When it comes to maintaining high-performance equipment, familiarity with its intricate components is essential. Each element plays a crucial role in ensuring efficient operation, making it vital for users to comprehend how they interact. This knowledge not only aids in troubleshooting but also enhances overall safety during use.

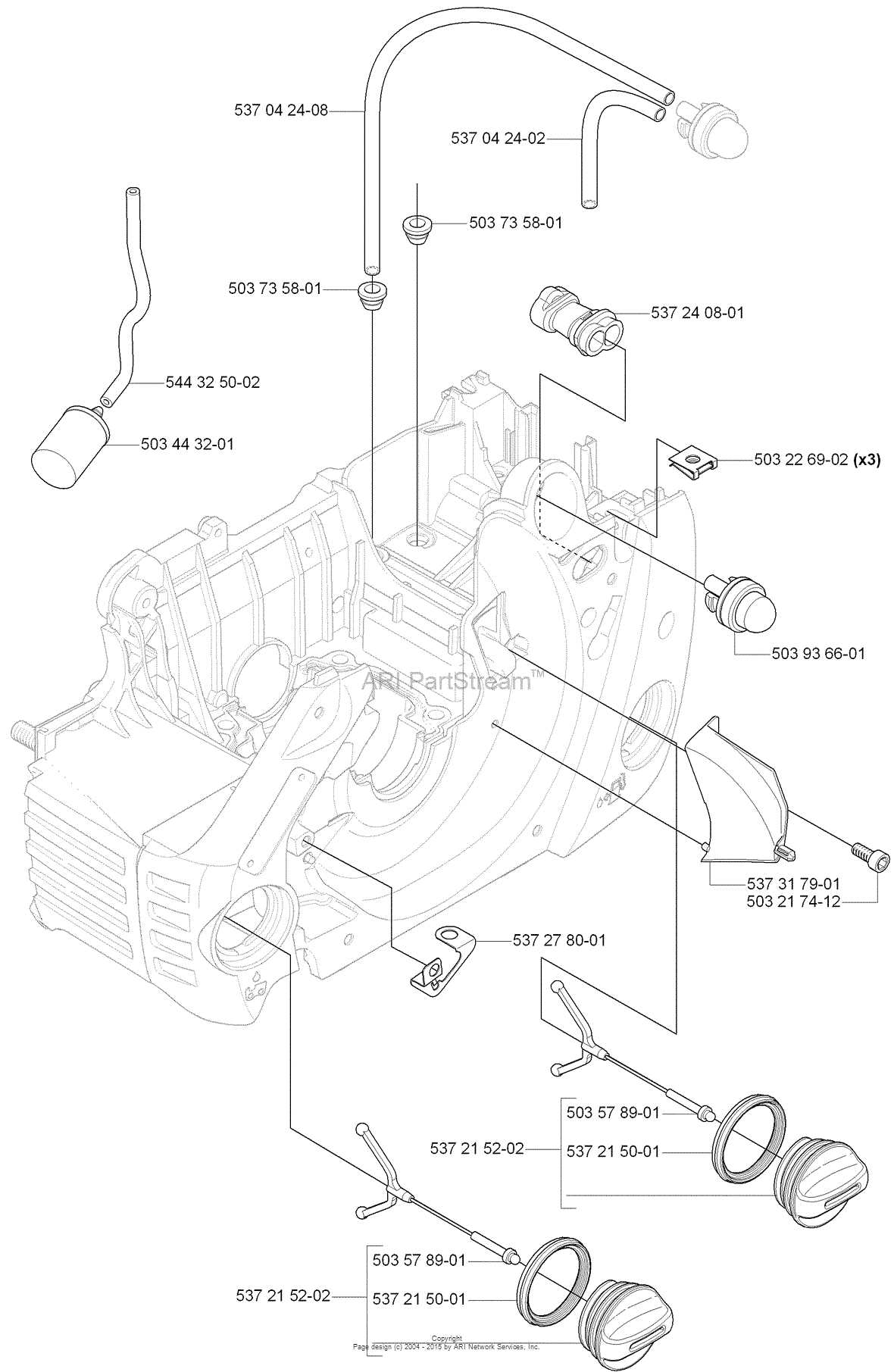

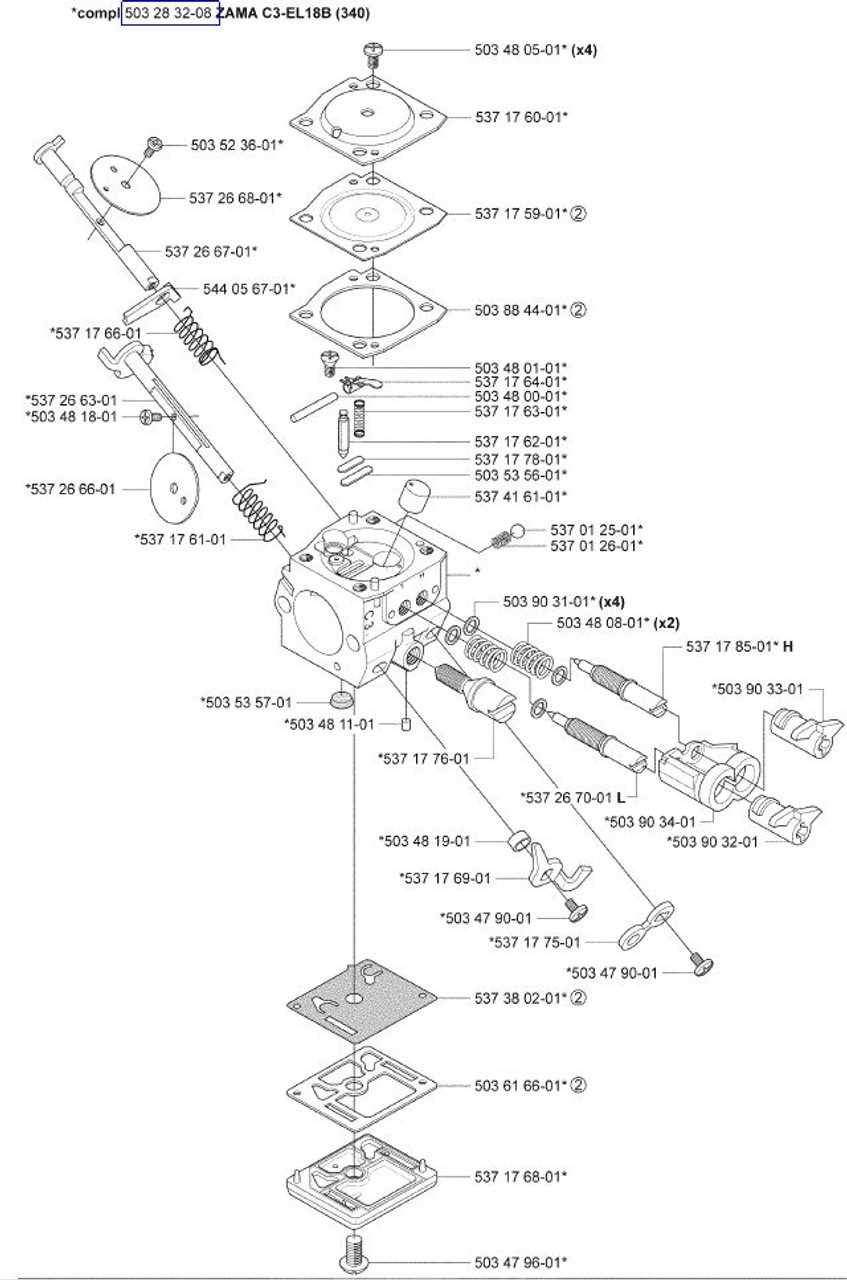

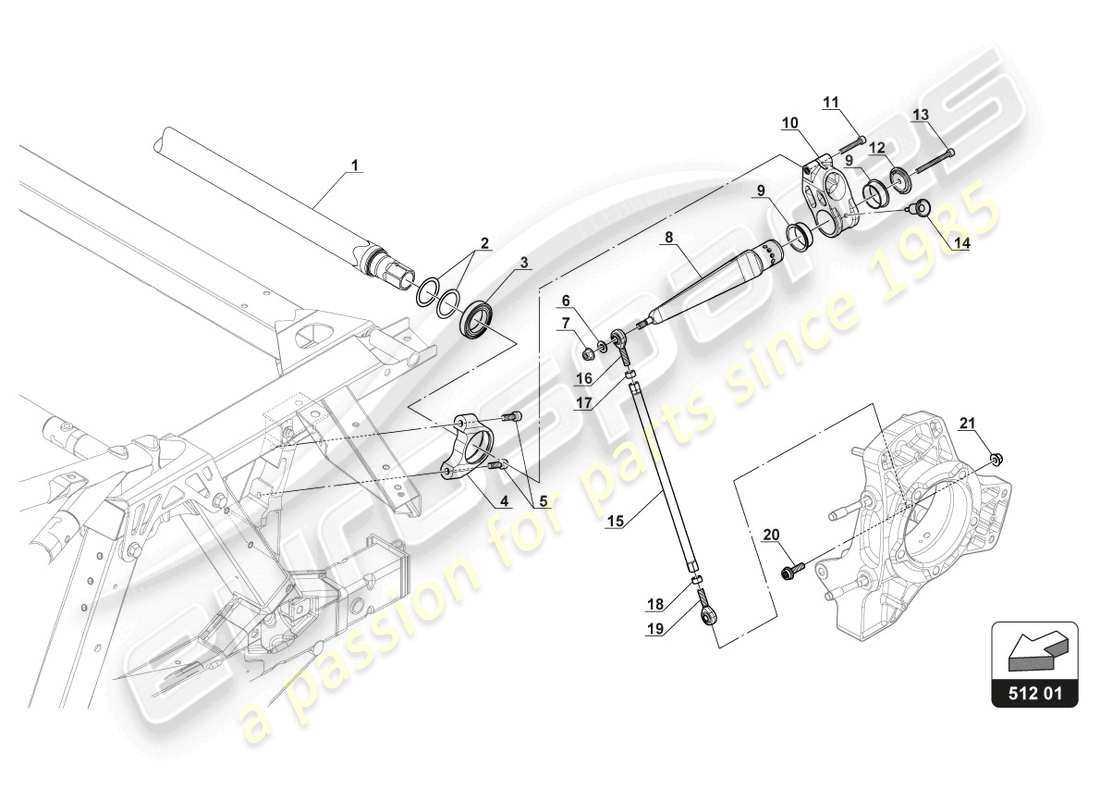

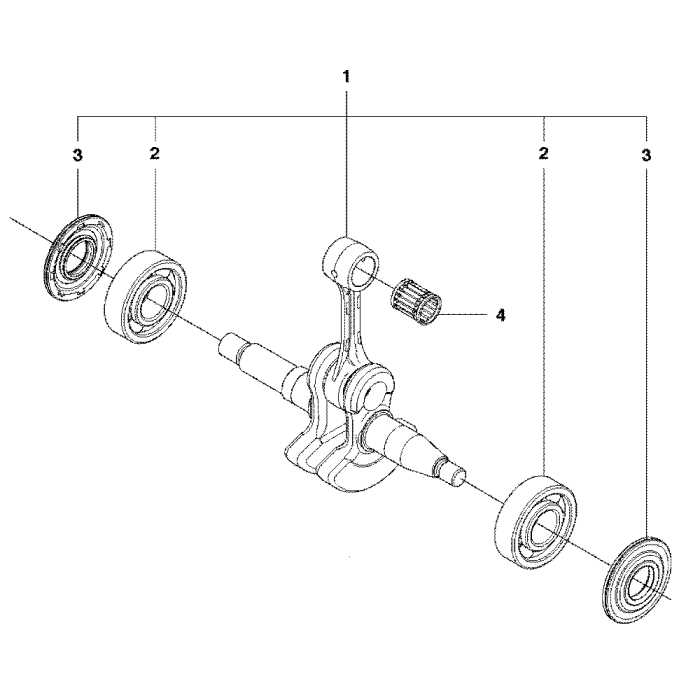

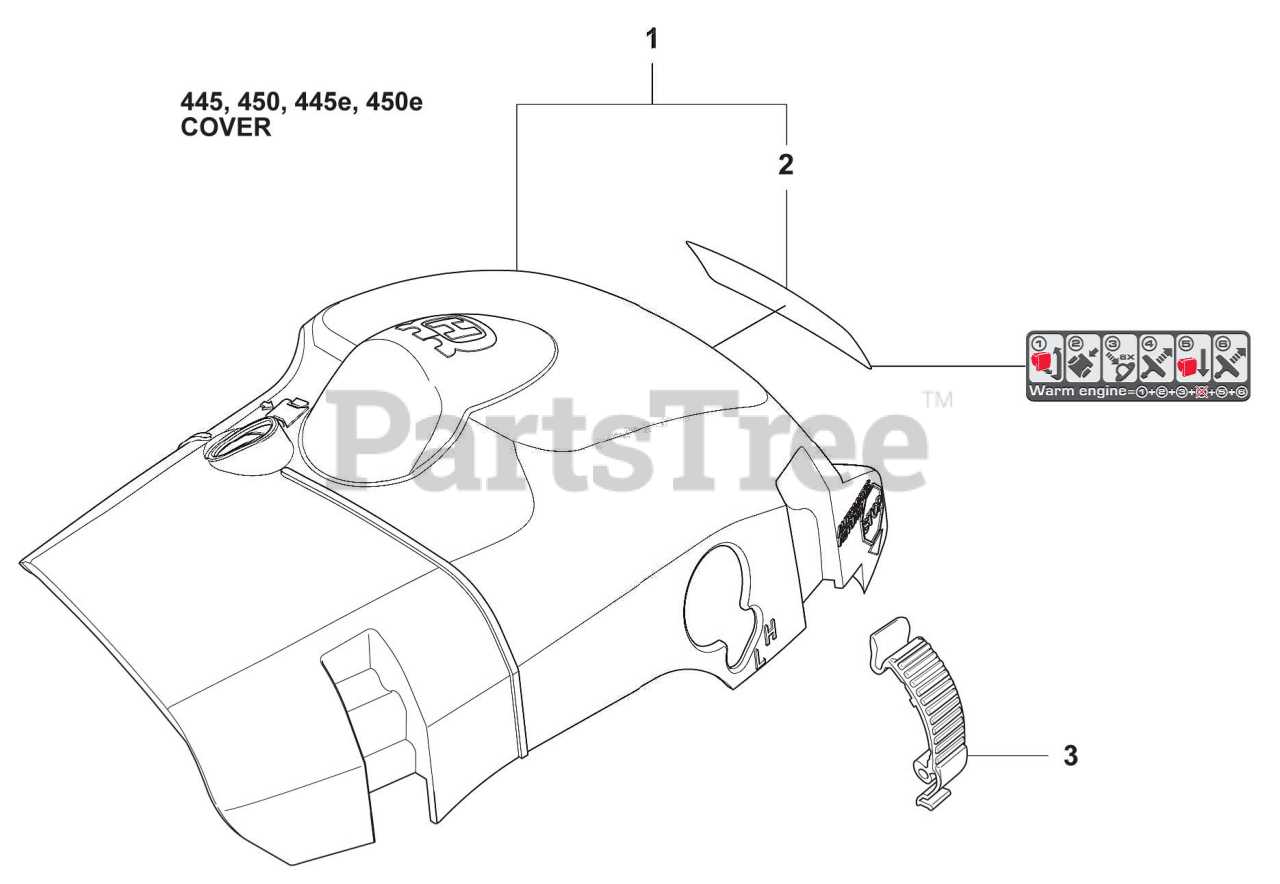

In this section, we will explore a visual representation of various elements that make up a popular model in the industry. By delving into this comprehensive overview, you can identify specific pieces, understand their functions, and grasp how they contribute to the machine’s performance.

Furthermore, a clear understanding of the machinery’s layout can simplify the maintenance process. Whether you are looking to replace a worn part or conduct routine checks, knowing where each component is located will save time and effort, ultimately prolonging the lifespan of your equipment.

Understanding Husqvarna 445 Chainsaw Design

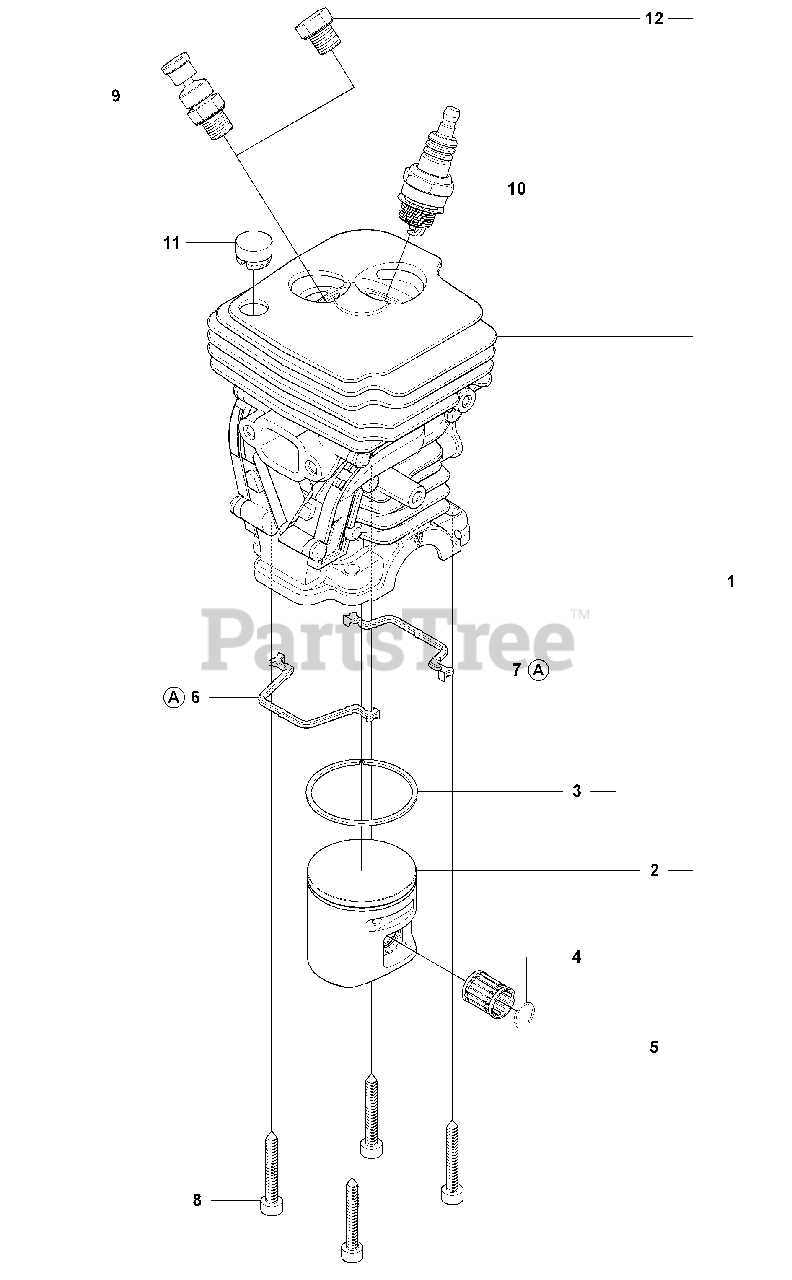

Examining the structure and functionality of a cutting tool reveals the intricate engineering that supports its performance. Each component plays a vital role in ensuring efficiency, safety, and ease of use. A thorough grasp of the design elements allows users to appreciate how these machines operate and maintain their effectiveness over time.

The layout of a typical model consists of various interconnected elements that contribute to its overall functionality. From the motor assembly to the cutting mechanism, understanding the relationship between these parts enhances the user experience and facilitates better maintenance practices.

| Component | Function |

|---|---|

| Engine | Powers the device, converting fuel into mechanical energy. |

| Bar | Guides the chain, providing stability during operation. |

| Chain | Engages with the bar to perform cutting tasks. |

| Throttle | Controls the engine speed and power output. |

| Handle | Provides grip and maneuverability for the user. |

| Safety Features | Includes mechanisms that prevent accidental activation and enhance user protection. |

Each of these elements is meticulously designed to work in harmony, ensuring a seamless operation that meets the demands of users. A comprehensive understanding of these components fosters not only better usage but also informed maintenance decisions, ultimately extending the lifespan of the equipment.

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool enhances both performance and maintenance. Each component plays a pivotal role in the overall functionality, contributing to efficiency and safety during operation.

Power Source

The heart of any cutting tool, the power source, drives all other functions. It can vary from gas-powered engines to electric motors, each offering distinct advantages in terms of power output and convenience.

Cutting Mechanism

This crucial element includes the bar and the cutting chain, which work in tandem to achieve precise cuts. The design and material of these components determine cutting efficiency and durability, making them vital for optimal performance.

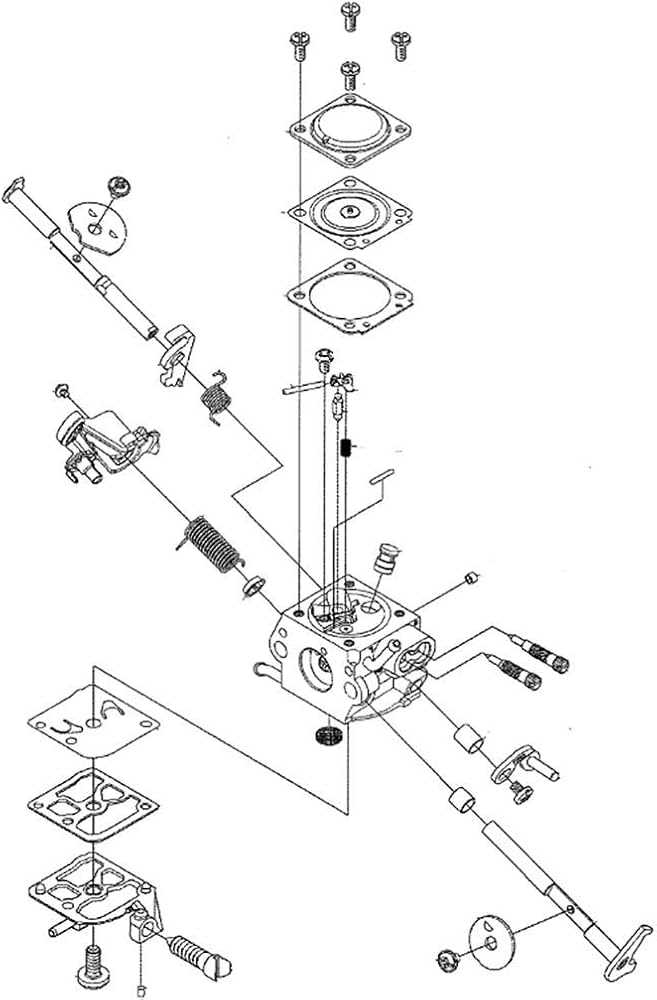

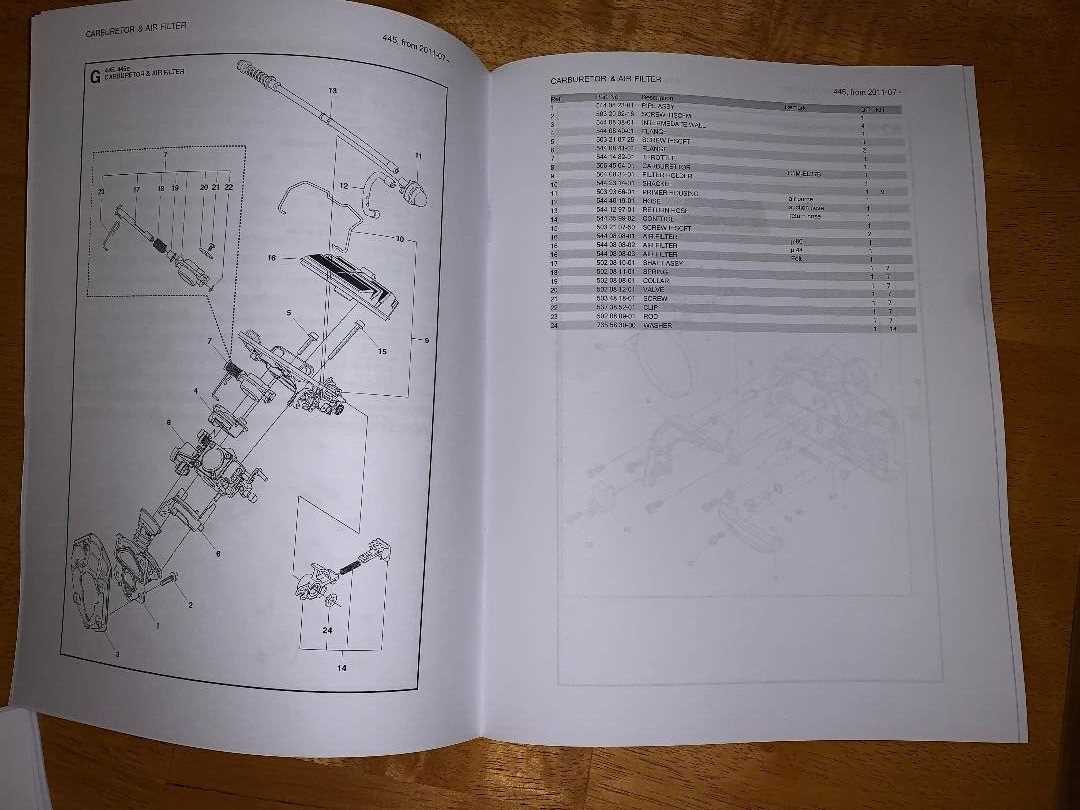

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a detailed overview of various elements, helping users identify, locate, and replace necessary items efficiently. Familiarity with these graphics can save time and enhance troubleshooting skills.

Decoding Symbols and Labels

Each representation typically includes specific symbols and labels that denote various elements. It is essential to familiarize yourself with these indicators, as they provide valuable information regarding sizes, connections, and functions. Pay attention to the legend, as it often clarifies the meanings of different icons.

Utilizing the Information

Once you comprehend the layout and symbols, you can effectively use the information for ordering replacements or conducting repairs. Reference the visual guide while working on your device, ensuring that you have all necessary components on hand. This approach ultimately leads to a more successful repair process.

Common Issues with Husqvarna 445

Many users encounter various challenges while operating their cutting tools. Understanding these problems can enhance performance and longevity.

- Fuel Delivery Problems:

- Clogged fuel lines

- Dirty filters

- Improper fuel mixture

- Starting Difficulties:

- Weak spark plug

- Low battery charge

- Obstructed air filters

- Chain Issues:

- Chain tension problems

- Worn-out teeth

- Improper lubrication

- Vibration and Noise:

- Loose components

- Worn bearings

- Unbalanced cutting equipment

Addressing these common issues promptly can lead to optimal performance and extended life of your tool.

Identifying Replacement Parts Easily

Understanding the components of your tool is crucial for maintaining its performance. Knowing how to locate and identify specific elements can save time and effort when seeking replacements. This section will guide you through the process of recognizing the various sections and features, enabling you to find what you need with ease.

Start by familiarizing yourself with the main assemblies of the equipment. Each part plays a significant role, and understanding their functions can help pinpoint issues and required replacements. Use manuals or online resources that provide clear visuals and descriptions to aid in identification.

When searching for a specific component, pay attention to model numbers and specifications. Many retailers and online platforms categorize items based on these details, making it easier to locate the exact replacement. Utilizing the correct terminology can also streamline your search, as it allows you to communicate effectively with suppliers or seek assistance in forums.

Keep an organized list of parts and their respective identifiers. This will not only assist you in future searches but also help you understand how various elements interact within the assembly. Regular maintenance checks can provide insights into wear and tear, allowing you to proactively replace components before they cause further issues.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your outdoor power tools. Regular care not only enhances performance but also extends the lifespan of your equipment, saving you time and money in the long run.

Regular Cleaning

Keeping your tool clean is vital. Remove debris and dirt after each use to prevent buildup that can cause wear. Use a soft brush and compressed air to reach tight spots, ensuring all components remain in optimal condition.

Check and Replace Components

Periodically inspect key elements such as the bar and chain. Replacing worn parts promptly can prevent further damage and maintain efficiency. Additionally, ensure that all fasteners are secure to avoid unexpected issues during operation.

Tools Needed for Repairs

When tackling maintenance tasks, having the right instruments is essential for efficient and effective repairs. This section outlines the necessary tools to ensure a smooth process, minimizing frustrations and maximizing results.

Essential Instruments

Gathering specific tools can significantly enhance the repair experience. Here are some of the must-haves:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | To loosen or tighten bolts and nuts. |

| Philips and Flathead Screwdrivers | For various screws encountered during disassembly. |

| Chain Tension Gauge | To ensure proper tension for optimal performance. |

| File | For sharpening and maintaining cutting edges. |

Additional Helpful Tools

Besides the essential instruments, having some supplementary tools can further aid the repair process:

| Tool | Purpose |

|---|---|

| Protective Gear | To ensure safety during the repair process. |

| Oil Can | For lubrication of moving parts. |

| Cleaning Brush | To remove debris and maintain cleanliness. |

Where to Buy Genuine Parts

Finding authentic components for your outdoor power tools is essential for maintaining performance and longevity. Reliable sources ensure that you receive high-quality items that meet the manufacturer’s specifications, allowing you to keep your equipment in optimal condition.

Consider the following options for purchasing genuine items:

| Source | Description |

|---|---|

| Authorized Dealers | Local retailers officially recognized by the brand, offering a wide range of certified components. |

| Online Stores | Reputable e-commerce platforms provide a convenient way to order genuine items with home delivery. |

| Manufacturer’s Website | Purchasing directly from the official site guarantees authenticity and often includes the latest components. |

| Specialty Shops | Stores focused on outdoor tools may have a curated selection of genuine components and knowledgeable staff. |

DIY Repairs: Step-by-Step Guide

Maintaining your equipment can be a rewarding experience, allowing you to save money while gaining valuable skills. This guide will walk you through essential repairs, helping you restore functionality with confidence. Follow these steps to ensure a smooth and effective repair process.

Tools You’ll Need

Before starting, gather the necessary tools for your repair project. This preparation will make the process more efficient and organized.

| Tool | Purpose |

|---|---|

| Screwdriver | To remove and tighten screws. |

| Wrench | To loosen or secure nuts and bolts. |

| Replacement Parts | To ensure your device operates effectively. |

| Safety Gear | To protect yourself during repairs. |

Repair Process

Begin by assessing the issue and identifying the components that need attention. Carefully disassemble the unit, keeping track of all parts. Replace any damaged components, then reassemble, ensuring all connections are secure. Finally, test the equipment to confirm functionality. With practice, these repairs will become second nature, enhancing your overall proficiency.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks on power equipment, adhering to safety measures is crucial to prevent accidents and injuries. Understanding the potential hazards and implementing proper precautions can make the process safer and more efficient.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and disconnected from the power source before starting any work.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep your workspace organized to prevent tripping hazards and loss of small components.

Handling Tools and Components

- Use the right tools for the job to avoid damage and ensure safety.

- Inspect tools regularly for wear and tear, replacing any that are damaged.

- Handle sharp or heavy parts with care, ensuring a secure grip at all times.

Comparing Models: Husqvarna 445 vs Others

In this section, we will explore the features and specifications of a particular model and how it stacks up against its competitors in the market. Understanding these differences can help users make informed choices based on their specific needs and preferences.

Key Specifications

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 2.5 kW | 2.3 kW | 2.8 kW |

| Weight | 4.8 kg | 5.0 kg | 4.5 kg |

| Bar Length | 16 inches | 14 inches | 18 inches |

Performance Insights

When evaluating performance, it’s essential to consider aspects such as efficiency, durability, and ease of use. Each model brings unique advantages that cater to different tasks, making some better suited for heavy-duty work while others excel in portability.

Resources for Chainsaw Owners

For individuals who operate cutting tools, having access to reliable information and support is essential for maintenance and effective use. Various resources are available to enhance the experience of owners, from manuals and guides to community forums and specialized websites. These tools help ensure safe operation and longevity of equipment.

Below is a table highlighting valuable resources that can assist users in understanding their equipment better:

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Official manuals provide detailed instructions on operation and care. | Visit here |

| Online Forums | Community-driven discussions offer tips and troubleshooting advice. | Join the discussion |

| Video Tutorials | Step-by-step videos cover maintenance and repair techniques. | Watch now |

| Replacement Suppliers | Specialized retailers offer a wide range of replacement components. | Find suppliers |

Leveraging these resources can significantly enhance the proficiency and confidence of tool users, ensuring a safer and more enjoyable experience.