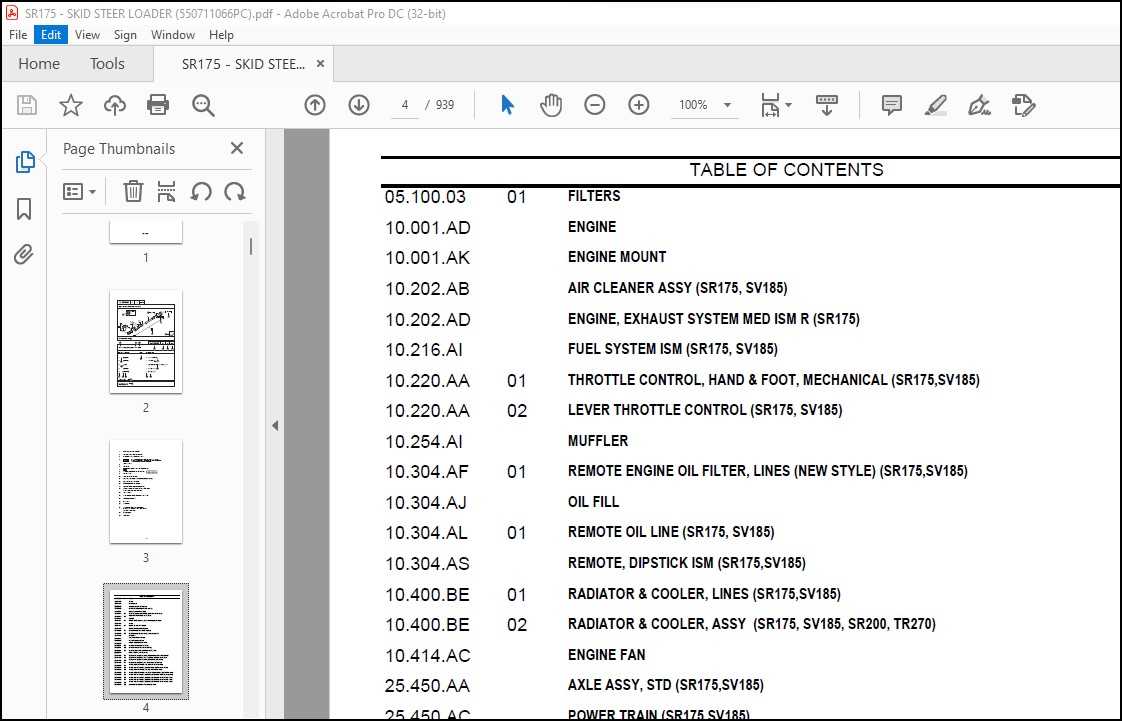

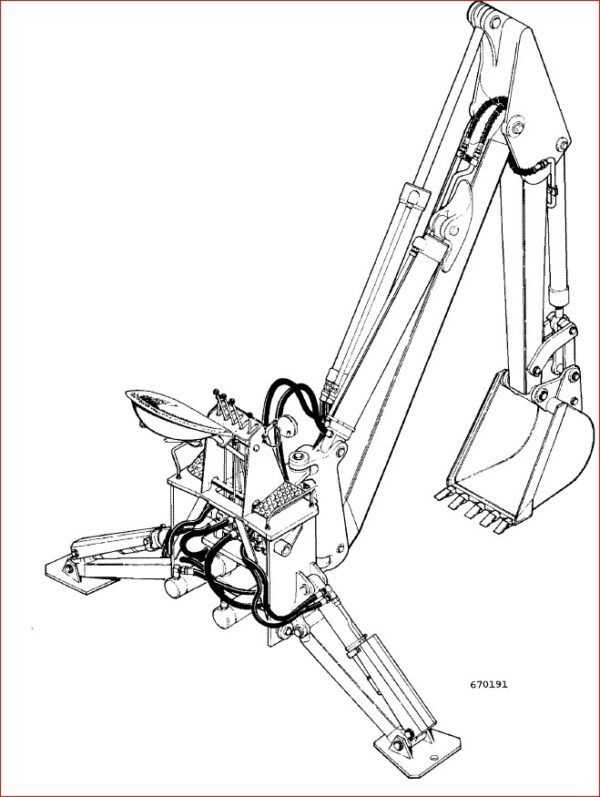

Exploring the Parts Diagram

This section delves into the intricate layout of components found in heavy machinery, providing a comprehensive overview of their arrangement and functionality. Understanding this layout is crucial for effective maintenance and repair, ensuring that each element operates harmoniously within the system.

| Component Name | Description | Function |

|---|---|---|

| Engine | Power unit for the machine | Drives all operations and functionalities |

| Hydraulic Pump | Fluid power source | Operates various attachments and controls |

| Chassis | Main frame structure | Supports all other components |

| Cab | Operator’s area | Houses controls and provides visibility |

Benefits of Using Original Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. Original pieces are designed to fit perfectly, reducing the risk of malfunction and enhancing the overall efficiency of the equipment. By choosing genuine items, operators can experience fewer breakdowns and lower maintenance costs over time.

Enhanced Performance

Genuine components provide superior functionality compared to aftermarket alternatives. They are engineered to meet specific standards, ensuring that the machinery operates as intended. This reliability translates to better productivity and smoother operations on the job site.

Long-Term Savings

Investing in authentic components often leads to long-term financial benefits. Although the initial cost may be higher, the durability and efficiency of original items result in fewer repairs and extended equipment life. This proactive approach minimizes downtime and maximizes profitability.

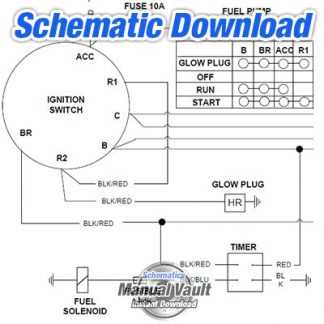

How to Read the Diagram

Understanding a schematic representation can greatly enhance your ability to identify components and their functions. This visual guide serves as a roadmap, illustrating the various elements and their interconnections. By familiarizing yourself with the layout, you can quickly locate specific items and comprehend their roles within the system.

Begin by examining the overall structure, noting the symbols used to represent different parts. Each symbol typically corresponds to a specific function, whether it’s mechanical, electrical, or hydraulic. Pay attention to any accompanying labels that provide additional context, as these can clarify the purpose of each component.

Next, follow the lines and arrows that indicate connections and flow. These pathways illustrate how elements interact, helping you grasp the operational dynamics. Understanding these relationships is crucial for effective troubleshooting and maintenance.

Finally, take your time to review the legend or key, which often accompanies such visual aids. This section will clarify any unfamiliar symbols or abbreviations, ensuring you have a complete understanding of the schematic. With practice, interpreting these illustrations will become an invaluable skill in managing and servicing your equipment.

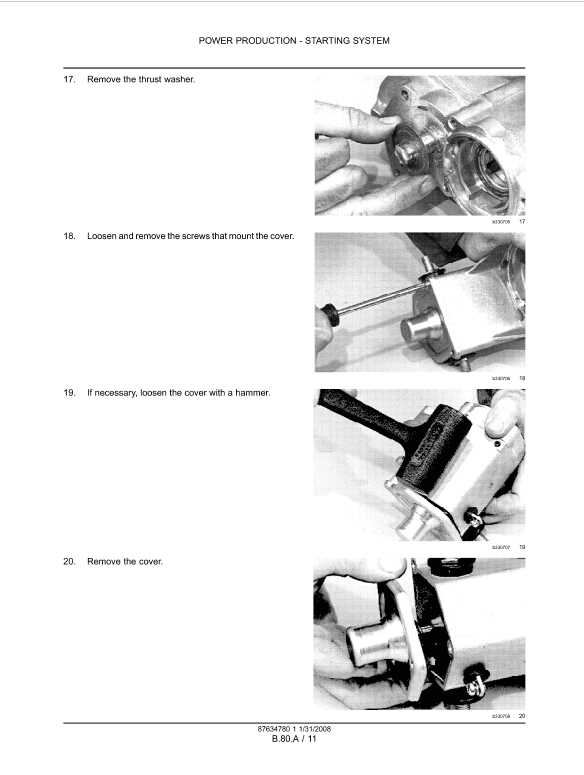

Tips for Efficient Repairs

Performing repairs effectively requires a systematic approach that can save time and resources. Whether you’re addressing a minor issue or a significant malfunction, having a plan in place will streamline the process and enhance your productivity.

Preparation is Key

- Gather all necessary tools and materials before starting.

- Review any manuals or documentation related to the equipment.

- Ensure a clean workspace to avoid losing components.

Follow a Methodical Process

- Identify the issue clearly before disassembly.

- Document each step of the repair for future reference.

- Replace damaged components with high-quality replacements.

- Test the equipment thoroughly after repairs to confirm functionality.

By adhering to these guidelines, you can enhance your repair efficiency and ensure the longevity of your machinery.

Upgrades and Modifications

Enhancing the capabilities of your machinery can significantly improve its performance and efficiency. By implementing various upgrades, you can tailor the equipment to better suit your specific tasks, whether that involves boosting power, increasing versatility, or improving safety features.

One common modification involves upgrading the hydraulic system to increase lifting capacity and speed. Additionally, adding attachments such as forks or buckets can enhance the functionality, making the machine suitable for a wider range of applications. Implementing a more efficient cooling system can also help in maintaining optimal operating temperatures during extended use.

Furthermore, consider upgrading the control systems for better precision and responsiveness. Advanced technology, such as GPS guidance or remote monitoring, can streamline operations and ensure that tasks are completed with greater accuracy. Investing in quality upgrades not only enhances performance but also extends the lifespan of the equipment.

Where to Buy Replacement Parts

Finding high-quality components for your machinery is essential for maintaining its efficiency and longevity. There are several reliable avenues to explore when seeking replacements, ensuring you have access to what you need.

Online Retailers: Numerous websites specialize in selling machinery components. These platforms often provide detailed descriptions and specifications, making it easier to find the exact items required. Always check customer reviews to gauge the reliability of the seller.

Local Distributors: Visiting nearby suppliers can be advantageous. They typically have knowledgeable staff who can assist in identifying the correct items and may offer same-day service for urgent needs. Establishing a relationship with local distributors can lead to better deals and timely support.

Manufacturer Websites: The official sites of equipment manufacturers often have dedicated sections for replacement components. This option guarantees authenticity and compatibility, as the items are specifically designed for your equipment. Furthermore, you may find useful resources such as installation guides and warranty information.

Salvage Yards: For those on a budget, salvage yards can be a treasure trove of functional parts at reduced prices. While it may require more effort to find the right components, this route can yield significant savings.

By exploring these various options, you can ensure that your equipment remains operational and efficient, minimizing downtime and maximizing productivity.

Frequently Asked Questions

This section addresses common inquiries related to machinery components and maintenance. Understanding the essential elements can enhance operational efficiency and prolong the lifespan of your equipment.

What should I consider when selecting components?

When choosing components, ensure compatibility with your equipment model, and assess quality and durability. Always consult the manufacturer’s recommendations to make informed decisions.

How can I troubleshoot common issues?

Start by identifying symptoms and consulting the user manual for guidance. Regular inspections and maintenance can prevent many problems, so stay proactive in your approach.