In the world of heavy machinery, comprehending the intricate structure of equipment is essential for effective maintenance and repair. A clear illustration of each element’s placement provides invaluable insights, enabling operators and technicians to troubleshoot issues efficiently. This knowledge is crucial for ensuring that the machinery operates at peak performance and longevity.

Such visual representations serve as guides, simplifying the complex relationships between various components. By familiarizing oneself with these layouts, individuals can quickly identify specific sections and their functions, making the repair process smoother. Understanding the overall assembly allows for a more systematic approach to addressing any challenges that may arise during operation.

Whether you are a seasoned professional or a novice in the field, mastering these visual aids is key to enhancing your expertise. The ability to navigate through the various assemblies not only improves problem-solving skills but also fosters confidence in handling the machinery. As you delve deeper into the anatomy of these powerful machines, you will discover how each part contributes to their robust functionality.

Understanding the Case 530 Backhoe

In the realm of heavy machinery, certain models stand out due to their versatility and reliability. This particular loader-excavator combination has gained a reputation for its robust construction and ability to handle a wide range of tasks in various environments. Whether employed in construction, landscaping, or agricultural applications, its design ensures efficiency and ease of use.

Key Features

- Powerful engine for enhanced performance

- Durable frame designed for stability

- Versatile attachments for diverse tasks

- User-friendly controls for operator convenience

Maintenance Considerations

To keep this machinery operating at peak performance, regular maintenance is crucial. Attention to key components will extend its lifespan and ensure reliable operation.

- Routine inspection of hydraulic systems

- Regular fluid changes to maintain engine health

- Check and replace worn-out attachments as needed

- Keep the chassis and undercarriage free from debris

Importance of Parts Diagrams

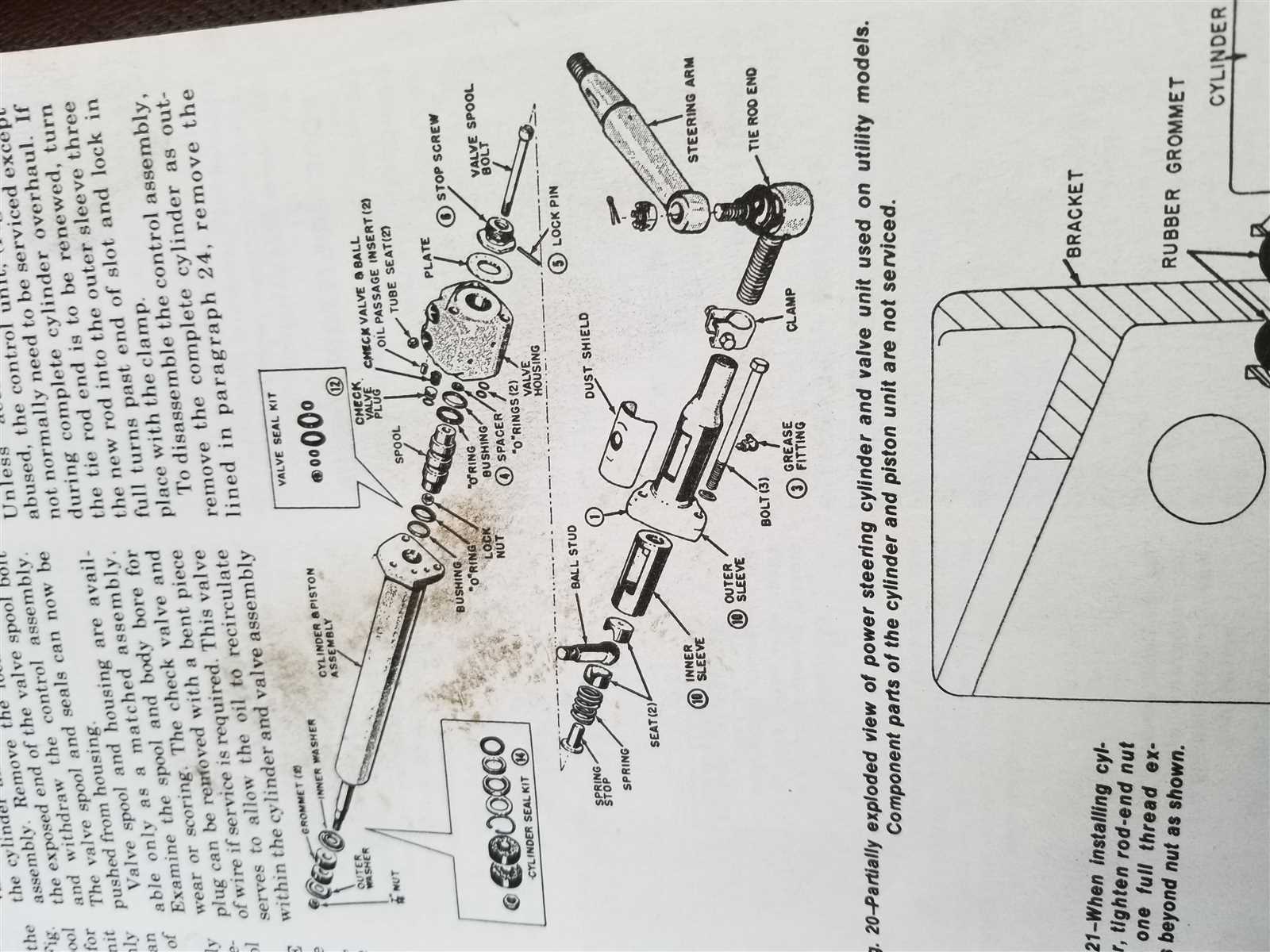

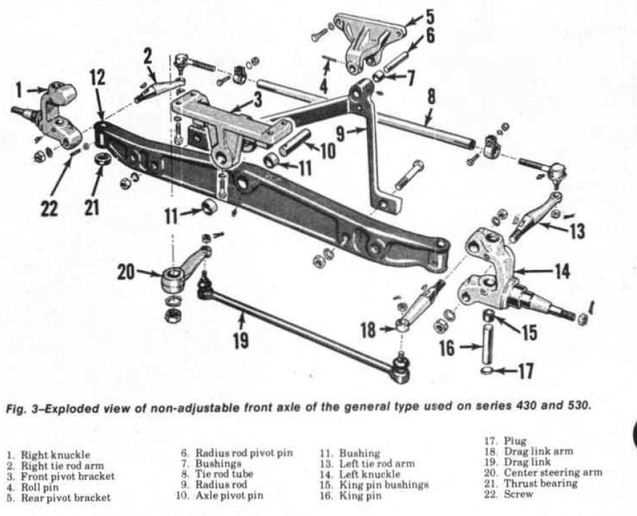

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools, allowing users to identify each element, comprehend its function, and ensure proper assembly. This clarity not only aids in troubleshooting but also enhances efficiency during repairs.

Enhancing Repair Efficiency

When faced with a malfunction, having a visual guide simplifies the process. Technicians can quickly locate the necessary components, reducing the time spent searching for parts and minimizing downtime. A well-organized illustration streamlines communication between team members, ensuring everyone is on the same page.

Facilitating Accurate Replacements

Utilizing these visual aids ensures that replacements are precise and compatible. Misunderstandings regarding specific parts can lead to costly errors and further complications. Clear depictions eliminate ambiguity, allowing for confident decision-making when sourcing new components.

| Benefit | Description |

|---|---|

| Time-saving | Reduces time needed for locating components during repairs. |

| Improved Communication | Enhances clarity among team members regarding parts and procedures. |

| Accurate Replacements | Ensures compatibility of new components with existing machinery. |

Common Issues with Backhoe Components

Heavy machinery often encounters a variety of complications that can hinder performance and efficiency. Understanding these common challenges is crucial for maintenance and troubleshooting. Identifying symptoms early can prevent more significant problems and ensure smooth operation.

Hydraulic System Problems

The hydraulic system is vital for the functionality of heavy equipment, and issues within this system can lead to decreased power and responsiveness. Common symptoms include leaks, slow movements, and unusual noises. Regular inspection and maintenance are essential to avoid costly repairs.

Electrical System Failures

The electrical components can also be a source of difficulties, affecting everything from starting mechanisms to operational controls. Frequent signs of electrical issues include malfunctioning gauges, failure to start, and erratic behavior of operational functions. Routine checks of wiring and connections can help mitigate these problems.

| Component | Common Issues | Symptoms |

|---|---|---|

| Hydraulic Cylinder | Leaks and Seal Damage | Loss of pressure, visible fluid leaks |

| Pump | Wear and Tear | Inconsistent operation, noises |

| Electrical Wiring | Corrosion and Breaks | Intermittent failures, dashboard warning lights |

| Engine | Overheating | Loss of power, engine stalls |

How to Read Parts Diagrams

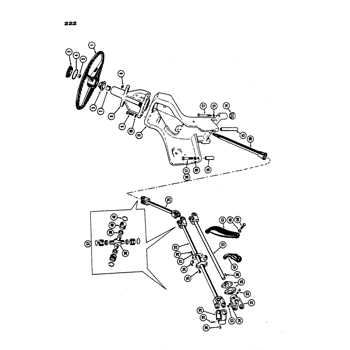

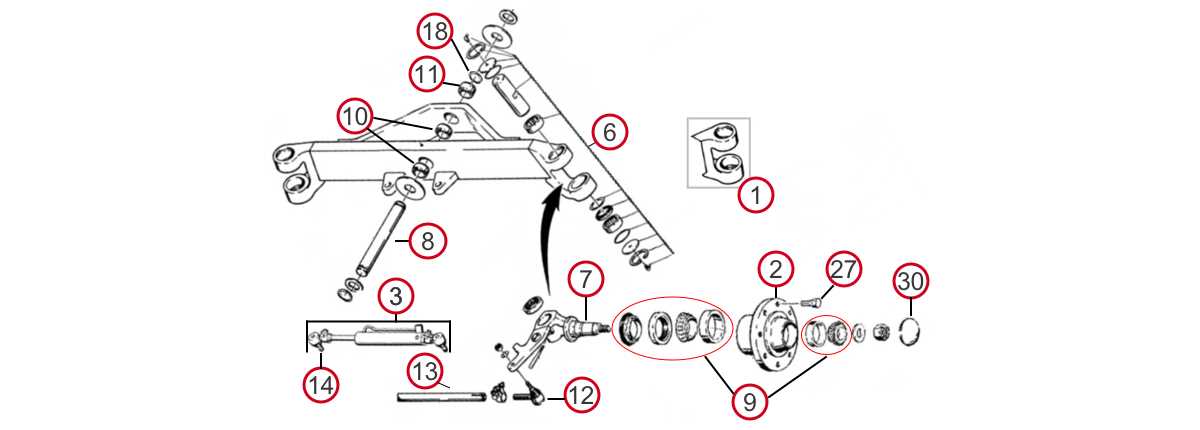

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual guides provide an organized representation of components, making it easier to identify and locate each element. Familiarizing yourself with how to interpret these illustrations can significantly enhance your troubleshooting efficiency.

Key Components of Technical Illustrations

Every technical illustration typically includes various sections, each representing different groups of components. Look for labels that indicate specific parts and their corresponding numbers. Often, a legend is provided, clarifying symbols and color codes used throughout the illustration. Pay attention to the orientation of the components, as this can impact their arrangement and functionality.

Step-by-Step Approach to Interpretation

Begin by examining the overall layout of the illustration. Identify the main assembly and follow the connecting lines or arrows to understand the relationships between components. Focus on the part numbers, which can be referenced in manuals or catalogs to find replacements or additional information. Taking notes on any unfamiliar elements can also be beneficial for further research.

With practice, your ability to quickly and accurately interpret these technical illustrations will improve, aiding in more effective repairs and maintenance tasks.

Essential Tools for Repairs

Effective maintenance and repair of heavy machinery require a well-equipped toolkit. Having the right instruments not only facilitates the repair process but also ensures that tasks are completed safely and efficiently. Understanding the essential tools can significantly enhance the quality of your work and prolong the lifespan of your equipment.

Basic Hand Tools

A solid collection of hand tools is fundamental for any repair job. Wrenches, pliers, and screwdrivers should be included to address various fasteners and components. Each tool should be chosen based on its durability and suitability for heavy-duty tasks, ensuring reliability during critical repairs.

Power Tools and Equipment

Power tools are invaluable for more intensive maintenance work. Drills, grinders, and impact wrenches can expedite tasks that would otherwise be time-consuming. Additionally, having specialized equipment, such as hydraulic lifts or jacks, can greatly enhance accessibility to hard-to-reach areas, making repairs more manageable.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a challenging task, but there are several reliable avenues to explore. Understanding where to look will save you time and ensure you obtain the quality you need to maintain performance.

Authorized Dealers

One of the most dependable sources for authentic components is through authorized dealers. These outlets offer original items and often provide expert advice tailored to your specific machinery. Additionally, they may have exclusive access to certain items that are not available elsewhere.

Online Marketplaces

The internet has revolutionized the way we shop for mechanical supplies. Numerous online marketplaces provide a vast selection of components, often at competitive prices. When shopping online, be sure to verify the seller’s reputation and read reviews to ensure you’re receiving quality items.

Considerations for Quality: Always prioritize quality over price. While it may be tempting to choose cheaper alternatives, investing in high-quality components will pay off in the long run by reducing the need for frequent replacements.

Remember: A well-maintained machine not only performs better but also has a longer lifespan.

Maintenance Tips for Longevity

Ensuring the extended life of heavy machinery involves a combination of regular care and informed practices. Proper upkeep not only enhances performance but also minimizes unexpected breakdowns, ultimately saving time and costs. Here are some essential strategies to keep your equipment in top shape.

Regular Inspections

Conducting frequent assessments is crucial. Look for signs of wear and tear, such as leaks or unusual noises. Pay attention to fluid levels, filters, and belts. Early detection of potential issues can prevent more significant problems down the line.

Routine Cleaning and Lubrication

Keeping machinery clean is vital for its functionality. Remove debris and dirt from all parts to prevent corrosion and damage. Additionally, regular lubrication of moving components reduces friction and wear, enhancing overall efficiency. Use recommended lubricants and follow the manufacturer’s guidelines to ensure optimal performance.

Aftermarket vs. OEM Parts

The choice between replacement components from original manufacturers and those produced by third parties is a crucial decision for equipment maintenance. Each option comes with its own set of advantages and potential drawbacks that can significantly impact performance, longevity, and cost-effectiveness.

Original Equipment Manufacturer (OEM) offerings are crafted to meet the precise specifications set by the original brand. This ensures a seamless fit and optimal functionality, often leading to enhanced reliability and peace of mind. Many users appreciate the assurance of quality and performance that accompanies these components, as they are designed specifically for the machinery in question.

On the other hand, aftermarket options often provide a more budget-friendly alternative. These products can deliver comparable performance at a fraction of the cost, making them appealing to those looking to manage expenses without sacrificing quality entirely. However, it is essential to research and choose reputable suppliers, as the quality of these components can vary significantly.

Ultimately, the decision hinges on individual needs and preferences. Evaluating factors such as cost, quality, and availability will help users make an informed choice that best suits their operational requirements.

Identifying Backhoe Model Variants

Understanding the differences among various models of construction machinery is essential for effective maintenance and operation. Each variant may feature unique specifications and components, impacting performance and compatibility. By recognizing these distinctions, operators can ensure they select the right machinery for their projects and maintain it effectively.

To aid in identifying different models, it is helpful to consider several key factors, including production year, design features, and specific attachments that may be included. These characteristics can provide insights into the model’s intended use and capabilities.

| Feature | Description |

|---|---|

| Year of Manufacture | Different years may indicate updates or changes in design. |

| Engine Type | Models may vary based on diesel or gas engines used. |

| Hydraulic System | Variations in hydraulic systems can affect lifting capacity and performance. |

| Attachment Compatibility | Different configurations may support various tools and accessories. |

| Dimensions | Size differences can impact maneuverability and suitability for specific jobs. |

By carefully analyzing these features, operators and technicians can more easily determine the specific variant they are dealing with, allowing for better decision-making regarding repairs, upgrades, and operational practices.

Upgrading Your Case 530 Equipment

Enhancing the performance and efficiency of your heavy machinery can significantly improve productivity and prolong its lifespan. By focusing on specific upgrades, operators can achieve better functionality, comfort, and reliability, ensuring that their investment pays off in the long run.

Performance Enhancements

Investing in modern components can lead to substantial performance gains. Consider upgrading the hydraulic system to increase lifting capacity and improve response times. Additionally, installing a more efficient engine can enhance fuel economy and reduce emissions, contributing to a greener operation.

Operator Comfort and Safety

Improving the operator’s workspace is crucial for safety and efficiency. Installing ergonomic seating, better visibility enhancements, and advanced control systems can lead to increased comfort and reduced fatigue during long working hours. Furthermore, incorporating safety features such as enhanced lighting and backup alarms can help mitigate risks on the job site.