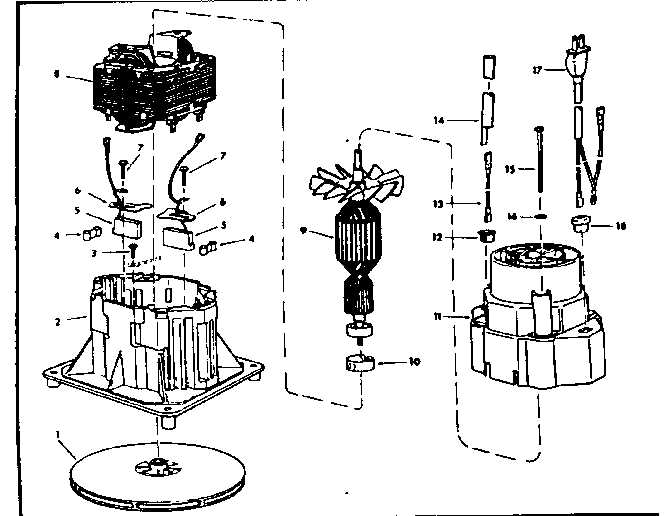

Understanding the various elements that make up a powerful cleaning machine can greatly enhance its efficiency and lifespan. Whether it is used for tackling heavy debris or more delicate cleanup tasks, knowing how each section fits together ensures smoother operation and easier maintenance. This guide delves into the intricate layout of a high-capacity cleaning tool, breaking down its key elements.

From the intricate motor assembly to the specially designed filters, each component plays a vital role in delivering effective performance. Learning the arrangement and purpose of these elements allows users to maintain the equipment properly, ensuring that it remains functional and reliable over time. This overview will help you identify the crucial elements and understand their functions, contributing to a more effective maintenance routine.

By gaining a deeper insight into the internal structure, users can better diagnose issues and replace specific elements when needed. This not only extends the service life of the device but also helps in achieving optimal performance in different cleaning scenarios. Explore how each section contributes to the seamless operation of this versatile tool.

Understanding the 16 Gallon Shop Vac

This powerful cleaning tool is designed for those who need a reliable solution for managing both wet and dry debris. Its robust structure and efficient motor make it suitable for various environments, from garages to workshops. The device offers versatility and durability, ensuring effective performance during demanding tasks.

Key Features of the Cleaning Device

The unit comes equipped with a high-capacity container that allows users to handle large volumes of waste without frequent emptying. Its motor provides strong suction power, making it easy to handle different types of messes. Additionally, the design includes features that facilitate mobility, such as sturdy wheels and a handle, allowing users to maneuver it effortlessly across various surfaces.

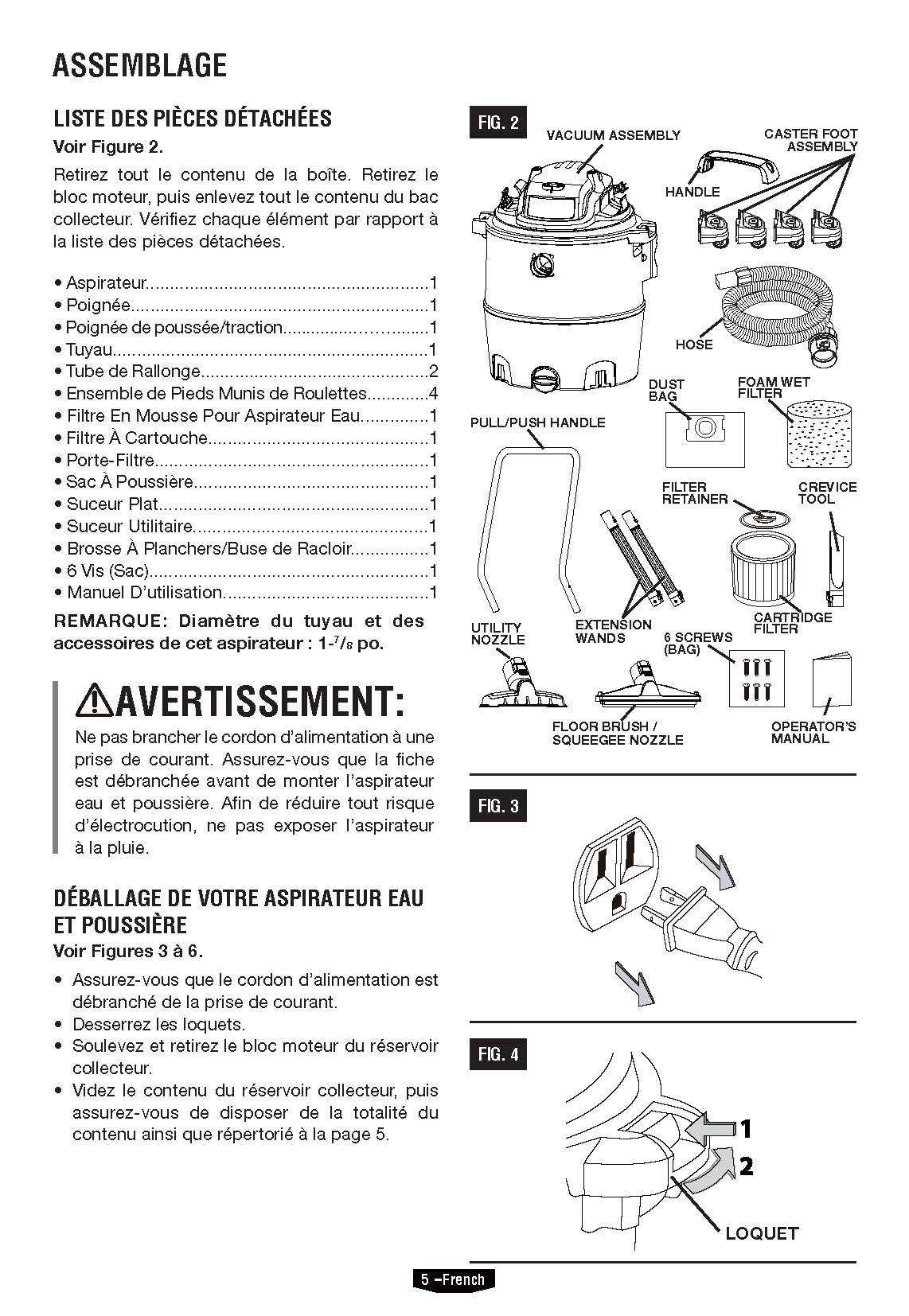

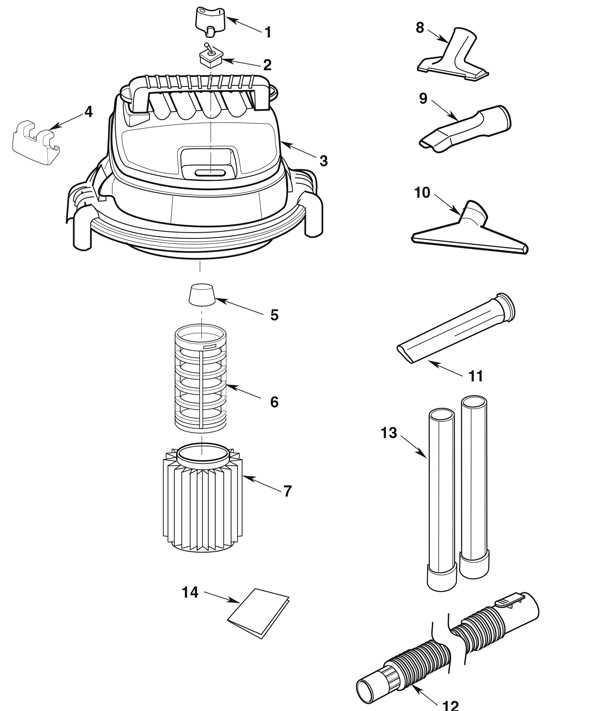

Essential Components and Accessories

To enhance its functionality, the cleaner is compatible with a range of attachments, such as nozzles for narrow spaces and brushes for delicate surfaces. Each accessory serves a specific purpose, making it possible to adapt the tool for detailed cleaning tasks. These add-ons extend the capability of the device, making it a versatile choice for multiple applications.

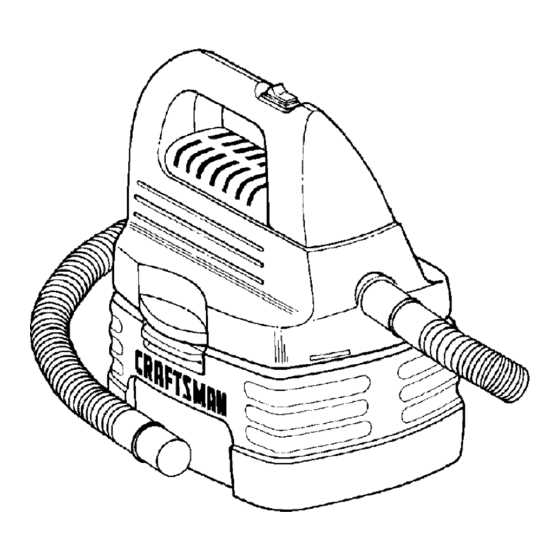

Key Features of the Craftsman Vacuum

The model offers several qualities that make it a reliable choice for diverse cleaning needs. It is designed to tackle a wide range of tasks, from removing dust in tight spaces to handling heavier debris in larger areas. The following aspects highlight what sets it apart.

Powerful Suction and Versatility

Equipped with a robust motor, this device provides strong airflow, ensuring effective collection of various materials. Its design allows for adaptability, making it suitable for use on different surfaces, both wet and dry. This flexibility is especially beneficial for users needing a solution that can handle unexpected spills or regular upkeep.

Durable Construction and User-Friendly Design

Constructed with longevity in mind, the unit features a tough exterior that withstands frequent use in demanding environments. Additionally, the ergonomic handle and maneuverable wheels enhance mobility, allowing users to transport it easily from one location to another. Its design also simplifies storage when not in use, helping to save space.

| Feature | Description | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Power | High-performance engine ensures consistent performance in various conditions. | |||||||||||||||||||||||||||||||

| Filtration System | Includes advanced filters

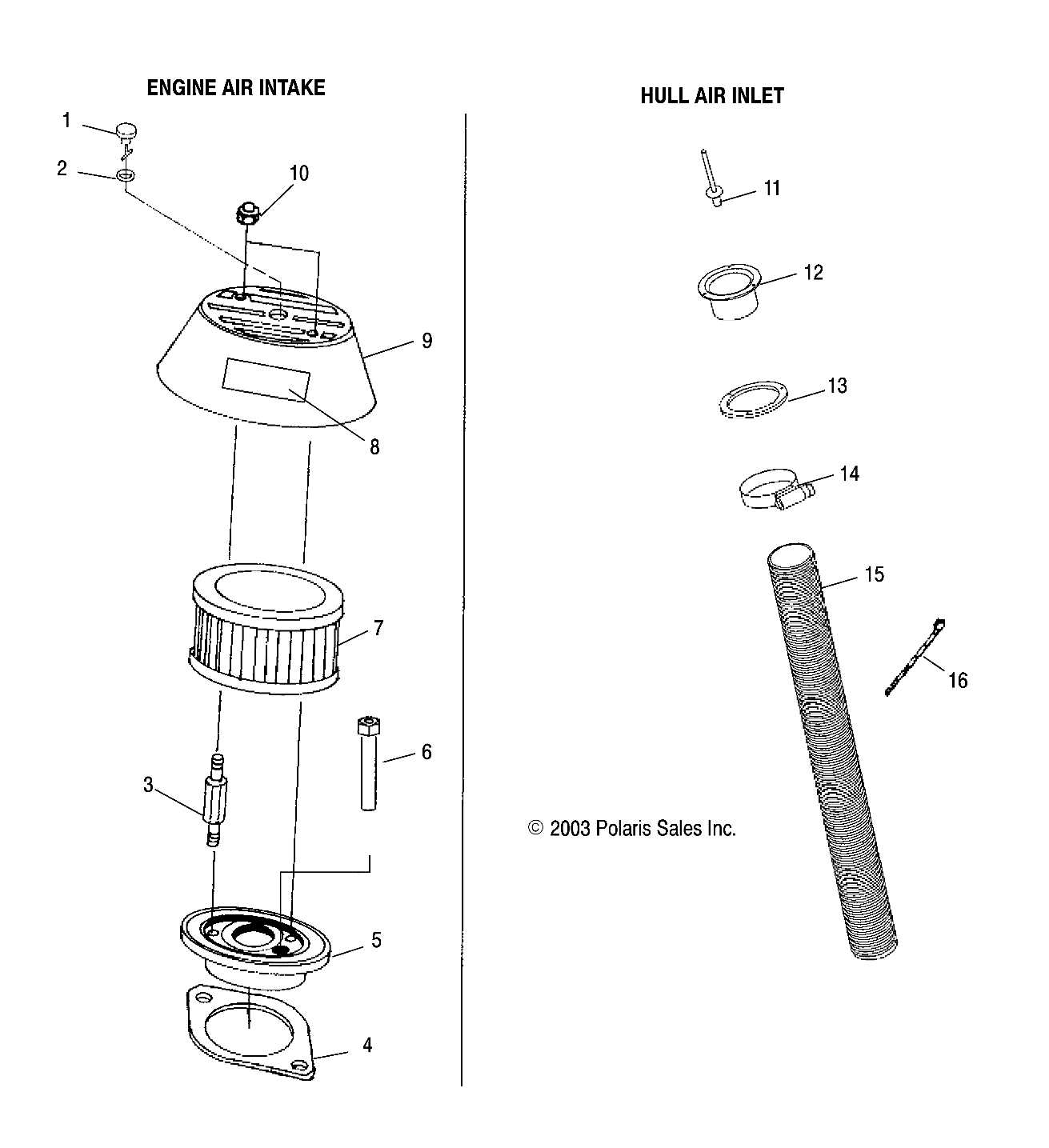

Exploring Different Components of the DeviceThe device in question consists of various interconnected elements, each playing a crucial role in its functionality. Understanding how these components work together can provide insights into maintaining and optimizing its performance. Below is a closer look at the essential elements that make this tool effective in handling its tasks. Main StructureThe core structure forms the foundation, offering a sturdy base for other elements. This includes a durable outer shell that houses the internal systems. The structure is designed to withstand external impacts and protect the internal components from damage. Functional AttachmentsSeveral attachments enhance the versatility of the equipment, allowing it to handle different situations. These include extensions for reaching narrow areas and specialized connectors that enable better adaptability for various tasks. The use of these attachments ensures that the device can perform efficiently in multiple scenarios.

|