In any mechanical system, the intricate design and functionality are greatly influenced by the various elements that come together to create a cohesive unit. Each individual piece plays a vital role, ensuring that the entire mechanism operates efficiently and effectively. By examining the layout of these components, users can gain valuable insights into the assembly and maintenance of their equipment.

Detailed exploration of these components not only facilitates troubleshooting but also enhances overall performance. Users can identify wear patterns and potential issues that may arise over time. Understanding the relationship between each part aids in making informed decisions regarding repairs and upgrades, ultimately prolonging the lifespan of the machinery.

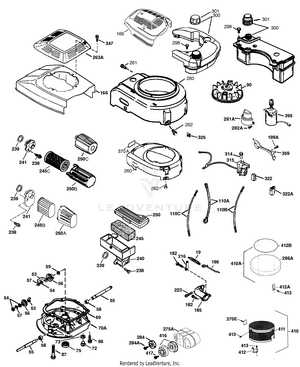

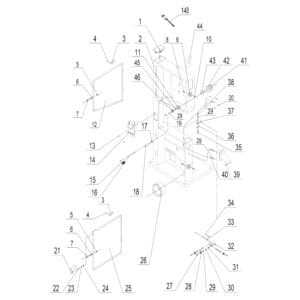

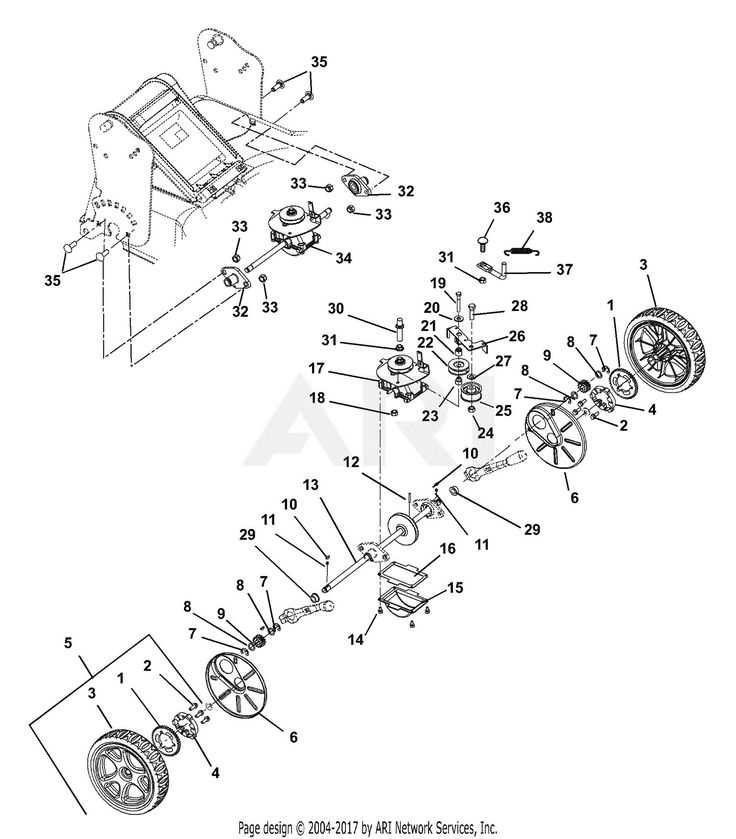

By utilizing comprehensive illustrations, individuals can visualize how each element interacts within the larger framework. This approach simplifies the complexities often associated with mechanical maintenance, empowering users to take control of their equipment’s functionality. Whether for repair purposes or general knowledge, a thorough grasp of component arrangements is essential for anyone involved in machinery operation and upkeep.

Each illustration typically showcases a range of parts, offering a comprehensive overview of the machinery. By categorizing components, users can quickly locate specific elements, facilitating repairs and replacements without confusion.

| Component Type | Description | Common Issues |

|---|---|---|

| Motor | Drives the machinery | Overheating, failure to start |

| Gears | Transmits power within the system | Worn teeth, misalignment |

| Belts | Transfers motion from one component to another | Fraying, slipping |

Utilizing Illustrations for Repairs

When performing maintenance or troubleshooting, referring to visual aids significantly enhances the process. Users can match the labeled components with the physical parts, ensuring accurate identification and effective problem-solving strategies.

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in the effective assembly and maintenance of machinery. These visual representations serve as essential guides, enabling users to comprehend complex systems easily. By depicting the relationships and configurations of components, they facilitate a smoother workflow and minimize the likelihood of errors during repairs or upgrades.

Having well-defined visuals not only aids in understanding but also enhances the efficiency of the repair process. Users can quickly identify the necessary elements and follow the correct procedures, saving time and effort. Moreover, accurate visuals contribute to the longevity of equipment by ensuring that all parts are installed correctly, reducing the risk of malfunction.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Visual aids simplify complex systems, making them easier to comprehend. |

| Improved Efficiency | Clear visuals streamline the assembly process, reducing time spent on repairs. |

| Minimized Errors | Accurate illustrations decrease the chances of mistakes during assembly or maintenance. |

| Increased Longevity | Correct installation of components leads to better performance and durability of equipment. |

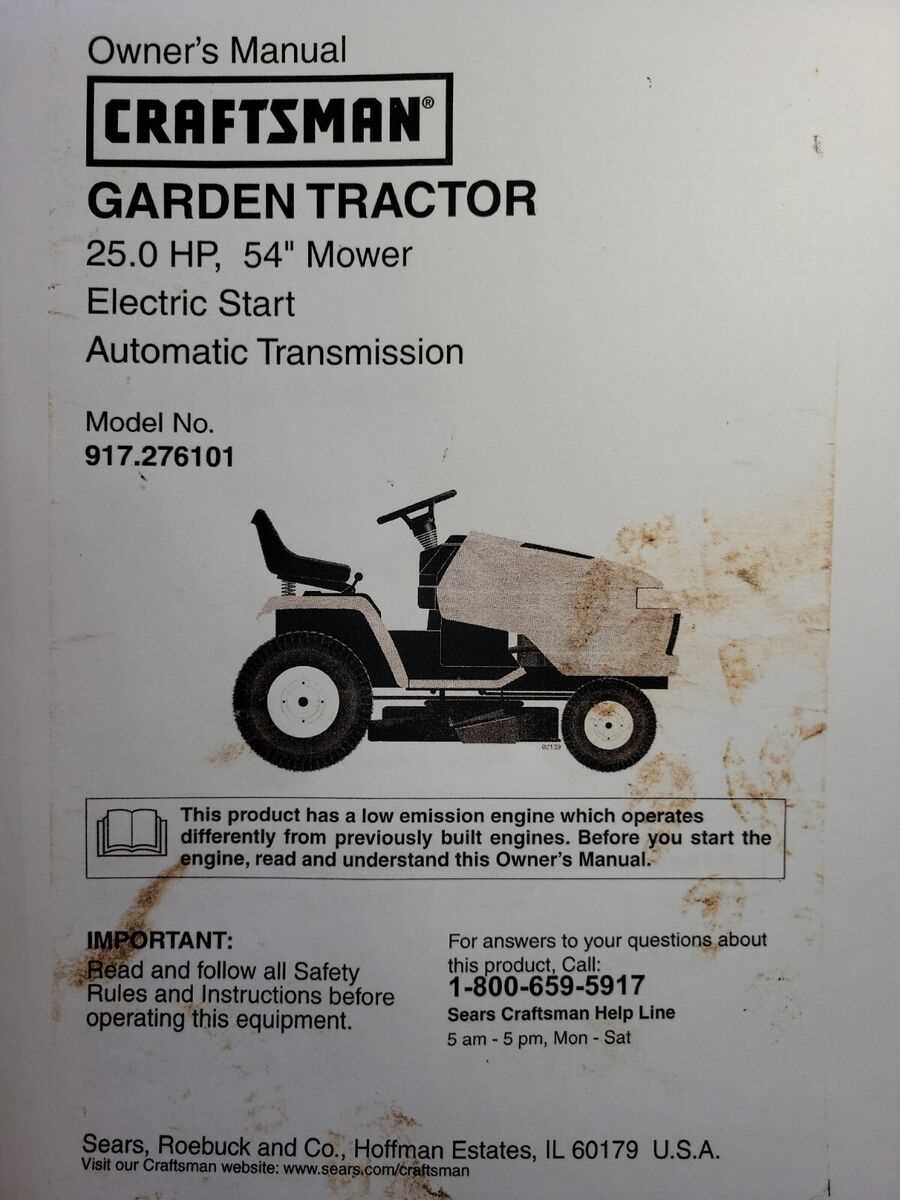

Common Components in Craftsman Tools

This section highlights the frequently utilized elements found in various tools designed for home improvement and maintenance. Understanding these fundamental components is essential for both novice users and seasoned professionals, as it aids in the proper handling and maintenance of equipment.

The construction and functionality of these tools typically rely on a combination of durable materials and innovative designs. Each element plays a vital role in ensuring efficiency and effectiveness, allowing users to complete tasks with ease.

| Component | Description |

|---|---|

| Motor | Drives the tool, providing the necessary power for operation. |

| Handle | Offers grip and control, allowing for precise maneuvering. |

| Blade | Essential for cutting and shaping materials with accuracy. |

| Switch | Enables users to turn the tool on and off, enhancing safety. |

| Battery | Powers cordless models, providing mobility and ease of use. |

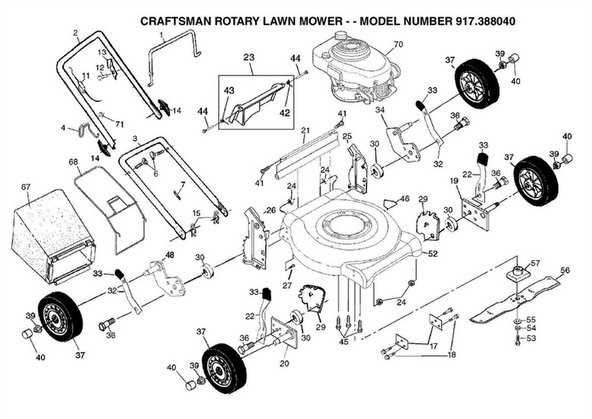

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective repairs and maintenance. These visual guides can help users identify various elements and their relationships within a machine or device. By familiarizing yourself with the layout and symbols used, you can streamline the process of locating and replacing individual items.

Begin by examining the overall layout. Typically, these visuals are organized to reflect the actual arrangement of components within the device. Look for labeled sections that indicate different areas, allowing you to focus on specific parts as needed. The accompanying legends or keys provide essential information about symbols and numbering conventions used throughout the illustration.

To facilitate comprehension, here is a sample representation of a schematic layout:

| Component | Description | Part Number |

|---|---|---|

| Motor | Drives the main function of the device | 123456 |

| Blade | Cuts through materials efficiently | 789012 |

| Switch | Controls power to the unit | 345678 |

By using these visual guides and understanding their structure, you will enhance your ability to perform maintenance tasks accurately and efficiently.

Identifying Replacement Parts Easily

Understanding how to pinpoint and locate components for various tools and machinery is essential for effective maintenance and repair. This knowledge can help users minimize downtime and enhance the longevity of their equipment.

Steps to Identify Components

- Consult the manufacturer’s manual for a comprehensive overview of the device.

- Use online resources or forums dedicated to the specific equipment for additional insights.

- Take note of the model number and serial number to ensure accurate identification.

Utilizing Visual References

Visual aids can significantly simplify the identification process. Consider the following methods:

- Access online image libraries or databases for reference images.

- Use exploded views that showcase each element and its placement within the assembly.

- Compare physical components against visual guides to confirm compatibility.

By following these guidelines, users can efficiently locate the necessary components for their tools, ensuring smooth operation and effective repairs.

Tips for Maintaining Your Tools

Proper care and upkeep of your equipment are essential for ensuring their longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs and replacements. Following some basic practices can significantly extend the life of your tools and keep them in top condition.

Regular Cleaning

Cleaning your tools after each use is crucial. Dirt, dust, and debris can accumulate, leading to rust and corrosion over time. Use a soft brush or cloth to remove any particles, and consider applying a protective lubricant to metal parts to prevent moisture buildup. This simple step will help maintain their functionality and appearance.

Routine Inspections

Performing routine inspections of your tools is vital to identify any signs of wear or damage early. Check for loose screws, cracked handles, or worn-out components. Addressing these issues promptly can prevent further damage and ensure safe usage. Additionally, keeping a record of your inspections can help track maintenance schedules and any repairs needed.

Where to Find Parts Diagrams

Locating technical illustrations for various equipment can be essential for effective maintenance and repairs. These resources provide a visual representation of components, helping users identify and source necessary items for their tools or appliances. Below are some common avenues to explore when searching for these valuable resources.

Manufacturer Websites

Many manufacturers offer online resources where users can access detailed visuals of their products. By visiting the official websites, individuals can often find comprehensive documentation, including assembly guides and component breakdowns. This information is frequently categorized by product type, making it easier to navigate.

Online Retailers and Part Suppliers

Numerous online retailers and suppliers specialize in equipment components and accessories. These platforms often feature searchable databases where users can enter their model numbers or descriptions to find related illustrations. Additionally, many sites provide downloadable resources for further convenience.

| Source Type | Description |

|---|---|

| Manufacturer Website | Official sites offering comprehensive product details and illustrations. |

| Online Retailers | Platforms specializing in components with searchable databases and downloadable resources. |

| User Forums | Community-driven spaces where users share insights and resources, including visuals. |

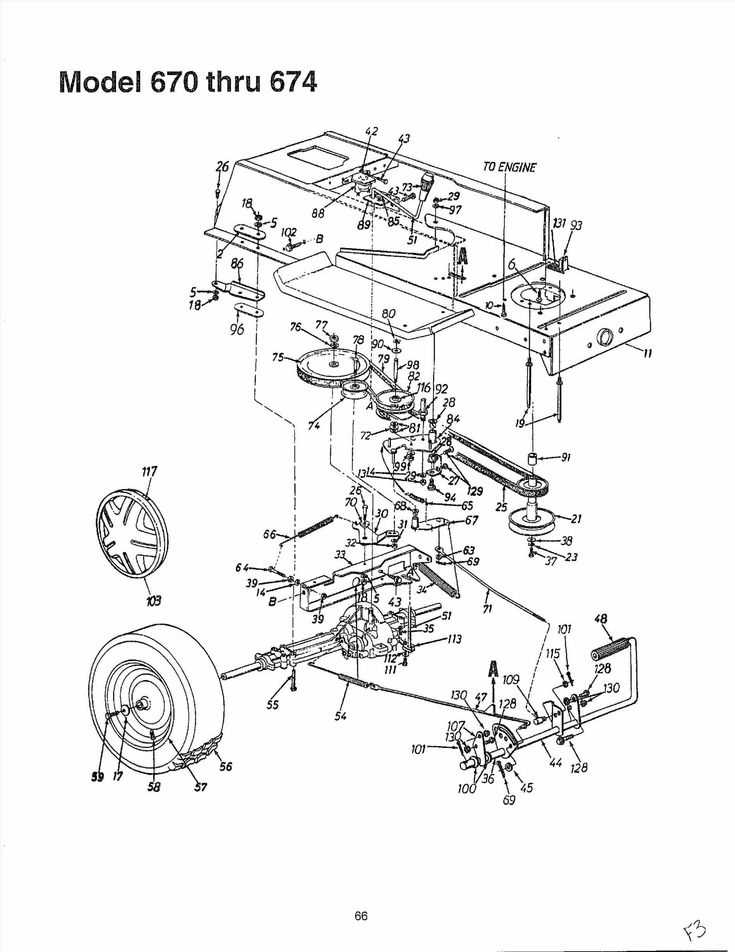

Comparing Different Models’ Diagrams

When examining various designs and their configurations, it is essential to understand the nuances that distinguish each version. By analyzing the visual representations of different models, users can gain insights into their functionalities and potential compatibility with one another.

Each model showcases unique features that can affect performance and usability. The following points highlight key aspects to consider when comparing these illustrations:

- Component Layout: Each version may arrange elements differently, affecting accessibility and maintenance.

- Functionality: Certain models might include additional features or specialized components that enhance their performance.

- Compatibility: Understanding how parts fit together can help users identify interchangeable pieces across models.

- Upgrades: Some designs may allow for upgrades or modifications that can extend the lifespan or enhance efficiency.

By closely inspecting these visual representations, individuals can make informed decisions when selecting tools or seeking replacements, ensuring they choose the most suitable option for their needs.

Common Issues Addressed in Diagrams

Understanding the common problems associated with equipment assembly and maintenance can significantly enhance efficiency and prolong the lifespan of the tools. Visual representations play a crucial role in identifying potential issues and ensuring that users can effectively resolve them. These illustrations serve as a guide for troubleshooting and provide insights into various components, making the repair process more manageable.

One frequent challenge is the misalignment of parts, which can lead to improper functioning. Accurate visuals allow users to pinpoint the exact placement of components, minimizing the risk of errors during assembly. Furthermore, these illustrations often highlight wear and tear signs, alerting users to the need for replacement parts.

Another issue that can arise is the confusion over similar-looking components. Diagrams can clarify the distinctions between these elements, helping individuals select the correct parts for their repairs. This level of detail is essential for avoiding costly mistakes and ensuring that equipment operates smoothly.

Lastly, comprehensive visual guides can assist in the identification of common troubleshooting steps, allowing users to address issues quickly without extensive technical knowledge. By effectively utilizing these resources, users can enhance their understanding and maintenance of their tools.

Utilizing Diagrams for Repairs

Visual representations are invaluable tools in the repair process, providing clear guidance and enhancing the efficiency of maintenance tasks. These illustrations simplify complex assemblies, allowing individuals to understand the arrangement and interaction of components easily.

When engaging in repairs, following a visual guide can lead to numerous advantages:

- Clarity: Visual aids remove ambiguity, showcasing how parts fit together.

- Organization: Illustrations help keep track of the sequence of disassembly and reassembly.

- Efficiency: Accessing a visual reference can significantly reduce the time spent searching for information.

- Accuracy: Diagrams minimize the risk of errors during repairs, ensuring that all components are correctly positioned.

To maximize the effectiveness of visual references in repair work, consider the following strategies:

- Identify the specific areas that need attention and locate the corresponding visual aids.

- Follow the instructions step by step, referring back to the illustrations as needed.

- Keep the visuals accessible during the entire repair process for quick reference.

- Take notes or mark important steps directly on the illustrations for future reference.

Incorporating these techniques will not only enhance the repair experience but also improve overall understanding and proficiency in handling various tasks.

Resources for Further Assistance

When seeking additional support and information, there are numerous avenues available to enhance your understanding and troubleshooting abilities. Various platforms offer guidance, manuals, and community forums where individuals can connect and share their experiences. These resources can significantly aid in addressing any queries or challenges encountered during maintenance and repair tasks.

Here are some valuable resources to consider:

| Resource Type | Description | Link |

|---|---|---|

| Official Manuals | Access to detailed guides and specifications related to your device. | Visit Here |

| Online Forums | Engage with a community of users to exchange tips and solutions. | Visit Here |

| Video Tutorials | Visual guides demonstrating common repairs and maintenance tasks. | Visit Here |

| Customer Support | Direct assistance from experts to address specific concerns. | Contact Support |