When it comes to maintaining outdoor equipment, having a clear understanding of its components is essential. This section delves into the intricate arrangement of various elements within a specific lawn mower model, providing valuable insights for both seasoned users and newcomers. By familiarizing oneself with the layout and functionality of these components, users can ensure better performance and longevity of their machinery.

Whether you’re troubleshooting an issue or planning a repair, comprehending the configuration of the machine can make a significant difference. Detailed visual references can guide you through the assembly, helping to identify each crucial element and its role. This knowledge not only aids in efficient repairs but also enhances the overall user experience.

Equipped with this information, you’ll find yourself better prepared to tackle maintenance tasks. Understanding the layout fosters confidence in managing your lawn care tools, allowing you to approach repairs with a clearer perspective. Join us as we explore the specifics of this popular model and uncover the essential features that keep it running smoothly.

When delving into the intricate design of lawn care machinery, it’s essential to comprehend the components that work in unison to achieve optimal performance. Understanding how these elements are arranged and function together can greatly enhance maintenance efforts and facilitate repairs. This section aims to provide clarity on the various components involved in the assembly, emphasizing their roles and interconnections.

To better understand the assembly of this machinery, consider the following key elements:

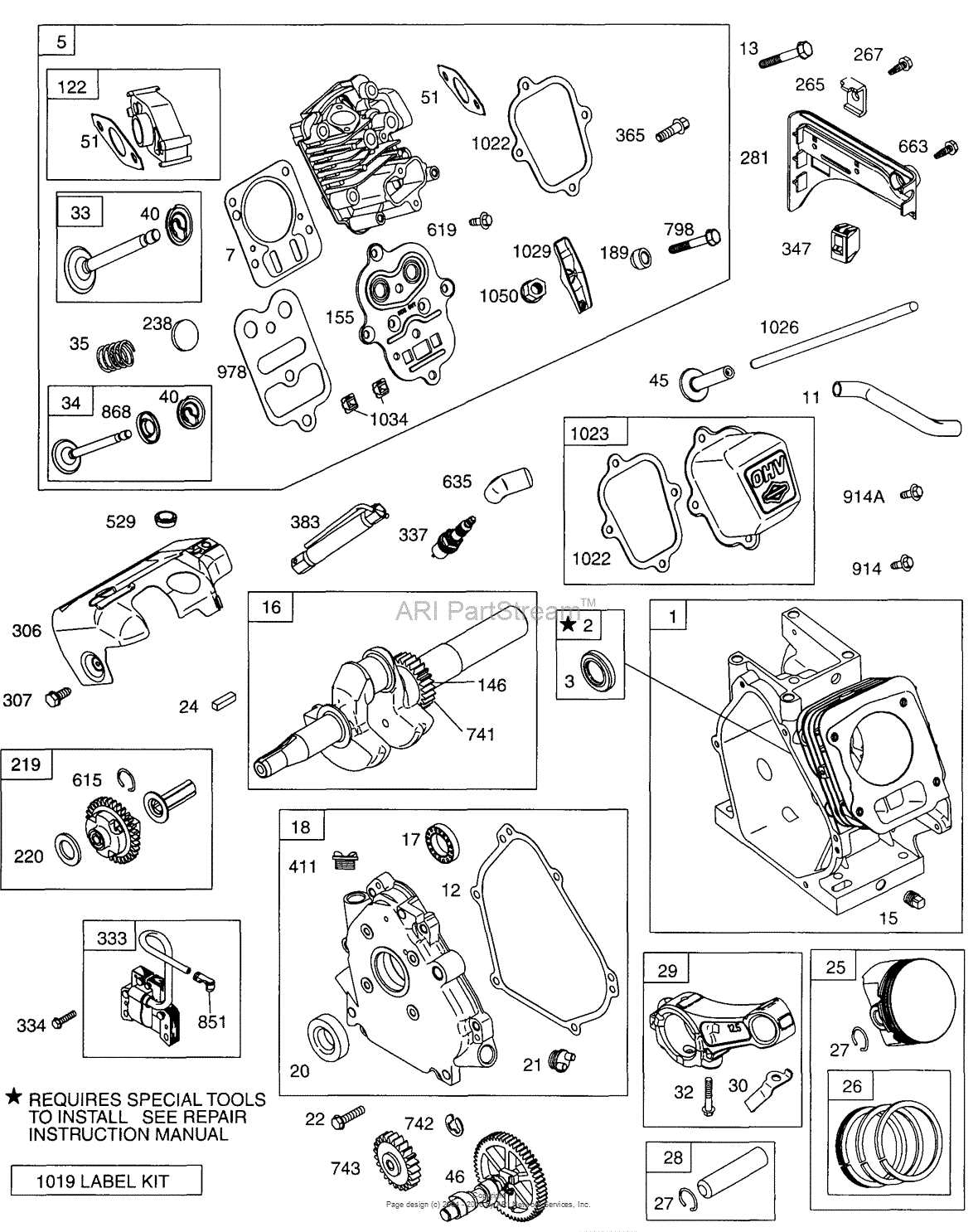

- Engine Unit: The powerhouse that drives the entire system, responsible for converting fuel into mechanical energy.

- Chassis Structure: The framework that houses the engine and supports other essential parts, ensuring stability and durability.

- Cutting Mechanism: Comprising blades and associated components, this assembly is crucial for achieving a clean cut.

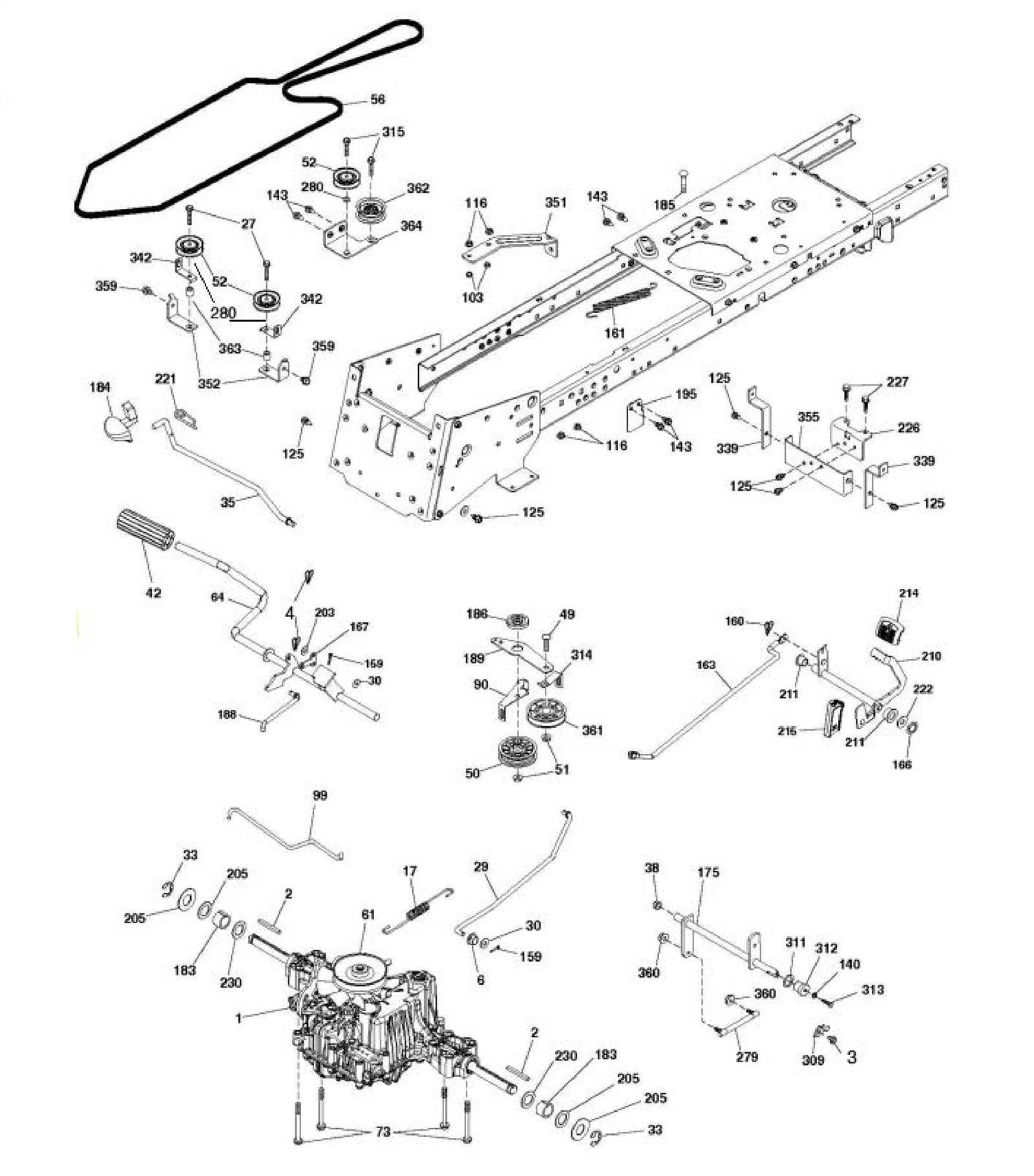

- Transmission System: This segment transfers power from the engine to the wheels, enabling movement and control.

- Control Panel: The interface that allows the operator to manage various functions, enhancing user experience and efficiency.

To facilitate a thorough understanding of each component’s position and function, a systematic approach is beneficial. Here’s a structured outline for further exploration:

- Overview of the Engine Unit

- Details on the Chassis Structure

- In-depth Analysis of the Cutting Mechanism

- Exploration of the Transmission System

- Understanding the Control Panel Functions

By systematically addressing these components, users can develop a comprehensive understanding of the machinery’s assembly and its operational dynamics.

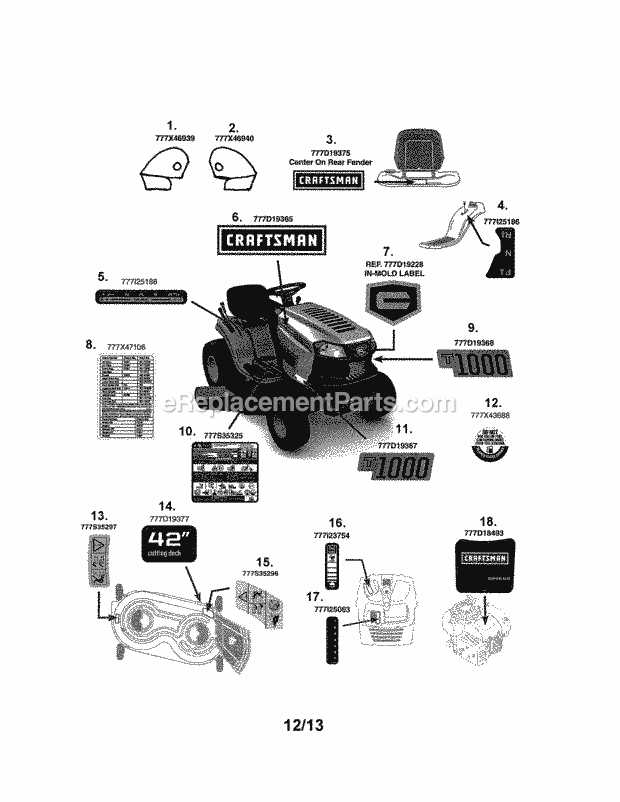

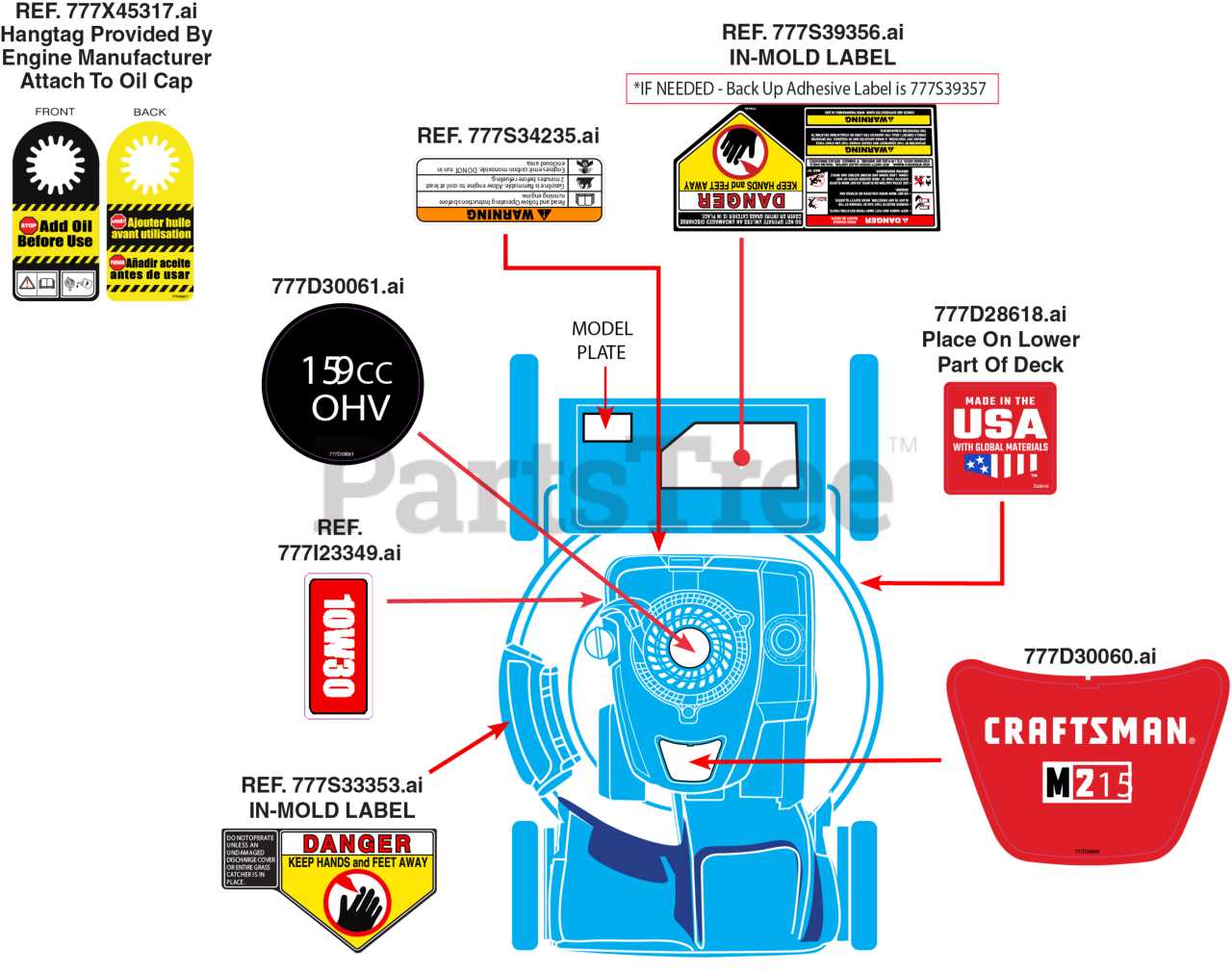

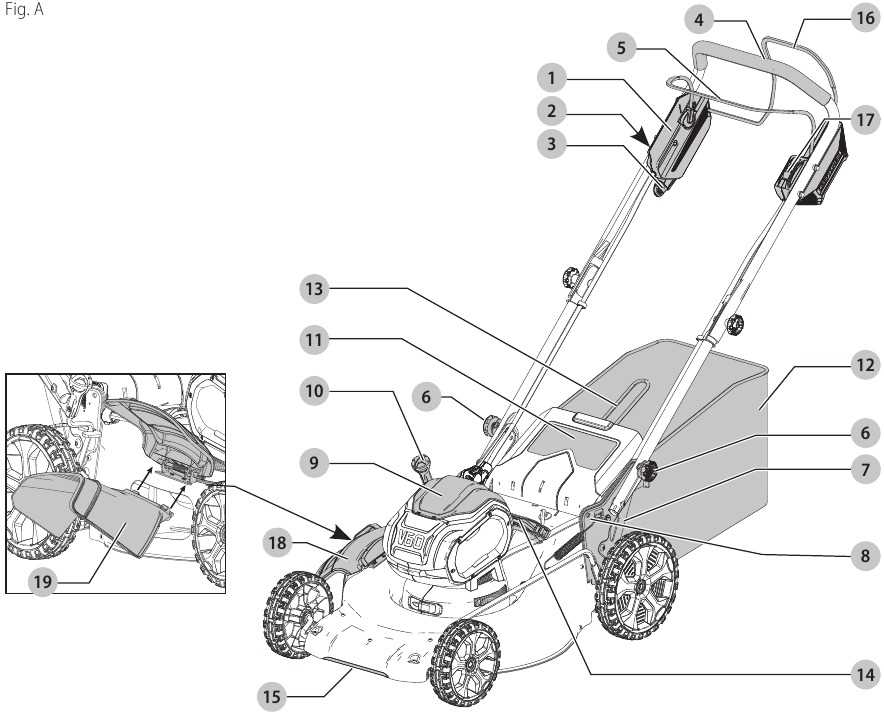

Key Components of the M220 Model

The design of this particular model includes several essential elements that work together to enhance its performance and reliability. Each component plays a vital role in ensuring that the unit operates smoothly and efficiently, contributing to its overall effectiveness in various tasks. Understanding these crucial parts can help users appreciate the engineering and functionality behind this well-crafted machine.

One of the primary elements is the power system, which is responsible for providing the necessary energy to operate the unit. This component is designed for optimal energy efficiency, ensuring that the machine can perform demanding tasks without excessive power consumption. Additionally, the cutting mechanism is another critical feature that allows for precise operations, facilitating various applications with ease and accuracy.

Furthermore, the chassis structure adds stability and support, making the unit robust and durable even under challenging conditions. This framework is designed to withstand wear and tear, ensuring longevity and reliability. Lastly, the control interface allows users to interact with the machine seamlessly, offering intuitive navigation and adjustments to enhance user experience. Together, these key components form a cohesive system that exemplifies quality and functionality.

Importance of Accurate Parts Identification

Ensuring precise identification of components is crucial for effective maintenance and repair tasks. Proper recognition of each element allows for seamless replacements and enhances the overall functionality of equipment. Inaccuracies in identifying specific elements can lead to complications, increased costs, and prolonged downtime.

Enhanced Efficiency

When each component is correctly recognized, the process of sourcing replacements becomes significantly streamlined. This efficiency not only reduces the time spent on repairs but also minimizes the risk of errors that could arise from selecting incorrect items. A systematic approach fosters quicker troubleshooting and restoration of operational capabilities.

Cost-Effectiveness

Misidentifying elements can result in purchasing unnecessary or incorrect replacements, leading to wasted resources. Conversely, accurate recognition ensures that only the needed components are acquired, thereby optimizing budget allocations and enhancing overall cost management.

| Component Type | Common Issues | Consequences of Inaccuracy |

|---|---|---|

| Fasteners | Incorrect size or type | Weak connections, potential safety hazards |

| Belts | Wrong length or width | Reduced performance, increased wear |

| Filters | Incompatible model | Decreased efficiency, possible damage |

Common Repairs for Craftsman M220

Maintaining equipment is crucial for ensuring its longevity and optimal performance. This section explores typical issues that may arise with lawn care tools, along with practical solutions. Understanding these common repairs can help users troubleshoot effectively and keep their devices running smoothly.

Engine Troubles

One of the most frequent problems encountered involves engine difficulties. Symptoms may include difficulty starting or unexpected stalling during operation. Often, these issues can be traced back to a clogged fuel filter or stale fuel. Cleaning or replacing the filter and using fresh fuel can resolve these issues, restoring functionality.

Blade Maintenance

Another area that often requires attention is the cutting blade. Dull or damaged blades can lead to poor cutting performance and uneven results. Regularly inspecting the blade for wear is essential. Sharpening or replacing the blade as needed will enhance cutting efficiency and promote healthier lawn growth.

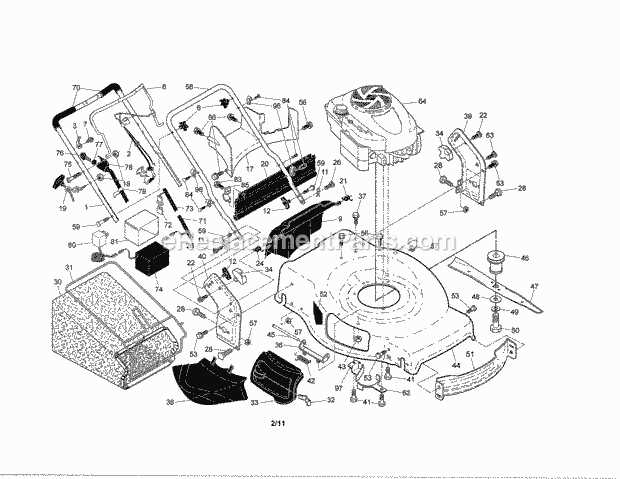

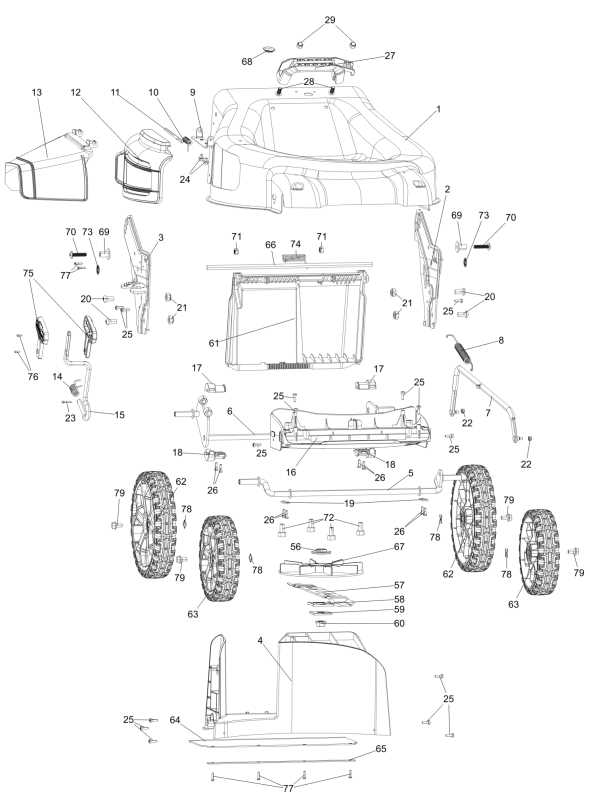

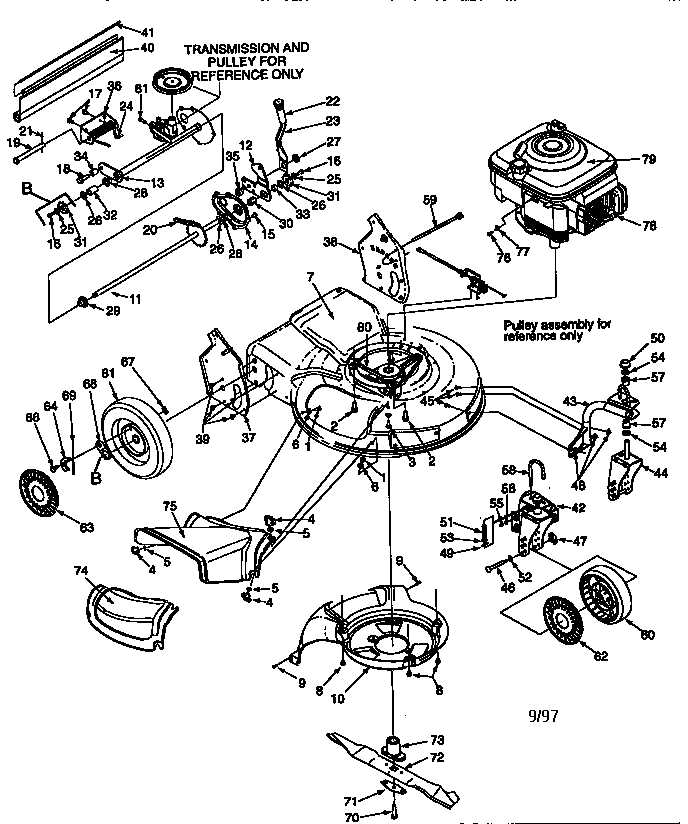

How to Use the Parts Diagram

Understanding the visual representation of components can greatly enhance your ability to maintain and repair your equipment. By familiarizing yourself with the layout, you can efficiently identify individual elements and their functions within the system.

To effectively utilize this visual guide, consider the following steps:

- Familiarize Yourself with the Layout: Take a moment to observe how the components are arranged. Notice the grouping of similar items, which can help you identify them during your maintenance tasks.

- Identify Each Element: Use the reference numbers or labels associated with each component to learn about their specific roles. This knowledge is essential for troubleshooting issues that may arise.

- Refer to the User Manual: Cross-reference the visual guide with the user manual for detailed descriptions of each item. This will provide you with additional insights on functionality and replacement procedures.

- Plan Your Repairs: Before starting any repair work, outline the steps you need to take based on the information gathered. Having a clear plan will streamline your efforts and minimize mistakes.

By following these steps, you can maximize your understanding of the equipment and ensure it operates smoothly.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a straightforward process when you know where to look. Whether you’re repairing a machine or upgrading your tools, understanding the various sources available can save you both time and effort. With a bit of guidance, you can efficiently track down the exact items you need.

Online Retailers offer a vast selection of components, making them a prime choice for sourcing replacements. Websites specializing in tools and machinery typically have extensive catalogs. By entering the model number or description of the required item, you can quickly filter through available options.

Local Supply Stores can be invaluable resources for immediate needs. Many stores maintain a collection of essential items for different brands, ensuring that you can find what you need without waiting for shipping. Consulting with staff can also lead to discovering alternative solutions if the exact match is unavailable.

Additionally, consider joining Online Forums and communities related to your equipment. Members often share experiences, recommendations, and even links to reliable suppliers. This collaborative approach can provide insights that enhance your search and may introduce you to innovative alternatives.

Maintenance Tips for M220 Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires regular care and attention. By adopting simple yet effective maintenance practices, you can extend the lifespan of your machinery, preventing costly repairs and enhancing overall functionality. This section will provide you with essential strategies to keep your unit running smoothly for years to come.

Routine Cleaning and Inspection

Regularly cleaning the exterior and components of your equipment is vital for preventing dirt buildup and corrosion. Make it a habit to inspect critical parts for wear or damage, addressing any issues promptly to avoid further complications. A well-maintained machine not only performs better but also has a longer service life.

Proper Storage Techniques

Storing your equipment correctly is crucial for its longevity. Keep it in a dry, sheltered area to protect it from harsh weather conditions. If you plan on storing it for an extended period, consider draining fluids and performing a thorough cleaning. This proactive approach will help preserve the integrity of the unit and ensure it’s ready for use when needed.

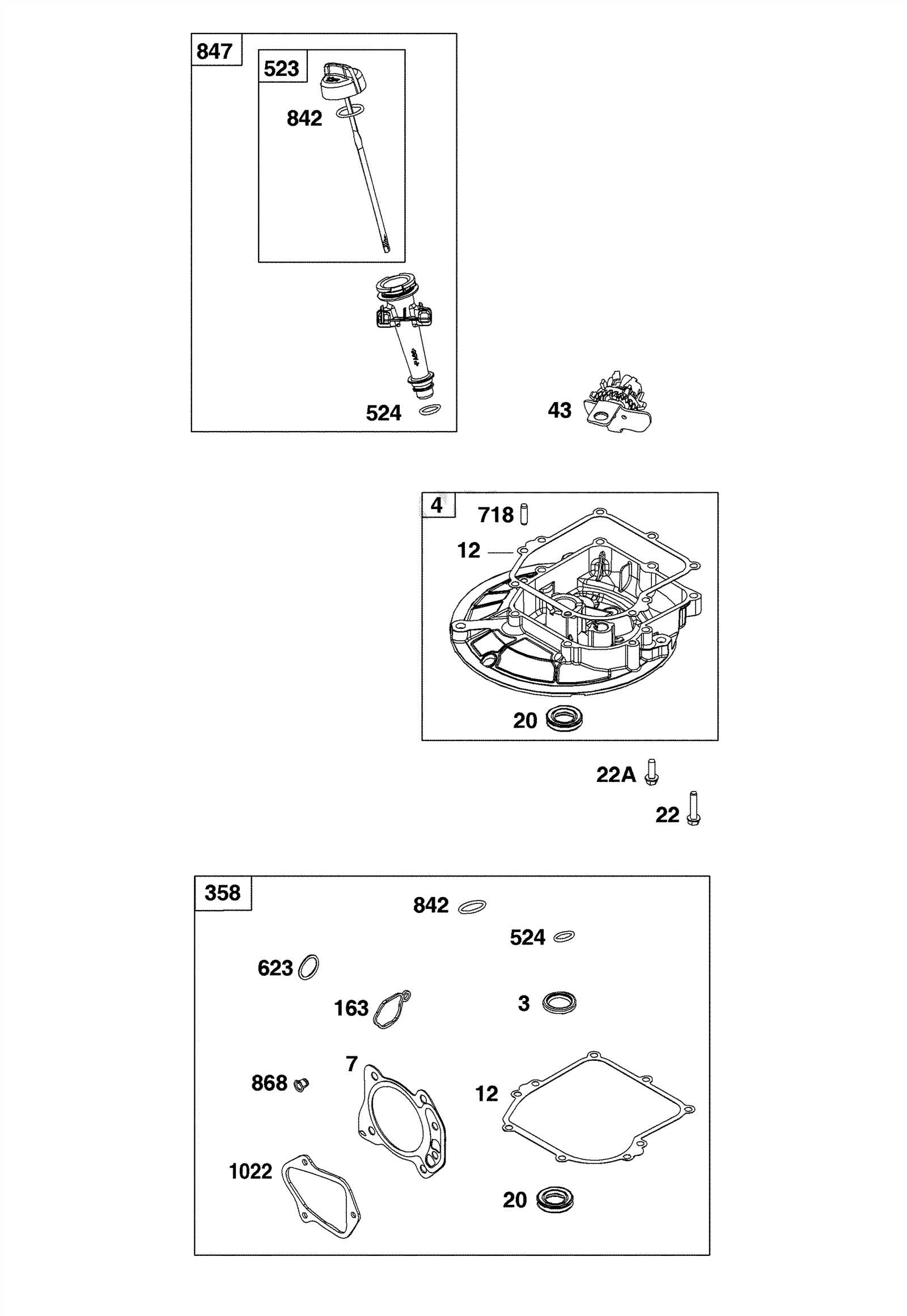

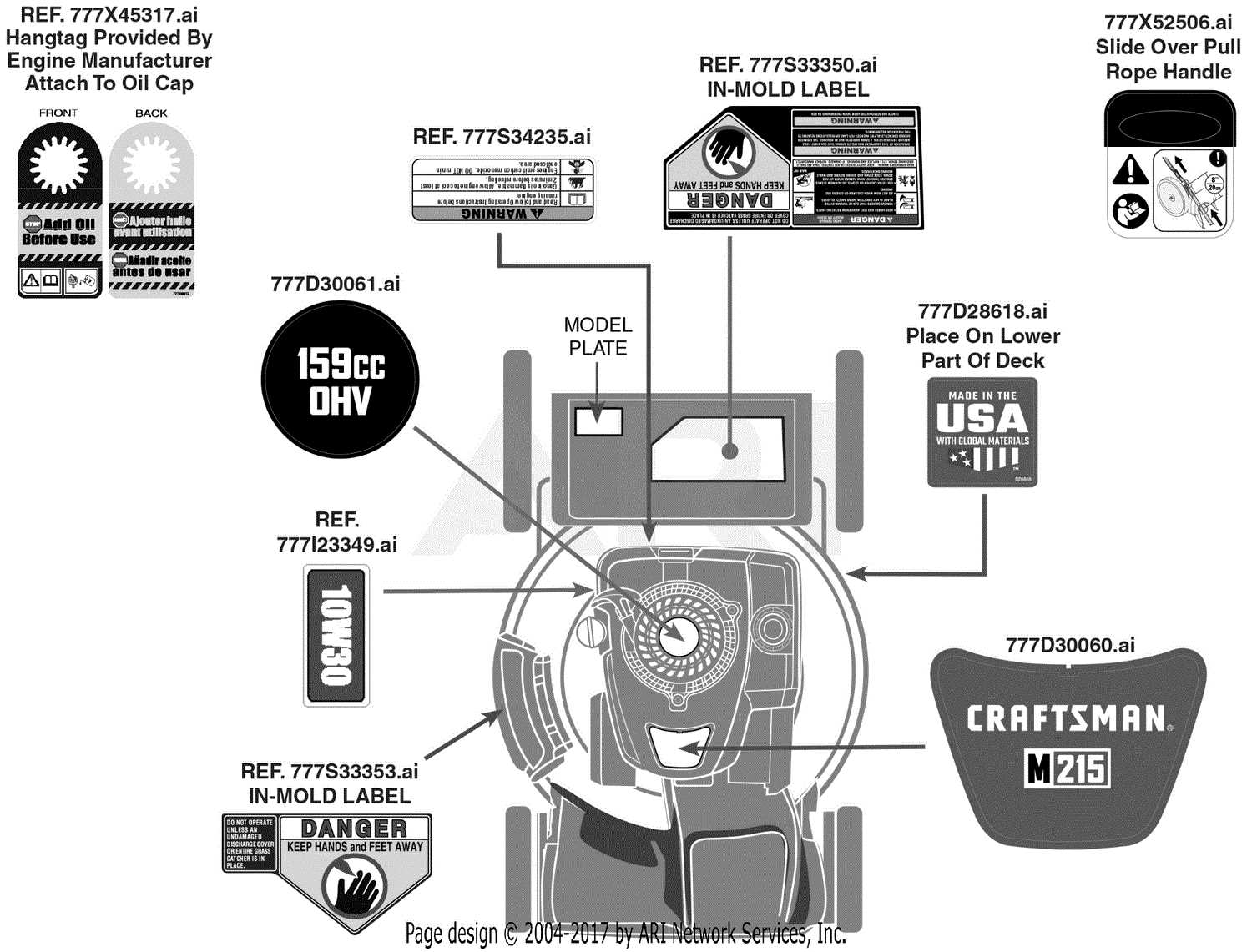

Visual Breakdown of M220 Parts

Understanding the various components of your equipment is crucial for effective maintenance and optimal performance. This section delves into the essential elements that make up the machinery, providing clarity on each segment’s function and placement. Familiarity with these elements can enhance your ability to troubleshoot issues and ensure proper operation.

- Engine Assembly: The heart of the machinery, responsible for providing power and performance.

- Chassis Frame: The structural foundation that supports all other components and provides stability.

- Fuel System: Comprising the tank, lines, and filter, this system delivers the necessary energy for operation.

- Transmission System: Facilitates the transfer of power from the engine to the wheels, affecting speed and control.

- Control Panel: The interface that allows users to operate the machine and monitor its functions.

Each component plays a vital role in the overall efficiency and functionality. By familiarizing yourself with these parts, you can enhance your understanding and ensure the longevity of your equipment.

Frequently Asked Questions about M220

This section addresses common inquiries related to the specified model. Here, users can find valuable insights and solutions regarding its operation, maintenance, and components.

General Inquiries

Many users often wonder about the best practices for ensuring longevity and optimal performance of their equipment. Understanding routine maintenance procedures can significantly enhance the overall experience.

Technical Support

For troubleshooting and resolving issues, users frequently seek guidance on diagnosing problems effectively. Knowing how to identify common faults can save time and reduce frustration.

| Question | Answer |

|---|---|

| What should I do if my device won’t start? | Check the power source and ensure all connections are secure. If the problem persists, consult the user manual for further troubleshooting steps. |

| How often should I perform maintenance? | Regular maintenance should be carried out according to the manufacturer’s recommendations, typically every few months or after a specific number of uses. |

| Where can I find replacement components? | Replacement components are available through authorized dealers or online retailers specializing in equipment supplies. |

| What is the warranty coverage? | The warranty usually covers manufacturing defects for a specified period. Refer to the warranty policy for detailed information. |

Upgrading Components for Better Performance

Enhancing the functionality of your equipment can lead to significant improvements in efficiency and overall satisfaction. By focusing on key elements, you can ensure that your machinery operates at peak performance, providing you with a more reliable and effective experience.

Identifying Key Areas for Improvement

To begin the upgrade process, consider evaluating the following components:

- Engine: A more powerful engine can increase output and speed.

- Transmission: Upgrading to a higher-grade transmission enhances power transfer.

- Wheels: Better traction and stability can be achieved with improved wheel designs.

- Brakes: High-performance brakes ensure safety and responsiveness during operation.

Benefits of Upgrading

Investing in superior components yields numerous advantages:

- Increased efficiency reduces operational costs.

- Enhanced durability prolongs the lifespan of the equipment.

- Improved safety features minimize the risk of accidents.

- Higher resale value can be achieved with upgraded machinery.

Resources for Craftsman M220 Users

For individuals seeking to enhance their understanding of a popular lawn care device, a variety of valuable materials are readily available. These resources encompass manuals, online guides, and community forums that facilitate users in troubleshooting issues, performing maintenance, and optimizing performance.

User Manuals and Guides

Official manuals provide comprehensive instructions and specifications essential for effective operation. Users can access these documents online, ensuring they have the latest information at their fingertips. Additionally, various guides available on DIY websites offer step-by-step procedures for common tasks, from routine maintenance to advanced repairs.

Community Forums and Support

Engaging with fellow enthusiasts through forums can significantly enhance the user experience. These platforms allow individuals to share insights, ask questions, and receive advice from seasoned users. By participating in these discussions, users can gain practical tips and discover solutions to common challenges faced during operation.