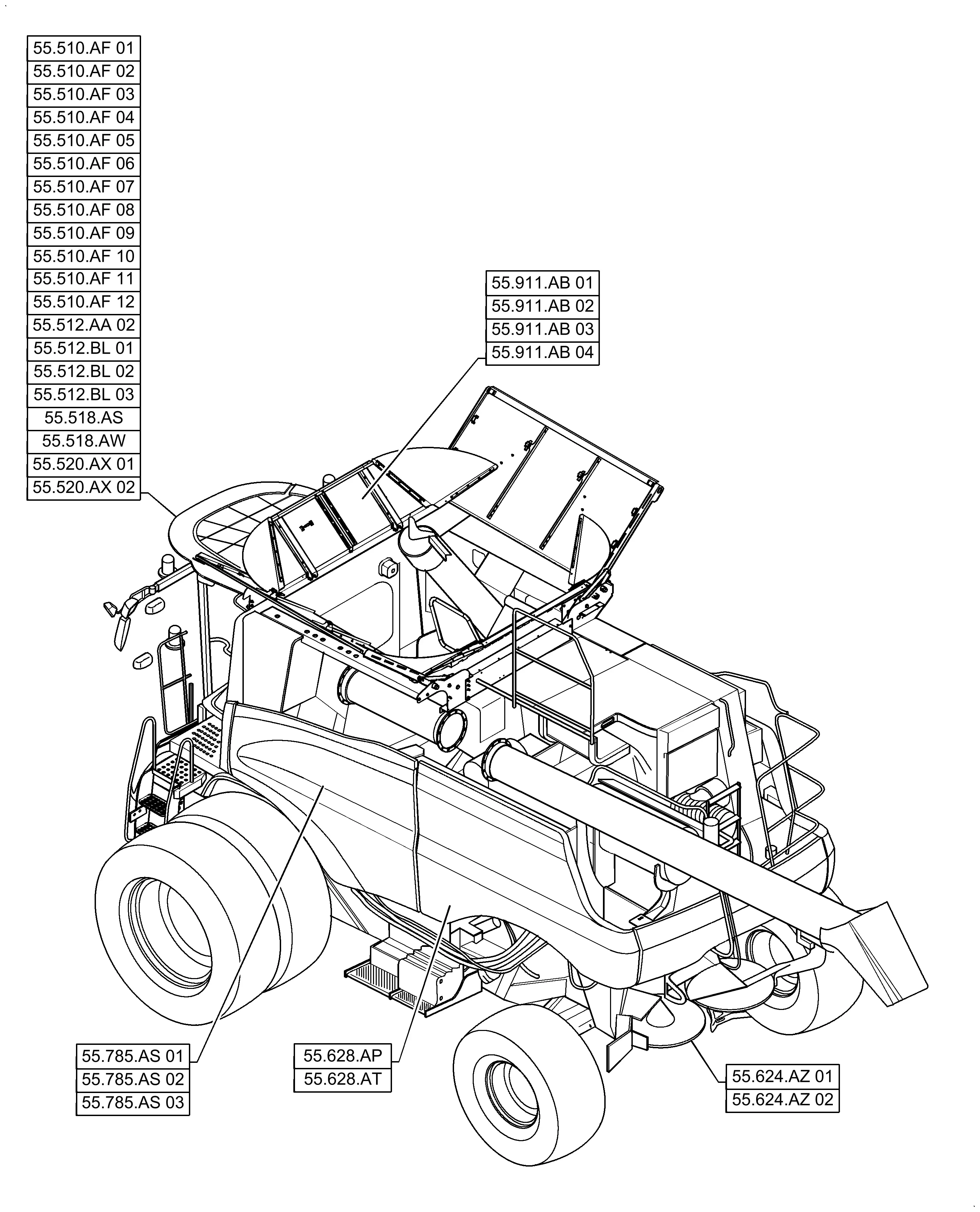

In the realm of farming machinery, a thorough grasp of the various components is essential for effective maintenance and operation. Each piece plays a crucial role in the overall functionality of the equipment, ensuring smooth performance and longevity. Familiarity with the layout and connections of these elements can greatly enhance the efficiency of agricultural tasks.

Visual aids are invaluable tools that assist operators and technicians in identifying and understanding the intricate relationships between different elements. By examining these representations, individuals can quickly pinpoint the specific sections that require attention, facilitating more effective troubleshooting and repairs. This knowledge not only saves time but also helps to minimize downtime in the field.

Furthermore, having access to detailed resources fosters a proactive approach to equipment care. Operators can better anticipate issues before they escalate, leading to a more reliable and productive farming experience. In this context, understanding how each component contributes to the overall operation of the machinery becomes increasingly important.

Understanding Case IH Components

This section provides an overview of the essential elements found in agricultural machinery produced by the brand. Recognizing these components is crucial for effective maintenance and optimal performance of the equipment. Each element plays a specific role, contributing to the overall functionality and efficiency of the machinery.

Familiarity with these components helps operators identify potential issues, enabling timely interventions. Knowing how different parts interact enhances troubleshooting capabilities, leading to reduced downtime and increased productivity. This understanding also aids in making informed decisions regarding repairs and upgrades.

In addition, comprehending the layout and function of these components can assist in effective training for new operators. By developing a solid foundation of knowledge about these essential elements, users can maximize the lifespan and performance of their equipment, ensuring reliable operation in the field.

Importance of Parts Diagrams

Understanding the layout and function of various components in machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for users, enabling them to identify individual elements and their relationships within the assembly. Such illustrations streamline the troubleshooting process and enhance overall operational efficiency.

Having access to clear schematics allows technicians and operators to quickly locate specific items, reducing downtime during repairs. Additionally, these visuals facilitate better communication between service providers and clients, ensuring that everyone involved has a mutual understanding of the equipment’s configuration.

Moreover, these resources can significantly aid in the training of new personnel, helping them to familiarize themselves with the machinery and its elements. As a result, comprehensive visuals not only assist in day-to-day operations but also contribute to long-term skill development and safety protocols.

| Benefits | Description |

|---|---|

| Efficiency | Enables quick identification of components, minimizing repair time. |

| Communication | Enhances dialogue between users and service providers, fostering better understanding. |

| Training | Assists in educating new personnel about equipment layout and functionality. |

How to Access PDF Resources

Exploring digital documents for detailed information can greatly enhance understanding and operational efficiency. Accessing electronic resources in portable document format requires familiarity with navigating digital libraries and utilizing search functionalities effectively.

Navigation Techniques

To efficiently locate resources, utilize directory structures or keyword searches within digital repositories. Familiarize yourself with categorization methods and tagging systems to streamline access to relevant materials.

Utilizing Search Functions

Mastering advanced search techniques enhances precision when seeking specific details within PDF documents. Utilize Boolean operators and advanced filters to refine search results and locate pertinent information swiftly.

Benefits of Using Diagrams

Visual representations serve as powerful tools for understanding complex systems and components. By simplifying intricate information into manageable visuals, they enable users to quickly grasp essential relationships and functions. This approach enhances comprehension, especially when dealing with technical or mechanical subjects.

One significant advantage of employing visual aids is their ability to facilitate effective communication. Whether for training, troubleshooting, or maintenance, these illustrations convey ideas more clearly than text alone, reducing the chances of misunderstandings. Users can easily identify specific elements and their interactions, leading to more efficient problem-solving.

Additionally, visuals can enhance retention of information. When individuals engage with graphics, they are more likely to remember details long after their initial exposure. This memory boost is particularly beneficial in educational and practical applications, where recalling procedures and configurations is crucial for successful outcomes.

In summary, utilizing visual aids can streamline the learning process, improve communication, and increase information retention, making them invaluable assets in any technical field.

Identifying Essential Parts Quickly

When it comes to maintaining and repairing machinery, recognizing critical components is essential for efficient workflow. A clear understanding of each element’s function allows for swift identification and resolution of issues. This knowledge not only enhances productivity but also reduces downtime during operations.

Familiarity with common elements, such as their shapes, sizes, and connections, can significantly streamline the process of locating the right items. Utilizing resources that visually represent these elements can further aid in enhancing comprehension and recall. Being able to swiftly pinpoint necessary components ensures that tasks are completed promptly, ultimately leading to smoother operations.

Case IH Models and Compatibility

This section explores various agricultural machinery models and their compatibility with different components. Understanding the relationships between models and their respective elements is essential for optimal performance and efficiency in operations. Proper knowledge of these connections can significantly enhance functionality and ensure seamless integration within the equipment.

Key Models Overview

Several renowned models dominate the agricultural landscape, each designed with specific features and functionalities. Below is a brief overview of some key models, highlighting their compatibility with various components.

| Model Name | Engine Type | Compatible Equipment |

|---|---|---|

| Maxxum | Diesel | Plows, Seeders |

| Puma | Turbo Diesel | Harvesters, Cultivators |

| Magnum | High-Performance Diesel | Tillage Tools, Spreaders |

Ensuring Compatibility

To guarantee proper functioning and prevent mechanical issues, it is crucial to ensure compatibility between the machinery and its components. Regular checks and consultations with equipment manuals or experts can aid in maintaining the right relationships and extending the lifespan of the machinery.

Common Issues with Equipment

Equipment frequently encounters a range of challenges that can impact performance and efficiency. Understanding these common problems can aid in preventive measures and timely repairs. Operators should be vigilant in recognizing signs of malfunction to ensure smooth operation.

One prevalent issue is wear and tear on components due to prolonged usage. This can lead to reduced functionality, increased friction, and eventual failure of parts. Regular inspections can help identify worn-out elements before they cause significant disruptions.

Another concern is the accumulation of dirt and debris, which can obstruct moving parts and hinder overall effectiveness. Implementing routine cleaning practices is essential for maintaining optimal conditions and prolonging the life of the machinery.

Additionally, improper lubrication can result in overheating and excessive wear. Ensuring that lubricants are applied correctly and at appropriate intervals is crucial for preventing these complications. Regular maintenance schedules should include lubrication checks as a priority.

Repair and Maintenance Tips

Effective upkeep and timely repairs are essential for the longevity and optimal performance of agricultural machinery. Implementing routine checks and addressing minor issues promptly can prevent more significant problems down the line. Here are some essential practices to ensure your equipment remains in peak condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Fluid Checks | Every 50 hours | Inspect and replenish engine oil, hydraulic fluid, and coolant levels to ensure smooth operation. |

| Filter Replacement | Every 100 hours | Replace air and fuel filters to maintain engine efficiency and prevent contamination. |

| Lubrication | Every 100 hours | Apply lubricant to all moving parts to minimize wear and ensure optimal performance. |

| Tire Inspection | Weekly | Check tire pressure and tread condition to guarantee safe operation and reduce the risk of accidents. |

| Belt and Hose Check | Monthly | Inspect belts and hoses for signs of wear and tear to prevent breakdowns during operation. |

By following these guidelines, operators can significantly enhance the reliability and functionality of their machinery, ensuring it serves them well for years to come.

Tools Needed for Parts Replacement

When it comes to replacing components in machinery, having the right tools is essential for a successful and efficient process. Proper equipment not only simplifies the task but also minimizes the risk of damage to the items being worked on. This section outlines the necessary tools that facilitate effective component swaps and maintenance.

Essential Hand Tools

Hand tools are fundamental for any replacement task. A sturdy wrench set allows for the secure loosening and tightening of bolts and nuts. Additionally, a reliable screwdriver set is crucial for dealing with various screws. Other handy implements include pliers, which assist in gripping and bending, and a hammer for driving or adjusting parts when needed.

Power Tools for Efficiency

Incorporating power tools can greatly enhance the efficiency of the replacement process. An electric drill is invaluable for drilling holes or removing screws quickly. A socket set combined with a power ratchet speeds up the removal and installation of larger components. These tools help save time and effort, allowing for a more streamlined workflow.

Enhancing Equipment Longevity

Maximizing the lifespan of machinery is crucial for maintaining efficiency and reducing operational costs. Proper maintenance, timely repairs, and adherence to best practices can significantly extend the usable life of agricultural tools. By implementing these strategies, users can minimize wear and tear, ensuring that their equipment remains reliable and effective over time.

Regular Inspections: Conducting routine assessments is essential for identifying potential issues before they escalate. Regular check-ups allow for the early detection of wear or malfunction, enabling proactive measures to be taken. This practice not only enhances performance but also mitigates the risk of unexpected breakdowns.

Quality Lubrication: Using the appropriate lubricants is vital in reducing friction between moving parts. Proper lubrication minimizes wear, prevents overheating, and helps maintain the integrity of components. Choosing high-quality products tailored to specific machinery needs ensures optimal performance and durability.

Training and Education: Investing in training for operators is an often-overlooked aspect of equipment care. Knowledgeable personnel can utilize tools more effectively, recognize warning signs, and follow maintenance schedules diligently. This understanding contributes to fewer mistakes and better overall care for the machinery.

Finding Reliable Suppliers

Locating trustworthy sources for components is crucial for maintaining the efficiency and longevity of your equipment. A reliable supplier not only provides quality items but also ensures timely delivery and excellent customer service. To make informed choices, it’s essential to conduct thorough research and leverage various strategies to evaluate potential vendors.

Research and Recommendations

Start by gathering information from multiple channels. Online reviews, forums, and industry-specific websites can offer insights into the reputation of different suppliers. Additionally, asking for recommendations from peers or professionals in your network can lead you to reputable vendors with proven track records.

Evaluating Supplier Credibility

Once you have a list of potential suppliers, assess their credibility by checking their certifications and affiliations with recognized industry organizations. Emphasize suppliers who demonstrate transparency in their operations and offer clear communication regarding pricing, shipping, and return policies. Engaging with a supplier through direct contact can also help gauge their responsiveness and willingness to assist.

Safety Precautions During Repairs

When engaging in maintenance or restoration activities, it is essential to prioritize safety. Following established guidelines can significantly reduce the risk of accidents and ensure a secure working environment. Proper preparation and awareness are crucial for both personal protection and the integrity of the machinery being serviced.

Personal Protective Equipment

Always utilize appropriate protective gear, including gloves, goggles, and steel-toed boots. Wearing a helmet is also advisable when working in areas with potential overhead hazards. These items serve as a barrier against injuries and enhance overall safety while performing tasks.

Workspace Organization

A tidy and well-organized workspace is vital for effective operations. Ensure that tools and materials are neatly arranged and easily accessible. Eliminating clutter helps prevent accidents and allows for a more efficient workflow, allowing technicians to focus on the job at hand without unnecessary distractions.

Customer Support and Resources

Ensuring a smooth experience for users is essential, and having access to the right support and resources can significantly enhance satisfaction. Various options are available to assist customers in finding solutions, information, and guidance related to their equipment. Below are key resources and support channels designed to help users maximize their experience.

| Resource Type | Description | Contact Information |

|---|---|---|

| Online Support Center | A comprehensive platform providing manuals, troubleshooting tips, and FAQs. | Visit here |

| Customer Service Hotline | Speak directly with knowledgeable representatives for immediate assistance. | 1-800-555-0199 |

| Local Dealer Network | Access to trained professionals who can provide personalized support and service. | Find a dealer |

| Community Forums | Engage with other users to share experiences, tips, and solutions. | Join the discussion |