In the world of heavy machinery, a thorough comprehension of the various elements that make up a machine is essential for effective operation and maintenance. This section aims to provide a comprehensive overview of the key components involved, ensuring that users can navigate through the intricate relationships between different parts. By gaining insight into how these elements work together, operators can enhance their proficiency in managing their equipment.

Knowing the specific functions and locations of individual components can greatly simplify troubleshooting and repairs. This understanding fosters a more efficient workflow, as it empowers users to identify potential issues before they escalate. With a clear visual representation, operators can familiarize themselves with the arrangement of essential elements, ultimately leading to improved performance and longevity of the machinery.

By delving into the intricacies of the assembly, users will be better equipped to handle maintenance tasks confidently. This resource serves as a guide to help individuals navigate through the essential features of their machinery, ensuring that they are well-prepared to tackle any challenges that may arise during operation.

The effective functioning of this machinery relies on several critical elements, each designed to perform specific tasks that enhance overall productivity. Understanding these key components is essential for optimizing performance and ensuring maintenance routines are effectively carried out.

Essential Parts

- Loader Arm: This robust structure facilitates lifting and moving materials with precision.

- Bucket: A vital tool for excavation, it comes in various shapes and sizes to suit different tasks.

- Hydraulic System: This system powers various movements and operations, providing the necessary force for lifting and digging.

- Stabilizers: These components enhance stability during operation, ensuring safety and balance on uneven terrain.

- Cabin: The operator’s workspace, equipped with controls and visibility features to enhance user experience.

Additional Features

- Engine: The heart of the machine, providing the power required for all functions.

- Transmission: This system transmits power from the engine to the wheels, affecting speed and maneuverability.

- Tracks or Wheels: Essential for mobility, they enable the machine to navigate various terrains effectively.

- Control Panel: A user-friendly interface that allows operators to manage all machine functions easily.

Understanding Hydraulic System Layout

The hydraulic system in heavy machinery plays a crucial role in enabling efficient and powerful operations. By converting fluid pressure into mechanical force, this intricate setup allows various components to work seamlessly together. A comprehensive grasp of its configuration is essential for optimal performance and maintenance.

Here are the key components typically found in hydraulic configurations:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy by moving fluid through the system.

- Control Valves: Regulate the flow and pressure of the hydraulic fluid, directing it to the appropriate functions.

- Actuators: Convert hydraulic energy back into mechanical energy to perform tasks such as lifting or digging.

- Reservoir: Stores hydraulic fluid and provides a space for fluid to expand and contract.

- Hoses and Fittings: Facilitate the transportation of hydraulic fluid between components while maintaining pressure.

Understanding the layout and interaction of these elements can enhance troubleshooting, repair, and overall efficiency of machinery operations.

Engine Specifications and Parts

This section provides an overview of the essential specifications and components that contribute to the functionality and performance of the machinery in question. Understanding these elements is crucial for effective maintenance and optimal operation, ensuring longevity and reliability in various working conditions.

Engine Overview

The heart of this equipment features a robust power unit designed for efficiency and durability. It typically incorporates a multi-cylinder configuration, allowing for smoother operation and improved torque delivery. The engine’s design is optimized for fuel efficiency while delivering sufficient horsepower for demanding tasks. Moreover, it includes advanced cooling and lubrication systems to maintain optimal operating temperatures and reduce wear.

Key Components

Essential components of the power unit include the crankshaft, camshaft, and pistons, each playing a vital role in the engine’s operation. The fuel injection system ensures precise delivery of fuel, enhancing combustion efficiency. Additionally, the air intake and exhaust systems are engineered to maximize airflow, promoting better engine performance and reducing emissions. Regular inspection and maintenance of these components are essential to ensure optimal functionality.

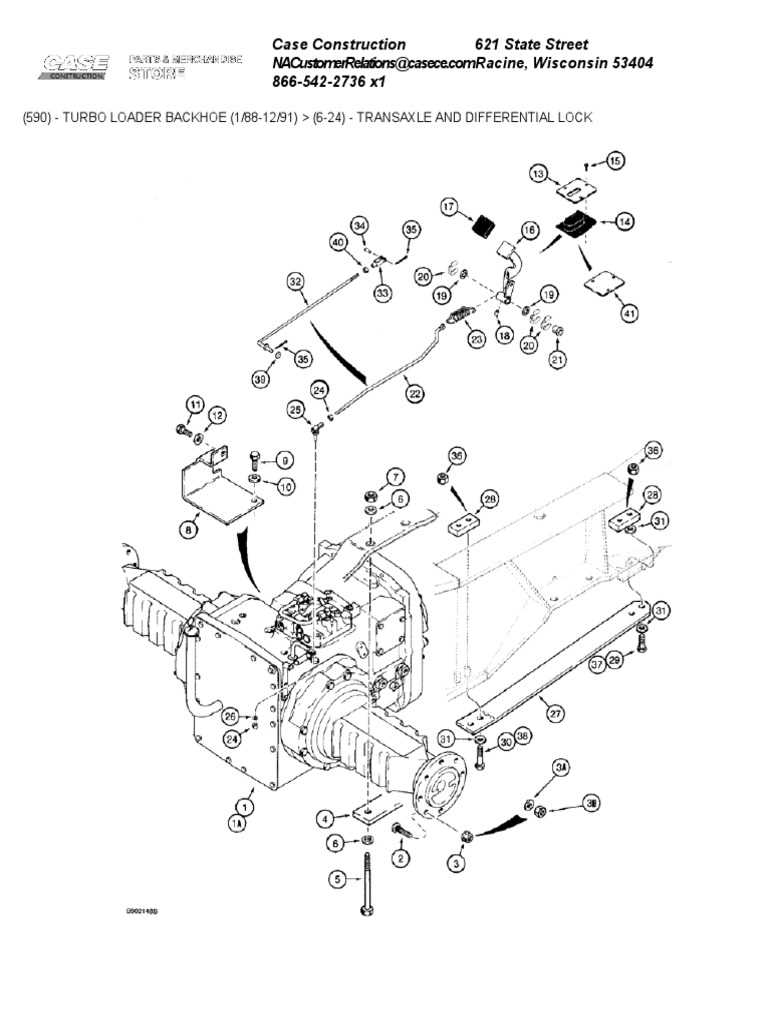

Transmission Assembly Breakdown

This section provides an overview of the assembly related to the power transfer mechanism, focusing on its individual components and their interactions. Understanding this assembly is crucial for efficient operation and maintenance of the machinery.

The transmission assembly is composed of several key elements that work together to ensure smooth operation. Below is a detailed table illustrating the primary components, their functions, and relevant specifications:

| Component | Description | Function |

|---|---|---|

| Gear Set | Includes various gears that adjust torque and speed | Modulates power output for different operational conditions |

| Hydraulic Pump | Pumps hydraulic fluid throughout the system | Provides necessary pressure for operation of hydraulic components |

| Torque Converter | Transmits and amplifies engine torque | Facilitates smooth acceleration and improves efficiency |

| Clutch Assembly | Engages and disengages power flow | Allows for smooth shifting between different gears |

| Control Valve | Regulates hydraulic flow within the system | Ensures proper operation of various hydraulic functions |

By familiarizing oneself with the components of the transmission assembly, operators can enhance their understanding of the equipment’s functionality and ensure effective maintenance practices.

Front Loader and Bucket Parts

The functionality of a loader and its attachment is crucial for various earth-moving tasks. Understanding the components that make up these tools is essential for maintenance and efficient operation. This section delves into the key elements that ensure optimal performance in different applications.

Essential Components of a Loader

- Loader Frame: The sturdy structure that supports all other components and provides stability.

- Hydraulic System: A vital mechanism that powers the lifting and lowering functions of the loader.

- Lift Arms: These arms connect the frame to the attachment, allowing for elevation and lowering.

- Bucket Attachment: The front tool that scoops and transports materials.

Bucket Features

- Bucket Cutting Edge: The front edge designed for effective digging and scraping.

- Bucket Capacity: The volume that the bucket can hold, affecting how much material can be moved at once.

- Side Walls: They help contain materials while lifting and transporting them.

- Quick Attach System: A mechanism that allows for fast swapping of attachments, enhancing versatility.

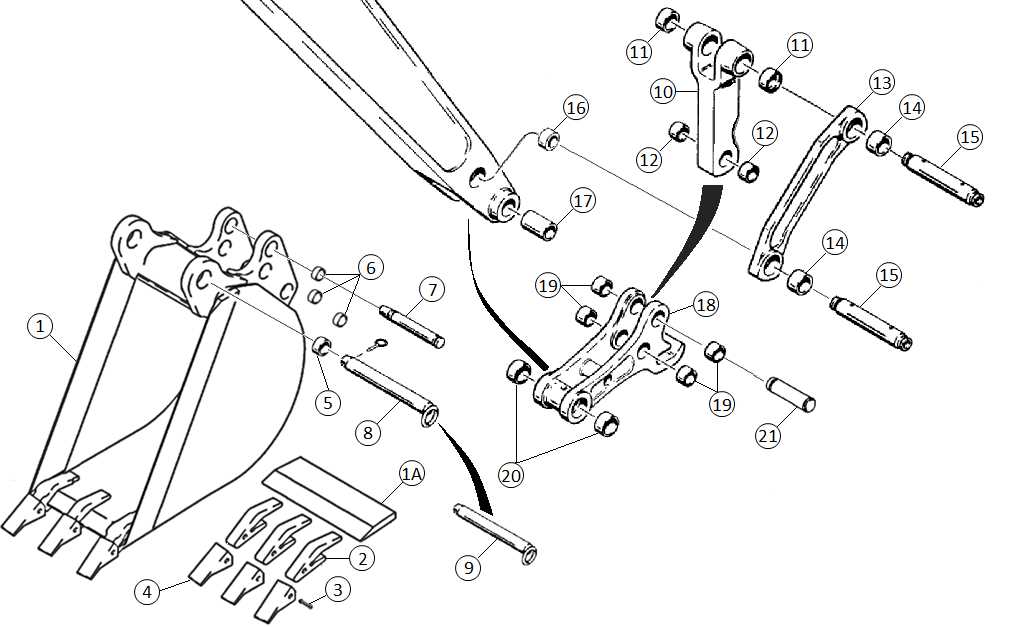

Backhoe Boom and Arm Details

The boom and arm assembly of a construction machine plays a crucial role in its operational efficiency. These components work together to extend the reach of the equipment, allowing it to perform various tasks such as digging, lifting, and moving materials with precision. Understanding the intricacies of these elements is essential for optimal performance and maintenance.

Components of the Boom and Arm

This assembly is composed of several key elements that contribute to its functionality. Each part has a specific role, ensuring that the entire mechanism operates smoothly. Here are some of the primary components:

| Component | Description |

|---|---|

| Boom | The primary arm that extends from the machine, allowing for increased reach and versatility. |

| Arm | The segment connected to the boom, providing additional extension and articulation for digging and lifting tasks. |

| Hydraulic Cylinders | These actuators provide the necessary force to move the boom and arm, enabling powerful movements. |

| Links and Pins | These components connect the boom and arm, allowing for controlled movement and flexibility. |

Maintenance Considerations

Regular inspection and maintenance of the boom and arm assembly are vital to prevent wear and tear. Operators should check for hydraulic leaks, ensure all connections are secure, and lubricate moving parts to maintain optimal performance. Understanding the structure and function of these elements helps in troubleshooting issues and extending the lifespan of the equipment.

Electrical Wiring Diagram Insights

The intricate network of electrical connections within machinery plays a crucial role in ensuring optimal performance and safety. Understanding this layout is essential for troubleshooting issues, performing maintenance, and making informed upgrades. This section delves into the significance of these schematics, highlighting their role in the seamless operation of heavy equipment.

Importance of Understanding Electrical Layouts

Grasping the nuances of electrical configurations aids technicians in pinpointing faults efficiently. Each wire and connection is vital, as they contribute to the overall functionality. Familiarity with these layouts can save time and resources during repairs, enhancing the longevity of the equipment.

Common Electrical Components

Several key components are frequently encountered in these configurations, each serving a specific purpose. Below is a table outlining some of the typical elements found in electrical layouts:

| Component | Description |

|---|---|

| Batteries | Store electrical energy to power the system. |

| Switches | Control the flow of electricity in the circuit. |

| Fuses | Protect circuits from overload by breaking the connection. |

| Relays | Act as switches operated by electrical signals. |

| Sensors | Detect and measure various parameters, sending signals for adjustments. |

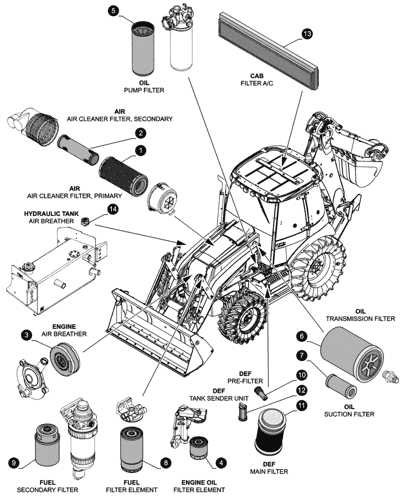

Maintenance and Replacement Guidelines

Regular upkeep and timely component substitution are essential for ensuring the longevity and efficient operation of heavy machinery. Following recommended practices not only enhances performance but also minimizes the risk of unexpected breakdowns. This section outlines key strategies for maintaining optimal functionality and when to consider replacements.

Routine Inspections: Conducting frequent evaluations of machinery allows operators to identify wear and tear early. Focus on critical elements such as hydraulic systems, transmission components, and structural integrity. Implementing a consistent inspection schedule can prevent minor issues from escalating into major repairs.

Fluid Checks: Maintaining proper fluid levels is crucial for optimal operation. Regularly check hydraulic fluid, engine oil, and coolant to ensure they are within the recommended ranges. Replenish or change fluids as needed, adhering to the manufacturer’s specifications to maintain performance.

Component Replacement: Certain elements are prone to wear and may require replacement over time. Items such as filters, belts, and hoses should be monitored closely. Replace these components promptly when signs of degradation appear to avoid potential failures.

Professional Servicing: While many maintenance tasks can be performed by operators, engaging professionals for complex issues or regular servicing is advisable. Certified technicians possess the expertise to diagnose problems accurately and perform necessary repairs efficiently.

Documentation: Keeping detailed records of maintenance activities and replacements can assist in tracking the history of the machine. This information is invaluable for future servicing and can aid in predicting when parts may need to be replaced again.

Finding OEM Parts for Repairs

When it comes to maintaining heavy machinery, sourcing original components is crucial for ensuring reliability and optimal performance. Whether you’re repairing or upgrading equipment, utilizing authentic replacements guarantees compatibility and longevity. This section explores effective strategies for locating genuine items essential for your restoration needs.

One of the best approaches is to connect with authorized dealers and distributors. They often have access to a comprehensive inventory of original components. Additionally, utilizing online platforms that specialize in industrial equipment can streamline your search. Many of these websites offer detailed catalogs and can assist you in identifying the correct items for your model.

| Resource Type | Description | Benefits |

|---|---|---|

| Authorized Dealers | Local suppliers certified by manufacturers. | Reliable sources with warranty options. |

| Online Retailers | Websites specializing in industrial machinery. | Convenient access to a wide range of items. |

| Manufacturer Websites | Official sites of the equipment makers. | Direct access to product specifications and latest updates. |

Consider joining forums or community groups dedicated to equipment maintenance. Engaging with other enthusiasts can provide valuable insights and recommendations for reputable suppliers. By leveraging these resources, you can ensure your machinery remains in top-notch condition, ultimately enhancing its efficiency and lifespan.