The intricacies of heavy equipment often require a detailed examination to ensure optimal performance and maintenance. A comprehensive breakdown of machinery elements not only aids in troubleshooting but also enhances the efficiency of operations.

In this section, we will explore a structured representation that illustrates the various components involved. Such visual aids are invaluable for both seasoned professionals and novices alike, enabling them to grasp the complexities with greater ease.

Moreover, delving into the arrangement and function of each element reveals the ultimate synergy required for seamless machinery operation. By understanding these relationships, users can better appreciate the importance of each part in the overall system.

Understanding the Case 830 Parts Diagram

This section provides insight into the intricacies of a specific machine’s assembly and components. By exploring a visual representation of the various elements, users can gain a better grasp of how each part interacts within the overall system. This understanding is crucial for effective maintenance and troubleshooting.

Importance of Familiarity with Components

Recognizing individual elements and their functions can significantly enhance operational efficiency. Each segment plays a vital role, and knowing how they connect helps in identifying potential issues before they escalate.

Key Elements to Note

| Component | Description |

|---|---|

| Engine Assembly | The powerhouse of the machine, responsible for generating the necessary energy for operation. |

| Transmission System | This mechanism transfers power from the engine to the wheels, enabling movement. |

| Hydraulic Components | These parts facilitate the movement and control of various systems through fluid dynamics. |

| Chassis | The framework that supports all other elements, ensuring stability and strength. |

| Electrical System | This network powers various electronic components, essential for modern functionality. |

Overview of Case 830 Specifications

This section provides a comprehensive examination of the technical features and characteristics of a particular agricultural machine. Understanding these specifications is essential for operators and technicians to optimize performance, ensure proper maintenance, and enhance operational efficiency.

Engine Performance

The machine is equipped with a robust power unit designed to deliver high torque and efficiency. With a displacement that supports a reliable output, it is tailored for demanding tasks in various agricultural settings. The configuration of the engine contributes to both fuel efficiency and operational longevity, making it suitable for long hours of work.

Transmission and Drive System

The transmission system is engineered for smooth shifting and excellent control. It features multiple gears that allow the operator to adapt to different terrains and load conditions seamlessly. The drive system is designed to ensure maximum traction, enhancing the overall capability of the equipment in challenging environments.

Key Components of the Case 830

This section explores the essential elements that contribute to the functionality and performance of the machine, providing a comprehensive understanding of its design and operation.

- Engine: The powerhouse that drives the entire system, crucial for efficiency and power output.

- Transmission: A vital mechanism that manages the transfer of power to the wheels, influencing speed and torque.

- Hydraulic System: This component enables the operation of various attachments and implements, enhancing versatility.

- Chassis: The framework that supports all other components, ensuring stability and strength during operation.

- Electrical System: Responsible for powering lights, ignition, and other electronic features, essential for modern functionalities.

Understanding these key components allows operators and technicians to delve deeper into maintenance and repair, ultimately enhancing the longevity and performance of the equipment.

Importance of Accurate Parts Diagrams

In the realm of machinery and equipment maintenance, precision in representation is crucial. A well-crafted visual guide serves as a fundamental tool for understanding the intricate components of a system. It aids technicians and engineers in identifying, assembling, and replacing essential elements, ensuring optimal functionality and longevity of the machinery.

Enhancing Maintenance Efficiency

Clear and detailed representations significantly streamline the maintenance process. When individuals can easily discern the arrangement and relationships between components, it reduces the time spent on repairs and replacements. Effective visuals minimize the risk of errors, allowing for swift troubleshooting and ensuring that maintenance tasks are executed with confidence.

Facilitating Communication and Training

Accurate illustrations are also invaluable in training scenarios. New technicians benefit from visual aids that enhance their understanding of complex systems. These representations foster better communication among team members, as everyone can refer to the same detailed resources, promoting a shared understanding of machinery operation and care.

Common Issues with Case 830 Parts

In the realm of agricultural machinery, various components can encounter a range of challenges over time. These difficulties often stem from wear and tear, improper maintenance, or the inherent complexities of the machinery itself. Understanding these common problems can help users ensure optimal performance and longevity of their equipment.

Frequent Wear and Tear

One of the most prevalent issues involves the natural degradation of components due to regular use. Elements such as bearings, seals, and gaskets can wear out, leading to leaks or failures that compromise overall functionality. Routine inspections and timely replacements are crucial to prevent more significant complications that can arise from neglected wear.

Misalignment and Installation Errors

Another common challenge is misalignment during installation. When components are not positioned correctly, it can lead to uneven wear, increased friction, and eventual breakdowns. Ensuring precise alignment during assembly and adhering to manufacturer specifications can mitigate these risks, enhancing both efficiency and performance.

Where to Find Replacement Parts

Locating components for machinery can be crucial for maintaining optimal performance and longevity. Understanding the best sources for these items can save time and ensure reliability in your equipment.

Online Marketplaces

Many individuals turn to various online platforms for their needs. Websites specializing in agricultural equipment often offer a wide selection of items, providing users the ability to compare prices and availability easily.

Local Suppliers and Dealerships

Local distributors and authorized dealerships can be invaluable resources. They often stock a range of essential components and provide expert advice on selection and installation.

Tips for Maintaining Your Case 830

Ensuring the longevity and efficiency of your machinery requires consistent care and attention. By following some key practices, you can enhance performance, prevent breakdowns, and save on repair costs.

Regular Inspections

Conduct routine checks to identify any signs of wear or potential issues before they escalate. Pay special attention to fluid levels, belts, and filters to ensure everything is functioning smoothly.

Proper Cleaning and Lubrication

Keep your equipment clean to prevent dirt accumulation that can lead to operational problems. Additionally, regularly lubricate moving parts to minimize friction and prolong the life of components.

How to Read Parts Diagrams Effectively

Understanding visual representations of components is crucial for efficient assembly, repair, and maintenance. These illustrations serve as a roadmap, guiding users through complex structures and highlighting the relationships between various elements. Familiarity with symbols, labels, and numbering conventions can enhance comprehension and streamline the workflow.

Start by identifying the key features of the illustration. Look for the title or legend that often provides context, outlining the specific assembly or system depicted. Pay attention to the annotations that indicate part numbers or descriptions, as they can lead to essential details about functionality and compatibility.

Next, focus on the layout. Typically, components are arranged logically, reflecting their physical connections or assembly sequence. Trace lines or arrows often depict relationships, helping to visualize how parts interact within the whole. It’s beneficial to cross-reference these visuals with manuals or catalogs to gain a deeper understanding.

Finally, practice makes perfect. The more you engage with these visuals, the more intuitive they become. Over time, you’ll develop an ability to quickly decipher complex representations, making the process of working with them not just manageable, but ultimately efficient.

Comparing Case 830 with Other Models

This section explores the distinctions and similarities between a specific agricultural machine and its contemporaries, highlighting unique features and functionalities that set it apart in the market.

When evaluating different models, several key aspects emerge:

- Performance: Each machine offers varying levels of power and efficiency, affecting productivity.

- Design: The build quality and ergonomics play a crucial role in user experience and maintenance.

- Technology: Advanced features may include precision farming tools and improved fuel efficiency.

- Cost: Pricing can vary significantly, influencing purchasing decisions among buyers.

Ultimately, understanding these elements allows potential buyers to make informed choices based on their specific needs and preferences.

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right instruments at your disposal can make all the difference. These tools not only enhance efficiency but also ensure that tasks are completed with precision. Understanding the key equipment needed can streamline the repair process and lead to successful outcomes.

Basic Hand Tools

Every repair toolkit should include fundamental hand tools such as wrenches, pliers, and screwdrivers. These versatile instruments are crucial for loosening or tightening components, handling fasteners, and performing general adjustments. Selecting high-quality options will provide durability and reliability, allowing for better control during intricate tasks.

Power Tools for Efficiency

In addition to hand tools, incorporating power tools can significantly speed up the repair process. Drills, grinders, and impact wrenches are examples of equipment that can handle more demanding tasks with ease. Investing in these tools not only saves time but also increases the scope of work that can be accomplished effectively.

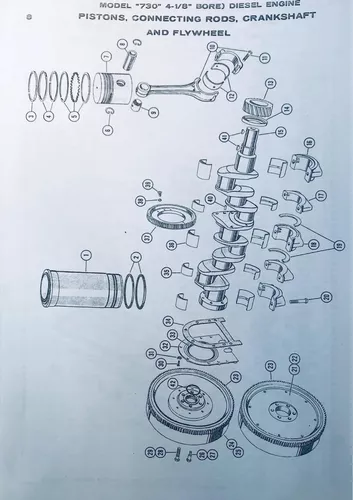

Case 830 Parts Diagram Explained

This section provides an insightful overview of the assembly layout for a specific model, highlighting the essential components that work in harmony to ensure optimal functionality. Understanding this layout is crucial for maintenance and repairs, as it facilitates easier identification of each element and its role within the machinery.

Understanding Component Functionality

Each individual part plays a vital role in the overall operation of the machine. By delving into the specifics of these components, one can grasp how they interact to achieve desired outcomes, making it easier to troubleshoot and perform necessary repairs.

Visual Representation

A visual reference can significantly enhance comprehension. The following table outlines key elements and their corresponding functions within the assembly:

| Component | Function |

|---|---|

| Engine | Powers the machinery |

| Transmission | Transfers power from the engine |

| Chassis | Provides structural support |

| Hydraulic System | Facilitates movement and control |

Real-life Repair Scenarios

This section explores practical examples where equipment maintenance and troubleshooting come into play. By examining various situations, we can understand the challenges faced by operators and technicians, as well as the solutions they implemented to restore functionality.

- Scenario 1: Engine Overheating

A technician discovered that a machine was overheating during operation. After thorough inspection, they found a clogged radiator and replaced it, improving cooling efficiency.

- Scenario 2: Hydraulic Failure

Operators noticed a drop in hydraulic pressure. The root cause was traced to a damaged hose, which was promptly replaced, restoring optimal performance.

- Scenario 3: Electrical Malfunction

A sudden power failure prompted a deep dive into the electrical system. A faulty fuse was identified and replaced, ensuring the equipment could function reliably once more.

These scenarios highlight the importance of regular inspections and timely repairs to maintain equipment efficiency and safety.

Frequently Asked Questions About Diagrams

This section addresses common inquiries related to visual representations that enhance understanding and organization of complex information. These illustrations serve as essential tools for various industries, aiding in clarity and efficiency.

Why are visual representations important?

Visual aids facilitate comprehension by breaking down intricate concepts into digestible formats. They enable quick reference and streamline communication, making them invaluable in technical fields.

How can I create effective visuals?

To produce impactful illustrations, focus on clarity and simplicity. Utilize consistent symbols, clear labels, and organized layouts to ensure your audience grasps the information effortlessly.