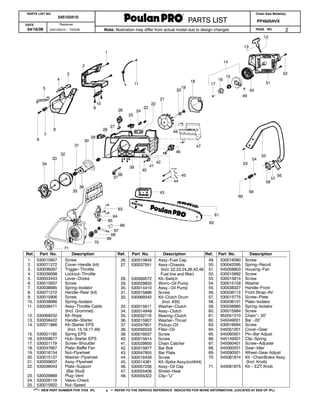

Maintaining and repairing outdoor equipment can be a daunting task without the right visual aids. A comprehensive illustration of each element involved in your tool can significantly enhance your understanding and efficiency. Knowing the layout and function of these components is essential for any owner looking to ensure longevity and performance.

Whether you are a seasoned user or a novice, familiarizing yourself with the assembly of your cutting apparatus can lead to more effective maintenance and troubleshooting. This guide will help you navigate the intricate details of your equipment, empowering you to tackle repairs and upgrades with confidence.

By delving into the schematic representation of the various components, you will gain insight into how each part interacts within the whole system. This knowledge not only aids in resolving issues but also enhances your overall experience with your outdoor tool, ultimately leading to better results in your yard work or projects.

Poulan Pro Chainsaw Overview

This section offers a comprehensive look at a well-regarded tool designed for cutting and trimming tasks. Known for its reliability and efficiency, this equipment is favored by both professionals and hobbyists alike. Understanding its components and functionality can enhance your experience and maintenance practices.

Key Features

- Powerful engine for efficient cutting.

- Lightweight design for ease of handling.

- Durable construction to withstand rigorous use.

- User-friendly controls for intuitive operation.

Maintenance Tips

- Regularly check and sharpen the blade for optimal performance.

- Inspect fuel and oil levels before each use.

- Clean air filters to ensure proper airflow.

- Store in a dry place to prevent corrosion.

Key Features of 42cc Model

This model stands out due to its robust design and functionality, making it an essential tool for both casual users and professionals. It is engineered to offer a perfect balance of power and efficiency, ensuring that tasks are completed with minimal effort.

Powerful Engine: The unit is equipped with a high-performance motor that delivers exceptional cutting capabilities. This ensures that even the toughest materials can be handled effortlessly.

Lightweight Construction: Despite its strength, this model is designed to be lightweight, enhancing user comfort during extended use. Its ergonomic features help reduce fatigue and improve handling.

Easy Maintenance: Maintenance is simplified with accessible components, allowing users to keep the equipment in optimal condition without extensive effort.

Safety Features: Integrated safety mechanisms provide added protection, ensuring that the tool is used responsibly and effectively.

These characteristics combine to make this model a reliable choice for anyone looking to tackle outdoor projects with confidence and ease.

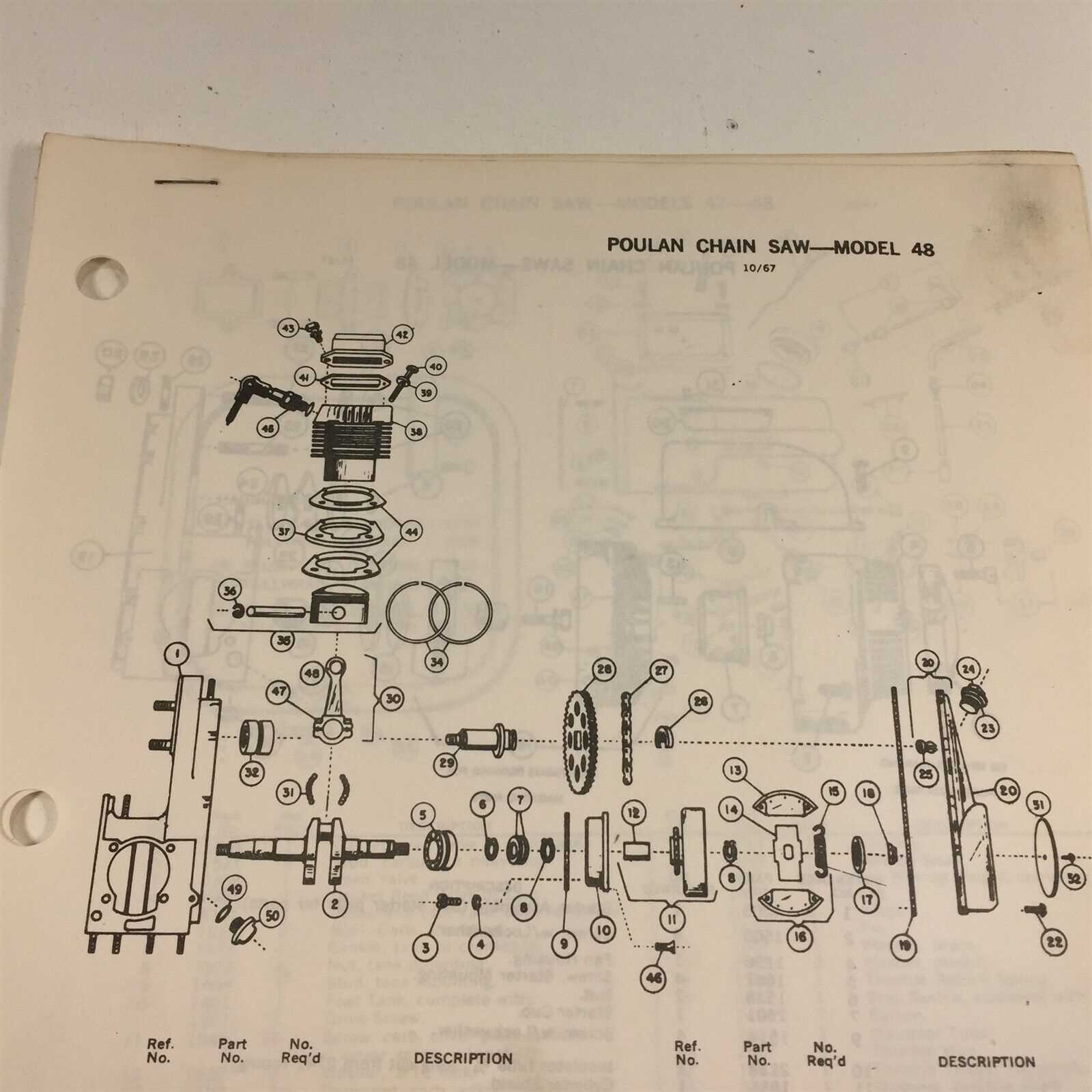

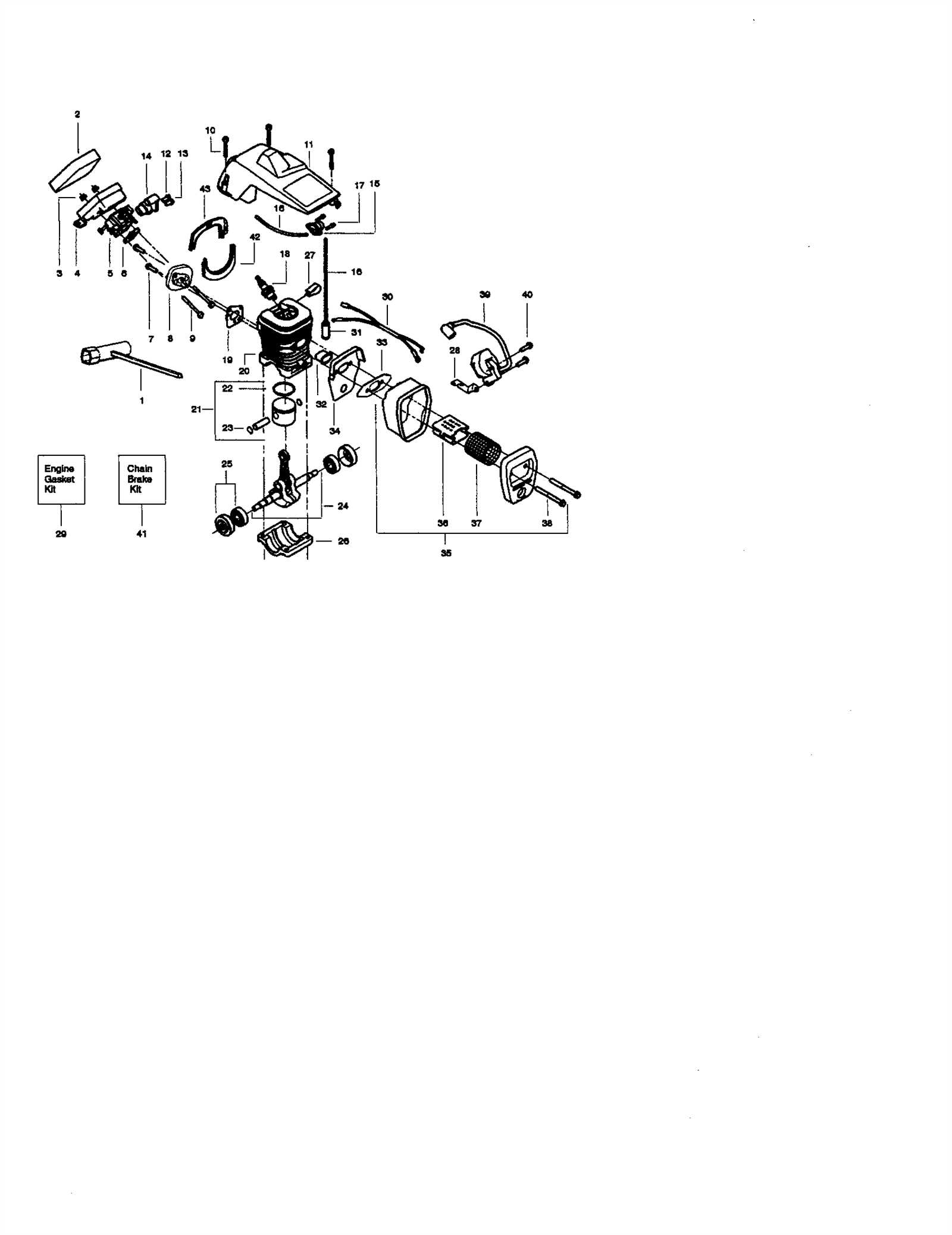

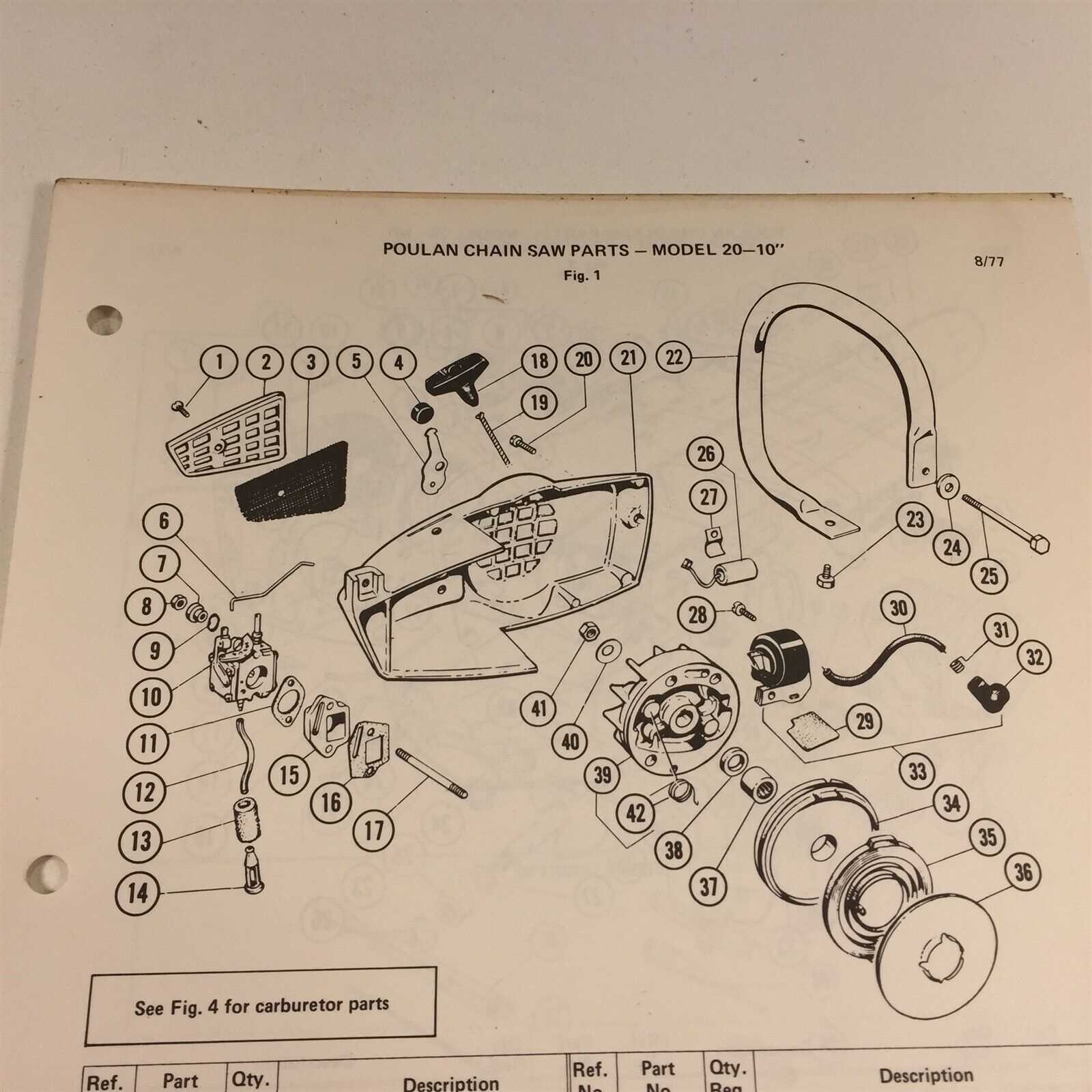

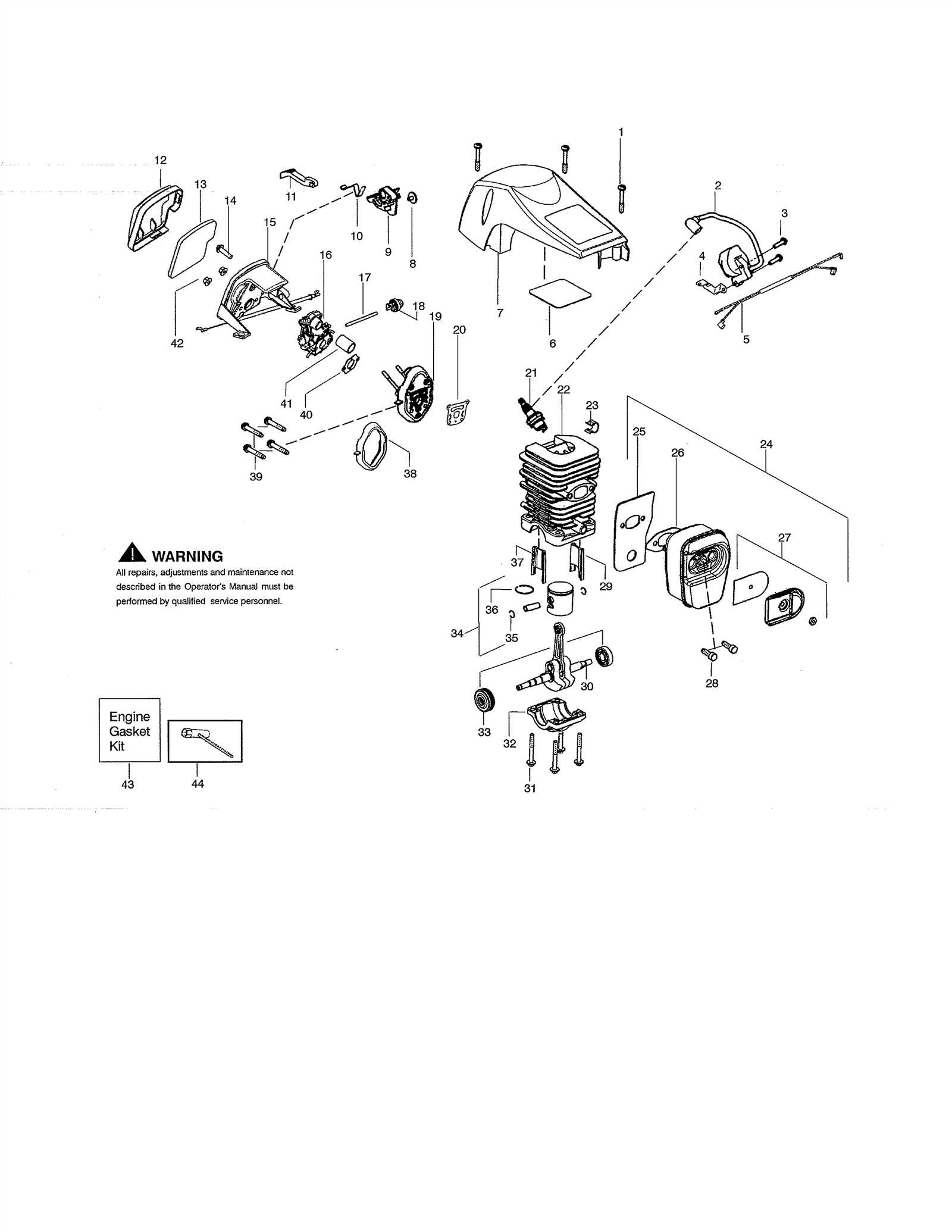

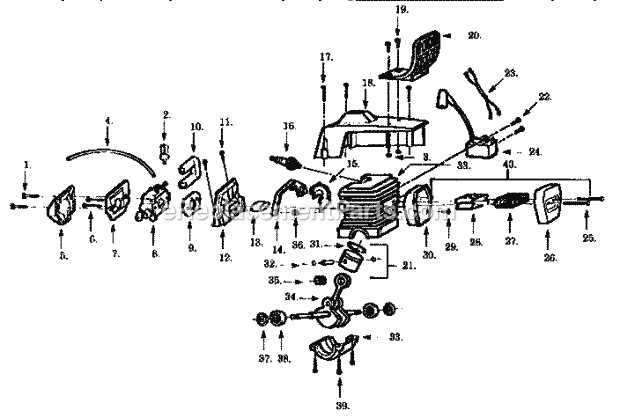

Understanding Chainsaw Parts

To effectively utilize a cutting tool, it’s essential to comprehend its individual components and their functions. Each element plays a vital role in ensuring optimal performance and safety during operation. A thorough understanding can enhance efficiency and prolong the lifespan of the equipment.

The primary section responsible for movement is the engine, which powers the entire mechanism. Additionally, the cutting blade, designed for precision, directly impacts the quality of the task at hand. Other crucial elements include the fuel system, which regulates energy supply, and the safety features that protect the user from potential hazards.

Moreover, maintenance components, such as the air filter and spark plug, are fundamental for keeping the tool in top condition. Regular checks and replacements can prevent malfunction and improve reliability. Ultimately, grasping the intricacies of each section is key to mastering the use of this essential equipment.

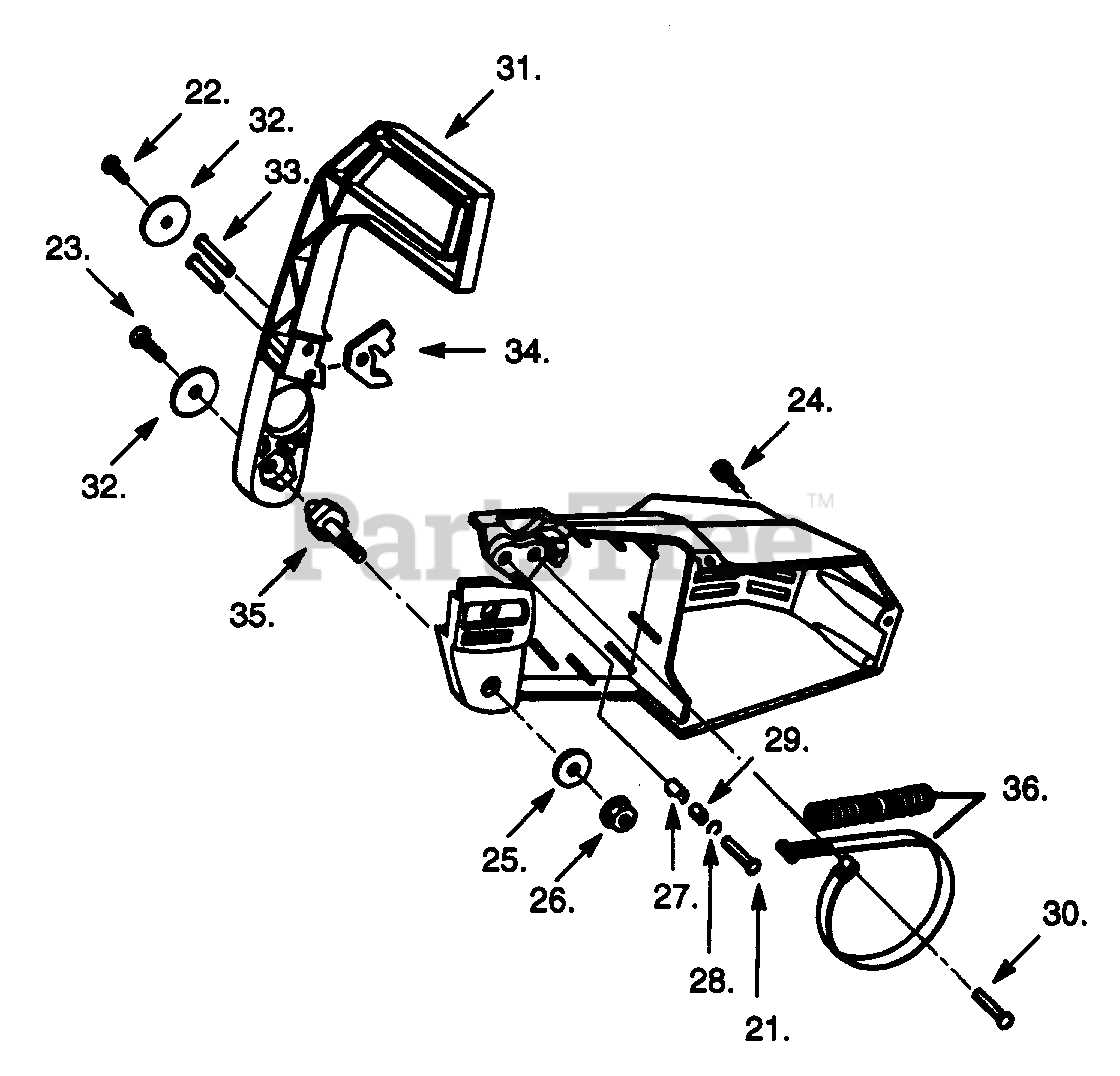

Importance of a Parts Diagram

A comprehensive visual representation of components is essential for anyone involved in maintenance or repair tasks. Such illustrations provide clarity, enabling users to identify various elements easily. This not only streamlines the repair process but also minimizes the risk of errors during assembly or disassembly.

Enhanced Understanding

Having access to a detailed schematic enhances one’s grasp of the inner workings of a machine. This knowledge empowers users to troubleshoot effectively, allowing for quicker identification of issues and more informed decision-making regarding repairs or replacements.

Efficient Repairs

Utilizing a visual guide can significantly reduce the time spent searching for specific components. It facilitates a more organized approach to repairs, ensuring that all necessary parts are accounted for. Ultimately, this leads to a smoother workflow and less frustration, making the entire process more efficient and rewarding.

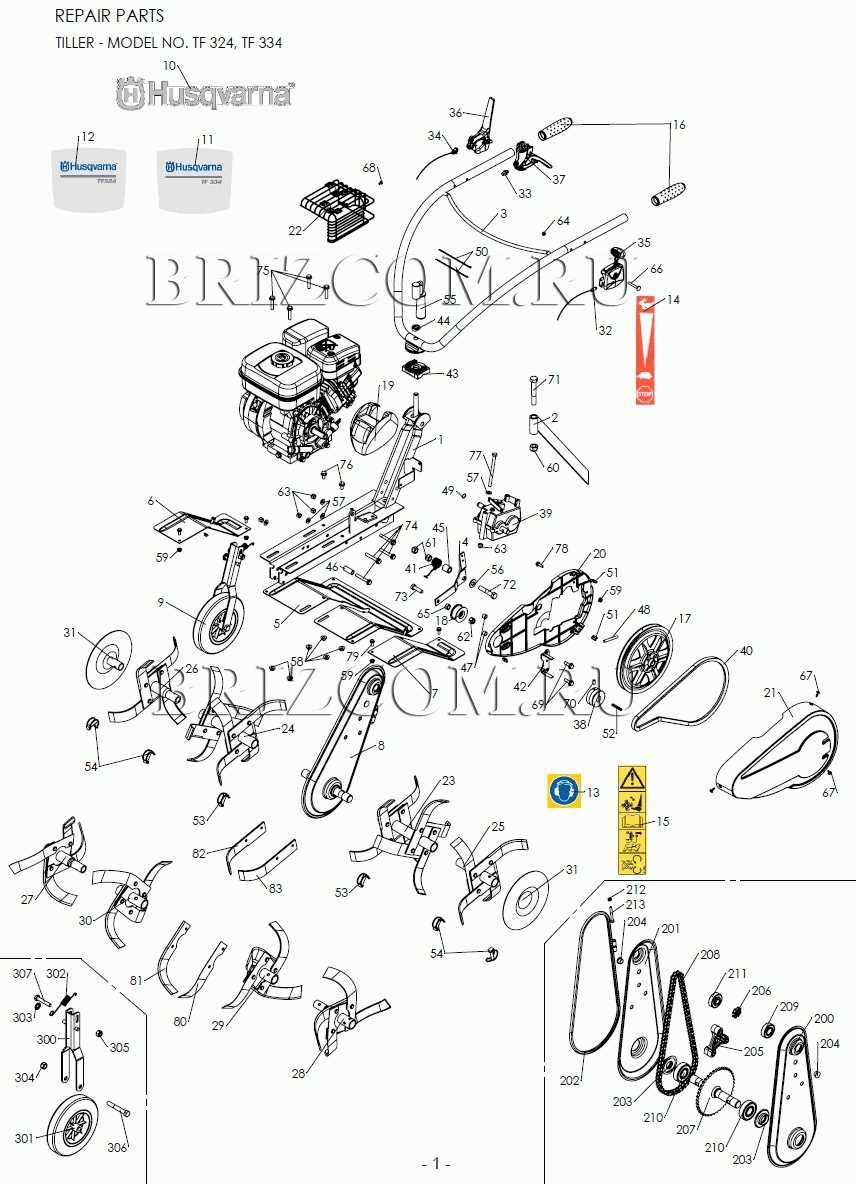

Common Replacement Parts

Maintaining equipment requires a keen understanding of essential components that often need to be replaced. Familiarity with these items ensures optimal performance and longevity of the machine.

Essential Components

- Bar and Chain: Vital for cutting efficiency and should be inspected regularly.

- Air Filter: Keeps the engine clean and functioning properly.

- Fuel Filter: Ensures clean fuel reaches the engine, preventing clogs.

- Spark Plug: Crucial for ignition; regular replacement enhances starting performance.

Wear and Tear Items

- Drive Sprocket: Should be replaced when worn to maintain cutting efficiency.

- Throttle Cable: Ensure it functions smoothly for better control.

- Oil Pump: Essential for lubricating the chain; replace if it fails to dispense oil.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your outdoor power equipment. By following specific care guidelines, you can enhance its lifespan and maintain optimal functionality, preventing unnecessary breakdowns and costly repairs.

Regular Cleaning

Keep the exterior and internal components clean from debris and residue. Cleaning helps prevent overheating and allows for efficient operation. Use compressed air or a soft brush to remove dust and dirt, ensuring all vents are unobstructed.

Routine Inspections

Conduct frequent inspections to identify wear and tear early on. Pay attention to critical parts such as filters and spark plugs. Replacing worn components promptly can prevent larger issues and extend the equipment’s overall life.

Troubleshooting Common Issues

When operating outdoor power tools, encountering malfunctions can be frustrating. Understanding the typical challenges and their solutions is essential for effective maintenance and optimal performance. This section aims to highlight prevalent problems users may face and provide straightforward troubleshooting methods to resolve them.

One common issue is difficulty starting the engine. This can often be attributed to fuel problems, such as stale gas or incorrect mixture. Ensure fresh fuel is used and check the fuel lines for blockages.

Another frequent challenge is inconsistent cutting performance. This might be caused by a dull blade or improper chain tension. Regularly inspect and sharpen the blade, and adjust the tension according to the manufacturer’s guidelines.

If the tool is producing excessive vibration, it may indicate loose components or wear. Tightening screws and examining for any damaged parts can often mitigate this issue.

Lastly, if the engine stalls during operation, it could result from overheating or air blockages. Regularly clean the air filter and allow the engine to cool down to prevent further interruptions.

Where to Buy Replacement Parts

Finding high-quality components for your outdoor equipment can significantly enhance its performance and longevity. There are several reliable sources where you can purchase the necessary items to keep your machinery running smoothly.

- Authorized Dealers: Visiting an official dealer ensures that you receive genuine components specifically designed for your model.

- Online Retailers: Websites such as Amazon, eBay, and specialized outdoor equipment sites offer a wide selection of items, often at competitive prices.

- Local Hardware Stores: Many local shops stock a variety of components and can provide personalized assistance in finding the right ones.

- Specialty Parts Suppliers: Online businesses dedicated to outdoor equipment often have extensive inventories and detailed catalogs to help you locate specific components.

When purchasing, ensure to verify compatibility with your equipment. Check reviews and ratings to confirm the quality of the items before making a decision.

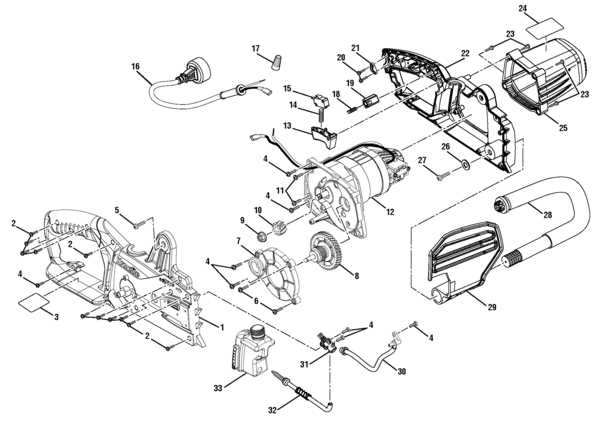

Step-by-Step Repair Guide

This guide provides a comprehensive approach to effectively address common issues encountered with a specific type of cutting tool. By following these structured steps, users can ensure optimal functionality and longevity of their equipment.

Tools and Preparation

Before beginning any maintenance or repair task, gather essential tools such as wrenches, screwdrivers, and a cleaning brush. Ensure that you have a safe workspace, free from distractions, and make sure to wear protective gear.

Inspection and Troubleshooting

Start with a thorough inspection of the device. Check for wear and tear on critical components. If you notice any discrepancies, delve into specific areas such as the ignition system or fuel lines. This will help identify the ultimate cause of the malfunction.

Safety Precautions for Users

Ensuring safety while operating power equipment is crucial to prevent accidents and injuries. Users must be well-informed about the necessary precautions to create a secure working environment. Adopting the right practices and being aware of potential hazards can significantly reduce risks.

Personal Protective Equipment

Always wear appropriate personal protective gear when handling tools. This includes gloves, eye protection, and sturdy footwear. Additionally, consider using a hard hat and hearing protection to shield yourself from potential debris and noise.

Operational Guidelines

Before starting any equipment, familiarize yourself with its features and controls. Always check the device for any signs of damage or wear. Keep the workspace clear of obstructions and ensure that bystanders maintain a safe distance. Proper handling techniques can prevent accidents and ensure efficient operation.