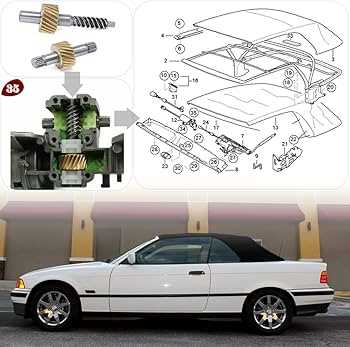

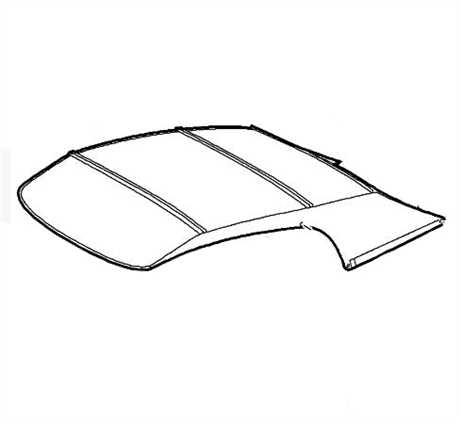

When it comes to the intricate mechanics of retractable roofs, a thorough understanding of their individual elements is essential for maintaining functionality and ensuring smooth operation. This section delves into the various components involved in the assembly and retraction processes, providing valuable insights for enthusiasts and professionals alike.

The seamless interaction between these components plays a pivotal role in the overall performance of the folding mechanism. By familiarizing oneself with the structure and function of each element, one can enhance the longevity and reliability of the system, ultimately leading to a more enjoyable driving experience.

Moreover, having a clear visual representation of these elements can significantly aid in troubleshooting common issues that may arise over time. This guide serves as a comprehensive resource for anyone looking to deepen their knowledge of convertible roof mechanisms and their maintenance.

tags: Overview of Convertible Top Mechanism

tags: Overview of Convertible Top Mechanism”>

tags: Overview of Convertible Top Mechanism”>

The mechanism responsible for the retractable cover of a vehicle plays a crucial role in ensuring both functionality and user satisfaction. Understanding how this system operates is essential for maintenance and repair, as it involves various components working in unison to facilitate smooth opening and closing actions. A well-functioning mechanism not only enhances the driving experience but also contributes to the longevity of the vehicle.

| Component | Function |

|---|---|

| Frame | Supports the structure and provides rigidity. |

| Motor | Drives the operation of the mechanism, enabling movement. |

| Linkages | Connects various parts, transferring motion throughout the system. |

| Seals | Prevents water and debris from entering the cabin. |

| Control Switch | Allows the driver to initiate the opening and closing process. |

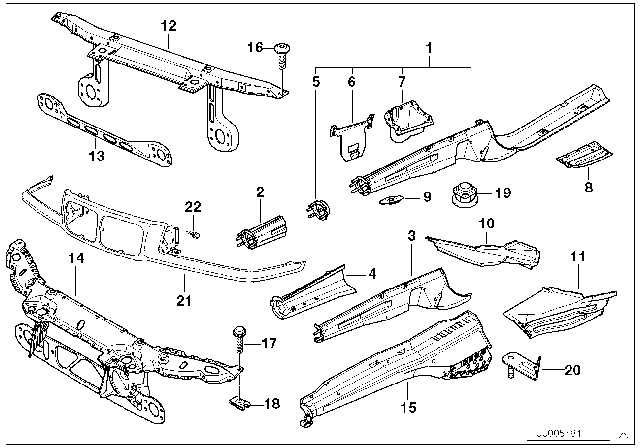

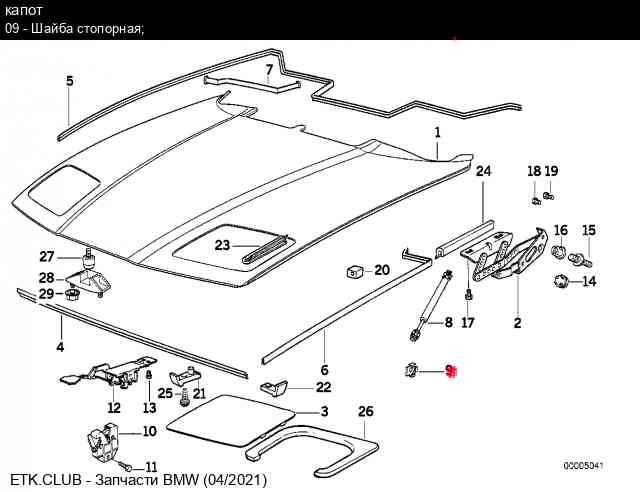

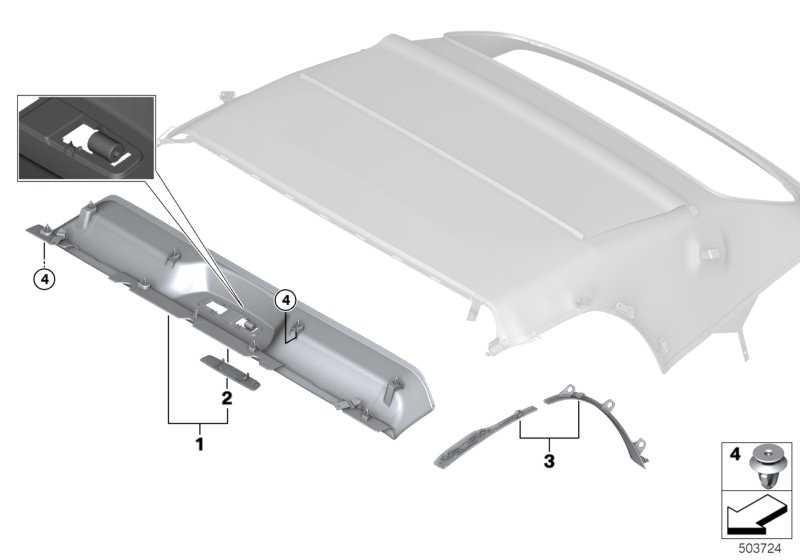

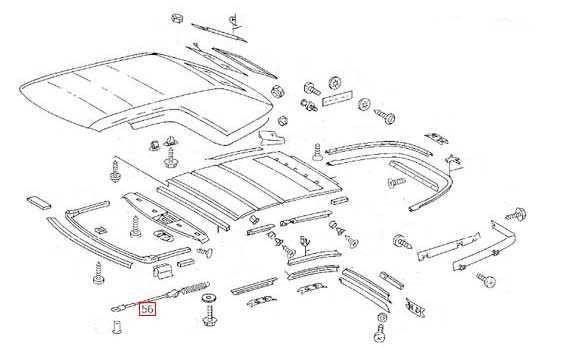

Essential Components of the Top

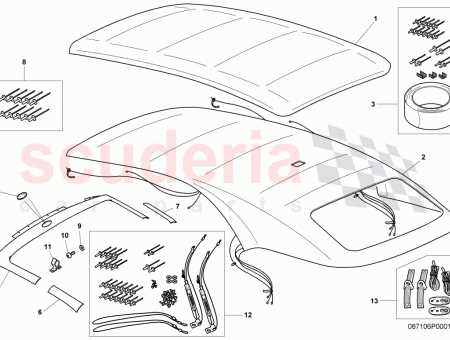

Understanding the crucial elements that make up a vehicle’s retractable covering is key to maintaining its functionality and longevity. Each component plays a significant role in ensuring the effective operation and protection of the interior, particularly against the elements.

Among the primary elements are the frame and the mechanism responsible for the opening and closing actions. The frame provides structural support, while the mechanism allows for smooth transitions between open and closed positions. Additionally, weather seals are vital for preventing water ingress and protecting against wind noise, ensuring a comfortable experience for passengers.

Another important aspect is the fabric or material used for the covering, which must be durable and resistant to various weather conditions. The use of quality materials not only enhances aesthetics but also contributes to the overall performance and lifespan of the entire assembly.

Lastly, hardware components, such as hinges and latches, are essential for securing the covering in place when closed. Regular inspection and maintenance of these components are necessary to avoid potential issues and to ensure that everything functions correctly.

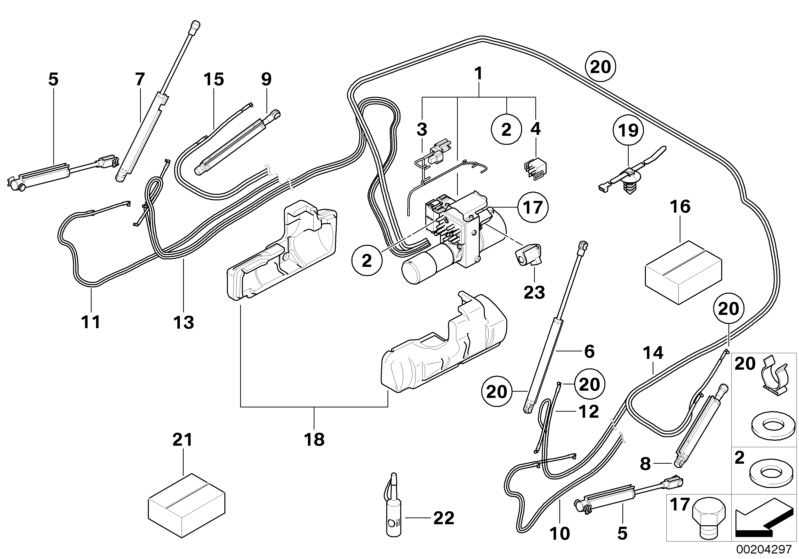

Understanding the Hydraulic System

The hydraulic mechanism plays a crucial role in the operation of various automotive functions, enabling smooth movement and control. This system uses fluid pressure to transmit force, allowing components to work together effectively. A well-functioning hydraulic system is essential for optimal performance and reliability.

Components of the Hydraulic Mechanism

- Fluid Reservoir: Holds the hydraulic fluid necessary for the system’s operation.

- Pump: Generates the pressure needed to move the fluid through the system.

- Actuators: Convert hydraulic energy into mechanical movement.

- Hoses and Fittings: Connect various components, ensuring the fluid flows smoothly between them.

Functioning of the Hydraulic System

This system operates by drawing fluid from the reservoir and sending it through the pump. The pump pressurizes the fluid, directing it to the actuators. As the fluid moves, it creates pressure that causes the actuators to function, resulting in the desired movement. Maintenance of the hydraulic fluid level and integrity is vital for preventing malfunctions.

Common Issues with Convertible Tops

Soft roofs on vehicles can encounter a variety of challenges that affect their functionality and durability. Understanding these common problems is essential for maintaining the integrity of the vehicle’s design and ensuring a smooth driving experience.

Some frequent issues include:

- Leaks: Water can seep through worn or damaged seals, leading to interior damage.

- Wear and Tear: Fabric can fray or fade over time due to exposure to the elements.

- Mechanical Failures: The lifting mechanism may become stuck or malfunction, hindering operation.

- Improper Alignment: Misalignment can prevent a snug fit, allowing air and water to enter.

- Window Seal Deterioration: The seals around the windows can degrade, causing drafts and leaks.

Regular inspections and maintenance can help prevent these issues, ensuring a longer lifespan and better performance of the vehicle’s roof system.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s mechanisms requires regular care and attention. By adopting a few essential practices, you can enhance the lifespan and performance of these components, allowing for a smooth and enjoyable driving experience. Proper maintenance not only prevents premature wear but also minimizes the need for costly repairs.

Regular Inspections

Conducting periodic assessments of the mechanical elements is crucial. Look for signs of wear, such as fraying or damage, and address any issues promptly. This proactive approach helps in identifying potential problems before they escalate, ensuring that your vehicle remains in optimal condition.

Cleaning and Lubrication

Keeping all moving parts clean and properly lubricated is vital for maintaining functionality. Use suitable cleaning agents to remove dirt and debris, and apply appropriate lubricants to reduce friction. This practice not only enhances performance but also extends the life of the components.

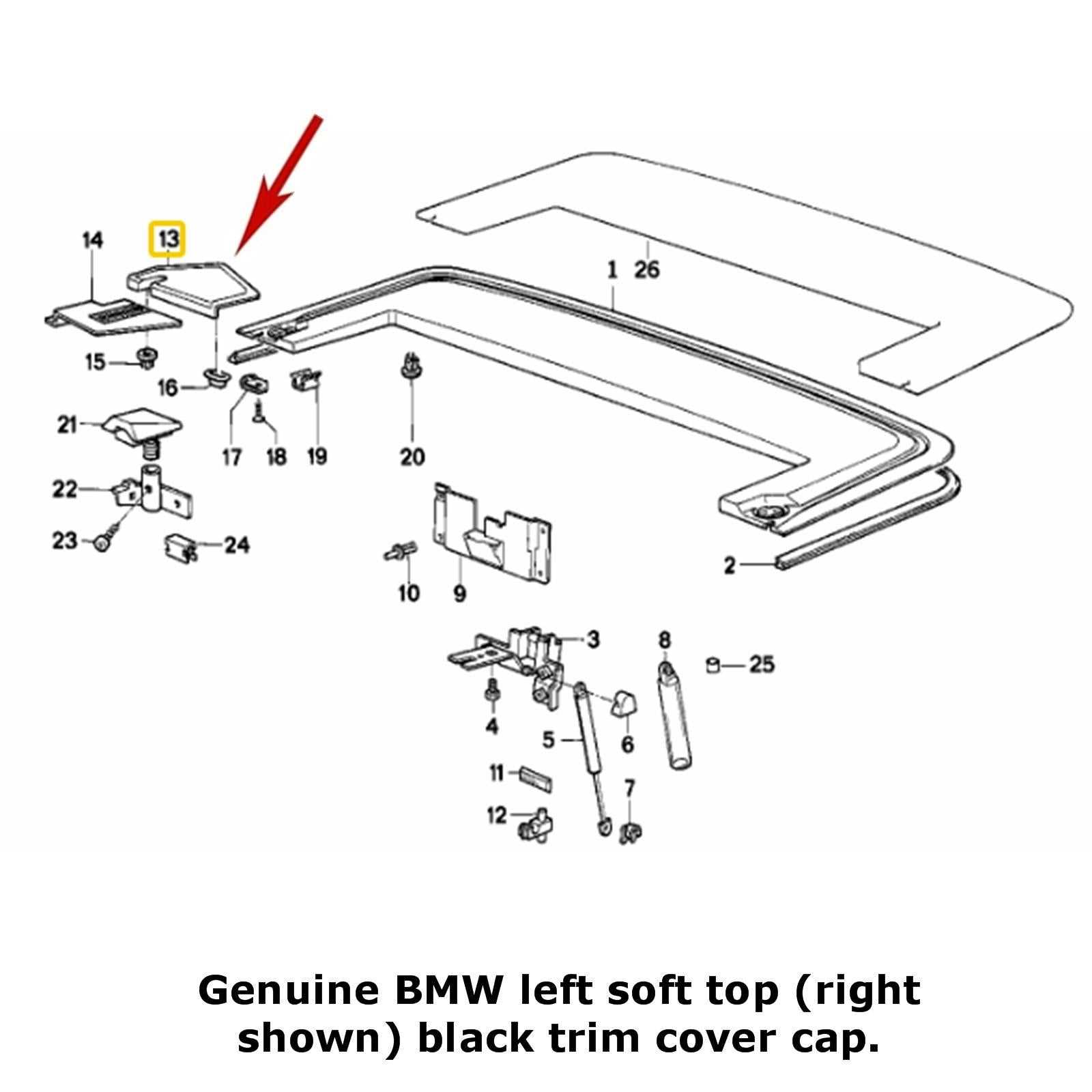

Identifying Replacement Parts Needed

When it comes to maintaining a vehicle with a retractable roof, understanding the essential components that may require replacement is crucial. A thorough assessment can help ensure that the roof mechanism operates smoothly and effectively. This section focuses on how to identify the specific elements that might need attention, allowing for a seamless restoration process.

Visual Inspection Techniques

Start by conducting a detailed visual examination of the mechanism. Look for any signs of wear, damage, or corrosion on the different components. Pay special attention to the hinges, seals, and actuators, as these are often subject to wear and tear due to their frequent use. Identifying any visible issues early can prevent more extensive damage later on.

Consulting Technical Resources

Utilizing technical manuals or online resources can provide valuable insights into the specific components related to the roof mechanism. These guides often contain diagrams and detailed descriptions of each element, assisting in identifying which pieces may need replacement. Ensure to cross-reference the information gathered with your visual inspections to create a comprehensive list of required components.

Tools Required for Repairs

When undertaking maintenance or repair tasks, having the right tools at your disposal is crucial for ensuring efficiency and precision. This section outlines essential instruments that will facilitate the process, making it smoother and more manageable. Familiarizing yourself with these tools can significantly enhance your ability to carry out repairs effectively.

Essential Instruments

The following instruments are commonly used for various maintenance tasks:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts |

| Wrenches | For gripping and turning fasteners |

| Screwdriver Set | For driving screws into place |

| Torque Wrench | For applying precise torque to fasteners |

| Pliers | For gripping, twisting, and cutting wires |

Additional Tools

In addition to the essential instruments, having the following items can further assist in performing repairs:

| Tool | Purpose |

|---|---|

| Multimeter | For measuring electrical current and voltage |

| Wire Cutters | For cutting electrical wires |

| Safety Glasses | For eye protection during repairs |

| Gloves | For hand protection while working |

| Flashlight | For illumination in dark areas |

Installation Guide for New Parts

When upgrading or replacing components of your vehicle’s structure, proper installation is crucial for ensuring functionality and longevity. This guide outlines the essential steps for fitting new elements effectively.

Before beginning the installation process, gather all necessary tools and components. A well-organized workspace will help streamline the procedure and reduce potential errors.

- Required Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches (various sizes)

- Pliers

- Torque wrench

- Jack and jack stands

- Safety Equipment:

- Gloves

- Safety goggles

- Work apron

Follow these steps to ensure a smooth installation:

- Prepare the Vehicle:

Ensure the vehicle is parked on a level surface and secured. Use jack stands for added safety.

- Remove Old Components:

Carefully detach any existing elements that need replacement. Keep track of screws and brackets for reinstallation.

- Install New Components:

Align the new elements properly and secure them using the original screws and brackets. Follow manufacturer instructions where applicable.

- Check for Proper Fit:

Verify that everything is aligned correctly. Make adjustments as needed to ensure a snug fit.

- Test Functionality:

Once installed, test the components to confirm they are operating as intended. Look for any unusual sounds or movements.

By adhering to this installation guide, you can enhance your vehicle’s structure while ensuring safety and performance. Always consult with professionals if uncertain about any steps in the process.

Safety Considerations During Work

Ensuring a safe working environment is crucial when handling mechanical components and systems. It is essential to adopt proper precautions to minimize the risk of injury or accidents. Understanding the equipment and following safety protocols will help in creating a secure workspace.

Before commencing any maintenance or repair tasks, it is important to gather all necessary tools and safety gear. This includes gloves, goggles, and protective clothing. Familiarizing yourself with the operating instructions and safety warnings related to the specific equipment is also vital.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from sharp edges and chemicals |

| Goggles | Shield eyes from debris and harmful substances |

| Protective Clothing | Prevent skin injuries and exposure to hazardous materials |

Additionally, keeping the workspace clean and organized can prevent accidents. Regularly inspecting tools and equipment for any damage will further enhance safety. If any issues are detected, it is imperative to address them before proceeding with any tasks.

FAQs About E36 Convertible Tops

This section addresses common inquiries regarding the mechanisms and components of retractable roofs. Understanding these elements is essential for enthusiasts and owners alike, as they play a significant role in the performance and maintenance of the vehicle.

What are the typical issues encountered with retractable roofs? Various challenges can arise, including wear and tear of fabric, malfunctioning motors, or problems with the hydraulic system. Regular inspections can help identify these issues early.

How can I maintain the mechanism of my retractable roof? Proper maintenance includes regular cleaning, lubricating moving parts, and ensuring that seals are intact to prevent water leaks. Consulting the user manual for specific guidelines is advisable.

Where can I find replacement components for the roof mechanism? Replacement components can typically be sourced from specialized auto parts retailers, online marketplaces, or authorized service centers that focus on vintage models.

Can I perform repairs on the roof system myself? While some repairs can be DIY, others may require professional assistance, especially when dealing with electrical or hydraulic systems. It’s crucial to assess your skill level before attempting significant repairs.

How often should I inspect the roof components? Routine inspections are recommended at least twice a year or before the start of the driving season. This helps ensure all parts are functioning correctly and can prevent larger issues down the line.