When it comes to maintaining and operating heavy lifting equipment, a comprehensive grasp of its internal structure is essential. This knowledge not only enhances efficiency but also ensures safety during use. By exploring the various components involved, users can optimize performance and prolong the lifespan of the equipment.

Identifying each element within the mechanism allows for targeted troubleshooting and repairs. Whether you’re looking to replace worn-out pieces or simply understand how everything works together, a clear visualization of these components is invaluable. Engaging with the intricate details fosters confidence and competence in handling the machinery.

In this section, we’ll delve into the essential elements that make up your lifting device. We’ll provide insights into their functions, interconnections, and maintenance tips, helping you make informed decisions and ensuring your equipment operates at its ultimate best.

Understanding Craftsman Floor Jack Components

When working with hydraulic lifting tools, it’s essential to grasp the various elements that ensure optimal performance and safety. Each component plays a crucial role in the overall functionality, contributing to a seamless lifting experience.

Key Elements of the Lifting Tool

- Chassis: The base structure providing stability.

- Pump Mechanism: Responsible for generating pressure to lift loads.

- Ram: The cylinder that elevates the lifted object.

- Release Valve: Controls the descent of the load.

Importance of Maintenance

Regular inspection and upkeep of these components are vital for longevity and safety. Users should:

- Check for hydraulic fluid levels.

- Inspect for leaks or damage.

- Ensure moving parts are lubricated.

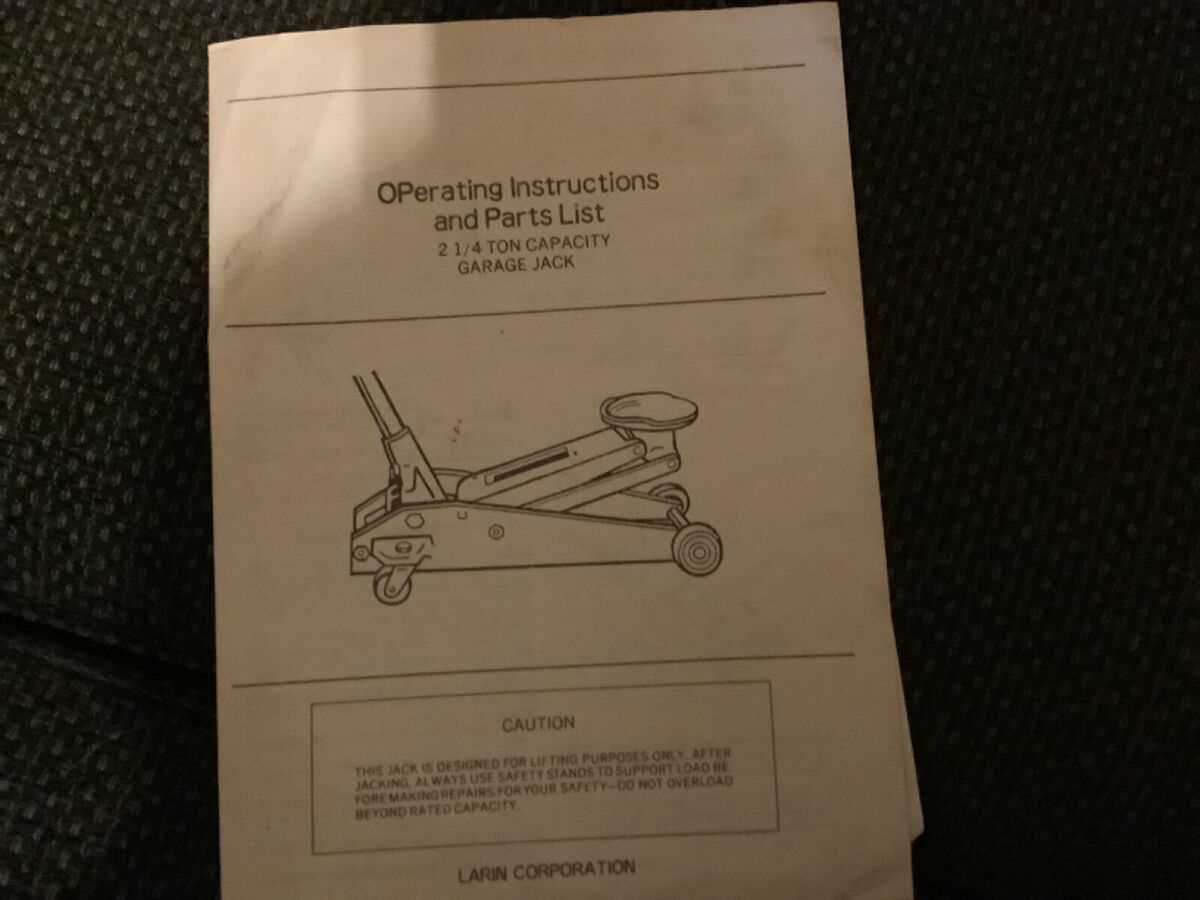

Overview of Craftsman 2 Ton Jack

This section provides an insight into a reliable lifting tool designed for various automotive and household tasks. Engineered for efficiency, it is essential for safely raising heavy objects with minimal effort. The design emphasizes durability, ensuring that users can depend on its performance for both routine maintenance and emergency situations.

Constructed with high-quality materials, this apparatus features a robust hydraulic system that allows for smooth operation. Its compact size makes it convenient for storage while still offering impressive lifting capabilities. This tool is particularly useful for anyone who frequently engages in vehicle repairs or upgrades, providing peace of mind during heavy lifting activities.

Additionally, the lifting mechanism is complemented by safety features that enhance user protection. Understanding the components and their functions is crucial for optimal usage and maintenance, ensuring longevity and reliability. Familiarity with this equipment promotes a safer and more efficient working environment.

Key Features of the Floor Jack

This section highlights the essential characteristics of a lifting device commonly used for maintenance tasks. Understanding these features is crucial for selecting the right model to meet various needs in automotive or heavy machinery applications.

Stability and Safety

Stability is a paramount consideration, ensuring that the equipment remains secure while lifting heavy loads. Safety features often include rubber pads or grip surfaces that prevent slipping and enhance overall performance.

Hydraulic System

The hydraulic mechanism is a core component that allows for efficient lifting. This system typically comprises several elements that work together to provide smooth operation and durability.

| Feature | Description |

|---|---|

| Load Capacity | Indicates the maximum weight the device can lift safely. |

| Height Range | Specifies the minimum and maximum height levels achievable. |

| Material Quality | Construction materials that affect durability and weight. |

| Portability | Design features that enhance mobility and ease of use. |

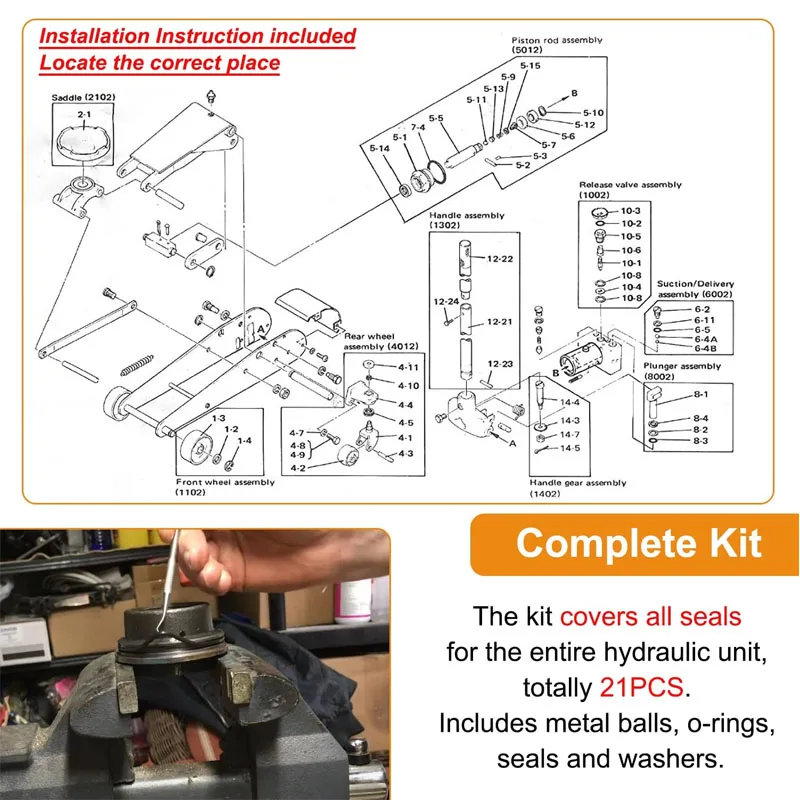

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding how various elements interact within a mechanical system. This clarity helps users identify specific sections that may require maintenance or replacement, ensuring optimal performance and longevity of the equipment.

Having a detailed illustration fosters efficiency in repairs, as it allows for quicker identification of necessary items, reducing downtime. Furthermore, it enhances communication among technicians, making it easier to discuss issues and solutions.

Ultimately, a well-structured visual guide not only simplifies troubleshooting but also empowers users to take proactive steps in equipment care, leading to safer and more reliable operation.

Identifying Main Parts of the Jack

Understanding the key components of a lifting device is essential for effective operation and maintenance. Each element plays a crucial role in ensuring safety and functionality. Familiarizing yourself with these main features will enhance your ability to use and care for the equipment properly.

Key Components

At the heart of the mechanism lies the hydraulic cylinder, responsible for generating the lifting force. This component relies on fluid pressure to elevate heavy loads efficiently. Adjacent to the cylinder is the pump handle, which users operate to activate the lifting process. Properly maintaining these elements is vital for optimal performance.

Support Structure

The base frame provides stability during operation, ensuring that the device remains securely positioned while lifting. The wheels facilitate easy maneuverability, allowing users to reposition the apparatus with minimal effort. Recognizing and caring for these structural elements can significantly prolong the lifespan of the equipment.

Common Issues with Floor Jacks

When working with lifting equipment, various challenges can arise that affect performance and safety. Understanding these issues is crucial for ensuring proper function and longevity.

Frequent Problems

- Hydraulic Fluid Leaks

- Insufficient Lifting Height

- Unstable Base

Maintenance Tips

- Regularly check and replace hydraulic fluid.

- Inspect seals and connections for wear.

- Store on a level surface to prevent instability.

How to Read a Parts Diagram

Understanding an illustration that details the components of a mechanism is essential for effective maintenance and repair. These visuals provide a clear representation of each element, allowing users to identify and source necessary replacements efficiently.

Key Elements to Identify

When examining the schematic, pay attention to various features that can aid in your comprehension:

| Element | Description |

|---|---|

| Labels | Markings that indicate specific parts, often with numbers or letters. |

| Lines | Connecting lines that show how components interact or fit together. |

| Legend | A guide that explains symbols used within the illustration. |

Practical Tips for Use

To maximize the utility of the visual guide, cross-reference it with a service manual for detailed instructions. This practice ensures you have the ultimate understanding of the assembly and enhances your repair skills.

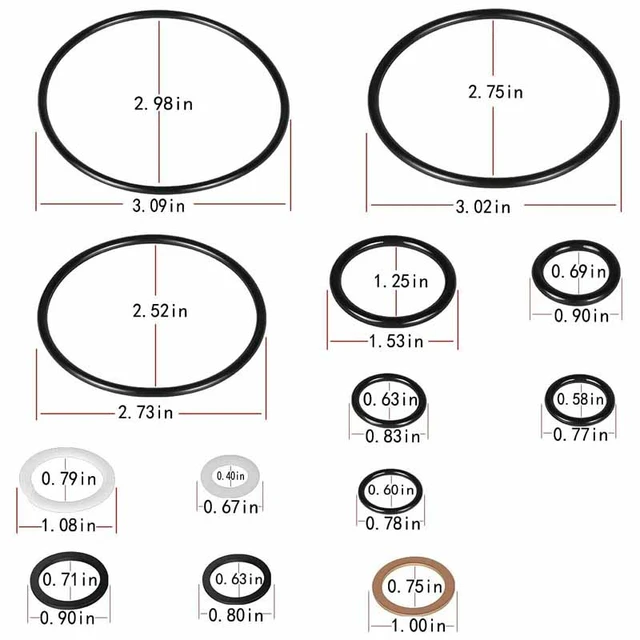

Replacing Worn-Out Components

Maintaining the integrity of your lifting equipment is essential for ensuring safety and optimal performance. Over time, certain elements may become less effective due to wear and tear. Regular inspections and timely replacements can enhance functionality and extend the lifespan of your tools.

Identifying Components That Need Replacement

Begin by thoroughly examining your equipment for signs of damage. Look for cracks, leaks, or unusual noises during operation. Components such as seals, hydraulic fluid, and structural parts may require attention. Keeping an eye on these indicators helps prevent further damage and ensures smooth operation.

Steps for Replacement

Once you’ve identified the components needing replacement, gather the necessary tools and materials. Carefully disassemble the affected sections, following the manufacturer’s guidelines. Take care to dispose of any worn-out parts properly. After installing the new components, perform a thorough check to ensure everything is functioning correctly. This proactive approach not only boosts performance but also enhances safety during use.

Maintenance Tips for Longevity

Ensuring the durability and performance of your lifting equipment requires regular attention and care. Adopting a consistent maintenance routine can significantly extend the lifespan of your tools while enhancing their efficiency. Here are some essential practices to keep in mind.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for leaks | Monthly | Check hydraulic fluid levels and look for any signs of leakage. |

| Clean and lubricate | Every three months | Ensure moving parts are free of dirt and grime; apply appropriate lubricants. |

| Tighten bolts and screws | Every six months | Loose components can affect performance and safety; regularly check connections. |

| Store properly | After each use | Keep in a dry, cool area to prevent rust and damage. |

| Check for rust | Monthly | Inspect surfaces for corrosion and treat immediately if found. |

Implementing these practices will not only enhance the reliability of your equipment but also contribute to safer operation. Regular maintenance ensures your tools are ready for use whenever needed.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is essential for a successful outcome. Proper tools not only enhance efficiency but also ensure safety during the repair process.

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: A set including both flathead and Phillips for versatility.

- Pliers: Essential for gripping, twisting, and cutting wires or other materials.

- Socket set: For easier handling of bolts and nuts in tight spaces.

- Rubber mallet: Useful for adjusting parts without causing damage.

- Safety gear: Gloves and goggles to protect yourself during repairs.

Having these tools on hand will streamline your repair efforts and help you tackle any issues that arise effectively.

Where to Find Replacement Parts

Locating the right components for your lifting equipment can enhance its functionality and extend its lifespan. Various sources are available to help you acquire the necessary items for repairs or upgrades. Whether you’re seeking online retailers, local hardware stores, or specialized suppliers, each option has its advantages.

Online marketplaces often offer a wide selection, allowing you to compare prices and read reviews. Websites dedicated to equipment and tools may also have specific listings tailored to your needs. Local stores, on the other hand, provide the benefit of immediate availability and personal assistance. Additionally, consider checking with the manufacturer or authorized dealers for authentic replacements, ensuring compatibility and quality.

Lastly, don’t overlook community forums and groups where enthusiasts share resources and recommendations. By exploring these avenues, you can confidently find the components required to keep your equipment in top condition.

DIY Repair vs. Professional Help

When faced with mechanical issues, individuals often grapple with the decision to tackle repairs independently or seek external expertise. Each option presents distinct advantages and challenges, influencing the overall outcome and experience of the repair process.

Benefits of DIY Repair

Taking on repairs yourself can foster a sense of accomplishment and enhance your skill set. With the right resources, such as manuals and online tutorials, you can often save money and time. However, this approach demands a solid understanding of the mechanics involved and a commitment to safety.

Advantages of Professional Assistance

Enlisting the help of a professional ensures that repairs are conducted with expertise and efficiency. Experts possess the necessary tools and knowledge to diagnose issues accurately, potentially preventing further damage. While this option may involve higher costs, the peace of mind it offers can be invaluable.

Safety Precautions When Using Jacks

When working with lifting equipment, it is essential to prioritize safety to prevent accidents and injuries. Proper handling and awareness of the equipment’s capabilities and limitations can make a significant difference in ensuring a secure working environment.

Always inspect the equipment before use. Check for any signs of wear, damage, or malfunction. This includes examining hydraulic systems, wheels, and lifting mechanisms. If any issues are detected, do not use the equipment until it is repaired or replaced.

Ensure a stable surface before positioning the equipment. It is crucial to use the device on a flat, solid ground to avoid slippage or tipping. Avoid using it on uneven terrain or soft surfaces that may compromise stability.

Use appropriate supports when lifting heavy loads. Always utilize safety stands or blocks to secure the load after lifting. Relying solely on lifting equipment for support can lead to catastrophic failure.

Maintain a clear workspace around the lifting area. Ensure that no one is within the danger zone while the equipment is in operation. Communicate effectively with all individuals nearby to prevent misunderstandings.

Follow weight limits specified by the manufacturer. Overloading the equipment can lead to mechanical failure and serious injury. Always double-check the weight of the item being lifted.

Wear appropriate personal protective equipment (PPE) during operation. This may include gloves, safety glasses, and steel-toed boots to safeguard against potential hazards.

By adhering to these safety guidelines, users can minimize risks and enhance their overall lifting experience.