When working with power equipment, familiarity with its intricate elements can greatly enhance performance and maintenance. Each mechanism plays a vital role, contributing to the overall efficiency and longevity of the device.

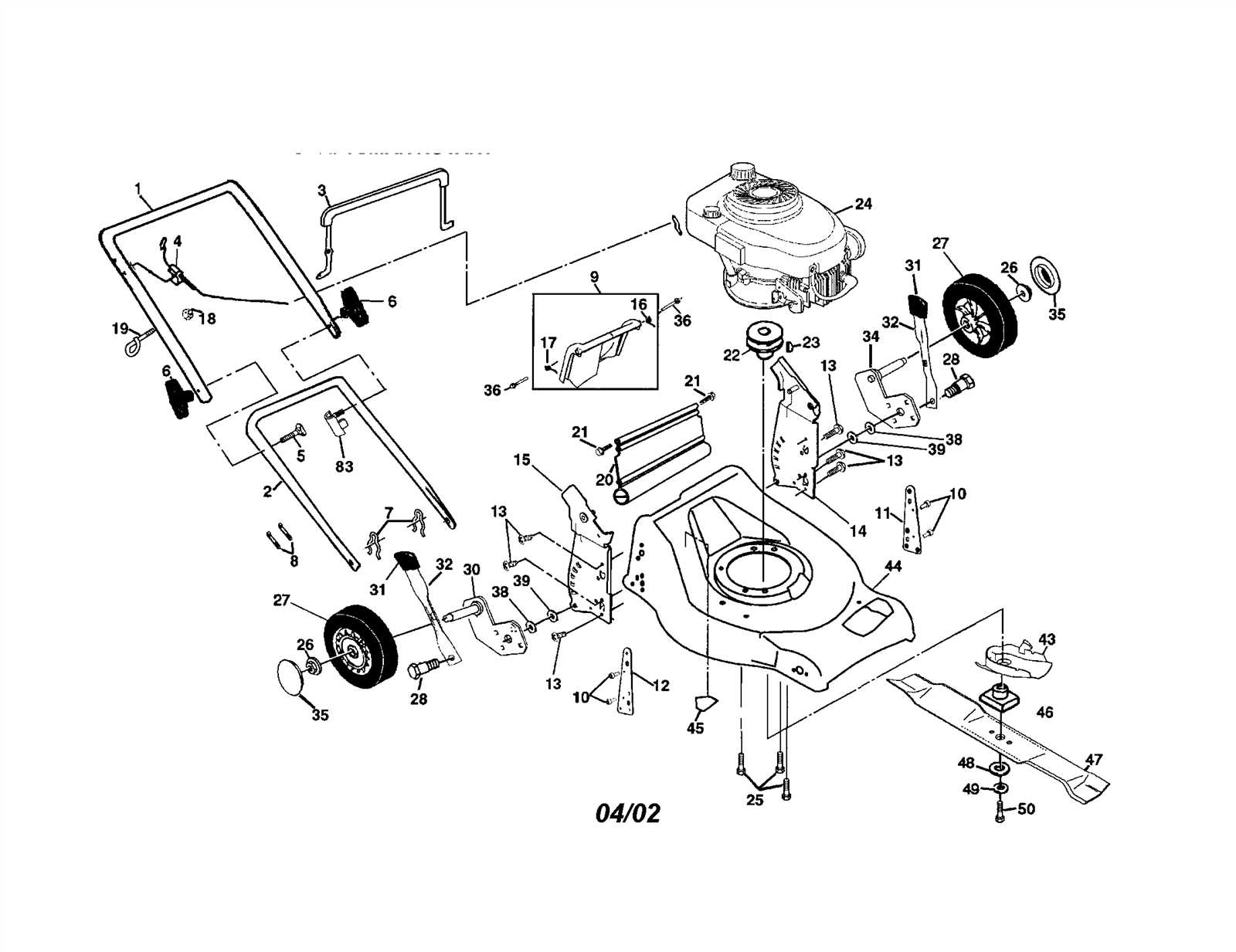

Having a clear visual representation of these individual pieces allows users to pinpoint issues quickly and streamline repairs. By examining the layout and functions of these components, one can delve into the intricacies of the machinery.

Ultimately, mastering this knowledge not only facilitates effective troubleshooting but also empowers enthusiasts to undertake DIY projects with confidence. This exploration opens doors to a deeper appreciation of the craftsmanship involved in these essential tools.

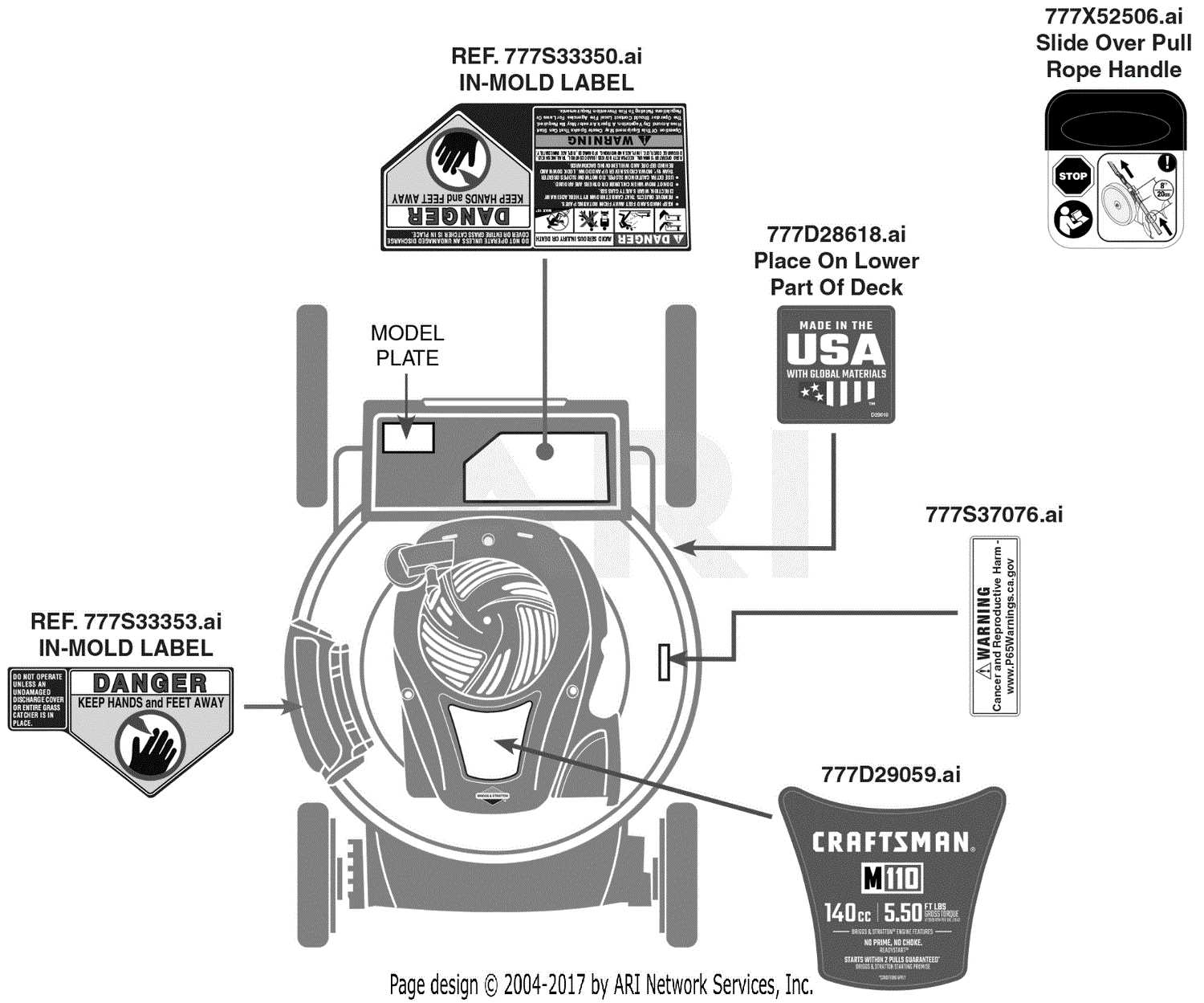

Understanding the Craftsman M110

When it comes to lawn maintenance equipment, having a clear grasp of how various components function together can significantly enhance performance and longevity. This knowledge allows users to troubleshoot issues effectively and ensure optimal operation throughout the seasons. Exploring the intricacies of a particular model can illuminate its design and usability, making it easier to navigate any challenges that arise during its use.

Each element of this equipment plays a pivotal role in its overall functionality. From the engine that powers it to the cutting mechanisms that deliver precise results, understanding the interaction between these components is essential. Familiarity with the arrangement and purpose of each part empowers users to maintain their device more efficiently and to address potential problems before they escalate.

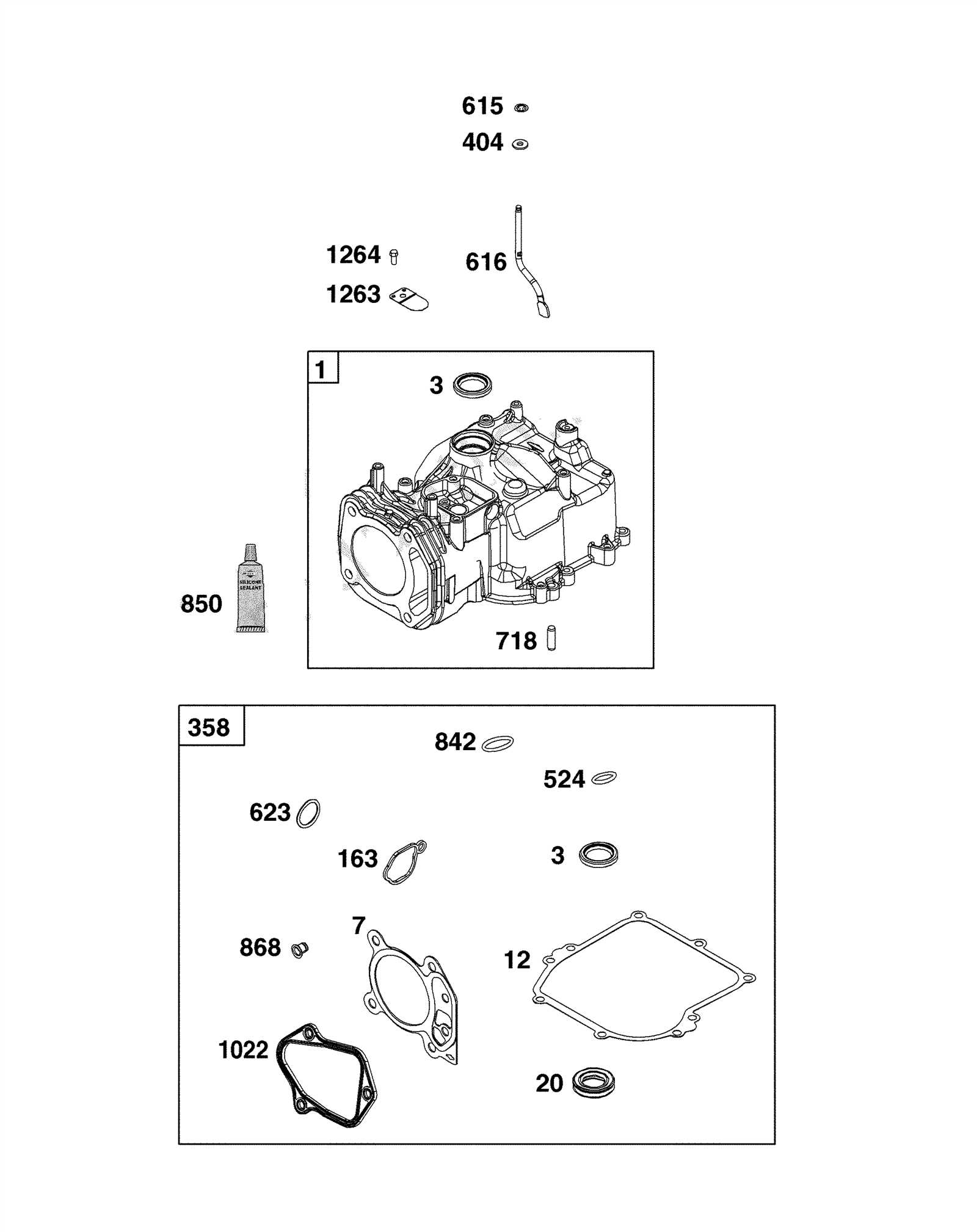

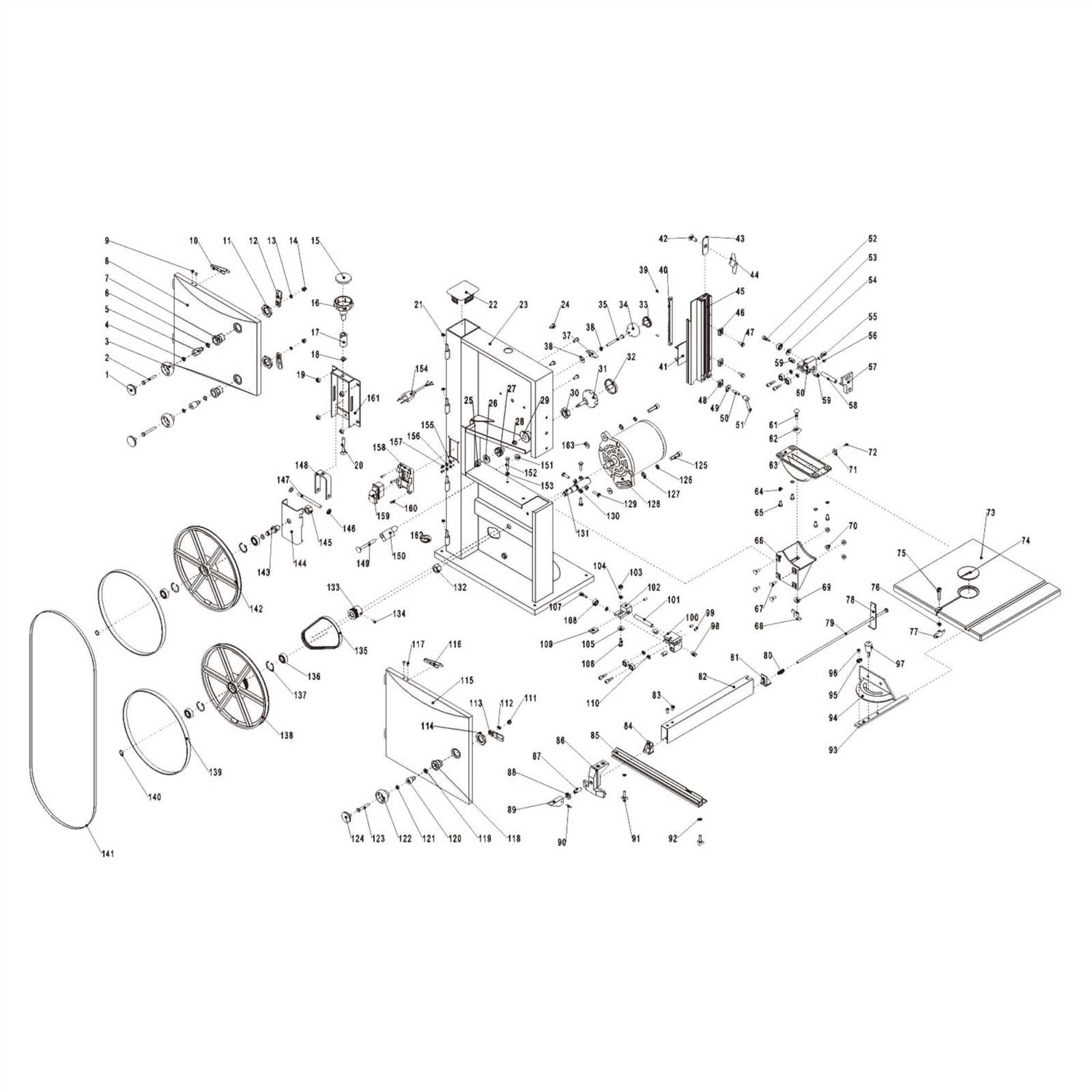

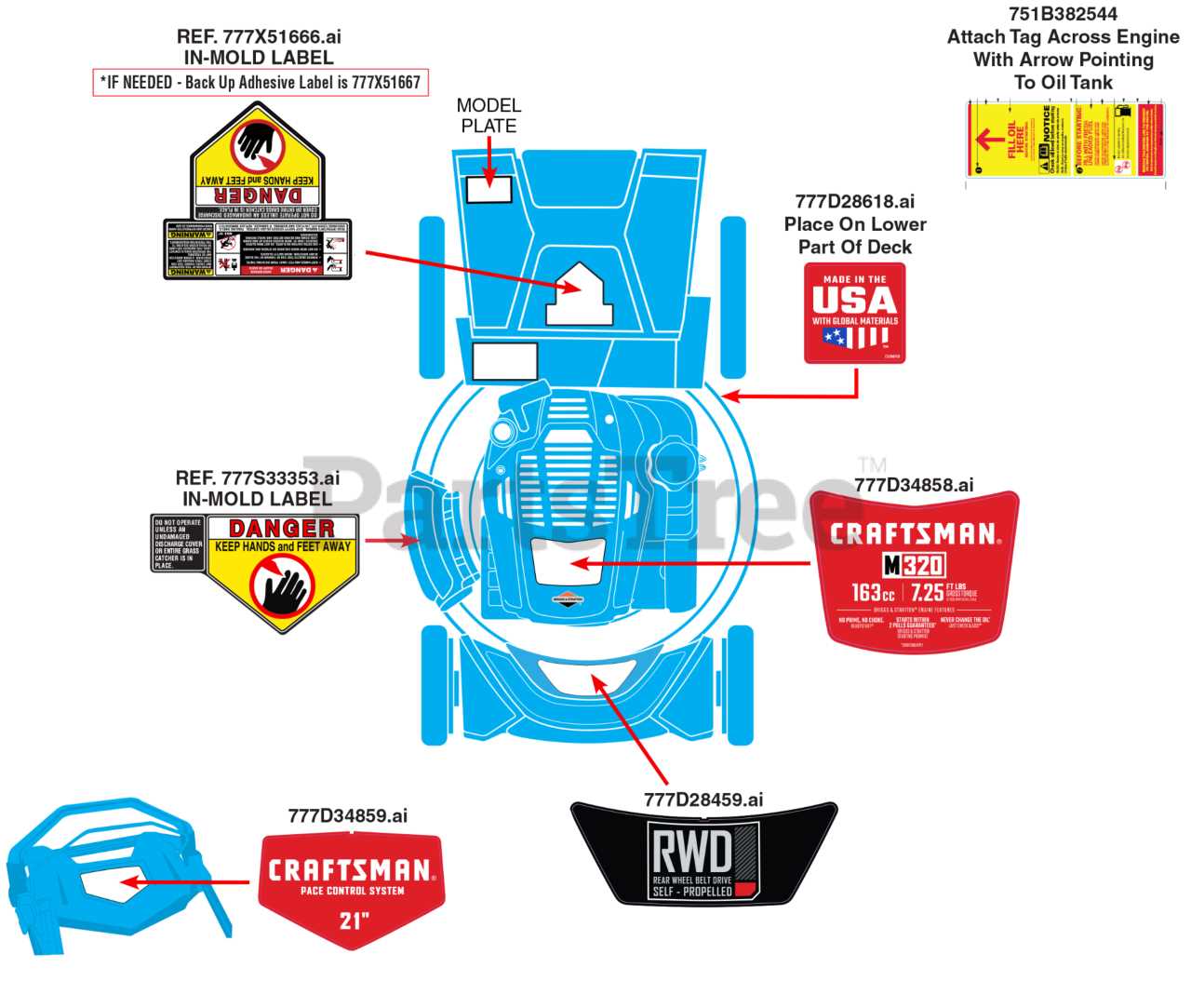

Moreover, having access to detailed illustrations or breakdowns of the machinery can serve as a valuable resource for both novice and experienced operators. This kind of visual guidance assists in the identification of specific areas that may require attention or repair, facilitating a hands-on approach to upkeep. Ultimately, investing time in understanding the structure of the equipment pays off in enhanced performance and satisfaction in its operation.

Key Features of the M110 Model

This model stands out in its category due to a combination of innovative design and user-friendly functionality. Each aspect has been carefully crafted to enhance performance and reliability, making it a popular choice among enthusiasts and professionals alike.

Durability: Built with robust materials, this unit ensures long-lasting performance, even under demanding conditions.

Efficiency: Engineered for optimal energy consumption, it allows users to achieve their tasks without unnecessary power usage.

Precision: The design incorporates advanced mechanisms that promote accurate and consistent results, ideal for detailed work.

Versatility: This model can handle a variety of applications, making it suitable for diverse projects, from simple tasks to complex undertakings.

User-Friendly Interface: The intuitive controls provide ease of use, allowing both beginners and experienced users to operate it effortlessly.

Importance of Parts Diagrams

Understanding the intricate relationships between components is essential for effective maintenance and repair. Visual representations allow users to identify each piece’s function and placement, facilitating efficient troubleshooting and assembly. This clarity enhances user confidence and promotes longevity in equipment use.

Enhancing Repair Efficiency

Having a visual reference significantly reduces the time spent searching for specific components. It provides a clear guide for disassembly and reassembly, ensuring that every part is correctly positioned, which is crucial for optimal performance.

Supporting Accurate Ordering

In cases where replacement is necessary, a visual aid assists users in accurately identifying and ordering the right components. This minimizes the risk of errors and ensures that repairs are conducted with the correct items, saving time and resources.

| Benefits | Description |

|---|---|

| Time-Saving | Quick reference reduces disassembly and reassembly time. |

| Increased Accuracy | Minimizes mistakes in identifying and ordering components. |

| Improved Understanding | Clarifies the function and relationship of each piece. |

Identifying Components of M110

Understanding the various elements of a specific tool is essential for effective maintenance and operation. Each component plays a vital role in ensuring optimal functionality and performance. By recognizing these parts, users can troubleshoot issues more efficiently and enhance their overall experience.

Key Elements: Begin by examining the outer casing, which protects internal mechanisms from damage. Next, consider the motor assembly, crucial for driving the tool’s operations. Additionally, identify the control systems that facilitate user interaction, allowing for precise adjustments.

Detailed Knowledge: Familiarizing yourself with the connections and fasteners is equally important, as these ensure the stability and integrity of the entire unit. Finally, understanding the electrical components will empower users to address any electrical malfunctions that may arise.

Common Repairs for Craftsman M110

Understanding routine maintenance and common issues can significantly enhance the longevity of your equipment. Addressing these problems promptly can lead to better performance and fewer interruptions in your tasks.

Frequent Issues and Solutions

- Engine Difficulties:

- Check spark plug condition and replace if worn.

- Inspect fuel lines for leaks or blockages.

- Cutting Performance:

- Sharpen or replace the cutting blade as needed.

- Adjust the height settings for optimal cutting results.

Maintenance Tips

- Regularly clean the air filter to ensure proper airflow.

- Keep the wheels and moving parts lubricated.

- Inspect belts for wear and replace them if necessary.

Where to Find Replacement Parts

Finding components for your tools can be a straightforward process if you know where to look. Numerous sources offer a range of options, from online retailers to local stores, ensuring you can locate what you need for repairs and maintenance.

Online Retailers

Many websites specialize in tool accessories, offering an extensive inventory. Websites like Amazon or eBay provide user-friendly interfaces to search for specific items. Additionally, manufacturer websites often have dedicated sections for replacements, making it easy to find compatible pieces.

Local Hardware Stores

Don’t overlook nearby hardware shops. They frequently carry a variety of essentials and can assist in ordering specific items if not readily available. Connecting with local suppliers may also lead to helpful recommendations or alternatives for hard-to-find components.

Tips for Using the Diagram

Understanding a visual representation of components can significantly enhance your repair and maintenance experience. By utilizing this resource effectively, you can ensure a smoother process when identifying and replacing elements in your equipment.

Familiarize Yourself with Symbols

Before diving into your project, take time to understand the various symbols and notations used in the visual guide. This will help you quickly locate parts and understand their functions.

- Review the legend carefully.

- Note any color codes that indicate different components.

- Pay attention to the layout, which often follows the assembly order.

Cross-Referencing Components

When working on repairs, it’s beneficial to cross-reference with the manual or specifications of your model. This practice can help you ensure compatibility and accuracy.

- Identify the components you need to replace.

- Check their specifications in the user manual.

- Confirm availability and compatibility before purchasing new items.

Maintenance Best Practices

Ensuring the longevity and efficiency of your tools requires a commitment to regular upkeep. By adopting systematic care routines, you can enhance performance, prevent breakdowns, and extend the lifespan of your equipment.

Regular Inspection: Conduct periodic checks to identify any signs of wear or damage. This proactive approach helps in addressing issues before they escalate.

Cleanliness: Keep your tools free from dirt and debris. Regular cleaning not only improves functionality but also prevents corrosion and buildup.

Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. This simple step can significantly enhance performance and efficiency.

Storage: Store your equipment in a dry, secure location. Proper storage protects against environmental damage and keeps tools organized.

Documentation: Maintain records of maintenance activities. Tracking repairs and services can help in understanding usage patterns and planning future upkeep.

Implementing these best practices will ensure that your tools remain reliable and efficient, ultimately maximizing their utility.

Tools Required for Repairs

Having the right equipment is essential for efficient maintenance and restoration tasks. A well-prepared toolkit not only enhances the repair process but also ensures that each component is addressed with precision. Familiarity with necessary instruments can significantly streamline your efforts.

Essential Hand Tools

Start with a solid set of hand tools, including screwdrivers, wrenches, and pliers. These instruments are fundamental for disassembling and reassembling various elements. Additionally, a multitool can be particularly useful for tackling multiple tasks without needing to switch tools frequently.

Power Tools and Accessories

For more complex repairs, consider incorporating power tools such as drills and saws. These devices can greatly reduce manual effort and time. Ensure to have a variety of drill bits and blades on hand, as the ultimate efficiency often depends on the right attachments for the job.

How to Read Parts Diagrams

Understanding the layout of component illustrations is essential for effective maintenance and repair. These visual guides provide a comprehensive overview of individual elements, their arrangement, and how they interact within the entire system.

Begin by identifying key labels associated with each item. These tags often include numbers or letters that correlate with a list of components, making it easier to find replacements. Familiarizing yourself with these identifiers is crucial for efficient navigation.

Next, note the relationships between the various pieces. Observing how parts connect or overlap can clarify their functions and assist in troubleshooting. Understanding these connections will lead to more informed decisions during repairs.

Finally, consult accompanying documentation for additional context. Manufacturer manuals or online resources often provide valuable insights into installation procedures and specifications, enhancing your overall comprehension.

Upgrading Your Craftsman M110

Enhancing your lawn care equipment can significantly improve its performance and longevity. Whether you are looking to increase efficiency, boost power, or simply modernize functionality, there are several key upgrades to consider. This section will explore various modifications that can transform your machine into a more effective tool for maintaining your yard.

Here are some effective ways to enhance your equipment:

- Engine Modifications: Consider upgrading to a higher-performance engine for better power and efficiency.

- Blade Replacement: Installing sharper, high-quality blades can improve cutting performance and reduce the effort needed for maintenance.

- Wheel Upgrades: Larger, all-terrain wheels can enhance maneuverability and grip on uneven surfaces.

- Fuel System Enhancements: Upgrading the fuel system can lead to better fuel efficiency and increased power output.

- Adding Accessories: Incorporating tools such as baggers or mulchers can expand the capabilities of your machine.

Before proceeding with any upgrades, it is essential to assess compatibility with your existing setup. Researching specific modifications and consulting with experts can help ensure that your enhancements yield the desired results. Additionally, regular maintenance remains crucial to maximize the benefits of any upgrades.

In summary, by strategically enhancing various components of your equipment, you can achieve improved performance, efficiency, and functionality, making yard maintenance a more enjoyable experience.

Resources for Further Learning

Expanding your knowledge in machinery and tools can significantly enhance your skills and understanding. Various resources are available to help you deepen your expertise, from online courses to community forums.

Online Courses

- Platforms like Udemy and Coursera offer extensive courses on tool maintenance and repair.

- Look for specific classes focused on mechanical engineering principles.

Community and Forums

- Join dedicated online communities where enthusiasts share insights and tips.

- Participate in local workshops and clubs to gain hands-on experience.